Efficiency degradation analysis of electrolyzers under long-term cycling

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyzer Efficiency Degradation Background and Objectives

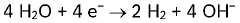

Electrolyzers represent a cornerstone technology in the global transition toward sustainable energy systems, enabling the conversion of renewable electricity into hydrogen—a versatile energy carrier with significant potential for decarbonizing various sectors. The historical development of electrolysis technology dates back to the early 19th century, with William Nicholson and Anthony Carlisle first demonstrating water electrolysis in 1800. However, only in recent decades has this technology gained renewed attention as a key component of the hydrogen economy and renewable energy integration strategies.

The evolution of electrolyzer technology has progressed through several generations, from traditional alkaline electrolyzers to more advanced proton exchange membrane (PEM) and solid oxide electrolyzer cells (SOEC). Each iteration has brought improvements in efficiency, durability, and cost-effectiveness. Despite these advancements, a critical challenge persists: efficiency degradation during long-term operation, particularly under dynamic cycling conditions that characterize renewable energy sources.

This efficiency degradation phenomenon represents a significant barrier to widespread electrolyzer deployment and the realization of green hydrogen's full potential. As electrolyzers are increasingly expected to operate in conjunction with intermittent renewable energy sources like wind and solar, they must endure frequent start-stop cycles, partial load operation, and rapid power fluctuations—operating conditions that accelerate degradation mechanisms and reduce system lifetime.

Current technical objectives in this field focus on understanding the fundamental mechanisms driving efficiency losses during cycling, quantifying degradation rates under various operational profiles, and developing mitigation strategies to extend electrolyzer lifetimes. Research aims to identify critical degradation pathways, including catalyst deactivation, membrane degradation, transport layer modifications, and interface deterioration across different electrolyzer technologies.

The industry targets achieving electrolyzer systems with less than 0.5% efficiency degradation per 1,000 operating hours under dynamic conditions, while maintaining lifetimes exceeding 50,000 hours for stationary applications and 20,000 hours for transportation-related systems. Meeting these targets would significantly improve the economic viability of green hydrogen production and facilitate deeper integration of renewable energy into existing infrastructure.

This technical investigation seeks to comprehensively analyze efficiency degradation mechanisms, establish accelerated testing protocols that accurately predict long-term performance, develop advanced in-situ and ex-situ characterization techniques, and ultimately propose design modifications and operational strategies to enhance electrolyzer durability under cycling conditions representative of real-world renewable energy integration scenarios.

The evolution of electrolyzer technology has progressed through several generations, from traditional alkaline electrolyzers to more advanced proton exchange membrane (PEM) and solid oxide electrolyzer cells (SOEC). Each iteration has brought improvements in efficiency, durability, and cost-effectiveness. Despite these advancements, a critical challenge persists: efficiency degradation during long-term operation, particularly under dynamic cycling conditions that characterize renewable energy sources.

This efficiency degradation phenomenon represents a significant barrier to widespread electrolyzer deployment and the realization of green hydrogen's full potential. As electrolyzers are increasingly expected to operate in conjunction with intermittent renewable energy sources like wind and solar, they must endure frequent start-stop cycles, partial load operation, and rapid power fluctuations—operating conditions that accelerate degradation mechanisms and reduce system lifetime.

Current technical objectives in this field focus on understanding the fundamental mechanisms driving efficiency losses during cycling, quantifying degradation rates under various operational profiles, and developing mitigation strategies to extend electrolyzer lifetimes. Research aims to identify critical degradation pathways, including catalyst deactivation, membrane degradation, transport layer modifications, and interface deterioration across different electrolyzer technologies.

The industry targets achieving electrolyzer systems with less than 0.5% efficiency degradation per 1,000 operating hours under dynamic conditions, while maintaining lifetimes exceeding 50,000 hours for stationary applications and 20,000 hours for transportation-related systems. Meeting these targets would significantly improve the economic viability of green hydrogen production and facilitate deeper integration of renewable energy into existing infrastructure.

This technical investigation seeks to comprehensively analyze efficiency degradation mechanisms, establish accelerated testing protocols that accurately predict long-term performance, develop advanced in-situ and ex-situ characterization techniques, and ultimately propose design modifications and operational strategies to enhance electrolyzer durability under cycling conditions representative of real-world renewable energy integration scenarios.

Market Analysis of Long-Duration Electrolyzer Applications

The global market for long-duration electrolyzer applications is experiencing significant growth, driven by the increasing demand for green hydrogen as a clean energy carrier. The market size for water electrolysis was valued at approximately $290 million in 2021 and is projected to reach $1.2 billion by 2028, with a compound annual growth rate (CAGR) of 24.6% during the forecast period. This growth trajectory is primarily fueled by governmental policies promoting decarbonization and substantial investments in renewable energy infrastructure.

Long-duration electrolyzer applications span across multiple sectors, with industrial processes representing the largest market segment. Steel manufacturing, ammonia production, and refining operations collectively account for over 60% of the current electrolyzer deployment. The transportation sector follows as the second-largest market, where hydrogen fuel cells are increasingly adopted for heavy-duty vehicles, maritime applications, and potentially aviation.

Energy storage represents the fastest-growing segment for long-duration electrolyzers, with a projected CAGR of 32% through 2030. This surge is attributed to the escalating need for seasonal energy storage solutions to balance intermittent renewable energy generation. Grid-scale hydrogen storage projects have increased by 200% between 2019 and 2022, highlighting the sector's rapid expansion.

Regionally, Europe leads the market with approximately 40% share, followed by Asia-Pacific at 30% and North America at 20%. European dominance stems from aggressive carbon neutrality targets and substantial government funding, exemplified by the European Hydrogen Strategy's €470 billion investment commitment through 2050. China's hydrogen industry development plan aims to have 50,000 hydrogen fuel cell vehicles on its roads by 2025, driving significant electrolyzer demand in the Asia-Pacific region.

Customer requirements for long-duration electrolyzers increasingly emphasize durability and efficiency retention under cycling conditions. End-users are willing to pay premium prices for systems demonstrating less than 10% efficiency degradation over 40,000 operating hours. This market preference has shifted manufacturer focus toward developing more resilient electrolyzer technologies rather than pursuing initial efficiency improvements alone.

The economic viability of long-duration electrolyzer applications depends heavily on electricity costs, which represent 60-70% of operational expenses. Consequently, market growth correlates strongly with regions offering low-cost renewable electricity. Countries with abundant solar and wind resources, such as Australia, Chile, and Morocco, are emerging as potential hydrogen production hubs despite their currently smaller market shares.

Long-duration electrolyzer applications span across multiple sectors, with industrial processes representing the largest market segment. Steel manufacturing, ammonia production, and refining operations collectively account for over 60% of the current electrolyzer deployment. The transportation sector follows as the second-largest market, where hydrogen fuel cells are increasingly adopted for heavy-duty vehicles, maritime applications, and potentially aviation.

Energy storage represents the fastest-growing segment for long-duration electrolyzers, with a projected CAGR of 32% through 2030. This surge is attributed to the escalating need for seasonal energy storage solutions to balance intermittent renewable energy generation. Grid-scale hydrogen storage projects have increased by 200% between 2019 and 2022, highlighting the sector's rapid expansion.

Regionally, Europe leads the market with approximately 40% share, followed by Asia-Pacific at 30% and North America at 20%. European dominance stems from aggressive carbon neutrality targets and substantial government funding, exemplified by the European Hydrogen Strategy's €470 billion investment commitment through 2050. China's hydrogen industry development plan aims to have 50,000 hydrogen fuel cell vehicles on its roads by 2025, driving significant electrolyzer demand in the Asia-Pacific region.

Customer requirements for long-duration electrolyzers increasingly emphasize durability and efficiency retention under cycling conditions. End-users are willing to pay premium prices for systems demonstrating less than 10% efficiency degradation over 40,000 operating hours. This market preference has shifted manufacturer focus toward developing more resilient electrolyzer technologies rather than pursuing initial efficiency improvements alone.

The economic viability of long-duration electrolyzer applications depends heavily on electricity costs, which represent 60-70% of operational expenses. Consequently, market growth correlates strongly with regions offering low-cost renewable electricity. Countries with abundant solar and wind resources, such as Australia, Chile, and Morocco, are emerging as potential hydrogen production hubs despite their currently smaller market shares.

Current Challenges in Electrolyzer Durability

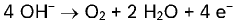

Despite significant advancements in electrolyzer technology, durability remains a critical challenge that impedes widespread commercial adoption. Current electrolyzers face several persistent issues that compromise their long-term performance under cycling conditions. The degradation of catalysts represents one of the most significant hurdles, with precious metal catalysts like platinum and iridium experiencing surface area reduction, particle agglomeration, and dissolution during extended operation. This catalyst degradation directly correlates with efficiency losses and increased overpotential requirements.

Membrane degradation constitutes another major challenge, particularly in PEM electrolyzers where the perfluorosulfonic acid membranes undergo chemical and mechanical deterioration. Under cycling conditions, these membranes experience thinning, pinhole formation, and fluoride release, leading to increased gas crossover and potential safety concerns. The membrane-electrode interface also suffers from delamination during thermal and pressure cycling, creating contact resistance that further diminishes performance.

Current generation electrolyzers exhibit significant issues with bipolar plate and current collector corrosion. Even with protective coatings, these components experience gradual degradation under the harsh electrochemical environment, leading to increased electrical resistance and contamination of catalyst layers with metal ions. This corrosion accelerates notably during start-stop cycles when potential excursions occur.

Water quality management presents ongoing challenges, as impurities accumulate over time and poison catalysts or foul ion exchange membranes. The industry still lacks standardized protocols for water purification systems that can maintain optimal water quality throughout the electrolyzer's operational lifetime under variable cycling conditions.

Temperature management during cycling operations remains problematic, with thermal gradients causing mechanical stress and accelerated degradation. Current thermal management systems struggle to maintain optimal operating temperatures during rapid power fluctuations, particularly when integrated with intermittent renewable energy sources.

The lack of standardized accelerated stress tests and in-situ diagnostic tools hampers progress in durability improvements. Existing testing protocols often fail to accurately simulate real-world cycling conditions, making it difficult to predict actual field performance and degradation rates. Advanced diagnostic capabilities that can monitor degradation mechanisms in real-time without disrupting operation remain underdeveloped.

Finally, the balance between durability and efficiency presents a fundamental challenge. Design modifications that enhance durability often compromise efficiency, creating a difficult optimization problem that has yet to be satisfactorily resolved for long-duration cycling applications.

Membrane degradation constitutes another major challenge, particularly in PEM electrolyzers where the perfluorosulfonic acid membranes undergo chemical and mechanical deterioration. Under cycling conditions, these membranes experience thinning, pinhole formation, and fluoride release, leading to increased gas crossover and potential safety concerns. The membrane-electrode interface also suffers from delamination during thermal and pressure cycling, creating contact resistance that further diminishes performance.

Current generation electrolyzers exhibit significant issues with bipolar plate and current collector corrosion. Even with protective coatings, these components experience gradual degradation under the harsh electrochemical environment, leading to increased electrical resistance and contamination of catalyst layers with metal ions. This corrosion accelerates notably during start-stop cycles when potential excursions occur.

Water quality management presents ongoing challenges, as impurities accumulate over time and poison catalysts or foul ion exchange membranes. The industry still lacks standardized protocols for water purification systems that can maintain optimal water quality throughout the electrolyzer's operational lifetime under variable cycling conditions.

Temperature management during cycling operations remains problematic, with thermal gradients causing mechanical stress and accelerated degradation. Current thermal management systems struggle to maintain optimal operating temperatures during rapid power fluctuations, particularly when integrated with intermittent renewable energy sources.

The lack of standardized accelerated stress tests and in-situ diagnostic tools hampers progress in durability improvements. Existing testing protocols often fail to accurately simulate real-world cycling conditions, making it difficult to predict actual field performance and degradation rates. Advanced diagnostic capabilities that can monitor degradation mechanisms in real-time without disrupting operation remain underdeveloped.

Finally, the balance between durability and efficiency presents a fundamental challenge. Design modifications that enhance durability often compromise efficiency, creating a difficult optimization problem that has yet to be satisfactorily resolved for long-duration cycling applications.

State-of-the-Art Degradation Mitigation Strategies

01 Electrode degradation mechanisms in electrolyzers

Electrode materials in electrolyzers can degrade over time due to various mechanisms including corrosion, poisoning, and physical damage. These degradation processes can lead to reduced catalytic activity, increased electrical resistance, and ultimately decreased efficiency of the electrolyzer. Understanding these mechanisms is crucial for developing strategies to mitigate efficiency losses and extend the operational lifetime of electrolyzer systems.- Electrode material degradation mechanisms: Electrolyzer efficiency degradation is often caused by electrode material deterioration over time. This includes corrosion, poisoning, and structural changes that reduce catalytic activity. Various factors such as operating conditions, impurities in feedstock, and electrochemical stress contribute to this degradation. Understanding these mechanisms is crucial for developing more durable electrode materials that can maintain high efficiency over extended operational periods.

- Membrane fouling and degradation: The efficiency of electrolyzers decreases significantly due to membrane fouling and degradation. Over time, membranes can become contaminated with impurities, develop physical defects, or undergo chemical degradation, leading to increased resistance and reduced ion transport capabilities. This results in higher energy consumption and lower production rates. Advanced membrane materials and protective measures can help mitigate these issues and extend the operational lifetime of electrolyzers.

- Operating conditions optimization: Suboptimal operating conditions significantly contribute to electrolyzer efficiency degradation. Factors such as temperature fluctuations, pressure variations, current density, and flow rates affect performance stability. Maintaining optimal operating parameters through advanced control systems and monitoring technologies can minimize degradation rates. Adaptive control strategies that adjust operating conditions based on real-time performance metrics help maintain efficiency over longer operational periods.

- Contamination and impurity management: Contaminants and impurities in feed water or reactant gases significantly impact electrolyzer efficiency over time. These impurities can deposit on catalytic surfaces, block active sites, and accelerate degradation of components. Implementing effective purification systems, filtration technologies, and regular maintenance protocols can reduce contamination-related efficiency losses. Advanced sensing technologies that detect impurities before they cause damage help maintain optimal performance.

- Regeneration and maintenance strategies: Various regeneration and maintenance strategies can be employed to restore electrolyzer efficiency after degradation. These include periodic polarity reversal, chemical cleaning procedures, component replacement schedules, and in-situ regeneration techniques. Implementing predictive maintenance based on performance monitoring helps identify the optimal timing for interventions. These approaches can significantly extend the operational lifetime of electrolyzers and maintain higher average efficiency levels over time.

02 Membrane fouling and contamination effects

Membrane fouling and contamination significantly impact electrolyzer efficiency. Impurities in feed water or electrolyte solutions can accumulate on membrane surfaces, blocking ion transport pathways and increasing resistance. This leads to higher voltage requirements and reduced efficiency. Contaminants may include metal ions, organic compounds, or particulate matter that interfere with the electrochemical processes, causing progressive performance degradation over the operational lifetime.Expand Specific Solutions03 Advanced monitoring and diagnostic techniques

Advanced monitoring and diagnostic techniques help identify and mitigate efficiency degradation in electrolyzers. These include real-time performance monitoring systems, electrochemical impedance spectroscopy, and predictive maintenance algorithms. By continuously analyzing operational parameters and detecting early signs of degradation, these techniques enable timely interventions to prevent efficiency losses and extend the service life of electrolyzer components.Expand Specific Solutions04 Novel materials and coatings for degradation resistance

Novel materials and protective coatings can significantly improve the degradation resistance of electrolyzer components. Advanced catalyst formulations, corrosion-resistant electrode materials, and specialized membrane compositions help maintain performance over extended operation periods. These innovations focus on enhancing durability while maintaining or improving electrochemical activity, thereby addressing the root causes of efficiency degradation in challenging operating environments.Expand Specific Solutions05 Operating condition optimization to minimize degradation

Optimizing operating conditions is essential for minimizing efficiency degradation in electrolyzers. This includes careful control of temperature, pressure, current density, and electrolyte composition. Strategic operational protocols such as controlled startup/shutdown procedures and periodic regeneration cycles can significantly extend component lifetimes. Implementing these optimized conditions helps balance maximum hydrogen production efficiency with minimal degradation rates for sustainable long-term operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrolyzer efficiency degradation analysis market is in a growth phase, with increasing focus on sustainable hydrogen production driving research and development. The market size is expanding as green hydrogen initiatives gain momentum globally, though still relatively niche compared to established energy sectors. Technologically, the field shows moderate maturity with significant ongoing innovation. Leading players include Siemens Energy and ThyssenKrupp Uhde Chlorine Engineers with established industrial-scale solutions, while Sunfire GmbH and De Nora are advancing specialized electrolyzer technologies. Research institutions like CEA and companies such as Toshiba Energy Systems are contributing significant innovations in durability testing methodologies. Automotive manufacturers including Hyundai and Kia are increasingly investing in this space to support hydrogen mobility applications.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed comprehensive electrolyzer degradation analysis systems utilizing their Silyzer technology platform. Their approach combines real-time monitoring with advanced diagnostic algorithms to track performance metrics during long-term operation. The system employs electrochemical impedance spectroscopy (EIS) to characterize cell degradation mechanisms without interrupting operation. Their proprietary SCADA system collects operational data including voltage efficiency, current density, temperature distribution, and gas purity to identify degradation patterns. Siemens has implemented machine learning algorithms that analyze historical performance data to predict future efficiency losses and optimize maintenance schedules. Their research has demonstrated that controlled operational parameters can extend electrolyzer stack lifetime by up to 30% while maintaining efficiency above 70% of initial values throughout the operational lifetime.

Strengths: Comprehensive integration with industrial control systems allows for seamless monitoring in large-scale applications. Advanced predictive maintenance capabilities reduce downtime and operational costs. Weaknesses: System complexity requires specialized technical expertise for implementation and maintenance. Higher initial investment compared to simpler monitoring solutions.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed sophisticated multi-scale modeling approaches for electrolyzer degradation analysis, combining molecular dynamics simulations with experimental validation. Their methodology integrates electrochemical, thermal, and mechanical degradation factors into unified models that predict efficiency losses during long-term cycling. CEA researchers have pioneered operando characterization techniques using synchrotron radiation to observe structural changes during operation without disassembling cells. Their approach includes isotope labeling studies to track material migration and contamination pathways during thousands of operational hours. The CEA has developed specialized impedance analysis protocols that can distinguish between different degradation mechanisms including catalyst activity loss, membrane resistance increases, and contact resistance evolution. Their research has demonstrated correlations between local current density distributions and spatially-resolved degradation patterns, enabling targeted design improvements. The CEA's comprehensive approach combines accelerated stress testing with multi-year field data to validate degradation models across different operational profiles.

Strengths: Exceptional scientific depth provides fundamental understanding of degradation mechanisms at atomic and molecular levels. Strong integration between modeling and experimental validation creates powerful predictive capabilities. Weaknesses: Highly academic approach sometimes lacks immediate practical implementation pathways for industrial applications.

Critical Patents and Research on Cycling Stability

Method and system for producing a hydrogen-containing product using electrolysis

PatentWO2024068048A2

Innovation

- Increasing the operating temperature of the electrolysis stack at a predetermined point during its life to compensate for performance degradation, while limiting maximum voltage and power consumption, and using a platinum-based catalyst to recombine permeated hydrogen and oxygen to ensure safety.

Method for regenerating an electrolyser

PatentWO2024132350A1

Innovation

- The method involves reducing the electrical voltage to 0 V, lowering cathode chamber pressure, removing the anode compartment's water or electrolyte, introducing hydrogen gas to react with oxygen microbubbles, and refilling with water or electrolyte, utilizing a bifunctional anode catalyst to catalytically initiate the reaction and remove bubbles quickly.

Lifecycle Cost Analysis of Electrolyzer Systems

The lifecycle cost analysis of electrolyzer systems represents a critical component in evaluating the economic viability of hydrogen production technologies. When examining electrolyzers under long-term cycling conditions, efficiency degradation emerges as a significant factor affecting the total cost of ownership over the system's operational lifetime.

Initial capital expenditure constitutes approximately 40-60% of the total lifecycle cost for modern electrolyzer systems, with the remainder distributed across operational expenses including electricity consumption, maintenance, stack replacement, and decommissioning costs. The degradation of efficiency over time directly impacts these operational costs, creating a compounding effect on the economic performance of the system.

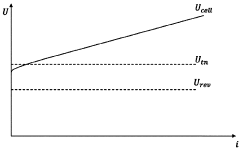

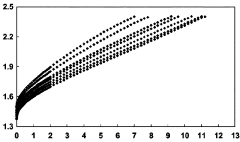

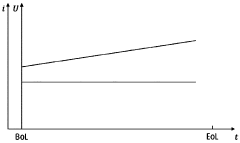

Electricity consumption typically represents 60-80% of operational expenses for electrolyzers, making efficiency losses particularly impactful on long-term economics. Research indicates that PEM electrolyzers operating under dynamic load conditions may experience efficiency degradation rates between 0.5-2% per 1,000 operating hours, significantly affecting the hydrogen production cost over the system's lifetime.

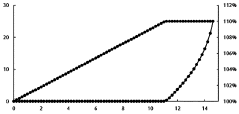

Stack replacement costs must be carefully factored into lifecycle analyses, as degradation accelerated by cycling operations may necessitate more frequent replacements than manufacturer specifications suggest. Data from field deployments shows that electrolyzers subjected to frequent start-stop cycles may require stack replacement after 30,000-40,000 hours rather than the often-cited 60,000-80,000 hours under steady-state operation.

Maintenance costs also increase non-linearly with system age and cycling frequency. Statistical analysis of operational data reveals that maintenance expenses may rise by 15-25% in the latter half of system life when subjected to dynamic operation profiles, compared to steady-state operation.

The levelized cost of hydrogen (LCOH) calculation must incorporate these degradation factors to accurately reflect real-world economics. Current models suggest that efficiency degradation under cycling conditions can increase LCOH by 0.2-0.5 $/kg H₂ over the system lifetime, depending on electricity prices and operational profiles.

Advanced techno-economic models now incorporate Monte Carlo simulations to account for uncertainty in degradation rates, providing probability distributions of lifecycle costs rather than single-point estimates. These probabilistic approaches offer more robust decision support for investors and system operators considering electrolyzer deployments in variable renewable energy contexts.

Initial capital expenditure constitutes approximately 40-60% of the total lifecycle cost for modern electrolyzer systems, with the remainder distributed across operational expenses including electricity consumption, maintenance, stack replacement, and decommissioning costs. The degradation of efficiency over time directly impacts these operational costs, creating a compounding effect on the economic performance of the system.

Electricity consumption typically represents 60-80% of operational expenses for electrolyzers, making efficiency losses particularly impactful on long-term economics. Research indicates that PEM electrolyzers operating under dynamic load conditions may experience efficiency degradation rates between 0.5-2% per 1,000 operating hours, significantly affecting the hydrogen production cost over the system's lifetime.

Stack replacement costs must be carefully factored into lifecycle analyses, as degradation accelerated by cycling operations may necessitate more frequent replacements than manufacturer specifications suggest. Data from field deployments shows that electrolyzers subjected to frequent start-stop cycles may require stack replacement after 30,000-40,000 hours rather than the often-cited 60,000-80,000 hours under steady-state operation.

Maintenance costs also increase non-linearly with system age and cycling frequency. Statistical analysis of operational data reveals that maintenance expenses may rise by 15-25% in the latter half of system life when subjected to dynamic operation profiles, compared to steady-state operation.

The levelized cost of hydrogen (LCOH) calculation must incorporate these degradation factors to accurately reflect real-world economics. Current models suggest that efficiency degradation under cycling conditions can increase LCOH by 0.2-0.5 $/kg H₂ over the system lifetime, depending on electricity prices and operational profiles.

Advanced techno-economic models now incorporate Monte Carlo simulations to account for uncertainty in degradation rates, providing probability distributions of lifecycle costs rather than single-point estimates. These probabilistic approaches offer more robust decision support for investors and system operators considering electrolyzer deployments in variable renewable energy contexts.

Environmental Impact of Electrolyzer Degradation

The environmental implications of electrolyzer degradation extend far beyond operational efficiency concerns, representing a critical dimension in the sustainability assessment of hydrogen production systems. As electrolyzers experience performance deterioration over extended cycling periods, their environmental footprint undergoes significant transformation, primarily through increased energy consumption per unit of hydrogen produced.

Degraded electrolyzers require greater electricity input to maintain production targets, directly amplifying the carbon footprint of hydrogen generation in grid-connected systems. Research indicates that a 10% efficiency loss in electrolyzer performance can result in an 8-12% increase in lifecycle greenhouse gas emissions, depending on the electricity source. This relationship becomes particularly problematic in regions where fossil fuels dominate the energy mix.

Water consumption patterns also shift with degradation progression. Deteriorating electrolyzers typically exhibit increased water requirements of 2-5% above baseline specifications to compensate for efficiency losses. In water-stressed regions, this additional consumption may exacerbate resource competition and ecological stress, particularly when scaled to industrial production volumes.

Material sustainability concerns emerge through accelerated replacement cycles necessitated by degradation. Premature component replacement increases demand for critical raw materials including platinum group metals, rare earth elements, and specialized polymers. Life cycle assessment studies demonstrate that manufacturing-phase environmental impacts can increase by 15-30% when electrolyzer stack lifetime decreases from the expected 80,000 hours to 50,000 hours due to accelerated degradation.

Waste management challenges intensify as degraded components enter disposal streams more frequently. Many electrolyzer materials require specialized recycling processes that remain underdeveloped in current waste management infrastructures. The recovery rates for precious metals from end-of-life electrolyzer components currently average only 60-70%, representing significant material loss and environmental burden.

Land use considerations also merit attention, as degradation-induced efficiency losses may necessitate larger electrolyzer installations to meet production targets. This expanded physical footprint can increase habitat disruption and land transformation impacts, particularly relevant for large-scale hydrogen production facilities in sensitive ecological zones.

Mitigation strategies focusing on degradation-resistant designs show promising environmental returns. Advanced materials that extend operational lifetimes by 20% demonstrate potential to reduce lifecycle environmental impacts by 12-18% across multiple impact categories, highlighting the environmental value of degradation-focused research and development initiatives.

Degraded electrolyzers require greater electricity input to maintain production targets, directly amplifying the carbon footprint of hydrogen generation in grid-connected systems. Research indicates that a 10% efficiency loss in electrolyzer performance can result in an 8-12% increase in lifecycle greenhouse gas emissions, depending on the electricity source. This relationship becomes particularly problematic in regions where fossil fuels dominate the energy mix.

Water consumption patterns also shift with degradation progression. Deteriorating electrolyzers typically exhibit increased water requirements of 2-5% above baseline specifications to compensate for efficiency losses. In water-stressed regions, this additional consumption may exacerbate resource competition and ecological stress, particularly when scaled to industrial production volumes.

Material sustainability concerns emerge through accelerated replacement cycles necessitated by degradation. Premature component replacement increases demand for critical raw materials including platinum group metals, rare earth elements, and specialized polymers. Life cycle assessment studies demonstrate that manufacturing-phase environmental impacts can increase by 15-30% when electrolyzer stack lifetime decreases from the expected 80,000 hours to 50,000 hours due to accelerated degradation.

Waste management challenges intensify as degraded components enter disposal streams more frequently. Many electrolyzer materials require specialized recycling processes that remain underdeveloped in current waste management infrastructures. The recovery rates for precious metals from end-of-life electrolyzer components currently average only 60-70%, representing significant material loss and environmental burden.

Land use considerations also merit attention, as degradation-induced efficiency losses may necessitate larger electrolyzer installations to meet production targets. This expanded physical footprint can increase habitat disruption and land transformation impacts, particularly relevant for large-scale hydrogen production facilities in sensitive ecological zones.

Mitigation strategies focusing on degradation-resistant designs show promising environmental returns. Advanced materials that extend operational lifetimes by 20% demonstrate potential to reduce lifecycle environmental impacts by 12-18% across multiple impact categories, highlighting the environmental value of degradation-focused research and development initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!