Ultrafast Laser Contributions to Wearable Tech Materials.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Evolution and Objectives

Ultrafast laser technology has evolved significantly over the past three decades, transforming from laboratory curiosities to essential industrial tools. The journey began in the 1980s with the development of femtosecond lasers, which initially operated at low repetition rates and required complex maintenance. By the early 2000s, these systems had become more reliable and commercially viable, enabling new applications in materials processing and scientific research.

The evolution accelerated dramatically in the 2010s with the introduction of high-power ultrafast fiber lasers and thin-disk technology, which overcame previous limitations in average power and pulse energy. These advancements enabled ultrafast lasers to transition from primarily scientific instruments to practical industrial tools capable of precision micromachining at unprecedented speeds.

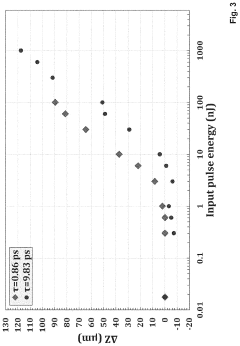

Today's ultrafast lasers operate with pulse durations in the femtosecond to picosecond range (10^-15 to 10^-12 seconds), delivering peak powers in the gigawatt to terawatt range while maintaining excellent beam quality. This combination of extreme temporal precision and high peak power creates unique material interaction mechanisms that avoid thermal effects, enabling "cold processing" of materials.

The primary objective of ultrafast laser technology in wearable tech materials is to develop processing techniques that can modify, structure, and functionalize advanced materials without compromising their inherent properties. This includes creating micro and nano-scale features in flexible substrates, thin films, and composite materials that are essential for next-generation wearable devices.

Specific technical goals include achieving sub-micron processing precision on flexible polymers, developing selective ablation techniques for multilayer thin films, and creating surface texturing methods that enhance material properties such as hydrophobicity, conductivity, or optical characteristics. These capabilities are crucial for manufacturing flexible electronics, sensors, and energy storage components in wearable technology.

Another key objective is to increase processing throughput while maintaining precision, as current ultrafast laser systems often face limitations in production speed compared to conventional manufacturing methods. This involves developing beam delivery systems capable of parallel processing and implementing advanced scanning strategies to optimize material interaction.

The technology also aims to enable direct writing of conductive traces on flexible substrates, selective removal of layers in complex material stacks, and creation of functional microstructures that can respond to environmental stimuli—all critical capabilities for advanced wearable devices that integrate sensing, computing, and communication functions in comfortable, lightweight form factors.

The evolution accelerated dramatically in the 2010s with the introduction of high-power ultrafast fiber lasers and thin-disk technology, which overcame previous limitations in average power and pulse energy. These advancements enabled ultrafast lasers to transition from primarily scientific instruments to practical industrial tools capable of precision micromachining at unprecedented speeds.

Today's ultrafast lasers operate with pulse durations in the femtosecond to picosecond range (10^-15 to 10^-12 seconds), delivering peak powers in the gigawatt to terawatt range while maintaining excellent beam quality. This combination of extreme temporal precision and high peak power creates unique material interaction mechanisms that avoid thermal effects, enabling "cold processing" of materials.

The primary objective of ultrafast laser technology in wearable tech materials is to develop processing techniques that can modify, structure, and functionalize advanced materials without compromising their inherent properties. This includes creating micro and nano-scale features in flexible substrates, thin films, and composite materials that are essential for next-generation wearable devices.

Specific technical goals include achieving sub-micron processing precision on flexible polymers, developing selective ablation techniques for multilayer thin films, and creating surface texturing methods that enhance material properties such as hydrophobicity, conductivity, or optical characteristics. These capabilities are crucial for manufacturing flexible electronics, sensors, and energy storage components in wearable technology.

Another key objective is to increase processing throughput while maintaining precision, as current ultrafast laser systems often face limitations in production speed compared to conventional manufacturing methods. This involves developing beam delivery systems capable of parallel processing and implementing advanced scanning strategies to optimize material interaction.

The technology also aims to enable direct writing of conductive traces on flexible substrates, selective removal of layers in complex material stacks, and creation of functional microstructures that can respond to environmental stimuli—all critical capabilities for advanced wearable devices that integrate sensing, computing, and communication functions in comfortable, lightweight form factors.

Market Demand for Advanced Wearable Materials

The wearable technology market has experienced unprecedented growth in recent years, with global revenues projected to reach $70 billion by 2025, representing a compound annual growth rate of approximately 18%. This remarkable expansion is driven by increasing consumer demand for multifunctional, comfortable, and durable wearable devices across various sectors including healthcare, fitness, military, and fashion industries.

Consumer preferences are rapidly evolving toward more sophisticated wearable products that seamlessly integrate into daily life while offering enhanced functionality. Market research indicates that 67% of consumers prioritize comfort and lightweight properties when purchasing wearable technology, while 58% consider durability and longevity as critical factors influencing their buying decisions. This creates substantial demand for advanced materials that can satisfy these requirements simultaneously.

Healthcare applications represent the fastest-growing segment within the wearable technology market, with particular emphasis on continuous health monitoring devices. The global medical wearables market is expected to reach $19.5 billion by 2024, creating significant opportunities for ultrafast laser-processed materials that can enable biocompatible, flexible sensors capable of accurate physiological monitoring without causing skin irritation or discomfort during prolonged wear.

The fitness and sports segment continues to dominate market share, accounting for approximately 39% of total wearable technology sales. Athletes and fitness enthusiasts increasingly demand wearables that can withstand extreme conditions while providing precise biometric measurements. This has created a substantial market for advanced materials that offer superior durability, water resistance, and breathability while maintaining comfort during intense physical activities.

Military and industrial applications represent emerging high-value markets for advanced wearable materials. These sectors require exceptionally durable, lightweight materials capable of withstanding harsh environments while integrating sophisticated sensing and communication capabilities. Market analysis reveals growing investment in this segment, with government contracts for military wearables exceeding $3.2 billion globally in 2022.

Fashion-tech integration represents another significant market opportunity, with major fashion brands increasingly incorporating technology into their product lines. Consumer willingness to pay premium prices for aesthetically pleasing wearable technology has created demand for materials that combine visual appeal with functionality. Market research indicates that 72% of consumers under 35 express interest in fashion-forward wearable technology, suggesting substantial growth potential in this segment.

The sustainability aspect of wearable materials is gaining prominence as environmental consciousness increases among consumers. Market surveys indicate that 63% of consumers prefer eco-friendly wearable products, creating demand for sustainable manufacturing processes like ultrafast laser material processing that can reduce waste and energy consumption compared to traditional manufacturing methods.

Consumer preferences are rapidly evolving toward more sophisticated wearable products that seamlessly integrate into daily life while offering enhanced functionality. Market research indicates that 67% of consumers prioritize comfort and lightweight properties when purchasing wearable technology, while 58% consider durability and longevity as critical factors influencing their buying decisions. This creates substantial demand for advanced materials that can satisfy these requirements simultaneously.

Healthcare applications represent the fastest-growing segment within the wearable technology market, with particular emphasis on continuous health monitoring devices. The global medical wearables market is expected to reach $19.5 billion by 2024, creating significant opportunities for ultrafast laser-processed materials that can enable biocompatible, flexible sensors capable of accurate physiological monitoring without causing skin irritation or discomfort during prolonged wear.

The fitness and sports segment continues to dominate market share, accounting for approximately 39% of total wearable technology sales. Athletes and fitness enthusiasts increasingly demand wearables that can withstand extreme conditions while providing precise biometric measurements. This has created a substantial market for advanced materials that offer superior durability, water resistance, and breathability while maintaining comfort during intense physical activities.

Military and industrial applications represent emerging high-value markets for advanced wearable materials. These sectors require exceptionally durable, lightweight materials capable of withstanding harsh environments while integrating sophisticated sensing and communication capabilities. Market analysis reveals growing investment in this segment, with government contracts for military wearables exceeding $3.2 billion globally in 2022.

Fashion-tech integration represents another significant market opportunity, with major fashion brands increasingly incorporating technology into their product lines. Consumer willingness to pay premium prices for aesthetically pleasing wearable technology has created demand for materials that combine visual appeal with functionality. Market research indicates that 72% of consumers under 35 express interest in fashion-forward wearable technology, suggesting substantial growth potential in this segment.

The sustainability aspect of wearable materials is gaining prominence as environmental consciousness increases among consumers. Market surveys indicate that 63% of consumers prefer eco-friendly wearable products, creating demand for sustainable manufacturing processes like ultrafast laser material processing that can reduce waste and energy consumption compared to traditional manufacturing methods.

Current Capabilities and Barriers in Laser Material Processing

Ultrafast laser technology has revolutionized material processing capabilities for wearable technology development. Current systems can achieve pulse durations in the femtosecond range (10^-15 seconds), enabling unprecedented precision in material modification without thermal damage. This capability is particularly valuable for processing temperature-sensitive polymers and composite materials commonly used in wearable devices.

The micromachining precision achieved by ultrafast lasers has reached sub-micron levels, allowing for the creation of intricate microstructures and channels necessary for advanced wearable sensors and microfluidic components. Modern systems can maintain beam quality with M² factors approaching 1.0, ensuring consistent processing quality across complex three-dimensional structures.

Processing speeds have significantly improved, with scanning velocities reaching several meters per second through the implementation of polygon scanner technology and advanced galvanometer systems. This advancement has made ultrafast laser processing increasingly viable for commercial-scale manufacturing of wearable components, reducing production time and costs.

Despite these capabilities, several barriers limit the full potential of ultrafast laser processing for wearable technology materials. The high initial investment cost remains prohibitive for many manufacturers, with sophisticated ultrafast laser systems priced between $250,000 and $1 million. This economic barrier restricts adoption primarily to large-scale operations or specialized research facilities.

Energy efficiency presents another significant challenge, as ultrafast lasers typically operate at 15-30% wall-plug efficiency. This limitation increases operational costs and contradicts sustainability goals in manufacturing processes, particularly problematic for wearable technology where energy efficiency is a core value proposition.

Material-specific processing parameters require extensive optimization through trial-and-error approaches. The lack of comprehensive databases for ultrafast laser interaction with novel composite materials and flexible substrates used in wearables necessitates time-consuming parameter development for each new material combination.

Integration challenges with existing manufacturing workflows persist, as ultrafast laser systems often require specialized environments and trained operators. The complexity of synchronizing these advanced systems with traditional production lines creates bottlenecks in manufacturing scalability.

Beam delivery limitations also constrain processing capabilities, particularly for complex three-dimensional wearable structures. Current optical systems struggle to maintain consistent focal properties when processing highly curved surfaces or working within confined geometries typical in miniaturized wearable devices.

The micromachining precision achieved by ultrafast lasers has reached sub-micron levels, allowing for the creation of intricate microstructures and channels necessary for advanced wearable sensors and microfluidic components. Modern systems can maintain beam quality with M² factors approaching 1.0, ensuring consistent processing quality across complex three-dimensional structures.

Processing speeds have significantly improved, with scanning velocities reaching several meters per second through the implementation of polygon scanner technology and advanced galvanometer systems. This advancement has made ultrafast laser processing increasingly viable for commercial-scale manufacturing of wearable components, reducing production time and costs.

Despite these capabilities, several barriers limit the full potential of ultrafast laser processing for wearable technology materials. The high initial investment cost remains prohibitive for many manufacturers, with sophisticated ultrafast laser systems priced between $250,000 and $1 million. This economic barrier restricts adoption primarily to large-scale operations or specialized research facilities.

Energy efficiency presents another significant challenge, as ultrafast lasers typically operate at 15-30% wall-plug efficiency. This limitation increases operational costs and contradicts sustainability goals in manufacturing processes, particularly problematic for wearable technology where energy efficiency is a core value proposition.

Material-specific processing parameters require extensive optimization through trial-and-error approaches. The lack of comprehensive databases for ultrafast laser interaction with novel composite materials and flexible substrates used in wearables necessitates time-consuming parameter development for each new material combination.

Integration challenges with existing manufacturing workflows persist, as ultrafast laser systems often require specialized environments and trained operators. The complexity of synchronizing these advanced systems with traditional production lines creates bottlenecks in manufacturing scalability.

Beam delivery limitations also constrain processing capabilities, particularly for complex three-dimensional wearable structures. Current optical systems struggle to maintain consistent focal properties when processing highly curved surfaces or working within confined geometries typical in miniaturized wearable devices.

Current Ultrafast Laser Applications in Wearable Materials

01 Ultrafast laser systems and components

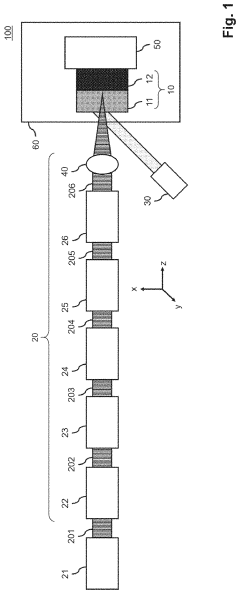

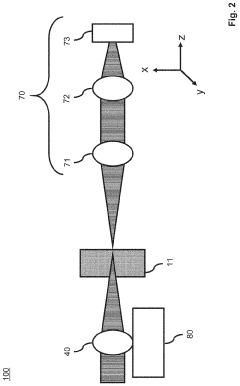

Ultrafast laser systems incorporate specialized components such as mode-locked oscillators, amplifiers, and pulse compressors to generate femtosecond or picosecond pulses. These systems typically utilize specialized optical materials and configurations to maintain pulse characteristics while achieving high peak powers. Key innovations include dispersion management techniques, cavity designs, and pump-probe configurations that enable precise control over pulse duration and energy.- Ultrafast laser systems and components: Ultrafast laser systems incorporate specialized components such as mode-locked oscillators, amplifiers, and pulse compressors to generate femtosecond or picosecond pulses. These systems often utilize specific gain media and optical arrangements to achieve ultrashort pulse durations while maintaining high peak powers. Advanced configurations may include chirped pulse amplification techniques to prevent damage to optical components while enabling high-energy ultrashort pulses.

- Material processing applications with ultrafast lasers: Ultrafast lasers enable precise material processing with minimal heat-affected zones due to their extremely short pulse durations. Applications include micromachining, drilling, cutting, and surface modification of various materials including metals, semiconductors, ceramics, and polymers. The non-thermal ablation process allows for high-precision manufacturing of microstructures and nanostructures with clean edges and minimal collateral damage.

- Medical and biological applications of ultrafast lasers: Ultrafast lasers are utilized in various medical procedures including ophthalmology, dermatology, and dentistry. The ultrashort pulses enable precise tissue ablation with minimal thermal damage to surrounding areas, making them ideal for delicate procedures such as corneal surgery and tattoo removal. Additionally, these lasers are employed in biological imaging techniques like multiphoton microscopy, allowing for high-resolution imaging of living tissues without causing damage.

- Ultrafast laser optical systems and beam delivery: Specialized optical systems are developed for ultrafast lasers to maintain pulse characteristics during beam delivery and manipulation. These systems include dispersion compensation elements, beam shaping optics, and scanning mechanisms designed to preserve the temporal and spatial properties of ultrashort pulses. Advanced beam delivery systems may incorporate adaptive optics to correct wavefront distortions and ensure optimal focusing at the target location.

- Ultrafast laser applications in data storage and electronics: Ultrafast lasers enable advanced applications in data storage and electronics manufacturing, including high-density optical data recording, semiconductor processing, and circuit modification. The precise energy deposition allows for controlled modification of material properties at the nanoscale, facilitating the fabrication of advanced electronic components and memory devices. These lasers are also used for testing and characterization of high-speed electronic circuits through optical sampling techniques.

02 Material processing applications

Ultrafast lasers enable precise material processing with minimal heat-affected zones due to their extremely short pulse durations. Applications include micromachining, drilling, cutting, and surface modification of various materials including metals, semiconductors, ceramics, and polymers. The non-thermal ablation process allows for high-precision manufacturing of microstructures, waveguides, and features with dimensions in the micrometer or nanometer range.Expand Specific Solutions03 Medical and biological applications

Ultrafast lasers are utilized in various medical procedures including ophthalmology, dermatology, and dentistry. The precise energy deposition with minimal thermal damage makes them ideal for delicate surgeries such as LASIK, tissue ablation, and tattoo removal. Additionally, these lasers enable advanced imaging techniques for biological tissues, allowing for non-invasive diagnostics and treatment monitoring with high spatial and temporal resolution.Expand Specific Solutions04 Optical communication and data processing

Ultrafast lasers play a crucial role in high-speed optical communications and data processing. They generate ultrashort pulses that can be modulated to carry information at extremely high data rates. Applications include optical time-division multiplexing, optical sampling, and all-optical signal processing. These technologies enable faster data transmission rates and more efficient information processing in telecommunications networks and computing systems.Expand Specific Solutions05 Scientific research and metrology

Ultrafast lasers are essential tools for advanced scientific research and precision measurement applications. They enable time-resolved spectroscopy for studying ultrafast phenomena in physics, chemistry, and materials science. Applications include pump-probe experiments, attosecond physics, frequency comb generation, and high-precision distance measurements. These capabilities allow researchers to observe and measure processes occurring on femtosecond or even attosecond timescales.Expand Specific Solutions

Leading Companies in Ultrafast Laser and Wearable Materials

The ultrafast laser market for wearable tech materials is in a growth phase, with increasing market size driven by demand for advanced wearable devices. The technology is approaching maturity but still evolving, with key players demonstrating varying levels of expertise. Academic institutions like Hong Kong Polytechnic University, Central South University, and University of Michigan are advancing fundamental research, while commercial entities including Toptica Photonics, TeraXion, and Procter & Gamble are developing practical applications. Research organizations such as Korea Research Institute of Standards & Science provide standardization support. The competitive landscape features collaboration between academia and industry, with companies like Merck Patent GmbH and OFS Fitel contributing specialized materials and fiber optic solutions essential for next-generation wearable technologies.

The Hong Kong Polytechnic University

Technical Solution: The Hong Kong Polytechnic University has developed advanced ultrafast laser processing techniques for wearable technology materials, focusing on flexible electronics and smart textiles. Their approach utilizes femtosecond laser micromachining to create precise micropatterns on polymer substrates with minimal thermal damage, enabling the development of highly flexible and durable wearable sensors. The university's research team has pioneered a laser-induced graphene (LIG) technique that converts carbon-containing polymers into porous graphene structures directly on flexible substrates, creating conductive patterns for wearable electronics without additional processing steps. They've also developed a laser-assisted selective metallization process that enables direct writing of conductive traces on textiles and polymers with resolution down to 10 micrometers, significantly advancing the integration of electronics into everyday clothing. Their recent work includes developing laser surface modification techniques that enhance the biocompatibility and comfort of wearable materials while maintaining sensing capabilities.

Strengths: Superior precision in creating microstructures without thermal damage, enabling higher component density in limited spaces. Their direct-write approach eliminates multiple manufacturing steps, reducing production costs and environmental impact. Weaknesses: The technology requires specialized equipment and expertise, potentially limiting widespread adoption in mass production environments. Some laser-modified materials may have reduced mechanical durability under repeated flexing conditions typical in wearable applications.

Toptica Photonics SE

Technical Solution: Toptica Photonics SE has developed specialized ultrafast laser systems specifically optimized for wearable technology material processing. Their proprietary FemtoFiber technology delivers ultrashort pulses (under 100 femtoseconds) with precise control over pulse characteristics, enabling cold ablation processes that minimize heat-affected zones when processing temperature-sensitive polymers and flexible substrates used in wearables. The company has engineered compact, industrial-grade femtosecond laser systems that maintain beam quality and stability while reducing the overall footprint, making them suitable for integration into production lines for wearable devices. Their systems feature automated beam delivery with multi-axis control for processing complex 3D surfaces typical in wearable form factors. Toptica has also pioneered wavelength-flexible systems that can be optimized for different material interactions, allowing selective processing of multilayer materials common in smart textiles and flexible electronics. Their latest innovations include real-time process monitoring capabilities that ensure consistent quality in high-volume manufacturing environments, addressing a critical need for scalable production of wearable technologies.

Strengths: Their systems offer exceptional pulse stability and beam quality, resulting in highly reproducible material processing outcomes critical for commercial wearable production. The compact design facilitates integration into existing manufacturing workflows. Weaknesses: The high precision systems come with significant capital investment costs that may be prohibitive for smaller manufacturers. The technology requires specialized knowledge for operation and maintenance, potentially limiting accessibility for some production environments.

Key Innovations in Ultrafast Laser Material Modification

Ultrafast laser system and application thereof

PatentInactiveUS20190357977A1

Innovation

- An ultrafast laser system comprising a control module, optical path module, movable platform, and visual locating module, with a laser that includes a beam expander, reflector, and vibrating mirror, allowing for adjustable sub-pulse energy, time interval, and wavelength, specifically designed for applications like mole, freckle, and tattoo removal with minimal trauma and pain.

Method and system for laser welding of a semiconductor material

PatentPendingUS20230129245A1

Innovation

- A method and system that utilize pulsed laser radiation to weld semiconductor workpieces by determining and compensating for the delocalization of the laser focus within the semiconductor material, ensuring the intensity maximum is positioned at the interface with the second workpiece, thereby achieving a permanent modification and optimized bonding strength.

Sustainability Impact of Laser Manufacturing Processes

The integration of ultrafast laser technology in wearable materials manufacturing represents a significant advancement toward more sustainable production processes. These laser systems offer precise material processing with minimal waste generation, dramatically reducing the environmental footprint compared to traditional manufacturing methods. The non-contact nature of laser processing eliminates the need for chemical etching agents and significantly decreases water consumption, addressing two critical environmental concerns in electronics manufacturing.

Energy efficiency stands as another notable sustainability benefit of ultrafast laser processing. The extremely short pulse duration—typically in femtosecond or picosecond ranges—delivers energy to materials with remarkable efficiency, reducing the overall energy requirements for production. Studies indicate that ultrafast laser systems can achieve up to 30-40% energy savings compared to conventional manufacturing techniques when optimized for wearable technology applications.

Material conservation represents perhaps the most significant sustainability impact. The precision of ultrafast lasers enables the creation of complex microstructures with minimal material removal, supporting the miniaturization trend in wearable technology while conserving valuable resources. This capability extends the functional lifespan of limited resources like rare earth elements and precious metals commonly used in flexible electronics.

The lifecycle benefits extend beyond manufacturing to product longevity. Wearable devices produced using ultrafast laser techniques demonstrate enhanced durability and resistance to environmental factors, potentially extending product lifespans by 20-30% according to recent industry analyses. This durability directly contributes to waste reduction in the electronics sector, which currently generates approximately 50 million tons of e-waste annually worldwide.

Furthermore, ultrafast laser processing facilitates easier material separation at end-of-life, supporting more effective recycling processes. The clean, precise modifications to materials allow for better component segregation without cross-contamination, increasing the recovery rate of valuable materials from discarded wearable devices. This circular economy approach represents a significant advancement over conventional manufacturing techniques that often create inseparable material composites.

As regulatory frameworks increasingly emphasize producer responsibility and sustainable manufacturing, ultrafast laser technology positions manufacturers advantageously for compliance with emerging environmental standards while simultaneously reducing production costs through material and energy efficiency. The technology thus represents a rare alignment of environmental and economic interests in advanced manufacturing.

Energy efficiency stands as another notable sustainability benefit of ultrafast laser processing. The extremely short pulse duration—typically in femtosecond or picosecond ranges—delivers energy to materials with remarkable efficiency, reducing the overall energy requirements for production. Studies indicate that ultrafast laser systems can achieve up to 30-40% energy savings compared to conventional manufacturing techniques when optimized for wearable technology applications.

Material conservation represents perhaps the most significant sustainability impact. The precision of ultrafast lasers enables the creation of complex microstructures with minimal material removal, supporting the miniaturization trend in wearable technology while conserving valuable resources. This capability extends the functional lifespan of limited resources like rare earth elements and precious metals commonly used in flexible electronics.

The lifecycle benefits extend beyond manufacturing to product longevity. Wearable devices produced using ultrafast laser techniques demonstrate enhanced durability and resistance to environmental factors, potentially extending product lifespans by 20-30% according to recent industry analyses. This durability directly contributes to waste reduction in the electronics sector, which currently generates approximately 50 million tons of e-waste annually worldwide.

Furthermore, ultrafast laser processing facilitates easier material separation at end-of-life, supporting more effective recycling processes. The clean, precise modifications to materials allow for better component segregation without cross-contamination, increasing the recovery rate of valuable materials from discarded wearable devices. This circular economy approach represents a significant advancement over conventional manufacturing techniques that often create inseparable material composites.

As regulatory frameworks increasingly emphasize producer responsibility and sustainable manufacturing, ultrafast laser technology positions manufacturers advantageously for compliance with emerging environmental standards while simultaneously reducing production costs through material and energy efficiency. The technology thus represents a rare alignment of environmental and economic interests in advanced manufacturing.

Scalability Challenges for Mass Production

The scaling of ultrafast laser processing for mass production of wearable technology materials presents significant challenges that must be addressed to achieve commercial viability. Current ultrafast laser systems, while offering unprecedented precision in material modification, typically operate at throughput rates insufficient for high-volume manufacturing environments. The fundamental bottleneck lies in the inverse relationship between processing speed and the quality of material modification, creating a technical dilemma for manufacturers.

Production-scale implementation faces hardware limitations, as most ultrafast laser systems are designed for research or small-batch production. The capital expenditure required for multiple high-power femtosecond laser systems remains prohibitively high for many manufacturers, with costs ranging from $500,000 to several million dollars per system. This creates a significant barrier to entry for smaller companies and startups in the wearable technology space.

Energy efficiency represents another critical challenge. Ultrafast lasers typically have wall-plug efficiencies of only 15-30%, resulting in substantial power consumption and heat management requirements when scaled to production levels. This inefficiency translates directly to increased operational costs and environmental impact, contradicting the sustainability goals often associated with advanced wearable technologies.

Process reliability and consistency across large production volumes remain problematic. Minor variations in laser parameters can significantly impact material properties, necessitating sophisticated real-time monitoring and feedback systems that are still in developmental stages. The complexity of maintaining consistent beam quality, pulse duration, and energy delivery across multiple processing stations further complicates mass production scenarios.

Integration with existing manufacturing workflows presents additional hurdles. Conventional production lines must be substantially modified to accommodate ultrafast laser processing stations, requiring significant reconfiguration of material handling systems and quality control protocols. The specialized knowledge required to operate and maintain these systems creates workforce development challenges that cannot be overlooked in scaling considerations.

Regulatory compliance adds another layer of complexity, particularly for wearable medical devices. The novel material properties created through ultrafast laser processing often require extensive validation studies to ensure biocompatibility and long-term stability, potentially extending time-to-market and increasing development costs. These regulatory hurdles can significantly impact the economic viability of mass production initiatives.

Production-scale implementation faces hardware limitations, as most ultrafast laser systems are designed for research or small-batch production. The capital expenditure required for multiple high-power femtosecond laser systems remains prohibitively high for many manufacturers, with costs ranging from $500,000 to several million dollars per system. This creates a significant barrier to entry for smaller companies and startups in the wearable technology space.

Energy efficiency represents another critical challenge. Ultrafast lasers typically have wall-plug efficiencies of only 15-30%, resulting in substantial power consumption and heat management requirements when scaled to production levels. This inefficiency translates directly to increased operational costs and environmental impact, contradicting the sustainability goals often associated with advanced wearable technologies.

Process reliability and consistency across large production volumes remain problematic. Minor variations in laser parameters can significantly impact material properties, necessitating sophisticated real-time monitoring and feedback systems that are still in developmental stages. The complexity of maintaining consistent beam quality, pulse duration, and energy delivery across multiple processing stations further complicates mass production scenarios.

Integration with existing manufacturing workflows presents additional hurdles. Conventional production lines must be substantially modified to accommodate ultrafast laser processing stations, requiring significant reconfiguration of material handling systems and quality control protocols. The specialized knowledge required to operate and maintain these systems creates workforce development challenges that cannot be overlooked in scaling considerations.

Regulatory compliance adds another layer of complexity, particularly for wearable medical devices. The novel material properties created through ultrafast laser processing often require extensive validation studies to ensure biocompatibility and long-term stability, potentially extending time-to-market and increasing development costs. These regulatory hurdles can significantly impact the economic viability of mass production initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!