Water resource management for large-scale green hydrogen projects

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Water Nexus Background and Objectives

The global transition to clean energy has positioned green hydrogen as a critical vector for decarbonization across multiple sectors. Green hydrogen, produced through electrolysis powered by renewable energy, represents a promising pathway toward achieving net-zero emissions targets. However, this production method faces a significant constraint: water resource management. The water-energy nexus in hydrogen production presents complex challenges that require innovative solutions, particularly as projects scale to industrial levels.

Water serves as both a feedstock and utility in hydrogen production, with approximately 9 kg of water required to produce 1 kg of hydrogen through electrolysis. For large-scale projects targeting production capacities of hundreds or thousands of tons per day, water consumption becomes a substantial consideration, especially in water-stressed regions where renewable energy resources are often abundant.

The historical context of hydrogen production has primarily centered on gray hydrogen derived from natural gas, with minimal attention to water consumption. As the industry pivots toward green hydrogen, water resource management emerges as a critical factor in project feasibility and sustainability. This shift necessitates a comprehensive understanding of water requirements, treatment technologies, and conservation strategies specific to electrolysis operations.

Current technological trajectories indicate growing electrolyzer efficiencies and decreasing costs, potentially enabling gigawatt-scale green hydrogen facilities by 2030. These developments amplify the urgency of addressing water management challenges, as water consumption will scale proportionally with production capacity unless mitigating technologies are implemented.

The primary objective of this technical research is to evaluate existing and emerging water management strategies for large-scale green hydrogen projects, focusing on technologies that optimize water use efficiency, minimize environmental impact, and ensure operational reliability. This includes assessing water sourcing options (seawater, brackish water, wastewater), treatment requirements, and recycling possibilities within the hydrogen production ecosystem.

Additionally, this research aims to identify regulatory frameworks and standards governing water use in hydrogen production across different jurisdictions, highlighting best practices and potential barriers to implementation. The analysis will consider geographical variations in water availability and quality, providing context-specific recommendations for different project environments.

By establishing a comprehensive understanding of the hydrogen-water nexus, this research seeks to inform strategic planning for industrial-scale green hydrogen deployment, supporting sustainable growth of this emerging sector while minimizing pressure on increasingly scarce water resources.

Water serves as both a feedstock and utility in hydrogen production, with approximately 9 kg of water required to produce 1 kg of hydrogen through electrolysis. For large-scale projects targeting production capacities of hundreds or thousands of tons per day, water consumption becomes a substantial consideration, especially in water-stressed regions where renewable energy resources are often abundant.

The historical context of hydrogen production has primarily centered on gray hydrogen derived from natural gas, with minimal attention to water consumption. As the industry pivots toward green hydrogen, water resource management emerges as a critical factor in project feasibility and sustainability. This shift necessitates a comprehensive understanding of water requirements, treatment technologies, and conservation strategies specific to electrolysis operations.

Current technological trajectories indicate growing electrolyzer efficiencies and decreasing costs, potentially enabling gigawatt-scale green hydrogen facilities by 2030. These developments amplify the urgency of addressing water management challenges, as water consumption will scale proportionally with production capacity unless mitigating technologies are implemented.

The primary objective of this technical research is to evaluate existing and emerging water management strategies for large-scale green hydrogen projects, focusing on technologies that optimize water use efficiency, minimize environmental impact, and ensure operational reliability. This includes assessing water sourcing options (seawater, brackish water, wastewater), treatment requirements, and recycling possibilities within the hydrogen production ecosystem.

Additionally, this research aims to identify regulatory frameworks and standards governing water use in hydrogen production across different jurisdictions, highlighting best practices and potential barriers to implementation. The analysis will consider geographical variations in water availability and quality, providing context-specific recommendations for different project environments.

By establishing a comprehensive understanding of the hydrogen-water nexus, this research seeks to inform strategic planning for industrial-scale green hydrogen deployment, supporting sustainable growth of this emerging sector while minimizing pressure on increasingly scarce water resources.

Market Analysis for Water-Efficient Green Hydrogen

The green hydrogen market is experiencing unprecedented growth, driven by global decarbonization initiatives and the push for sustainable energy solutions. Current market projections indicate that the global green hydrogen market, valued at approximately $2.14 billion in 2021, is expected to reach $89.18 billion by 2030, representing a compound annual growth rate (CAGR) of 54.7%. This explosive growth trajectory underscores the critical importance of addressing water resource management challenges in large-scale hydrogen production.

Water demand for green hydrogen production presents a significant market consideration, as electrolysis typically requires 9-10 kilograms of water to produce 1 kilogram of hydrogen. For gigawatt-scale projects, this translates to millions of liters of water annually. The market for water-efficient electrolysis technologies is consequently emerging as a high-value segment, with specialized water treatment and recycling solutions specifically designed for hydrogen production facilities gaining traction.

Regional market dynamics reveal varying approaches to water resource management. In water-scarce regions like the Middle East and North Africa, which are positioning themselves as future green hydrogen hubs, investments in desalination technologies integrated with hydrogen production facilities are increasing. Meanwhile, in Europe, the focus is on closed-loop water systems and wastewater recycling technologies that minimize freshwater consumption.

The market for water management solutions in green hydrogen production is segmented by technology type, with membrane-based water treatment systems currently holding the largest market share at approximately 38%. Advanced filtration systems and electrochemical water treatment technologies are experiencing the fastest growth rates, with projected CAGRs of 25% and 31% respectively through 2030.

Industry analysis indicates that water management costs currently represent 5-8% of total green hydrogen production costs. However, as production scales up and water scarcity intensifies in key production regions, this percentage is expected to increase. This cost pressure is creating market opportunities for innovative water-efficient electrolysis designs and integrated water management systems.

Market research identifies several high-growth segments within the water-efficient green hydrogen ecosystem: seawater electrolysis technologies (eliminating the need for separate desalination), vapor-fed electrolysis systems (reducing liquid water requirements), and water recovery systems that can recapture up to 95% of water from hydrogen production processes. These segments are attracting significant venture capital investment, with funding increasing from $450 million in 2020 to over $1.2 billion in 2022.

Water demand for green hydrogen production presents a significant market consideration, as electrolysis typically requires 9-10 kilograms of water to produce 1 kilogram of hydrogen. For gigawatt-scale projects, this translates to millions of liters of water annually. The market for water-efficient electrolysis technologies is consequently emerging as a high-value segment, with specialized water treatment and recycling solutions specifically designed for hydrogen production facilities gaining traction.

Regional market dynamics reveal varying approaches to water resource management. In water-scarce regions like the Middle East and North Africa, which are positioning themselves as future green hydrogen hubs, investments in desalination technologies integrated with hydrogen production facilities are increasing. Meanwhile, in Europe, the focus is on closed-loop water systems and wastewater recycling technologies that minimize freshwater consumption.

The market for water management solutions in green hydrogen production is segmented by technology type, with membrane-based water treatment systems currently holding the largest market share at approximately 38%. Advanced filtration systems and electrochemical water treatment technologies are experiencing the fastest growth rates, with projected CAGRs of 25% and 31% respectively through 2030.

Industry analysis indicates that water management costs currently represent 5-8% of total green hydrogen production costs. However, as production scales up and water scarcity intensifies in key production regions, this percentage is expected to increase. This cost pressure is creating market opportunities for innovative water-efficient electrolysis designs and integrated water management systems.

Market research identifies several high-growth segments within the water-efficient green hydrogen ecosystem: seawater electrolysis technologies (eliminating the need for separate desalination), vapor-fed electrolysis systems (reducing liquid water requirements), and water recovery systems that can recapture up to 95% of water from hydrogen production processes. These segments are attracting significant venture capital investment, with funding increasing from $450 million in 2020 to over $1.2 billion in 2022.

Water Management Challenges in Hydrogen Production

Green hydrogen production, particularly through water electrolysis, faces significant water management challenges that can impact project viability and sustainability. The water requirements for large-scale hydrogen production are substantial, with estimates suggesting that producing 1 kg of hydrogen requires approximately 9-10 kg of purified water. For industrial-scale facilities targeting production capacities of hundreds or thousands of tons per day, this translates to considerable water demand that must be carefully managed.

Water scarcity presents a primary challenge, as many regions with abundant renewable energy resources for green hydrogen production often coincide with water-stressed areas. This geographical mismatch creates a fundamental tension between optimal energy availability and water accessibility. Projects in desert regions with excellent solar resources, for instance, must address how to secure reliable water supplies without depleting local resources.

Water quality requirements compound these challenges. Electrolysis demands highly purified water to prevent electrode degradation and maintain system efficiency. Conventional purification processes like reverse osmosis and deionization add significant capital and operational costs to projects, while also generating waste streams that require proper management.

The energy intensity of water treatment represents another critical challenge. Desalination, often necessary in coastal locations, can consume 3-5 kWh per cubic meter of water processed. This additional energy requirement reduces the overall efficiency of hydrogen production and potentially undermines its green credentials if powered by non-renewable sources.

Wastewater management presents further complications. Electrolysis systems produce reject water containing concentrated impurities and potentially hazardous chemicals from treatment processes. Proper handling of these waste streams is essential to prevent environmental contamination and comply with increasingly stringent regulations.

Seasonal variability in water availability introduces operational uncertainties. Projects must design robust water storage and management systems to maintain continuous production during dry periods, adding infrastructure costs and complexity to project planning.

Regulatory frameworks governing water rights and usage add another layer of complexity. Securing water permits can involve lengthy processes with multiple stakeholders, potentially delaying project implementation. In many jurisdictions, regulations are still evolving to address the specific needs of hydrogen production facilities, creating regulatory uncertainty.

Competition with other water users, particularly agriculture and municipal needs, can create social tensions and opposition to large-scale hydrogen projects. This necessitates careful stakeholder engagement and potentially the development of water-sharing agreements to ensure project acceptance and long-term viability.

Water scarcity presents a primary challenge, as many regions with abundant renewable energy resources for green hydrogen production often coincide with water-stressed areas. This geographical mismatch creates a fundamental tension between optimal energy availability and water accessibility. Projects in desert regions with excellent solar resources, for instance, must address how to secure reliable water supplies without depleting local resources.

Water quality requirements compound these challenges. Electrolysis demands highly purified water to prevent electrode degradation and maintain system efficiency. Conventional purification processes like reverse osmosis and deionization add significant capital and operational costs to projects, while also generating waste streams that require proper management.

The energy intensity of water treatment represents another critical challenge. Desalination, often necessary in coastal locations, can consume 3-5 kWh per cubic meter of water processed. This additional energy requirement reduces the overall efficiency of hydrogen production and potentially undermines its green credentials if powered by non-renewable sources.

Wastewater management presents further complications. Electrolysis systems produce reject water containing concentrated impurities and potentially hazardous chemicals from treatment processes. Proper handling of these waste streams is essential to prevent environmental contamination and comply with increasingly stringent regulations.

Seasonal variability in water availability introduces operational uncertainties. Projects must design robust water storage and management systems to maintain continuous production during dry periods, adding infrastructure costs and complexity to project planning.

Regulatory frameworks governing water rights and usage add another layer of complexity. Securing water permits can involve lengthy processes with multiple stakeholders, potentially delaying project implementation. In many jurisdictions, regulations are still evolving to address the specific needs of hydrogen production facilities, creating regulatory uncertainty.

Competition with other water users, particularly agriculture and municipal needs, can create social tensions and opposition to large-scale hydrogen projects. This necessitates careful stakeholder engagement and potentially the development of water-sharing agreements to ensure project acceptance and long-term viability.

Current Water Resource Management Solutions

01 Smart water management systems

Smart water management systems utilize advanced technologies to monitor, control, and optimize water usage. These systems incorporate sensors, IoT devices, and data analytics to provide real-time monitoring of water consumption, detect leaks, and automate water distribution. By implementing smart water management systems, water efficiency can be significantly improved through better resource allocation and reduced wastage.- Smart water management systems: Smart water management systems utilize advanced technologies to monitor, control, and optimize water usage. These systems incorporate sensors, IoT devices, and data analytics to provide real-time monitoring of water consumption, detect leaks, and automate water distribution. By implementing smart water management systems, water efficiency can be significantly improved through better resource allocation, reduced wastage, and enhanced decision-making capabilities.

- Water recycling and reuse technologies: Water recycling and reuse technologies focus on treating and repurposing wastewater for various applications, thereby reducing the demand for fresh water resources. These technologies include advanced filtration systems, biological treatment processes, and purification methods that enable the safe reuse of water in agricultural, industrial, and domestic settings. Implementing water recycling and reuse technologies contributes significantly to water efficiency by creating circular water usage patterns.

- Rainwater harvesting and storage solutions: Rainwater harvesting and storage solutions involve collecting, storing, and utilizing rainwater for various purposes. These systems typically include collection surfaces, filtration mechanisms, storage tanks, and distribution networks. By capturing rainwater that would otherwise be lost as runoff, these solutions provide an alternative water source that can be used for irrigation, toilet flushing, and other non-potable applications, thereby enhancing overall water efficiency.

- Efficient irrigation and agricultural water management: Efficient irrigation and agricultural water management techniques focus on optimizing water use in farming and landscaping. These approaches include precision irrigation systems, soil moisture monitoring, drought-resistant crop selection, and scheduled watering based on environmental conditions. By delivering water directly to plant roots in appropriate amounts and at optimal times, these methods significantly reduce water waste while maintaining or improving agricultural productivity.

- Water-efficient fixtures and appliances: Water-efficient fixtures and appliances are designed to minimize water consumption while maintaining performance. These include low-flow toilets, faucets with aerators, water-efficient washing machines, dishwashers, and showerheads. By incorporating advanced design features and technologies, these products can reduce water usage by significant percentages compared to conventional alternatives, contributing to overall water conservation efforts in residential, commercial, and industrial settings.

02 Water recycling and reuse technologies

Water recycling and reuse technologies focus on treating and repurposing wastewater for various applications. These technologies include filtration systems, biological treatment processes, and purification methods that enable the safe reuse of water in agricultural, industrial, and domestic settings. By implementing water recycling and reuse technologies, the demand for fresh water resources can be reduced, contributing to overall water efficiency.Expand Specific Solutions03 Rainwater harvesting and storage solutions

Rainwater harvesting and storage solutions involve collecting, storing, and utilizing rainwater for various purposes. These solutions include collection systems, storage tanks, and filtration mechanisms that enable the effective capture and use of rainwater. By implementing rainwater harvesting and storage solutions, dependency on traditional water sources can be reduced, contributing to water conservation and efficiency.Expand Specific Solutions04 Water-efficient irrigation systems

Water-efficient irrigation systems are designed to deliver water directly to plant roots with minimal waste. These systems include drip irrigation, precision sprinklers, and soil moisture sensors that optimize water delivery based on plant needs and environmental conditions. By implementing water-efficient irrigation systems, agricultural water consumption can be significantly reduced while maintaining or improving crop yields.Expand Specific Solutions05 Water conservation monitoring and analytics

Water conservation monitoring and analytics involve the collection, analysis, and interpretation of water usage data to identify inefficiencies and opportunities for improvement. These approaches include water auditing tools, consumption tracking software, and predictive analytics that enable data-driven decision-making for water resource management. By implementing water conservation monitoring and analytics, organizations and communities can develop targeted strategies to enhance water efficiency.Expand Specific Solutions

Key Players in Green Hydrogen Water Management

The water resource management landscape for large-scale green hydrogen projects is currently in an early growth phase, with market size expanding rapidly as hydrogen gains prominence in global decarbonization strategies. The competitive environment features diverse players across multiple sectors: traditional energy companies (Chevron, RWE), technology giants (Huawei, Toshiba), specialized hydrogen firms (Sungrow Hydrogen, CibusCell), and infrastructure developers (Powerchina Huadong). Technical maturity varies significantly, with established players like ABB Group and Halliburton bringing industrial-scale water management expertise, while research institutions (IIT Madras, Beijing Institute of Technology) drive innovation in water-efficient electrolysis. Chinese state-backed entities (State Grid Xinjiang) are emerging as significant players, leveraging their experience in large-scale infrastructure development and government support to accelerate deployment.

Sungrow Hydrogen SCI & Tech Co. Ltd.

Technical Solution: Sungrow Hydrogen has developed an integrated water management system specifically for large-scale green hydrogen production facilities. Their solution combines advanced water purification technologies with real-time monitoring systems to optimize water usage throughout the hydrogen production process. The system employs a multi-stage filtration process that includes reverse osmosis, deionization, and electrodeionization to achieve ultra-pure water quality required for efficient electrolysis. Their proprietary water recirculation technology captures and treats wastewater from the electrolysis process, allowing for up to 85% water recovery and reuse. Additionally, Sungrow has implemented AI-driven predictive analytics to forecast water demand and optimize resource allocation based on hydrogen production schedules and environmental conditions. The system integrates with renewable energy sources to time water purification operations during periods of excess renewable generation, further enhancing the sustainability of the entire hydrogen production ecosystem.

Strengths: High water recovery rate (up to 85%) significantly reduces freshwater requirements; AI-driven optimization reduces operational costs and improves resource efficiency; Seamless integration with renewable energy systems maximizes overall sustainability. Weaknesses: Higher initial capital investment compared to conventional water treatment systems; Requires specialized maintenance expertise; System performance may vary in regions with highly variable water quality.

RWE Technology GmbH

Technical Solution: RWE Technology has pioneered a comprehensive water resource management framework for their large-scale green hydrogen initiatives called "HydroBalance." This system addresses the entire water lifecycle in hydrogen production, from sourcing to discharge. The technology incorporates advanced membrane-based water treatment systems specifically designed to handle varying water quality inputs, making it adaptable to diverse geographical locations. RWE's approach includes a modular water treatment architecture that can be scaled according to production capacity, with each module capable of processing 50-200 cubic meters of water daily. Their system features a closed-loop design that minimizes freshwater consumption by capturing, treating, and recycling process water, achieving water reuse rates of approximately 75-80%. RWE has also developed specialized heat exchangers that recover thermal energy from the electrolysis process to assist in water treatment, reducing the overall energy footprint. The system incorporates real-time monitoring with over 200 sensor points tracking water quality parameters, system performance, and predictive maintenance needs.

Strengths: Modular design allows for flexible deployment and scaling based on project requirements; Integrated energy recovery systems reduce operational costs; Comprehensive monitoring enables proactive maintenance and optimization. Weaknesses: Relatively high upfront capital costs; Complex integration requirements with existing infrastructure; Performance efficiency decreases in extremely arid environments where water recycling becomes more energy-intensive.

Advanced Water Treatment Technologies Analysis

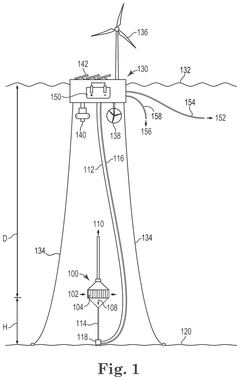

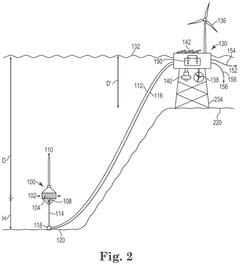

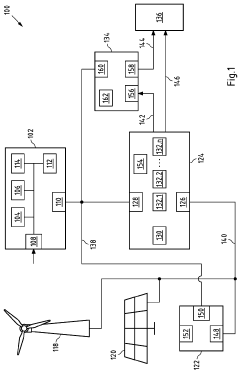

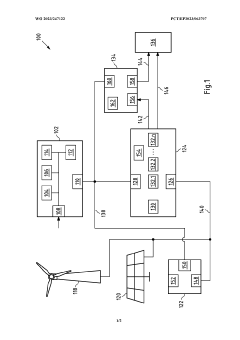

Apparatus and method for green hydrogen production using submerged desalination system

PatentPendingUS20240318323A1

Innovation

- A submerged desalination system integrated with an offshore renewable energy source and water electrolysis apparatus, utilizing hydrostatic pressure to reduce energy consumption and capital expenditures, enabling efficient green hydrogen production.

Method for operating a hydrogen production system

PatentWO2023247122A1

Innovation

- A method for controlling electrolysis systems in hydrogen production that integrates renewable energy forecasts and energy storage to optimize energy supply, allowing the system to prioritize renewable energy sources and adjust energy distribution dynamically.

Environmental Impact Assessment

The environmental impact assessment of water resource management for large-scale green hydrogen projects reveals significant ecological considerations that must be addressed. Water withdrawal for hydrogen production can alter local hydrological cycles, potentially affecting aquatic ecosystems and biodiversity. In regions where water scarcity is already a concern, excessive extraction may exacerbate drought conditions and reduce water availability for competing uses such as agriculture, municipal supply, and natural ecosystem maintenance.

Wastewater discharge from electrolysis processes presents another environmental challenge. Though generally less contaminated than industrial effluents, these discharges may contain trace metals, altered pH levels, or increased salinity that can impact receiving water bodies if not properly managed. Monitoring programs must be established to ensure compliance with local environmental regulations and prevent cumulative impacts on aquatic ecosystems.

Land use changes associated with water infrastructure development for hydrogen projects can fragment habitats and disrupt wildlife corridors. Construction of pipelines, pumping stations, and water treatment facilities may lead to soil erosion, sedimentation in waterways, and temporary disturbances to local fauna. These impacts require careful mitigation through proper site selection and construction management practices.

Climate change considerations add another layer of complexity to environmental assessments. As precipitation patterns become less predictable, water resource management strategies must incorporate climate resilience measures. Projects in coastal areas must also consider potential impacts from sea-level rise on water infrastructure and saltwater intrusion into freshwater sources.

The carbon footprint of water management operations themselves must be evaluated as part of a comprehensive environmental assessment. Energy-intensive processes such as desalination or long-distance water transport can partially offset the carbon benefits of green hydrogen if powered by non-renewable sources. Life cycle assessment methodologies should quantify these indirect emissions to ensure the overall environmental benefit of projects.

Cumulative impacts present perhaps the greatest challenge for environmental assessment. When multiple hydrogen projects or other industrial developments share the same watershed, their combined water withdrawals may exceed sustainable limits even if individual projects appear manageable. Regional planning approaches and watershed-level governance mechanisms are essential to address these cumulative effects and ensure long-term ecological sustainability.

Wastewater discharge from electrolysis processes presents another environmental challenge. Though generally less contaminated than industrial effluents, these discharges may contain trace metals, altered pH levels, or increased salinity that can impact receiving water bodies if not properly managed. Monitoring programs must be established to ensure compliance with local environmental regulations and prevent cumulative impacts on aquatic ecosystems.

Land use changes associated with water infrastructure development for hydrogen projects can fragment habitats and disrupt wildlife corridors. Construction of pipelines, pumping stations, and water treatment facilities may lead to soil erosion, sedimentation in waterways, and temporary disturbances to local fauna. These impacts require careful mitigation through proper site selection and construction management practices.

Climate change considerations add another layer of complexity to environmental assessments. As precipitation patterns become less predictable, water resource management strategies must incorporate climate resilience measures. Projects in coastal areas must also consider potential impacts from sea-level rise on water infrastructure and saltwater intrusion into freshwater sources.

The carbon footprint of water management operations themselves must be evaluated as part of a comprehensive environmental assessment. Energy-intensive processes such as desalination or long-distance water transport can partially offset the carbon benefits of green hydrogen if powered by non-renewable sources. Life cycle assessment methodologies should quantify these indirect emissions to ensure the overall environmental benefit of projects.

Cumulative impacts present perhaps the greatest challenge for environmental assessment. When multiple hydrogen projects or other industrial developments share the same watershed, their combined water withdrawals may exceed sustainable limits even if individual projects appear manageable. Regional planning approaches and watershed-level governance mechanisms are essential to address these cumulative effects and ensure long-term ecological sustainability.

Policy Framework and Water Rights

The development of large-scale green hydrogen projects requires a robust policy framework and clear water rights allocation to ensure sustainable water resource management. Currently, many jurisdictions lack specific regulations addressing the unique water needs of hydrogen production, creating regulatory uncertainty for project developers. Comprehensive policies must balance industrial water demands with environmental protection and community needs, especially in water-stressed regions where hydrogen projects may compete with agriculture, municipal use, and ecosystem requirements.

Water rights allocation systems vary significantly across regions, from prior appropriation doctrines in western United States to riparian rights in eastern states and different national frameworks globally. These existing systems often predate the emergence of green hydrogen as a significant water user, necessitating adaptation or creation of new frameworks. The complexity increases in transboundary watersheds where international agreements may govern water allocation, requiring diplomatic coordination alongside technical solutions.

Regulatory approaches to water for hydrogen production are evolving, with some jurisdictions beginning to incorporate hydrogen-specific provisions in their water management policies. These include prioritization schemes for different water uses, requirements for water recycling and efficiency measures, and mechanisms for seasonal water allocation adjustments. Progressive policies are implementing water permitting processes that consider the full lifecycle impacts of hydrogen projects, including source water protection and wastewater management.

Economic instruments are increasingly employed within policy frameworks to encourage efficient water use. These include tiered water pricing structures that reflect true resource costs, tradable water rights markets that allow for flexible allocation, and financial incentives for implementing advanced water conservation technologies. Such market-based approaches can complement regulatory requirements while providing flexibility for project developers to optimize their water management strategies.

Public participation mechanisms represent another critical component of effective policy frameworks. Transparent processes for community consultation during project planning stages help address concerns about water access and potential impacts on local water resources. Some jurisdictions now require water impact assessments with mandatory public disclosure and comment periods before large-scale hydrogen projects can proceed, fostering greater social acceptance and more equitable outcomes.

Looking forward, adaptive governance models that can respond to changing climate conditions and evolving technology capabilities will be essential. These frameworks must incorporate regular reassessment of water allocations based on updated hydrological data and climate projections, ensuring long-term sustainability of water resources while supporting the growth of the green hydrogen sector as a crucial component of the clean energy transition.

Water rights allocation systems vary significantly across regions, from prior appropriation doctrines in western United States to riparian rights in eastern states and different national frameworks globally. These existing systems often predate the emergence of green hydrogen as a significant water user, necessitating adaptation or creation of new frameworks. The complexity increases in transboundary watersheds where international agreements may govern water allocation, requiring diplomatic coordination alongside technical solutions.

Regulatory approaches to water for hydrogen production are evolving, with some jurisdictions beginning to incorporate hydrogen-specific provisions in their water management policies. These include prioritization schemes for different water uses, requirements for water recycling and efficiency measures, and mechanisms for seasonal water allocation adjustments. Progressive policies are implementing water permitting processes that consider the full lifecycle impacts of hydrogen projects, including source water protection and wastewater management.

Economic instruments are increasingly employed within policy frameworks to encourage efficient water use. These include tiered water pricing structures that reflect true resource costs, tradable water rights markets that allow for flexible allocation, and financial incentives for implementing advanced water conservation technologies. Such market-based approaches can complement regulatory requirements while providing flexibility for project developers to optimize their water management strategies.

Public participation mechanisms represent another critical component of effective policy frameworks. Transparent processes for community consultation during project planning stages help address concerns about water access and potential impacts on local water resources. Some jurisdictions now require water impact assessments with mandatory public disclosure and comment periods before large-scale hydrogen projects can proceed, fostering greater social acceptance and more equitable outcomes.

Looking forward, adaptive governance models that can respond to changing climate conditions and evolving technology capabilities will be essential. These frameworks must incorporate regular reassessment of water allocations based on updated hydrological data and climate projections, ensuring long-term sustainability of water resources while supporting the growth of the green hydrogen sector as a crucial component of the clean energy transition.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!