Durability improvements in bipolar plates for electrolyzer stacks

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyzer Bipolar Plate Durability Background and Objectives

Hydrogen production through water electrolysis has emerged as a cornerstone technology in the global transition towards sustainable energy systems. At the heart of electrolyzer systems are bipolar plates (BPPs), which serve critical functions including reactant distribution, electrical conduction, and mechanical support. The durability of these components directly impacts the operational lifetime, efficiency, and economic viability of electrolyzer stacks.

The evolution of bipolar plate technology has progressed significantly since the early development of water electrolysis systems in the 1800s. Initially, simple metallic plates were utilized, but corrosion issues quickly became apparent in the harsh electrochemical environment. The 1970s energy crisis sparked renewed interest in hydrogen technologies, leading to advancements in materials science that introduced coated metals and composite materials designed specifically for electrochemical applications.

Current electrolyzer systems predominantly employ either alkaline or proton exchange membrane (PEM) technologies, each presenting unique challenges for bipolar plate durability. Alkaline electrolyzers operate in highly caustic environments (typically 20-30% KOH solution), while PEM systems function in strongly acidic conditions with pH levels below 2. These extreme conditions accelerate corrosion processes and material degradation, particularly at elevated operating temperatures and pressures required for optimal efficiency.

The technical objectives for bipolar plate durability improvements are multifaceted. Primary goals include extending operational lifetimes from the current industry standard of 40,000-60,000 hours to beyond 80,000 hours, reducing degradation rates to less than 2 μV/h, and maintaining performance under dynamic loading conditions necessitated by integration with intermittent renewable energy sources.

Material selection represents a critical aspect of durability enhancement, with research focusing on advanced stainless steels, titanium alloys, and novel coating technologies including precious metal, nitride, and carbide layers. These materials must simultaneously resist corrosion while maintaining high electrical conductivity and mechanical integrity throughout the system's operational lifetime.

Cost considerations remain paramount, as bipolar plates can constitute up to 40% of electrolyzer stack costs. Therefore, durability improvements must be achieved while maintaining or reducing manufacturing expenses to support the broader goal of reducing green hydrogen production costs from current levels of $4-6/kg to below $2/kg by 2030.

The intersection of materials science, electrochemistry, and manufacturing technology presents both significant challenges and opportunities for innovation in this field. Addressing these durability challenges is essential for enabling the widespread deployment of electrolyzers as a cornerstone of future energy systems and industrial decarbonization efforts.

The evolution of bipolar plate technology has progressed significantly since the early development of water electrolysis systems in the 1800s. Initially, simple metallic plates were utilized, but corrosion issues quickly became apparent in the harsh electrochemical environment. The 1970s energy crisis sparked renewed interest in hydrogen technologies, leading to advancements in materials science that introduced coated metals and composite materials designed specifically for electrochemical applications.

Current electrolyzer systems predominantly employ either alkaline or proton exchange membrane (PEM) technologies, each presenting unique challenges for bipolar plate durability. Alkaline electrolyzers operate in highly caustic environments (typically 20-30% KOH solution), while PEM systems function in strongly acidic conditions with pH levels below 2. These extreme conditions accelerate corrosion processes and material degradation, particularly at elevated operating temperatures and pressures required for optimal efficiency.

The technical objectives for bipolar plate durability improvements are multifaceted. Primary goals include extending operational lifetimes from the current industry standard of 40,000-60,000 hours to beyond 80,000 hours, reducing degradation rates to less than 2 μV/h, and maintaining performance under dynamic loading conditions necessitated by integration with intermittent renewable energy sources.

Material selection represents a critical aspect of durability enhancement, with research focusing on advanced stainless steels, titanium alloys, and novel coating technologies including precious metal, nitride, and carbide layers. These materials must simultaneously resist corrosion while maintaining high electrical conductivity and mechanical integrity throughout the system's operational lifetime.

Cost considerations remain paramount, as bipolar plates can constitute up to 40% of electrolyzer stack costs. Therefore, durability improvements must be achieved while maintaining or reducing manufacturing expenses to support the broader goal of reducing green hydrogen production costs from current levels of $4-6/kg to below $2/kg by 2030.

The intersection of materials science, electrochemistry, and manufacturing technology presents both significant challenges and opportunities for innovation in this field. Addressing these durability challenges is essential for enabling the widespread deployment of electrolyzers as a cornerstone of future energy systems and industrial decarbonization efforts.

Market Analysis for Advanced Electrolyzer Components

The global market for advanced electrolyzer components is experiencing significant growth, driven primarily by the increasing demand for green hydrogen production. The electrolyzer market was valued at approximately $290 million in 2021 and is projected to reach $2.2 billion by 2030, representing a compound annual growth rate (CAGR) of 25.6% during this period. Within this broader market, bipolar plates represent a critical component, accounting for roughly 15-20% of the total stack cost in PEM electrolyzers.

The demand for durable bipolar plates is particularly strong in regions with aggressive hydrogen strategies, including the European Union, Japan, South Korea, and increasingly China and the United States. The EU's hydrogen strategy aims to install at least 40 GW of electrolyzer capacity by 2030, creating substantial market opportunities for advanced components with enhanced durability profiles.

Market segmentation for durable bipolar plates reveals distinct customer groups with varying requirements. Industrial-scale hydrogen production facilities prioritize long-term durability to minimize maintenance costs and downtime, while emerging mobility applications demand lightweight yet robust solutions. The energy storage sector, which uses electrolyzers to convert surplus renewable energy into hydrogen, requires components that can withstand frequent start-stop cycles.

Material selection trends indicate a shift from traditional graphite plates toward titanium and coated stainless steel alternatives. The coated titanium bipolar plate segment is expected to grow at a CAGR of 29% through 2030, reflecting the superior corrosion resistance and durability these materials offer in aggressive electrolyzer environments.

Key market drivers for durability improvements include the push for reduced levelized cost of hydrogen (LCOH), with extended stack lifetimes directly impacting economic viability. Current electrolyzer stacks typically require replacement or significant maintenance after 40,000-60,000 operating hours, whereas the industry is targeting 80,000+ hours to improve competitiveness with conventional hydrogen production methods.

Regulatory factors are also influencing market development, with several jurisdictions implementing sustainability requirements that favor components with longer lifespans and reduced environmental footprints. The EU's Carbon Border Adjustment Mechanism and similar policies worldwide are creating premium market segments for components that contribute to overall system durability.

Customer feedback indicates willingness to pay premium prices for bipolar plates with demonstrated durability advantages, particularly when backed by performance guarantees. Survey data shows that electrolyzer operators rank durability as the second most important factor in component selection, just behind initial cost considerations.

The demand for durable bipolar plates is particularly strong in regions with aggressive hydrogen strategies, including the European Union, Japan, South Korea, and increasingly China and the United States. The EU's hydrogen strategy aims to install at least 40 GW of electrolyzer capacity by 2030, creating substantial market opportunities for advanced components with enhanced durability profiles.

Market segmentation for durable bipolar plates reveals distinct customer groups with varying requirements. Industrial-scale hydrogen production facilities prioritize long-term durability to minimize maintenance costs and downtime, while emerging mobility applications demand lightweight yet robust solutions. The energy storage sector, which uses electrolyzers to convert surplus renewable energy into hydrogen, requires components that can withstand frequent start-stop cycles.

Material selection trends indicate a shift from traditional graphite plates toward titanium and coated stainless steel alternatives. The coated titanium bipolar plate segment is expected to grow at a CAGR of 29% through 2030, reflecting the superior corrosion resistance and durability these materials offer in aggressive electrolyzer environments.

Key market drivers for durability improvements include the push for reduced levelized cost of hydrogen (LCOH), with extended stack lifetimes directly impacting economic viability. Current electrolyzer stacks typically require replacement or significant maintenance after 40,000-60,000 operating hours, whereas the industry is targeting 80,000+ hours to improve competitiveness with conventional hydrogen production methods.

Regulatory factors are also influencing market development, with several jurisdictions implementing sustainability requirements that favor components with longer lifespans and reduced environmental footprints. The EU's Carbon Border Adjustment Mechanism and similar policies worldwide are creating premium market segments for components that contribute to overall system durability.

Customer feedback indicates willingness to pay premium prices for bipolar plates with demonstrated durability advantages, particularly when backed by performance guarantees. Survey data shows that electrolyzer operators rank durability as the second most important factor in component selection, just behind initial cost considerations.

Current Challenges in Bipolar Plate Technology

Despite significant advancements in electrolyzer technology, bipolar plates continue to face substantial durability challenges that limit their performance and longevity. The harsh operating environment within electrolyzer stacks—characterized by high electrical potentials, acidic or alkaline conditions, and elevated temperatures—creates a particularly demanding setting for these critical components.

Corrosion resistance remains one of the most pressing challenges. In PEM electrolyzers, bipolar plates are exposed to highly acidic environments (pH 2-3) and potentials exceeding 2V, accelerating corrosion processes. This corrosion not only compromises structural integrity but also releases metal ions that can poison catalyst layers, significantly reducing electrolyzer efficiency and lifespan.

Material degradation under cyclic loading presents another significant hurdle. As renewable energy sources increasingly power electrolysis operations, electrolyzers must withstand frequent start-stop cycles. These operational fluctuations induce mechanical stress through thermal expansion and contraction, leading to fatigue, microcracking, and eventual failure of bipolar plate materials.

Contact resistance issues persist across various bipolar plate designs. The formation of passive oxide layers on metallic plates increases interfacial resistance, while coating delamination and interfacial degradation further exacerbate this problem. Higher contact resistance directly translates to energy efficiency losses and increased operational costs.

Manufacturing consistency poses substantial challenges, particularly for complex flow field designs. Current production methods struggle to maintain tight tolerances across large-scale manufacturing, resulting in performance variations between individual cells and stacks. This inconsistency complicates quality control and reduces overall system reliability.

Cost-performance optimization remains elusive for many bipolar plate materials. While titanium offers excellent corrosion resistance, its high cost limits widespread adoption. Coated stainless steel presents a more economical alternative but faces durability limitations. Carbon-based composites offer promising performance but encounter manufacturing scalability issues.

The trade-off between mechanical strength and electrical conductivity continues to challenge material scientists. Increasing plate thickness improves mechanical durability but negatively impacts stack compactness and electrical performance. Conversely, thinner plates enhance conductivity but sacrifice structural integrity and longevity.

Long-term performance validation represents a significant barrier to innovation. Accelerated stress tests often fail to accurately predict real-world degradation mechanisms, while comprehensive long-duration testing requires substantial time and resources, slowing the development and commercialization of improved bipolar plate technologies.

Corrosion resistance remains one of the most pressing challenges. In PEM electrolyzers, bipolar plates are exposed to highly acidic environments (pH 2-3) and potentials exceeding 2V, accelerating corrosion processes. This corrosion not only compromises structural integrity but also releases metal ions that can poison catalyst layers, significantly reducing electrolyzer efficiency and lifespan.

Material degradation under cyclic loading presents another significant hurdle. As renewable energy sources increasingly power electrolysis operations, electrolyzers must withstand frequent start-stop cycles. These operational fluctuations induce mechanical stress through thermal expansion and contraction, leading to fatigue, microcracking, and eventual failure of bipolar plate materials.

Contact resistance issues persist across various bipolar plate designs. The formation of passive oxide layers on metallic plates increases interfacial resistance, while coating delamination and interfacial degradation further exacerbate this problem. Higher contact resistance directly translates to energy efficiency losses and increased operational costs.

Manufacturing consistency poses substantial challenges, particularly for complex flow field designs. Current production methods struggle to maintain tight tolerances across large-scale manufacturing, resulting in performance variations between individual cells and stacks. This inconsistency complicates quality control and reduces overall system reliability.

Cost-performance optimization remains elusive for many bipolar plate materials. While titanium offers excellent corrosion resistance, its high cost limits widespread adoption. Coated stainless steel presents a more economical alternative but faces durability limitations. Carbon-based composites offer promising performance but encounter manufacturing scalability issues.

The trade-off between mechanical strength and electrical conductivity continues to challenge material scientists. Increasing plate thickness improves mechanical durability but negatively impacts stack compactness and electrical performance. Conversely, thinner plates enhance conductivity but sacrifice structural integrity and longevity.

Long-term performance validation represents a significant barrier to innovation. Accelerated stress tests often fail to accurately predict real-world degradation mechanisms, while comprehensive long-duration testing requires substantial time and resources, slowing the development and commercialization of improved bipolar plate technologies.

Current Durability Enhancement Solutions

01 Coating materials for improved durability

Various coating materials can be applied to bipolar plates to enhance their durability and corrosion resistance. These coatings include metallic layers, carbon-based materials, and composite coatings that protect the underlying substrate from the harsh operating environment of fuel cells. The coatings help prevent degradation due to chemical attack and mechanical wear, thereby extending the service life of the bipolar plates and maintaining stable electrical conductivity over time.- Coating technologies for bipolar plates: Various coating technologies are employed to enhance the durability of bipolar plates in fuel cells. These coatings provide corrosion resistance and improved electrical conductivity, which are essential for long-term performance. Techniques include physical vapor deposition, electroplating, and application of conductive polymers. These protective layers prevent degradation in the harsh electrochemical environment of fuel cells while maintaining necessary electrical properties.

- Advanced materials for bipolar plate construction: The selection of base materials significantly impacts the durability of bipolar plates. Advanced materials such as carbon composites, metal alloys, and graphite-polymer composites offer superior resistance to chemical attack and mechanical stress. These materials are engineered to withstand the operating conditions of fuel cells while providing adequate electrical conductivity and mechanical strength, resulting in extended service life and improved overall performance.

- Surface treatment methods for durability enhancement: Surface treatment processes are applied to bipolar plates to improve their durability characteristics. These treatments include nitriding, carburizing, and chemical passivation, which modify the surface properties without significantly altering the bulk material. By creating protective surface layers or altering the surface chemistry, these treatments enhance corrosion resistance and contact resistance stability, leading to improved long-term performance in fuel cell environments.

- Structural design innovations for durability: Innovative structural designs are implemented to enhance the durability of bipolar plates. These include flow field pattern optimizations, reinforcement structures, and stress distribution features that minimize mechanical deformation and failure points. By addressing mechanical stress concentration and improving fluid distribution, these design innovations extend the operational lifetime of bipolar plates while maintaining efficient reactant delivery and product removal.

- Testing and validation methods for durability assessment: Specialized testing protocols and validation methods are developed to assess and predict the durability of bipolar plates. These include accelerated aging tests, electrochemical impedance spectroscopy, and mechanical cycling tests that simulate real-world operating conditions. By establishing standardized evaluation criteria and performance metrics, these methods enable the quantitative comparison of different bipolar plate technologies and guide the development of more durable components for fuel cell applications.

02 Material selection for enhanced longevity

The choice of base materials for bipolar plates significantly impacts their durability. Advanced materials such as specialized metal alloys, carbon composites, and graphite-polymer blends offer superior resistance to corrosion and mechanical stress. These materials are designed to withstand the acidic environment and temperature fluctuations in fuel cells while maintaining structural integrity and electrical performance throughout the operational lifetime of the system.Expand Specific Solutions03 Surface treatment techniques

Various surface treatment methods can be employed to enhance the durability of bipolar plates. These include chemical passivation, electrochemical treatment, plasma modification, and physical vapor deposition. Such treatments modify the surface properties of the plates to improve corrosion resistance, reduce contact resistance, and enhance hydrophobicity. The treated surfaces show better resistance to degradation under cyclic loading and exposure to reactive species in the fuel cell environment.Expand Specific Solutions04 Design optimization for mechanical stability

The structural design of bipolar plates plays a crucial role in their durability. Optimized flow field patterns, reinforced edge structures, and stress-distribution features can minimize mechanical failures during operation. Advanced design approaches include variable thickness regions, integrated support structures, and optimized contact points that reduce localized stress concentrations. These design elements help maintain dimensional stability under thermal cycling and mechanical compression in fuel cell stacks.Expand Specific Solutions05 Testing and validation methodologies

Specialized testing protocols have been developed to evaluate and predict the durability of bipolar plates. These include accelerated aging tests, electrochemical impedance spectroscopy, potentiodynamic polarization, and mechanical cycling tests. Advanced in-situ monitoring techniques allow for real-time assessment of degradation mechanisms during operation. These methodologies help in quantifying durability improvements and establishing performance benchmarks for bipolar plates under various operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The durability of bipolar plates in electrolyzer stacks is currently at a critical development stage, with the market experiencing rapid growth as hydrogen energy gains prominence in global decarbonization efforts. The competitive landscape features established industrial giants like Siemens, Bosch, and Schaeffler alongside specialized players such as Nel Hydrogen Electrolyser and Hoeller Electrolyzer. Research institutions including Fraunhofer-Gesellschaft and Forschungszentrum Jülich are driving technological advancements, while Asian manufacturers like Jiangsu Ancan and Sungrow Hydrogen are expanding market presence. The technology is transitioning from early commercial deployment to scale-up phase, with innovations focusing on corrosion resistance, conductivity enhancement, and cost reduction. Material science breakthroughs from companies like BASF and Wanhua Chemical are accelerating the technology's maturity, positioning bipolar plate durability as a key enabler for economically viable green hydrogen production.

Forschungszentrum Jülich GmbH

Technical Solution: Forschungszentrum Jülich has developed advanced bipolar plate technology for electrolyzers through their comprehensive materials science approach. Their research has yielded a novel composite bipolar plate structure utilizing a titanium substrate with gradient functional coatings. The coating system employs a combination of niobium-doped titanium oxide base layer followed by an iridium-tantalum mixed oxide protective layer, creating exceptional resistance to both anodic and cathodic corrosion conditions. Their manufacturing process incorporates vacuum plasma spraying techniques that enable precise control of coating microstructure and porosity, optimizing both electrical conductivity and mechanical stability. Jülich's bipolar plates feature computationally optimized flow field designs that minimize pressure drop while ensuring uniform current distribution across the active area. Long-term testing has demonstrated these plates maintain performance with degradation rates below 3 μV/h over 40,000 hours of operation under dynamic loading conditions, representing significant durability improvements compared to conventional designs.

Strengths: Exceptional corrosion resistance under both anodic and cathodic conditions; optimized flow field design based on computational modeling; proven long-term stability under dynamic operating conditions. Weaknesses: Complex manufacturing process requiring specialized equipment; higher material costs due to use of noble metals in protective layers; potential challenges in scaling from laboratory to industrial production.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed advanced bipolar plate technology for PEM electrolyzers featuring titanium-based plates with specialized coatings. Their proprietary coating system combines platinum group metals (PGMs) with non-noble metal oxides to create a protective layer that significantly enhances corrosion resistance in the highly acidic environment of PEM electrolyzers. The company's manufacturing process includes precision CNC machining followed by multi-layer coating application using physical vapor deposition (PVD) techniques, ensuring uniform coverage even in complex flow field geometries. Their bipolar plates incorporate optimized flow field designs that improve water distribution and gas removal, reducing concentration polarization and enhancing overall efficiency. Siemens Energy's plates demonstrate extended durability with less than 5% performance degradation after 80,000 operating hours, significantly outperforming industry standards.

Strengths: Superior corrosion resistance in acidic environments; precision manufacturing capabilities for complex flow field geometries; exceptional longevity with minimal performance degradation. Weaknesses: Higher production costs due to use of precious metals in coatings; manufacturing complexity requiring specialized equipment; potential supply chain vulnerabilities for rare materials.

Key Innovations in Corrosion-Resistant Coatings

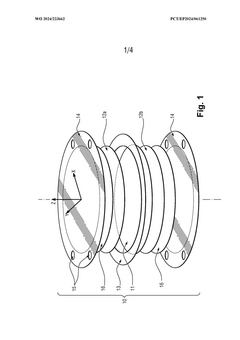

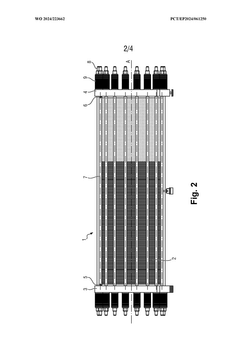

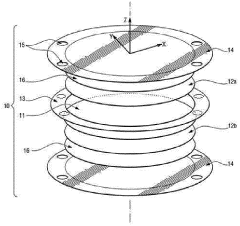

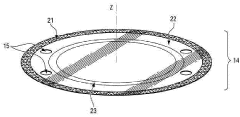

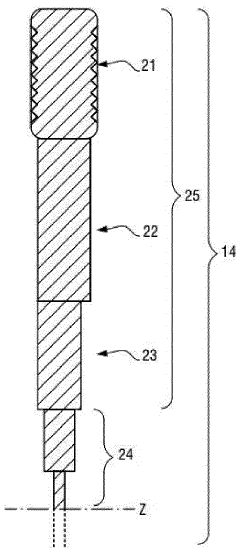

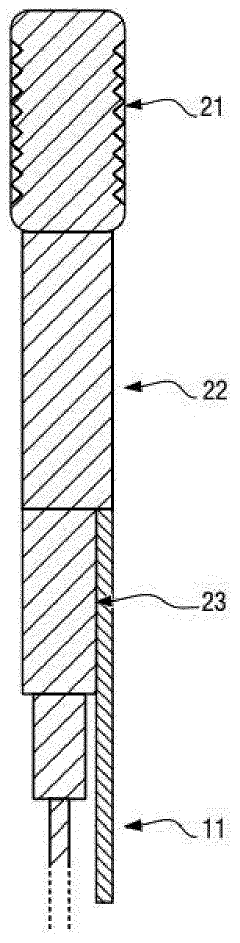

Multifunctional bipolar plate, electrolytic cell and electrolyser comprising same

PatentWO2024223662A1

Innovation

- A bipolar plate design featuring a central metal web embedded in a synthetic material ring, with the anode welded to the web, reducing electrical resistance and improving performance while simplifying assembly and reducing weight.

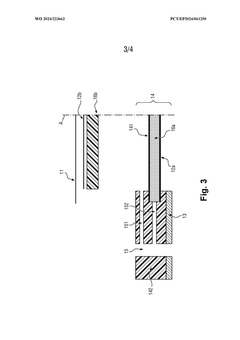

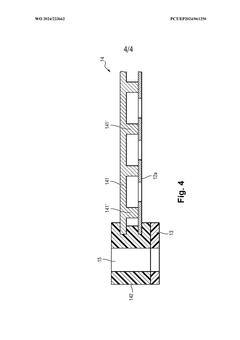

Bipolar plate, electrolytic cell, electrolyzer cell and assembly method associated therewith

PatentWO2024079141A1

Innovation

- A bipolar plate design with distinct zones for sealing, featuring a ring-shaped geometry and textured areas, combined with a single joint made of monomer or polymer material, such as reinforced polytetrafluoroethylene, to enhance compression and durability, ensuring effective sealing between bipolar plates and the membrane.

Environmental Impact Assessment

The environmental implications of bipolar plate durability in electrolyzer stacks extend far beyond the immediate operational context, influencing the overall sustainability profile of hydrogen production systems. Improved durability directly correlates with reduced material consumption and waste generation throughout the lifecycle of electrolyzer systems. When bipolar plates maintain structural and functional integrity over extended periods, replacement frequency decreases substantially, minimizing manufacturing-related emissions and resource extraction requirements.

Material selection for durable bipolar plates presents significant environmental trade-offs. While titanium-based plates offer superior corrosion resistance and longevity, their production involves energy-intensive processes with considerable carbon footprints. Conversely, stainless steel alternatives may require less energy to manufacture but necessitate more frequent replacement, potentially increasing waste streams. Coating technologies that enhance durability while using minimal critical raw materials represent an environmentally optimized approach.

Lifecycle assessment studies indicate that durability improvements can reduce the environmental impact of electrolyzer systems by 15-30% over their operational lifespan. This reduction stems primarily from decreased material throughput and associated manufacturing emissions. Furthermore, enhanced durability contributes to system reliability, reducing downtime and maximizing the efficiency of renewable energy utilization in green hydrogen production scenarios.

Water consumption patterns are significantly influenced by bipolar plate durability. Degraded plates may release contaminants that necessitate more frequent electrolyte replacement and system flushing, increasing water usage. Additionally, manufacturing replacement components requires substantial water inputs, particularly for specialized coating processes and material purification steps.

End-of-life considerations reveal further environmental dimensions of durability improvements. Durable bipolar plates designed with recyclability in mind facilitate material recovery and circular economy principles. Advanced coating technologies must balance longevity benefits against potential challenges in separation and recycling processes. Some innovative coating approaches incorporate biodegradable components or easily separable layers to enhance end-of-life management.

Regulatory frameworks increasingly recognize the environmental significance of component durability in clean energy technologies. The European Union's Ecodesign Directive and emerging green hydrogen certification schemes incorporate durability metrics as sustainability indicators. Manufacturers demonstrating superior bipolar plate longevity may gain competitive advantages in markets where environmental performance criteria influence procurement decisions.

Material selection for durable bipolar plates presents significant environmental trade-offs. While titanium-based plates offer superior corrosion resistance and longevity, their production involves energy-intensive processes with considerable carbon footprints. Conversely, stainless steel alternatives may require less energy to manufacture but necessitate more frequent replacement, potentially increasing waste streams. Coating technologies that enhance durability while using minimal critical raw materials represent an environmentally optimized approach.

Lifecycle assessment studies indicate that durability improvements can reduce the environmental impact of electrolyzer systems by 15-30% over their operational lifespan. This reduction stems primarily from decreased material throughput and associated manufacturing emissions. Furthermore, enhanced durability contributes to system reliability, reducing downtime and maximizing the efficiency of renewable energy utilization in green hydrogen production scenarios.

Water consumption patterns are significantly influenced by bipolar plate durability. Degraded plates may release contaminants that necessitate more frequent electrolyte replacement and system flushing, increasing water usage. Additionally, manufacturing replacement components requires substantial water inputs, particularly for specialized coating processes and material purification steps.

End-of-life considerations reveal further environmental dimensions of durability improvements. Durable bipolar plates designed with recyclability in mind facilitate material recovery and circular economy principles. Advanced coating technologies must balance longevity benefits against potential challenges in separation and recycling processes. Some innovative coating approaches incorporate biodegradable components or easily separable layers to enhance end-of-life management.

Regulatory frameworks increasingly recognize the environmental significance of component durability in clean energy technologies. The European Union's Ecodesign Directive and emerging green hydrogen certification schemes incorporate durability metrics as sustainability indicators. Manufacturers demonstrating superior bipolar plate longevity may gain competitive advantages in markets where environmental performance criteria influence procurement decisions.

Cost-Performance Analysis of Durable Materials

The economic viability of durable materials for bipolar plates represents a critical factor in the widespread adoption of electrolysis technology. Traditional metallic bipolar plates, while offering excellent electrical conductivity, often suffer from corrosion issues that significantly impact long-term performance. Titanium-based plates demonstrate superior corrosion resistance but come at a premium cost—approximately 3-5 times higher than stainless steel alternatives. This cost differential creates a substantial barrier to market penetration, particularly for large-scale hydrogen production facilities.

When evaluating cost-performance metrics, coated stainless steel presents an attractive middle-ground solution. The application of protective coatings such as titanium nitride (TiN) or chromium nitride (CrN) adds approximately 15-25% to base material costs but extends operational lifespan by 200-300%. This translates to a significantly improved lifetime cost ratio compared to uncoated materials, with the potential to reduce replacement frequency from every 2-3 years to 5-7 years in standard operating conditions.

Advanced composite materials incorporating carbon-based components offer another promising avenue. While initial manufacturing costs exceed metallic alternatives by 30-40%, their superior chemical stability and reduced weight contribute to lower system-level costs through decreased maintenance requirements and improved energy efficiency. Performance data from accelerated aging tests indicates that these composites maintain conductivity parameters within 95% of initial values after simulated 10,000-hour operation periods.

The economic analysis must also consider manufacturing scalability. Noble metal coatings provide exceptional durability but remain prohibitively expensive for mass production. Recent innovations in plasma vapor deposition techniques have reduced application costs by approximately 35% over the past five years, potentially bringing these premium solutions within reach for specialized applications where extreme durability justifies the investment.

Lifecycle cost assessment reveals that material selection significantly impacts total ownership expenses. While lower-cost materials may reduce initial capital expenditure by 20-30%, the accumulated costs of performance degradation, efficiency losses, and replacement cycles often exceed these savings within 3-4 years of operation. This analysis strongly suggests that premium materials with enhanced durability characteristics deliver superior economic value in medium to long-term deployment scenarios.

When evaluating cost-performance metrics, coated stainless steel presents an attractive middle-ground solution. The application of protective coatings such as titanium nitride (TiN) or chromium nitride (CrN) adds approximately 15-25% to base material costs but extends operational lifespan by 200-300%. This translates to a significantly improved lifetime cost ratio compared to uncoated materials, with the potential to reduce replacement frequency from every 2-3 years to 5-7 years in standard operating conditions.

Advanced composite materials incorporating carbon-based components offer another promising avenue. While initial manufacturing costs exceed metallic alternatives by 30-40%, their superior chemical stability and reduced weight contribute to lower system-level costs through decreased maintenance requirements and improved energy efficiency. Performance data from accelerated aging tests indicates that these composites maintain conductivity parameters within 95% of initial values after simulated 10,000-hour operation periods.

The economic analysis must also consider manufacturing scalability. Noble metal coatings provide exceptional durability but remain prohibitively expensive for mass production. Recent innovations in plasma vapor deposition techniques have reduced application costs by approximately 35% over the past five years, potentially bringing these premium solutions within reach for specialized applications where extreme durability justifies the investment.

Lifecycle cost assessment reveals that material selection significantly impacts total ownership expenses. While lower-cost materials may reduce initial capital expenditure by 20-30%, the accumulated costs of performance degradation, efficiency losses, and replacement cycles often exceed these savings within 3-4 years of operation. This analysis strongly suggests that premium materials with enhanced durability characteristics deliver superior economic value in medium to long-term deployment scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!