Ultrafast Laser Strategies for Sustainable Manufacturing Practices.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Background and Objectives

Ultrafast laser technology has evolved significantly over the past three decades, transforming from laboratory curiosities to essential tools in advanced manufacturing. The journey began in the 1980s with the development of femtosecond lasers, which demonstrated unprecedented precision in material processing. By the early 2000s, these systems had become commercially viable, though primarily limited to research applications due to their complexity and cost.

The fundamental advantage of ultrafast lasers lies in their extremely short pulse duration—typically in the femtosecond (10^-15 seconds) to picosecond (10^-12 seconds) range. This characteristic enables "cold ablation," a process where material is removed with minimal heat transfer to surrounding areas, resulting in exceptional precision and reduced collateral damage compared to conventional laser technologies.

Recent technological advancements have focused on increasing average power, improving beam quality, and enhancing system reliability while reducing operational costs. These developments have expanded ultrafast laser applications beyond traditional sectors into emerging fields such as medical device manufacturing, electronics miniaturization, and sustainable manufacturing processes.

The current technological trajectory points toward more energy-efficient systems with higher throughput capabilities. Industry trends indicate growing integration of ultrafast lasers with automation and AI-driven process optimization, enabling adaptive manufacturing techniques that minimize material waste and energy consumption—key factors in sustainable manufacturing practices.

The primary objective of ultrafast laser implementation in sustainable manufacturing is to develop processes that significantly reduce environmental impact while maintaining or improving production efficiency. Specific goals include minimizing material waste through precision processing, reducing or eliminating chemical processes in manufacturing, decreasing energy consumption per unit produced, and enabling the processing of new sustainable materials that may be challenging to work with using conventional methods.

Secondary objectives include extending product lifecycles through improved component quality, facilitating repair and remanufacturing through precise material addition and removal capabilities, and developing closed-loop manufacturing systems where real-time monitoring ensures optimal resource utilization. These objectives align with broader industrial sustainability initiatives and increasingly stringent environmental regulations worldwide.

The convergence of ultrafast laser technology with sustainability imperatives represents a promising frontier in manufacturing innovation, potentially enabling a paradigm shift from traditional resource-intensive production methods to more efficient, precise, and environmentally responsible manufacturing approaches.

The fundamental advantage of ultrafast lasers lies in their extremely short pulse duration—typically in the femtosecond (10^-15 seconds) to picosecond (10^-12 seconds) range. This characteristic enables "cold ablation," a process where material is removed with minimal heat transfer to surrounding areas, resulting in exceptional precision and reduced collateral damage compared to conventional laser technologies.

Recent technological advancements have focused on increasing average power, improving beam quality, and enhancing system reliability while reducing operational costs. These developments have expanded ultrafast laser applications beyond traditional sectors into emerging fields such as medical device manufacturing, electronics miniaturization, and sustainable manufacturing processes.

The current technological trajectory points toward more energy-efficient systems with higher throughput capabilities. Industry trends indicate growing integration of ultrafast lasers with automation and AI-driven process optimization, enabling adaptive manufacturing techniques that minimize material waste and energy consumption—key factors in sustainable manufacturing practices.

The primary objective of ultrafast laser implementation in sustainable manufacturing is to develop processes that significantly reduce environmental impact while maintaining or improving production efficiency. Specific goals include minimizing material waste through precision processing, reducing or eliminating chemical processes in manufacturing, decreasing energy consumption per unit produced, and enabling the processing of new sustainable materials that may be challenging to work with using conventional methods.

Secondary objectives include extending product lifecycles through improved component quality, facilitating repair and remanufacturing through precise material addition and removal capabilities, and developing closed-loop manufacturing systems where real-time monitoring ensures optimal resource utilization. These objectives align with broader industrial sustainability initiatives and increasingly stringent environmental regulations worldwide.

The convergence of ultrafast laser technology with sustainability imperatives represents a promising frontier in manufacturing innovation, potentially enabling a paradigm shift from traditional resource-intensive production methods to more efficient, precise, and environmentally responsible manufacturing approaches.

Market Demand for Sustainable Manufacturing Solutions

The global market for sustainable manufacturing solutions has witnessed significant growth in recent years, driven by increasing environmental concerns, regulatory pressures, and corporate sustainability initiatives. Ultrafast laser technology has emerged as a critical enabler for sustainable manufacturing practices, offering substantial reductions in energy consumption, material waste, and environmental impact compared to conventional manufacturing methods.

Market research indicates that the sustainable manufacturing solutions market is expected to grow at a compound annual growth rate of over 8% through 2030, with ultrafast laser technologies representing one of the fastest-growing segments within this space. This growth is primarily fueled by industries seeking to reduce their carbon footprint while maintaining or improving production efficiency and product quality.

The automotive and aerospace sectors demonstrate particularly strong demand for ultrafast laser solutions, as these industries face stringent environmental regulations and increasing pressure to adopt cleaner production methods. These sectors value the precision cutting and welding capabilities of ultrafast lasers, which minimize material waste and reduce the need for environmentally harmful chemical processes in manufacturing.

Electronics manufacturing represents another significant market, with consumer electronics companies increasingly incorporating sustainability metrics into their production goals. The ability of ultrafast lasers to process materials with minimal heat-affected zones and exceptional precision aligns perfectly with the miniaturization trends in electronics while reducing resource consumption.

Medical device manufacturing has also emerged as a high-growth segment for sustainable laser manufacturing solutions. The industry's requirements for biocompatible materials and precision components make ultrafast laser processing particularly valuable, as it enables complex geometries with minimal material waste and without chemical contamination.

Regional analysis reveals that Europe currently leads in adoption of sustainable manufacturing technologies, driven by stringent environmental regulations and strong governmental support for green manufacturing initiatives. However, the Asia-Pacific region is experiencing the fastest growth rate, as countries like China, Japan, and South Korea invest heavily in modernizing their manufacturing infrastructure with sustainability as a core principle.

Customer surveys indicate that manufacturers are increasingly willing to invest in premium-priced ultrafast laser solutions when clear return on investment can be demonstrated through reduced material costs, lower energy consumption, decreased waste management expenses, and enhanced product quality. This represents a shift from purely cost-driven purchasing decisions toward value-based procurement that considers total environmental impact and lifecycle costs.

Market research indicates that the sustainable manufacturing solutions market is expected to grow at a compound annual growth rate of over 8% through 2030, with ultrafast laser technologies representing one of the fastest-growing segments within this space. This growth is primarily fueled by industries seeking to reduce their carbon footprint while maintaining or improving production efficiency and product quality.

The automotive and aerospace sectors demonstrate particularly strong demand for ultrafast laser solutions, as these industries face stringent environmental regulations and increasing pressure to adopt cleaner production methods. These sectors value the precision cutting and welding capabilities of ultrafast lasers, which minimize material waste and reduce the need for environmentally harmful chemical processes in manufacturing.

Electronics manufacturing represents another significant market, with consumer electronics companies increasingly incorporating sustainability metrics into their production goals. The ability of ultrafast lasers to process materials with minimal heat-affected zones and exceptional precision aligns perfectly with the miniaturization trends in electronics while reducing resource consumption.

Medical device manufacturing has also emerged as a high-growth segment for sustainable laser manufacturing solutions. The industry's requirements for biocompatible materials and precision components make ultrafast laser processing particularly valuable, as it enables complex geometries with minimal material waste and without chemical contamination.

Regional analysis reveals that Europe currently leads in adoption of sustainable manufacturing technologies, driven by stringent environmental regulations and strong governmental support for green manufacturing initiatives. However, the Asia-Pacific region is experiencing the fastest growth rate, as countries like China, Japan, and South Korea invest heavily in modernizing their manufacturing infrastructure with sustainability as a core principle.

Customer surveys indicate that manufacturers are increasingly willing to invest in premium-priced ultrafast laser solutions when clear return on investment can be demonstrated through reduced material costs, lower energy consumption, decreased waste management expenses, and enhanced product quality. This represents a shift from purely cost-driven purchasing decisions toward value-based procurement that considers total environmental impact and lifecycle costs.

Current State and Challenges in Ultrafast Laser Applications

Ultrafast laser technology has evolved significantly over the past two decades, transitioning from laboratory curiosities to essential tools in advanced manufacturing. Currently, these systems operate primarily in three temporal regimes: picosecond (10^-12 s), femtosecond (10^-15 s), and emerging attosecond (10^-18 s) domains. Each regime offers distinct advantages for specific applications, with femtosecond lasers dominating sustainable manufacturing implementations due to their minimal heat-affected zone and high precision material processing capabilities.

The global market for ultrafast lasers in manufacturing has reached approximately $2.3 billion in 2023, with projected annual growth rates of 14-16% through 2030. This growth is driven primarily by semiconductor, medical device, and renewable energy sectors seeking more energy-efficient and waste-reducing manufacturing processes. However, adoption remains constrained by several critical challenges that limit broader implementation.

Technical barriers represent the most significant impediment to widespread adoption. Current ultrafast laser systems suffer from reliability issues during continuous operation in industrial environments, with mean time between failures typically ranging from 2,000-5,000 hours—substantially lower than conventional laser systems. Beam quality degradation over extended operation periods further complicates integration into 24/7 manufacturing environments.

Cost factors present another substantial challenge. The average capital investment for industrial-grade ultrafast laser systems ranges from $250,000 to over $1 million, with operational costs approximately 3-4 times higher than conventional laser systems. This economic barrier restricts adoption primarily to high-value manufacturing applications where traditional processes are inadequate.

Energy efficiency paradoxically remains problematic despite the technology's sustainability promise. While ultrafast lasers enable more precise material processing with reduced waste, the wall-plug efficiency of most systems remains below 20%, significantly lower than the 30-40% efficiency of conventional industrial lasers. This contradiction undermines some sustainability benefits and represents a critical area for improvement.

Material compatibility limitations also constrain applications. Current ultrafast laser technologies demonstrate excellent results with metals and certain ceramics but face significant challenges with highly reflective materials, transparent polymers, and composite materials increasingly common in sustainable product designs. The processing parameters window remains narrow for many advanced materials, requiring extensive optimization for each application.

Scaling challenges persist in transitioning from laboratory demonstrations to industrial implementation. Most sustainable manufacturing applications require processing speeds of several meters per second, while maintaining sub-micron precision—a combination that remains difficult to achieve consistently with current ultrafast laser systems.

The global market for ultrafast lasers in manufacturing has reached approximately $2.3 billion in 2023, with projected annual growth rates of 14-16% through 2030. This growth is driven primarily by semiconductor, medical device, and renewable energy sectors seeking more energy-efficient and waste-reducing manufacturing processes. However, adoption remains constrained by several critical challenges that limit broader implementation.

Technical barriers represent the most significant impediment to widespread adoption. Current ultrafast laser systems suffer from reliability issues during continuous operation in industrial environments, with mean time between failures typically ranging from 2,000-5,000 hours—substantially lower than conventional laser systems. Beam quality degradation over extended operation periods further complicates integration into 24/7 manufacturing environments.

Cost factors present another substantial challenge. The average capital investment for industrial-grade ultrafast laser systems ranges from $250,000 to over $1 million, with operational costs approximately 3-4 times higher than conventional laser systems. This economic barrier restricts adoption primarily to high-value manufacturing applications where traditional processes are inadequate.

Energy efficiency paradoxically remains problematic despite the technology's sustainability promise. While ultrafast lasers enable more precise material processing with reduced waste, the wall-plug efficiency of most systems remains below 20%, significantly lower than the 30-40% efficiency of conventional industrial lasers. This contradiction undermines some sustainability benefits and represents a critical area for improvement.

Material compatibility limitations also constrain applications. Current ultrafast laser technologies demonstrate excellent results with metals and certain ceramics but face significant challenges with highly reflective materials, transparent polymers, and composite materials increasingly common in sustainable product designs. The processing parameters window remains narrow for many advanced materials, requiring extensive optimization for each application.

Scaling challenges persist in transitioning from laboratory demonstrations to industrial implementation. Most sustainable manufacturing applications require processing speeds of several meters per second, while maintaining sub-micron precision—a combination that remains difficult to achieve consistently with current ultrafast laser systems.

Current Ultrafast Laser Solutions for Sustainable Production

01 Energy-efficient ultrafast laser systems

Energy-efficient ultrafast laser systems incorporate advanced power management technologies to reduce energy consumption while maintaining high performance. These systems utilize optimized pump sources, regenerative amplifiers, and pulse compression techniques to minimize energy waste. The sustainability of these systems is enhanced through the use of efficient cooling mechanisms and power-saving operational modes that reduce the environmental footprint while extending the lifetime of components.- Energy-efficient ultrafast laser systems: Energy-efficient ultrafast laser systems incorporate design elements that reduce power consumption while maintaining high performance. These systems utilize advanced cooling mechanisms, optimized optical components, and power management techniques to minimize energy waste. By improving energy efficiency, these laser systems contribute to sustainability by reducing their environmental footprint while still delivering the precision and power required for various applications.

- Sustainable materials for ultrafast laser components: The development of sustainable materials for ultrafast laser components focuses on using environmentally friendly substances that reduce the ecological impact of laser manufacturing. These materials include recyclable optical elements, non-toxic gain media, and components with extended operational lifetimes. By incorporating sustainable materials, manufacturers can reduce waste, minimize the use of rare earth elements, and create more environmentally responsible laser systems.

- Renewable energy integration with ultrafast laser systems: Integrating renewable energy sources with ultrafast laser systems involves designing laser equipment that can operate efficiently using solar, wind, or other sustainable power sources. These systems may include energy storage solutions, smart power management, and adaptive control mechanisms that optimize performance based on available renewable energy. This approach reduces reliance on conventional power grids and decreases the carbon footprint of laser operations.

- Lifecycle optimization of ultrafast laser equipment: Lifecycle optimization focuses on extending the operational lifespan of ultrafast laser equipment through modular design, upgradeable components, and preventive maintenance protocols. These approaches enable the refurbishment and reuse of laser systems, reducing electronic waste and resource consumption. By designing for disassembly and recycling, manufacturers can minimize the environmental impact throughout the entire lifecycle of the laser equipment.

- Sustainable manufacturing processes using ultrafast lasers: Ultrafast lasers enable sustainable manufacturing processes through precise material processing that minimizes waste and energy consumption. These lasers can perform high-precision cutting, welding, and surface modification with minimal heat-affected zones, reducing the need for secondary processing and coolants. By optimizing process parameters and implementing closed-loop control systems, manufacturers can achieve more sustainable production methods with reduced environmental impact.

02 Eco-friendly materials and manufacturing processes for ultrafast lasers

Sustainable approaches to ultrafast laser manufacturing involve the use of environmentally friendly materials and production processes. These include lead-free optical components, recyclable housing materials, and reduced use of rare earth elements. Manufacturing techniques focus on minimizing waste through precise fabrication methods, reducing harmful chemical usage, and implementing closed-loop production systems that recover and reuse materials. These approaches significantly reduce the environmental impact of ultrafast laser production.Expand Specific Solutions03 Longevity and maintenance optimization of ultrafast laser systems

Enhancing the operational lifespan of ultrafast laser systems involves advanced maintenance strategies and component design. Self-diagnostic capabilities allow for predictive maintenance, reducing downtime and extending system life. Modular designs facilitate easy replacement of worn components rather than entire systems. Thermal management solutions prevent premature degradation, while robust optical coatings resist damage from high-intensity pulses. These approaches collectively improve the sustainability of ultrafast laser systems by reducing waste from premature equipment replacement.Expand Specific Solutions04 Sustainable applications of ultrafast laser technology

Ultrafast lasers contribute to sustainability through various industrial and research applications. In manufacturing, they enable precise material processing with minimal waste and reduced energy consumption compared to conventional methods. In renewable energy, they facilitate the production of more efficient solar cells and energy storage devices. Medical applications include minimally invasive treatments that reduce recovery time and resource use. Environmental monitoring systems utilizing ultrafast lasers help track pollution and climate change indicators with high precision.Expand Specific Solutions05 Recycling and end-of-life management for ultrafast laser components

Sustainable end-of-life management strategies for ultrafast laser systems include specialized recycling processes for optical components, electronic parts, and cooling systems. These approaches focus on recovering valuable materials such as rare earth elements from gain media, precious metals from electronic components, and specialized glasses from optical elements. Design for disassembly principles enable easier separation of components for recycling. Take-back programs and circular economy initiatives by manufacturers help ensure proper handling of decommissioned laser systems, reducing landfill waste and resource depletion.Expand Specific Solutions

Key Industry Players in Ultrafast Laser Manufacturing

Ultrafast laser technology for sustainable manufacturing is evolving rapidly in a growth market phase, with increasing adoption across industries seeking energy-efficient and waste-reducing production methods. The global market is expanding significantly, driven by environmental regulations and corporate sustainability initiatives. Technologically, the field shows varying maturity levels among key players: IPG Photonics and Corning lead with established commercial solutions, while Han's Laser and Electro Scientific Industries demonstrate strong industrial applications. Academic institutions like Harbin Institute of Technology and Central South University are advancing fundamental research. Panasonic and Olympus are integrating these technologies into consumer and medical products, while specialized firms like Refined Laser Systems and Femto Blanc focus on niche applications, creating a diverse competitive landscape balancing innovation and commercialization.

IPG Photonics Corp.

Technical Solution: IPG Photonics has developed advanced fiber laser technology for sustainable manufacturing, focusing on their YLS series high-power fiber lasers that deliver up to 20kW of continuous output power with wall-plug efficiency exceeding 50%[1]. Their ultrafast laser solutions incorporate direct diode pumping architecture that significantly reduces energy consumption compared to traditional lamp-pumped systems. IPG's ECO family specifically targets sustainable manufacturing with pulse durations in the picosecond and femtosecond ranges, enabling "cold ablation" processes that minimize heat-affected zones and reduce material waste[2]. The company has pioneered closed-loop water cooling systems that recycle over 95% of cooling water, dramatically reducing water consumption in manufacturing environments. Their QCW (Quasi-Continuous Wave) technology allows for precise energy delivery with minimal thermal impact, supporting applications in thin-film patterning and precision cutting of temperature-sensitive materials with material utilization rates above 90%[3].

Strengths: Industry-leading wall-plug efficiency (>50%) significantly reduces energy consumption; proprietary fiber technology enables maintenance-free operation for over 100,000 hours, reducing resource waste from replacement parts; compact design requires less factory floor space and cooling infrastructure. Weaknesses: Higher initial capital investment compared to conventional laser systems; requires specialized knowledge for integration into existing manufacturing lines; limited effectiveness for certain highly reflective materials without additional process development.

Corning Research & Development Corp.

Technical Solution: Corning Research & Development has pioneered ultrafast laser technology specifically designed for sustainable glass manufacturing processes. Their proprietary ULE® (Ultra-Low Expansion) glass processing technique utilizes femtosecond lasers operating at pulse durations below 400 femtoseconds to achieve precision micro-machining with virtually no heat-affected zone[1]. This enables material removal through cold ablation rather than thermal processes, reducing energy consumption by approximately 40% compared to conventional methods. Corning's system incorporates adaptive optics that dynamically compensate for beam distortions, maintaining consistent processing quality while minimizing waste material. Their closed-loop monitoring system uses real-time spectroscopy to analyze the ablation plume, automatically adjusting laser parameters to optimize material removal rates and energy efficiency[2]. For display glass manufacturing, Corning has developed a proprietary "zero-waste cutting" technique using spatially shaped ultrafast laser beams that create self-propagating cleaves, allowing full-sheet utilization and eliminating edge trimming waste that typically accounts for 8-12% of material loss in traditional processes[3].

Strengths: Achieves near-zero kerf width in glass cutting applications, maximizing material utilization; eliminates need for cooling fluids and chemical etchants in many applications, reducing environmental impact; enables complex 3D microstructures in glass that support next-generation photonic devices with improved energy efficiency. Weaknesses: Technology primarily optimized for silica-based materials with more limited applications for metals and polymers; requires highly specialized equipment with significant initial investment; processing speeds still lower than some conventional methods for certain high-volume applications.

Core Innovations in Ultrafast Laser Processing Techniques

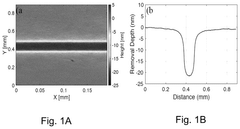

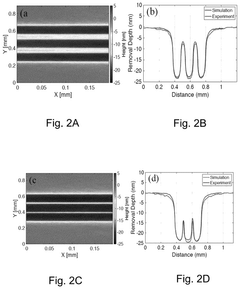

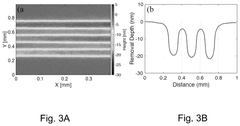

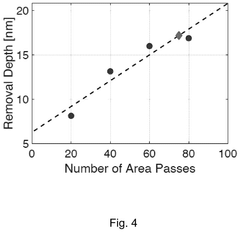

Ultrafast-laser-based figuring and mid-spatial frequency error correction

PatentPendingUS20250242443A1

Innovation

- Utilizing ultrafast lasers for non-contact material removal, measuring and quantifying MSF errors, and removing material with nanometer precision to correct these errors by generating and overlapping grooves according to a predicted pattern, achieving single-digit-nanometer surface roughness.

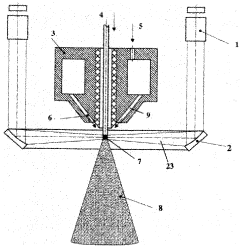

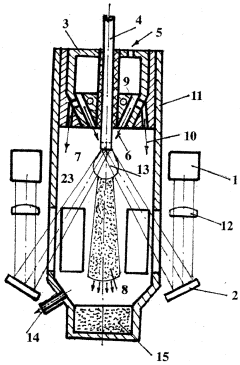

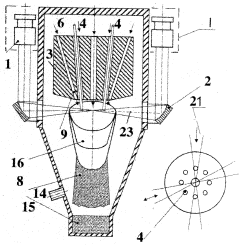

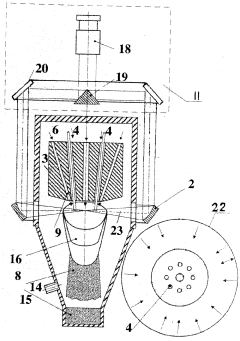

Laser method for producing powders and device for the implementation thereof

PatentWO2023214214A1

Innovation

- A laser method combining conical geometry laser radiation for rapid heating and supersonic gas flows for atomization, along with optical discharge plasma for evaporation and condensation, allowing for high-energy concentration and efficient production of micro and nano-sized particles with reduced energy costs.

Environmental Impact Assessment of Ultrafast Laser Processes

The environmental impact assessment of ultrafast laser processes reveals significant advantages over conventional manufacturing methods. Ultrafast laser technology demonstrates reduced energy consumption by up to 30-40% compared to traditional machining processes, primarily due to the elimination of secondary processing steps and the precision of material removal that minimizes waste generation.

Water usage in ultrafast laser manufacturing shows remarkable efficiency, with studies indicating a reduction of approximately 80% compared to conventional wet-cutting and chemical etching processes. This substantial decrease stems from the inherently dry nature of laser processing, which eliminates the need for cooling fluids and chemical solutions typically required in traditional manufacturing.

Material efficiency represents another critical environmental benefit. Ultrafast laser processing achieves material utilization rates exceeding 90% in many applications, significantly higher than conventional subtractive manufacturing methods. The precise ablation capabilities allow for minimal kerf width and highly controlled material removal, resulting in substantially reduced waste streams.

Carbon footprint analyses of manufacturing facilities implementing ultrafast laser technology show promising results. Life cycle assessments indicate potential reductions of 25-35% in greenhouse gas emissions when compared to conventional manufacturing lines producing equivalent components. These reductions derive from both direct energy savings and decreased material transportation requirements due to localized production capabilities.

Waste toxicity profiles also demonstrate environmental advantages. Ultrafast laser processes typically generate minimal hazardous waste compared to chemical etching and electrochemical machining. The absence of chemical etchants, heavy metal solutions, and other environmentally problematic substances significantly reduces the environmental burden associated with waste disposal and treatment.

Noise pollution levels from ultrafast laser manufacturing facilities measure considerably lower than conventional machine shops. Typical readings show 15-20 dB reductions, creating healthier work environments and reducing community impact in manufacturing zones. This aspect, often overlooked in environmental assessments, contributes significantly to overall sustainability metrics.

Recovery and recycling potential for materials processed via ultrafast laser technology exceeds that of conventionally manufactured components. The clean, precise cuts and minimal thermal effects preserve material properties, allowing for higher-grade recycling streams. This circular economy advantage extends the environmental benefits beyond the manufacturing phase into product end-of-life considerations.

Water usage in ultrafast laser manufacturing shows remarkable efficiency, with studies indicating a reduction of approximately 80% compared to conventional wet-cutting and chemical etching processes. This substantial decrease stems from the inherently dry nature of laser processing, which eliminates the need for cooling fluids and chemical solutions typically required in traditional manufacturing.

Material efficiency represents another critical environmental benefit. Ultrafast laser processing achieves material utilization rates exceeding 90% in many applications, significantly higher than conventional subtractive manufacturing methods. The precise ablation capabilities allow for minimal kerf width and highly controlled material removal, resulting in substantially reduced waste streams.

Carbon footprint analyses of manufacturing facilities implementing ultrafast laser technology show promising results. Life cycle assessments indicate potential reductions of 25-35% in greenhouse gas emissions when compared to conventional manufacturing lines producing equivalent components. These reductions derive from both direct energy savings and decreased material transportation requirements due to localized production capabilities.

Waste toxicity profiles also demonstrate environmental advantages. Ultrafast laser processes typically generate minimal hazardous waste compared to chemical etching and electrochemical machining. The absence of chemical etchants, heavy metal solutions, and other environmentally problematic substances significantly reduces the environmental burden associated with waste disposal and treatment.

Noise pollution levels from ultrafast laser manufacturing facilities measure considerably lower than conventional machine shops. Typical readings show 15-20 dB reductions, creating healthier work environments and reducing community impact in manufacturing zones. This aspect, often overlooked in environmental assessments, contributes significantly to overall sustainability metrics.

Recovery and recycling potential for materials processed via ultrafast laser technology exceeds that of conventionally manufactured components. The clean, precise cuts and minimal thermal effects preserve material properties, allowing for higher-grade recycling streams. This circular economy advantage extends the environmental benefits beyond the manufacturing phase into product end-of-life considerations.

Energy Efficiency Metrics and Standards for Laser Technologies

Energy efficiency metrics and standards for laser technologies have become increasingly critical in the sustainable manufacturing landscape, particularly for ultrafast laser applications. The evaluation of energy consumption in laser-based manufacturing processes requires comprehensive metrics that account for both direct and indirect energy inputs. Currently, the industry employs several key performance indicators including Wall-Plug Efficiency (WPE), which measures the ratio of optical output power to electrical input power, typically ranging from 20-50% for ultrafast lasers depending on the technology.

Process Energy Efficiency (PEE) represents another vital metric, calculating the energy required per unit of processed material. For ultrafast laser applications, this metric often reveals significant advantages over conventional manufacturing methods, with energy savings of 30-70% reported in precision cutting and micromachining operations. The Total Energy Consumption (TEC) framework provides a more holistic approach by incorporating auxiliary systems such as cooling, gas delivery, and beam delivery mechanisms.

International standards governing laser energy efficiency have evolved substantially over the past decade. ISO 14955 specifically addresses the environmental evaluation of machine tools, including laser-based systems, while the IEC 60825 series covers safety aspects that indirectly influence energy consumption through required safety measures. The European Union's Ecodesign Directive (2009/125/EC) has recently expanded to include industrial laser equipment, mandating minimum efficiency requirements for new installations.

Industry-specific benchmarks have emerged through collaborative efforts between research institutions and manufacturing consortia. The Laser Energy Efficiency Partnership (LEEP) has established baseline performance metrics for various laser applications, providing manufacturers with comparative data to evaluate their systems. These benchmarks indicate that ultrafast laser technologies, despite their higher initial energy demands, often demonstrate superior lifecycle energy efficiency when considering reduced material waste and post-processing requirements.

Emerging evaluation frameworks are increasingly incorporating sustainability factors beyond direct energy consumption. The Sustainable Laser Manufacturing Index (SLMI) integrates energy efficiency with material utilization rates, waste reduction potential, and process optimization capabilities. This holistic approach reveals that ultrafast laser technologies often outperform conventional methods by 40-60% when all sustainability factors are considered.

The development of standardized testing protocols remains a challenge in the industry. Current efforts by organizations such as NIST and the Fraunhofer Institute aim to establish uniform testing methodologies that enable fair comparisons across different laser technologies and applications. These protocols will be essential for the continued advancement of energy-efficient ultrafast laser systems and their broader adoption in sustainable manufacturing practices.

Process Energy Efficiency (PEE) represents another vital metric, calculating the energy required per unit of processed material. For ultrafast laser applications, this metric often reveals significant advantages over conventional manufacturing methods, with energy savings of 30-70% reported in precision cutting and micromachining operations. The Total Energy Consumption (TEC) framework provides a more holistic approach by incorporating auxiliary systems such as cooling, gas delivery, and beam delivery mechanisms.

International standards governing laser energy efficiency have evolved substantially over the past decade. ISO 14955 specifically addresses the environmental evaluation of machine tools, including laser-based systems, while the IEC 60825 series covers safety aspects that indirectly influence energy consumption through required safety measures. The European Union's Ecodesign Directive (2009/125/EC) has recently expanded to include industrial laser equipment, mandating minimum efficiency requirements for new installations.

Industry-specific benchmarks have emerged through collaborative efforts between research institutions and manufacturing consortia. The Laser Energy Efficiency Partnership (LEEP) has established baseline performance metrics for various laser applications, providing manufacturers with comparative data to evaluate their systems. These benchmarks indicate that ultrafast laser technologies, despite their higher initial energy demands, often demonstrate superior lifecycle energy efficiency when considering reduced material waste and post-processing requirements.

Emerging evaluation frameworks are increasingly incorporating sustainability factors beyond direct energy consumption. The Sustainable Laser Manufacturing Index (SLMI) integrates energy efficiency with material utilization rates, waste reduction potential, and process optimization capabilities. This holistic approach reveals that ultrafast laser technologies often outperform conventional methods by 40-60% when all sustainability factors are considered.

The development of standardized testing protocols remains a challenge in the industry. Current efforts by organizations such as NIST and the Fraunhofer Institute aim to establish uniform testing methodologies that enable fair comparisons across different laser technologies and applications. These protocols will be essential for the continued advancement of energy-efficient ultrafast laser systems and their broader adoption in sustainable manufacturing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!