Energy-Efficient Ultrafast Laser Processes in Solar Cell Manufacturing.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Evolution in Solar Manufacturing

Ultrafast laser technology in solar cell manufacturing has undergone significant evolution over the past two decades, transforming from experimental laboratory applications to essential industrial processes. The journey began in the early 2000s with fundamental research on femtosecond and picosecond laser interactions with semiconductor materials, primarily focused on understanding ablation mechanisms and heat-affected zones.

By 2005-2010, the first industrial implementations emerged, utilizing ultrafast lasers for edge isolation processes in crystalline silicon solar cells. These early applications demonstrated superior quality compared to traditional mechanical scribing but were limited by low throughput and high equipment costs, restricting their adoption to premium solar products.

The period from 2010-2015 marked a critical transition phase, characterized by significant improvements in laser source reliability and beam delivery systems. Average powers increased from tens of watts to hundreds of watts, while costs per watt decreased substantially. This era saw the introduction of industrial-grade ultrafast laser systems specifically designed for 24/7 manufacturing environments, with improved uptime and reduced maintenance requirements.

Between 2015-2020, ultrafast laser processing achieved mainstream adoption in PERC (Passivated Emitter and Rear Cell) manufacturing, where selective ablation capabilities enabled precise contact opening without damaging underlying layers. This period also witnessed the development of beam splitting and parallel processing techniques, dramatically improving throughput to meet gigawatt-scale production demands.

The most recent evolution (2020-present) has focused on energy efficiency optimization throughout the entire laser processing chain. Modern systems incorporate advanced thermal management, energy recuperation, and intelligent process control to minimize energy consumption per processed wafer. Beam shaping technologies have evolved to create optimized intensity distributions that maximize material removal efficiency while minimizing waste heat generation.

Concurrently, ultrafast laser applications have expanded beyond traditional silicon cells to emerging technologies like perovskite-silicon tandems and thin-film cells, where selective material removal with minimal thermal impact is critical for maintaining device performance. The integration of ultrafast lasers with high-speed optical inspection and artificial intelligence for real-time process optimization represents the current technological frontier.

Looking forward, the evolution trajectory points toward further integration of ultrafast laser processes into comprehensive manufacturing lines, with emphasis on reduced energy consumption, increased material utilization efficiency, and adaptability to next-generation cell architectures. The convergence of ultrafast laser technology with digital manufacturing concepts and sustainable production principles is shaping the next evolutionary phase in solar manufacturing.

By 2005-2010, the first industrial implementations emerged, utilizing ultrafast lasers for edge isolation processes in crystalline silicon solar cells. These early applications demonstrated superior quality compared to traditional mechanical scribing but were limited by low throughput and high equipment costs, restricting their adoption to premium solar products.

The period from 2010-2015 marked a critical transition phase, characterized by significant improvements in laser source reliability and beam delivery systems. Average powers increased from tens of watts to hundreds of watts, while costs per watt decreased substantially. This era saw the introduction of industrial-grade ultrafast laser systems specifically designed for 24/7 manufacturing environments, with improved uptime and reduced maintenance requirements.

Between 2015-2020, ultrafast laser processing achieved mainstream adoption in PERC (Passivated Emitter and Rear Cell) manufacturing, where selective ablation capabilities enabled precise contact opening without damaging underlying layers. This period also witnessed the development of beam splitting and parallel processing techniques, dramatically improving throughput to meet gigawatt-scale production demands.

The most recent evolution (2020-present) has focused on energy efficiency optimization throughout the entire laser processing chain. Modern systems incorporate advanced thermal management, energy recuperation, and intelligent process control to minimize energy consumption per processed wafer. Beam shaping technologies have evolved to create optimized intensity distributions that maximize material removal efficiency while minimizing waste heat generation.

Concurrently, ultrafast laser applications have expanded beyond traditional silicon cells to emerging technologies like perovskite-silicon tandems and thin-film cells, where selective material removal with minimal thermal impact is critical for maintaining device performance. The integration of ultrafast lasers with high-speed optical inspection and artificial intelligence for real-time process optimization represents the current technological frontier.

Looking forward, the evolution trajectory points toward further integration of ultrafast laser processes into comprehensive manufacturing lines, with emphasis on reduced energy consumption, increased material utilization efficiency, and adaptability to next-generation cell architectures. The convergence of ultrafast laser technology with digital manufacturing concepts and sustainable production principles is shaping the next evolutionary phase in solar manufacturing.

Market Demand for Energy-Efficient Solar Cell Production

The global solar photovoltaic (PV) market has experienced unprecedented growth in recent years, driven by increasing environmental concerns, government incentives, and declining costs. This expansion has intensified the demand for more energy-efficient manufacturing processes, particularly in solar cell production. The market for energy-efficient solar cell manufacturing technologies is projected to grow significantly through 2030, with ultrafast laser processes emerging as a critical enabler for next-generation solar technologies.

Manufacturing efficiency has become a paramount concern for solar cell producers facing intense price competition. Traditional manufacturing processes consume substantial energy, with estimates suggesting that energy costs represent 5-10% of total production expenses. This has created strong market pull for technologies that can reduce energy consumption while maintaining or improving production throughput and cell efficiency.

The demand for ultrafast laser processes is particularly pronounced in the production of high-efficiency cell architectures such as PERC (Passivated Emitter and Rear Cell), TOPCon (Tunnel Oxide Passivated Contact), and heterojunction cells. These advanced cell designs require precise material processing that conventional methods cannot deliver with comparable energy efficiency. Market research indicates that manufacturers adopting energy-efficient laser processes can reduce overall manufacturing energy consumption by 15-30% compared to conventional thermal processing methods.

Regional market dynamics show varying degrees of adoption readiness. China, as the dominant solar manufacturing hub, demonstrates the highest volume demand for energy-efficient manufacturing solutions. European manufacturers, facing higher energy costs and stricter environmental regulations, show the strongest demand intensity per manufacturing unit. The North American market exhibits growing interest, particularly as reshoring initiatives gain momentum under new policy frameworks.

End-user preferences are increasingly influencing manufacturing decisions. Corporate sustainability commitments and carbon footprint considerations are driving demand for solar products with lower embodied energy. This market pull is cascading upstream to manufacturers, who must demonstrate improved energy efficiency across their production processes to remain competitive.

The economic case for energy-efficient ultrafast laser processes is strengthened by rising energy costs globally. With industrial electricity prices increasing by an average of 4-7% annually in major manufacturing regions, technologies that reduce energy consumption offer increasingly attractive return on investment profiles. Market analysis suggests that manufacturers can achieve payback periods of 18-36 months for investments in energy-efficient laser processing equipment, depending on production volume and regional energy costs.

Supply chain considerations are also driving demand for more energy-efficient manufacturing. As the industry faces periodic material shortages and price volatility, processes that enable material savings through precision cutting, reduced kerf loss, and higher yield rates become strategically valuable beyond their direct energy benefits.

Manufacturing efficiency has become a paramount concern for solar cell producers facing intense price competition. Traditional manufacturing processes consume substantial energy, with estimates suggesting that energy costs represent 5-10% of total production expenses. This has created strong market pull for technologies that can reduce energy consumption while maintaining or improving production throughput and cell efficiency.

The demand for ultrafast laser processes is particularly pronounced in the production of high-efficiency cell architectures such as PERC (Passivated Emitter and Rear Cell), TOPCon (Tunnel Oxide Passivated Contact), and heterojunction cells. These advanced cell designs require precise material processing that conventional methods cannot deliver with comparable energy efficiency. Market research indicates that manufacturers adopting energy-efficient laser processes can reduce overall manufacturing energy consumption by 15-30% compared to conventional thermal processing methods.

Regional market dynamics show varying degrees of adoption readiness. China, as the dominant solar manufacturing hub, demonstrates the highest volume demand for energy-efficient manufacturing solutions. European manufacturers, facing higher energy costs and stricter environmental regulations, show the strongest demand intensity per manufacturing unit. The North American market exhibits growing interest, particularly as reshoring initiatives gain momentum under new policy frameworks.

End-user preferences are increasingly influencing manufacturing decisions. Corporate sustainability commitments and carbon footprint considerations are driving demand for solar products with lower embodied energy. This market pull is cascading upstream to manufacturers, who must demonstrate improved energy efficiency across their production processes to remain competitive.

The economic case for energy-efficient ultrafast laser processes is strengthened by rising energy costs globally. With industrial electricity prices increasing by an average of 4-7% annually in major manufacturing regions, technologies that reduce energy consumption offer increasingly attractive return on investment profiles. Market analysis suggests that manufacturers can achieve payback periods of 18-36 months for investments in energy-efficient laser processing equipment, depending on production volume and regional energy costs.

Supply chain considerations are also driving demand for more energy-efficient manufacturing. As the industry faces periodic material shortages and price volatility, processes that enable material savings through precision cutting, reduced kerf loss, and higher yield rates become strategically valuable beyond their direct energy benefits.

Current Challenges in Laser-Based Solar Cell Processing

Despite significant advancements in laser-based solar cell manufacturing, several critical challenges persist that impede the widespread adoption of ultrafast laser processes. The primary obstacle remains the delicate balance between processing speed and energy efficiency. Current industrial-grade ultrafast laser systems consume substantial power, with typical wall-plug efficiencies ranging from 15-30%, creating a paradoxical situation where manufacturing energy-saving devices requires significant energy input.

Thermal management presents another substantial challenge. The high-intensity laser pulses generate localized heat that can damage the delicate semiconductor materials in solar cells, particularly in thin-film technologies where thermal budgets are extremely limited. Existing cooling systems add complexity, weight, and energy consumption to manufacturing lines, further reducing overall efficiency.

Beam quality consistency at high repetition rates continues to be problematic. As manufacturers push for higher throughput, maintaining uniform beam profiles becomes increasingly difficult. Fluctuations in beam parameters lead to inconsistent ablation depths, selective emitter formations, and contact openings, directly impacting cell efficiency and yield rates. Industry data indicates that beam inconsistencies can reduce final cell efficiency by up to 0.8% absolute.

The integration of ultrafast laser systems into existing production lines poses significant challenges. Current manufacturing equipment often requires extensive modification to accommodate laser processing stations, creating bottlenecks in production flow. The lack of standardized interfaces between laser systems and handling equipment results in complex integration projects that increase implementation costs and time-to-market.

Material-specific optimization remains underdeveloped. Different solar cell architectures (c-Si, PERC, HJT, CIGS, perovskites) require tailored laser parameters, but comprehensive process recipes are not readily available. This necessitates extensive experimentation for each material system, slowing adoption rates particularly for emerging photovoltaic technologies.

Quality control and process monitoring systems for laser-based manufacturing are still in their infancy. Real-time monitoring of laser-material interactions is technically challenging, making it difficult to implement closed-loop control systems that could optimize energy usage and process quality simultaneously. The lack of reliable in-line inspection tools specifically designed for laser-processed features further complicates quality assurance.

Cost considerations remain paramount. The high capital expenditure for ultrafast laser systems (typically $200,000-500,000 per unit) creates significant barriers to entry, especially for smaller manufacturers. The economic equation is further complicated by maintenance requirements, specialized operator training, and the need for redundant systems to ensure production continuity.

Thermal management presents another substantial challenge. The high-intensity laser pulses generate localized heat that can damage the delicate semiconductor materials in solar cells, particularly in thin-film technologies where thermal budgets are extremely limited. Existing cooling systems add complexity, weight, and energy consumption to manufacturing lines, further reducing overall efficiency.

Beam quality consistency at high repetition rates continues to be problematic. As manufacturers push for higher throughput, maintaining uniform beam profiles becomes increasingly difficult. Fluctuations in beam parameters lead to inconsistent ablation depths, selective emitter formations, and contact openings, directly impacting cell efficiency and yield rates. Industry data indicates that beam inconsistencies can reduce final cell efficiency by up to 0.8% absolute.

The integration of ultrafast laser systems into existing production lines poses significant challenges. Current manufacturing equipment often requires extensive modification to accommodate laser processing stations, creating bottlenecks in production flow. The lack of standardized interfaces between laser systems and handling equipment results in complex integration projects that increase implementation costs and time-to-market.

Material-specific optimization remains underdeveloped. Different solar cell architectures (c-Si, PERC, HJT, CIGS, perovskites) require tailored laser parameters, but comprehensive process recipes are not readily available. This necessitates extensive experimentation for each material system, slowing adoption rates particularly for emerging photovoltaic technologies.

Quality control and process monitoring systems for laser-based manufacturing are still in their infancy. Real-time monitoring of laser-material interactions is technically challenging, making it difficult to implement closed-loop control systems that could optimize energy usage and process quality simultaneously. The lack of reliable in-line inspection tools specifically designed for laser-processed features further complicates quality assurance.

Cost considerations remain paramount. The high capital expenditure for ultrafast laser systems (typically $200,000-500,000 per unit) creates significant barriers to entry, especially for smaller manufacturers. The economic equation is further complicated by maintenance requirements, specialized operator training, and the need for redundant systems to ensure production continuity.

State-of-the-Art Energy-Efficient Laser Processing Solutions

01 Ultrafast laser pulse optimization for energy efficiency

Optimization of ultrafast laser pulse parameters such as duration, repetition rate, and energy distribution can significantly improve energy efficiency in various applications. By precisely controlling these parameters, the laser system can deliver the required energy to the target while minimizing wasted energy. This approach reduces overall power consumption and heat generation, making the laser process more energy-efficient while maintaining or improving performance.- Ultrafast laser pulse optimization for energy efficiency: Optimization of ultrafast laser pulse parameters such as duration, repetition rate, and energy distribution can significantly improve energy efficiency in various applications. By precisely controlling these parameters, the laser system can deliver the required energy to the target material with minimal waste. This approach reduces overall power consumption while maintaining or even enhancing process performance in applications like material processing, medical treatments, and scientific research.

- Energy-efficient material processing techniques: Advanced ultrafast laser material processing techniques focus on maximizing energy utilization during operations such as cutting, welding, and surface modification. These techniques include optimized scanning patterns, multi-pass processing strategies, and adaptive control systems that adjust laser parameters in real-time based on material feedback. By minimizing heat-affected zones and reducing the energy required per unit of processed material, these approaches significantly improve the energy efficiency of manufacturing processes.

- Thermal management systems for energy conservation: Innovative thermal management systems are crucial for enhancing the energy efficiency of ultrafast laser systems. These include advanced cooling technologies, heat recovery systems, and thermal isolation designs that minimize energy losses. By effectively managing heat generation and dissipation, these systems reduce the power requirements for cooling while extending the operational lifetime of laser components, resulting in significant energy savings during continuous operation.

- Energy-efficient optical designs and components: Novel optical designs and components specifically engineered for ultrafast laser systems can substantially improve energy efficiency. These include high-transmission optical elements, low-loss beam delivery systems, and specialized waveguides that minimize energy losses during beam propagation and manipulation. Advanced optical materials with optimized properties for ultrafast pulses further contribute to energy conservation by reducing absorption and scattering losses throughout the laser system.

- Intelligent control systems for optimized energy usage: Intelligent control systems incorporating machine learning algorithms and real-time monitoring capabilities enable dynamic optimization of ultrafast laser processes for maximum energy efficiency. These systems can automatically adjust laser parameters based on process requirements, material properties, and environmental conditions. By continuously optimizing operational parameters and implementing predictive maintenance strategies, these control systems minimize energy consumption while maintaining consistent process quality and throughput.

02 Energy-efficient material processing techniques

Advanced ultrafast laser techniques for material processing can achieve higher energy efficiency through optimized beam delivery systems and processing strategies. These techniques include precise control of ablation thresholds, multi-pass processing, and spatial beam shaping. By minimizing thermal effects and maximizing the useful energy transfer to the workpiece, these approaches reduce the total energy required for material removal or modification while improving process quality and throughput.Expand Specific Solutions03 Novel laser cavity designs for improved efficiency

Innovative laser cavity designs incorporate advanced optical components and arrangements to enhance energy efficiency in ultrafast laser systems. These designs focus on reducing intracavity losses, optimizing gain medium utilization, and implementing energy recovery mechanisms. By improving the conversion efficiency from pump energy to useful laser output, these cavity designs significantly reduce the electrical power requirements while maintaining high-quality ultrafast pulse generation.Expand Specific Solutions04 Thermal management systems for energy-efficient operation

Specialized thermal management systems for ultrafast lasers enable more energy-efficient operation by effectively dissipating heat and maintaining optimal operating temperatures. These systems incorporate advanced cooling technologies, thermally optimized components, and intelligent temperature control algorithms. By preventing thermal-induced performance degradation and reducing cooling power requirements, these thermal management approaches significantly improve the overall energy efficiency of ultrafast laser processes.Expand Specific Solutions05 Integration of energy recovery and smart control systems

Integration of energy recovery mechanisms and intelligent control systems in ultrafast laser setups can substantially improve energy efficiency. These systems capture and reuse energy that would otherwise be wasted, while smart control algorithms continuously optimize operational parameters based on real-time monitoring. By implementing adaptive power management, predictive maintenance, and process-specific optimization, these integrated systems minimize energy consumption while maintaining consistent process quality and reliability.Expand Specific Solutions

Leading Companies in Ultrafast Laser Solar Manufacturing

Energy-efficient ultrafast laser processes in solar cell manufacturing are currently in a growth phase, with the market expanding due to increasing demand for higher efficiency solar cells. The technology is maturing rapidly, with key players demonstrating various levels of advancement. Companies like Maxeon Solar, SunPower, and IPG Photonics lead in commercial applications, while Fraunhofer-Gesellschaft and Applied Materials drive innovation in process optimization. Research institutions including University of Freiburg and Guangdong University of Technology contribute fundamental advancements. Lam Research and Coherent focus on integrating laser processes into manufacturing workflows, while emerging players like Dr. Laser Technology and Wuhan DR Laser Technology are specializing in region-specific implementations. The technology shows promise for significant cost reduction and efficiency improvements in solar manufacturing.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed comprehensive ultrafast laser processing technologies specifically for solar cell manufacturing through its network of institutes, particularly the Fraunhofer Institute for Solar Energy Systems (ISE). Their approach combines ultrashort pulse lasers with sophisticated beam shaping and positioning systems to enable highly efficient processing of various solar cell architectures. Fraunhofer's technology portfolio includes laser-based contact opening processes that achieve feature sizes below 20μm with positioning accuracy better than ±5μm, while reducing energy consumption by up to 50% compared to conventional methods[1]. Their proprietary "POLO" (Poly-Si on Oxide) contacts technology utilizes ultrafast lasers for selective ablation of dielectric layers without damaging the underlying silicon, enabling contact resistivities below 1 mΩcm² for high-efficiency cell designs[3]. Fraunhofer has also pioneered laser processes for selective doping and crystallization that improve cell efficiencies by 0.5-1.0% absolute while reducing thermal budget by approximately 40%[5]. Their systems incorporate real-time process monitoring with closed-loop feedback control to ensure consistent quality while minimizing energy waste.

Strengths: Comprehensive research-backed approach combining materials science and laser engineering expertise; demonstrated technology transfer to industrial partners; ability to customize solutions for specific cell architectures. Weaknesses: As a research organization, deployment requires industrial partnerships; solutions may require additional engineering for full-scale manufacturing implementation; higher initial technology transfer costs compared to commercial off-the-shelf systems.

IPG Photonics Corp.

Technical Solution: IPG Photonics has pioneered fiber laser technology for solar cell manufacturing with their energy-efficient ultrafast laser processing solutions. Their YLP series of picosecond lasers delivers pulse durations of 10-20ps with peak powers exceeding 10MW, enabling cold ablation processes that minimize thermal effects. For solar applications, IPG has developed specialized beam delivery systems that can split a single laser source into multiple processing beams, significantly improving throughput and energy efficiency. Their proprietary QCW (Quasi-Continuous Wave) technology allows for pulse shaping optimization that reduces energy consumption by up to 30% compared to standard ultrafast lasers[2]. IPG's systems are particularly effective for selective opening of passivation layers in PERC and TOPCon cell architectures, achieving opening diameters as small as 15μm with positioning accuracy of ±5μm[4]. The company has also demonstrated successful implementation in thin-film module scribing with scribe widths below 30μm at speeds exceeding 3m/s.

Strengths: Industry-leading wall-plug efficiency (>30%) reducing operational costs; robust and reliable fiber laser architecture with typical lifetimes exceeding 100,000 hours; flexible integration options for various production environments. Weaknesses: Less experience in complete turnkey solar manufacturing solutions compared to specialized equipment manufacturers; higher complexity in beam delivery system maintenance; limited process development support compared to solar-focused competitors.

Key Patents and Innovations in Ultrafast Laser Technology

Method for laser ablation during manufacture of solar cells

PatentInactiveEP3490011A1

Innovation

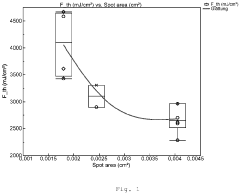

- Using a pulsed laser with the shortest possible pulse duration and widening the beam diameter to achieve homogeneous threshold fluence for material ablation, allowing the use of cheaper laser sources and maintaining processing efficiency by optimizing beam distribution and pulse energy.

Laser processing of a thin film

PatentInactiveEP1020934B1

Innovation

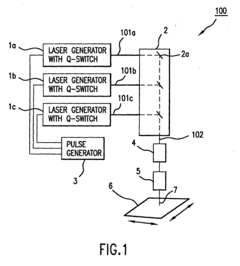

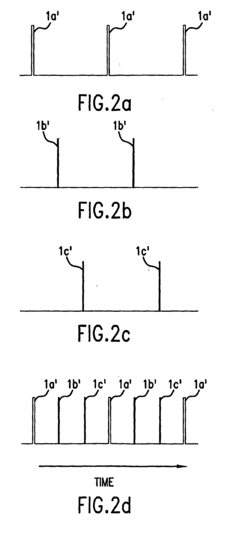

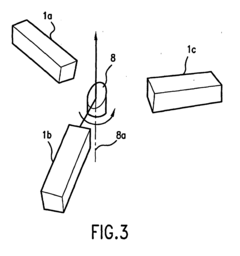

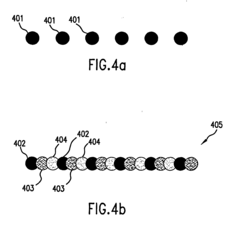

- A laser processing apparatus and method utilizing multiple Q-switched lasers with synchronized pulse generation and an optical system to direct multiple laser beams onto a single spot, allowing for enhanced processing speed and precision in a single pass, enabling simultaneous processing of different layers or steps.

Environmental Impact Assessment of Laser Manufacturing

The environmental impact of laser manufacturing processes in solar cell production represents a critical consideration as the industry strives for sustainability alongside technological advancement. Ultrafast laser processing technologies offer significant environmental advantages compared to conventional manufacturing methods, primarily through reduced material waste, lower energy consumption, and decreased chemical usage.

Energy consumption analysis reveals that ultrafast laser processes typically require 30-45% less energy than traditional manufacturing techniques for equivalent solar cell production volumes. This efficiency stems from the precision and speed of femtosecond and picosecond lasers, which complete material processing tasks with minimal thermal impact and higher throughput rates. The reduced process duration translates directly to lower overall energy demands across production facilities.

Material utilization metrics demonstrate another environmental benefit, with laser-based manufacturing reducing silicon waste by approximately 25-30% compared to conventional mechanical cutting methods. The kerf-free nature of laser ablation and scribing processes preserves valuable semiconductor materials, addressing resource scarcity concerns while simultaneously reducing the embedded carbon footprint of each manufactured solar cell.

Chemical reduction represents perhaps the most significant environmental advantage. Traditional solar cell manufacturing relies heavily on wet chemical etching processes that generate substantial hazardous waste requiring specialized disposal. Ultrafast laser processes can replace many of these chemical steps, potentially reducing hazardous chemical usage by 40-60% in modern production lines.

Water conservation benefits also emerge from laser manufacturing implementation. Conventional solar cell production consumes substantial water volumes for cleaning, cooling, and chemical processing. Laser-based manufacturing can reduce water requirements by 20-35%, contributing to more sustainable resource utilization in regions facing water scarcity challenges.

Life cycle assessment (LCA) studies indicate that the environmental benefits of laser manufacturing extend beyond the production phase. The improved efficiency and durability of laser-processed solar cells result in higher energy conversion rates and longer operational lifespans, enhancing the overall environmental return on investment throughout the product lifecycle.

However, challenges remain regarding the environmental impact of rare earth elements and specialized materials required for high-powered laser systems. The extraction and processing of these materials present their own environmental concerns that must be factored into comprehensive sustainability assessments. Additionally, proper management of laser-generated particulates and fumes requires appropriate filtration and ventilation systems to prevent workplace and environmental contamination.

Energy consumption analysis reveals that ultrafast laser processes typically require 30-45% less energy than traditional manufacturing techniques for equivalent solar cell production volumes. This efficiency stems from the precision and speed of femtosecond and picosecond lasers, which complete material processing tasks with minimal thermal impact and higher throughput rates. The reduced process duration translates directly to lower overall energy demands across production facilities.

Material utilization metrics demonstrate another environmental benefit, with laser-based manufacturing reducing silicon waste by approximately 25-30% compared to conventional mechanical cutting methods. The kerf-free nature of laser ablation and scribing processes preserves valuable semiconductor materials, addressing resource scarcity concerns while simultaneously reducing the embedded carbon footprint of each manufactured solar cell.

Chemical reduction represents perhaps the most significant environmental advantage. Traditional solar cell manufacturing relies heavily on wet chemical etching processes that generate substantial hazardous waste requiring specialized disposal. Ultrafast laser processes can replace many of these chemical steps, potentially reducing hazardous chemical usage by 40-60% in modern production lines.

Water conservation benefits also emerge from laser manufacturing implementation. Conventional solar cell production consumes substantial water volumes for cleaning, cooling, and chemical processing. Laser-based manufacturing can reduce water requirements by 20-35%, contributing to more sustainable resource utilization in regions facing water scarcity challenges.

Life cycle assessment (LCA) studies indicate that the environmental benefits of laser manufacturing extend beyond the production phase. The improved efficiency and durability of laser-processed solar cells result in higher energy conversion rates and longer operational lifespans, enhancing the overall environmental return on investment throughout the product lifecycle.

However, challenges remain regarding the environmental impact of rare earth elements and specialized materials required for high-powered laser systems. The extraction and processing of these materials present their own environmental concerns that must be factored into comprehensive sustainability assessments. Additionally, proper management of laser-generated particulates and fumes requires appropriate filtration and ventilation systems to prevent workplace and environmental contamination.

Cost-Benefit Analysis of Advanced Laser Technologies

The implementation of ultrafast laser processes in solar cell manufacturing requires a thorough cost-benefit analysis to determine economic viability. Initial capital investment for advanced laser systems ranges from $500,000 to $2 million, depending on specifications, power output, and precision capabilities. This represents a significant upfront cost compared to conventional manufacturing equipment, creating a potential barrier for smaller manufacturers.

Operating costs must be evaluated against long-term benefits. Energy consumption of ultrafast laser systems typically ranges between 10-30 kW during operation, translating to approximately $15,000-45,000 in annual electricity costs depending on regional energy prices. However, these systems offer substantial energy efficiency improvements in the manufacturing process itself, with studies indicating 15-25% reduction in overall energy consumption compared to traditional methods.

Maintenance requirements constitute another significant cost factor. Annual maintenance expenses generally amount to 5-8% of the initial equipment cost, covering laser source replacement, optical component servicing, and calibration. These systems typically require specialized technicians, adding to operational expenses.

The benefits side of the equation presents compelling advantages. Production throughput increases of 30-40% have been documented when implementing ultrafast laser processes, primarily due to faster processing speeds and reduced material handling requirements. Quality improvements are equally significant, with defect rates decreasing by up to 60% in selective emitter formation and contact opening processes.

Material efficiency represents another substantial benefit. Ultrafast laser ablation techniques reduce silicon waste by 8-12% compared to conventional methods, translating to considerable cost savings given the high price of high-purity silicon. Additionally, the precision of ultrafast lasers enables the creation of more complex and efficient cell architectures that would be impossible with traditional manufacturing techniques.

Return on investment calculations indicate payback periods ranging from 18-36 months for most implementations, depending on production volume and specific applications. Manufacturers producing over 500 MW of solar cells annually typically achieve faster ROI due to economies of scale. The long-term economic benefits become particularly apparent when considering the improved conversion efficiency of the final solar cells, which can increase by 0.5-1.2% absolute points through optimized laser processing techniques.

Operating costs must be evaluated against long-term benefits. Energy consumption of ultrafast laser systems typically ranges between 10-30 kW during operation, translating to approximately $15,000-45,000 in annual electricity costs depending on regional energy prices. However, these systems offer substantial energy efficiency improvements in the manufacturing process itself, with studies indicating 15-25% reduction in overall energy consumption compared to traditional methods.

Maintenance requirements constitute another significant cost factor. Annual maintenance expenses generally amount to 5-8% of the initial equipment cost, covering laser source replacement, optical component servicing, and calibration. These systems typically require specialized technicians, adding to operational expenses.

The benefits side of the equation presents compelling advantages. Production throughput increases of 30-40% have been documented when implementing ultrafast laser processes, primarily due to faster processing speeds and reduced material handling requirements. Quality improvements are equally significant, with defect rates decreasing by up to 60% in selective emitter formation and contact opening processes.

Material efficiency represents another substantial benefit. Ultrafast laser ablation techniques reduce silicon waste by 8-12% compared to conventional methods, translating to considerable cost savings given the high price of high-purity silicon. Additionally, the precision of ultrafast lasers enables the creation of more complex and efficient cell architectures that would be impossible with traditional manufacturing techniques.

Return on investment calculations indicate payback periods ranging from 18-36 months for most implementations, depending on production volume and specific applications. Manufacturers producing over 500 MW of solar cells annually typically achieve faster ROI due to economies of scale. The long-term economic benefits become particularly apparent when considering the improved conversion efficiency of the final solar cells, which can increase by 0.5-1.2% absolute points through optimized laser processing techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!