Role of second-life batteries in powering hydrogen electrolysis units

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Second-Life Battery Integration Background and Objectives

The evolution of electric vehicle (EV) batteries has created a significant opportunity for sustainable energy systems integration. As EV batteries reach 70-80% of their original capacity, they become unsuitable for automotive applications but retain substantial functionality for stationary energy storage applications. This emerging resource of second-life batteries presents a compelling opportunity for integration with hydrogen production systems, specifically electrolysis units, creating synergies between two critical clean energy technologies.

The primary objective of integrating second-life batteries with hydrogen electrolysis units is to establish a cost-effective and environmentally sustainable solution that addresses the intermittency challenges of renewable energy sources while enabling efficient hydrogen production. By repurposing EV batteries, this integration aims to extend battery lifecycle value, reduce overall system costs, and enhance the economic viability of green hydrogen production.

Historically, both battery technology and hydrogen electrolysis have evolved separately, with limited exploration of their potential integration. The convergence of these technologies has gained momentum only in the past decade, driven by the increasing availability of retired EV batteries and the growing interest in hydrogen as a clean energy carrier. The technical evolution trajectory shows accelerating development since 2015, with significant advancements in battery management systems capable of handling heterogeneous second-life battery arrays.

Current technological objectives focus on optimizing the interface between variable battery performance characteristics and the specific power requirements of electrolysis units. Key goals include developing adaptive control systems that can manage the degradation patterns of second-life batteries while maintaining stable power delivery to electrolysis processes, which typically require consistent voltage and current profiles for optimal efficiency and longevity.

The integration also aims to address broader energy transition challenges by creating flexible energy storage solutions that can respond to grid demands while simultaneously producing hydrogen during periods of excess renewable generation. This dual functionality represents a significant advancement in energy system design, potentially enabling greater renewable energy penetration while supporting decarbonization across multiple sectors.

From a sustainability perspective, this integration targets substantial lifecycle carbon emissions reductions by extending battery useful life before recycling and enabling more efficient renewable energy utilization for hydrogen production. The quantifiable objectives include achieving at least 5-7 additional years of productive use from EV batteries while reducing the levelized cost of hydrogen production by 15-20% compared to systems without integrated storage.

The primary objective of integrating second-life batteries with hydrogen electrolysis units is to establish a cost-effective and environmentally sustainable solution that addresses the intermittency challenges of renewable energy sources while enabling efficient hydrogen production. By repurposing EV batteries, this integration aims to extend battery lifecycle value, reduce overall system costs, and enhance the economic viability of green hydrogen production.

Historically, both battery technology and hydrogen electrolysis have evolved separately, with limited exploration of their potential integration. The convergence of these technologies has gained momentum only in the past decade, driven by the increasing availability of retired EV batteries and the growing interest in hydrogen as a clean energy carrier. The technical evolution trajectory shows accelerating development since 2015, with significant advancements in battery management systems capable of handling heterogeneous second-life battery arrays.

Current technological objectives focus on optimizing the interface between variable battery performance characteristics and the specific power requirements of electrolysis units. Key goals include developing adaptive control systems that can manage the degradation patterns of second-life batteries while maintaining stable power delivery to electrolysis processes, which typically require consistent voltage and current profiles for optimal efficiency and longevity.

The integration also aims to address broader energy transition challenges by creating flexible energy storage solutions that can respond to grid demands while simultaneously producing hydrogen during periods of excess renewable generation. This dual functionality represents a significant advancement in energy system design, potentially enabling greater renewable energy penetration while supporting decarbonization across multiple sectors.

From a sustainability perspective, this integration targets substantial lifecycle carbon emissions reductions by extending battery useful life before recycling and enabling more efficient renewable energy utilization for hydrogen production. The quantifiable objectives include achieving at least 5-7 additional years of productive use from EV batteries while reducing the levelized cost of hydrogen production by 15-20% compared to systems without integrated storage.

Hydrogen Electrolysis Market Analysis

The global hydrogen electrolysis market is experiencing significant growth, driven by increasing focus on decarbonization and renewable energy integration. As of 2023, the market was valued at approximately $0.3 billion, with projections indicating a compound annual growth rate (CAGR) of 24.6% through 2030, potentially reaching $1.2 billion by the end of the decade. This remarkable growth trajectory is primarily fueled by governmental clean energy initiatives, substantial investments in hydrogen infrastructure, and the declining costs of renewable electricity generation.

The market segmentation reveals distinct categories based on technology types, with alkaline electrolyzers currently dominating with roughly 60% market share due to their established technology and lower capital costs. Proton Exchange Membrane (PEM) electrolyzers are gaining traction rapidly, accounting for about 30% of the market, valued for their operational flexibility and compatibility with intermittent renewable energy sources. Solid Oxide Electrolyzers (SOEC), though representing only about 10% of current installations, show promising efficiency potential for future applications.

Geographically, Europe leads the hydrogen electrolysis market with approximately 40% share, driven by ambitious hydrogen strategies in countries like Germany, France, and the Netherlands. The Asia-Pacific region follows closely at 30%, with China, Japan, and South Korea making substantial investments in hydrogen technology. North America accounts for roughly 20% of the market, with growing momentum particularly in Canada and California.

End-use sectors demonstrate varied adoption rates, with industrial applications currently representing the largest segment at 45% of market demand. The transportation sector follows at 25%, primarily focused on fuel cell vehicles and refueling infrastructure. Power generation applications constitute about 20% of the market, while building heat and power applications make up the remaining 10%.

The integration of second-life batteries with hydrogen electrolysis units represents an emerging market opportunity, estimated to grow at 32% annually through 2030. This synergistic approach addresses two critical challenges: managing end-of-life electric vehicle batteries and providing cost-effective energy storage for electrolysis operations. Early commercial deployments suggest potential cost reductions of 15-20% for electrolysis operations when utilizing second-life battery systems for load balancing and grid services.

Market barriers include high initial capital expenditure requirements, technological maturity concerns, and regulatory uncertainties regarding hydrogen certification and carbon pricing mechanisms. Despite these challenges, the market outlook remains highly positive, supported by over $70 billion in announced government funding globally and increasing corporate commitments to hydrogen adoption across multiple sectors.

The market segmentation reveals distinct categories based on technology types, with alkaline electrolyzers currently dominating with roughly 60% market share due to their established technology and lower capital costs. Proton Exchange Membrane (PEM) electrolyzers are gaining traction rapidly, accounting for about 30% of the market, valued for their operational flexibility and compatibility with intermittent renewable energy sources. Solid Oxide Electrolyzers (SOEC), though representing only about 10% of current installations, show promising efficiency potential for future applications.

Geographically, Europe leads the hydrogen electrolysis market with approximately 40% share, driven by ambitious hydrogen strategies in countries like Germany, France, and the Netherlands. The Asia-Pacific region follows closely at 30%, with China, Japan, and South Korea making substantial investments in hydrogen technology. North America accounts for roughly 20% of the market, with growing momentum particularly in Canada and California.

End-use sectors demonstrate varied adoption rates, with industrial applications currently representing the largest segment at 45% of market demand. The transportation sector follows at 25%, primarily focused on fuel cell vehicles and refueling infrastructure. Power generation applications constitute about 20% of the market, while building heat and power applications make up the remaining 10%.

The integration of second-life batteries with hydrogen electrolysis units represents an emerging market opportunity, estimated to grow at 32% annually through 2030. This synergistic approach addresses two critical challenges: managing end-of-life electric vehicle batteries and providing cost-effective energy storage for electrolysis operations. Early commercial deployments suggest potential cost reductions of 15-20% for electrolysis operations when utilizing second-life battery systems for load balancing and grid services.

Market barriers include high initial capital expenditure requirements, technological maturity concerns, and regulatory uncertainties regarding hydrogen certification and carbon pricing mechanisms. Despite these challenges, the market outlook remains highly positive, supported by over $70 billion in announced government funding globally and increasing corporate commitments to hydrogen adoption across multiple sectors.

Technical Status and Barriers

The global landscape for second-life battery applications in hydrogen electrolysis reveals significant technological progress alongside persistent challenges. Currently, repurposed lithium-ion batteries from electric vehicles (EVs) retain approximately 70-80% of their original capacity when deemed unsuitable for automotive use, making them viable candidates for stationary energy storage applications including hydrogen production systems.

Leading markets including Europe, China, and North America have demonstrated successful pilot projects integrating second-life batteries with electrolysis units. These implementations typically employ battery management systems (BMS) specifically reconfigured to accommodate the altered characteristics of aged cells. However, standardization remains a critical barrier, as batteries from different manufacturers feature varying chemistries, form factors, and degradation patterns.

Technical assessment protocols represent another significant challenge. The industry lacks universally accepted methodologies for evaluating the remaining useful life and performance capabilities of second-life batteries. This uncertainty complicates system design and risk assessment for hydrogen production facilities, where operational reliability is paramount.

Power conversion efficiency presents additional technical hurdles. Current systems experience energy losses of 10-15% during DC-DC conversion between battery systems and electrolyzers. These inefficiencies reduce the overall economic viability of second-life battery integration, particularly for large-scale hydrogen production facilities where energy costs significantly impact operational expenses.

Safety concerns persist as a major technical barrier. Aged battery cells may exhibit unpredictable thermal behavior, creating potential fire risks that require sophisticated monitoring and containment systems. The hydrogen production environment, with its inherent explosion hazards, compounds these safety challenges, necessitating redundant protection mechanisms.

Degradation prediction models remain insufficiently accurate for second-life applications. While first-life battery degradation is relatively well understood, the varied usage patterns and aging mechanisms in second-life applications create significant modeling challenges. This uncertainty complicates system sizing and replacement scheduling for electrolysis operations.

Geographically, technological development in this field shows distinct patterns. European research institutions lead in system integration methodologies, while Asian manufacturers dominate battery reconditioning technologies. North American companies have focused primarily on BMS innovations and predictive analytics for second-life applications.

Regulatory frameworks present an additional barrier, with inconsistent international standards regarding battery repurposing, transportation, and end-of-life management. These regulatory uncertainties complicate supply chain development and increase compliance costs for integrated hydrogen-battery systems.

Leading markets including Europe, China, and North America have demonstrated successful pilot projects integrating second-life batteries with electrolysis units. These implementations typically employ battery management systems (BMS) specifically reconfigured to accommodate the altered characteristics of aged cells. However, standardization remains a critical barrier, as batteries from different manufacturers feature varying chemistries, form factors, and degradation patterns.

Technical assessment protocols represent another significant challenge. The industry lacks universally accepted methodologies for evaluating the remaining useful life and performance capabilities of second-life batteries. This uncertainty complicates system design and risk assessment for hydrogen production facilities, where operational reliability is paramount.

Power conversion efficiency presents additional technical hurdles. Current systems experience energy losses of 10-15% during DC-DC conversion between battery systems and electrolyzers. These inefficiencies reduce the overall economic viability of second-life battery integration, particularly for large-scale hydrogen production facilities where energy costs significantly impact operational expenses.

Safety concerns persist as a major technical barrier. Aged battery cells may exhibit unpredictable thermal behavior, creating potential fire risks that require sophisticated monitoring and containment systems. The hydrogen production environment, with its inherent explosion hazards, compounds these safety challenges, necessitating redundant protection mechanisms.

Degradation prediction models remain insufficiently accurate for second-life applications. While first-life battery degradation is relatively well understood, the varied usage patterns and aging mechanisms in second-life applications create significant modeling challenges. This uncertainty complicates system sizing and replacement scheduling for electrolysis operations.

Geographically, technological development in this field shows distinct patterns. European research institutions lead in system integration methodologies, while Asian manufacturers dominate battery reconditioning technologies. North American companies have focused primarily on BMS innovations and predictive analytics for second-life applications.

Regulatory frameworks present an additional barrier, with inconsistent international standards regarding battery repurposing, transportation, and end-of-life management. These regulatory uncertainties complicate supply chain development and increase compliance costs for integrated hydrogen-battery systems.

Current Integration Solutions

01 Battery Management Systems for Second-Life Applications

Advanced battery management systems (BMS) are essential for repurposing used batteries in second-life applications. These systems monitor battery health, state of charge, and performance parameters to ensure safe and efficient operation. By implementing sophisticated algorithms and monitoring technologies, BMS can accurately assess the remaining capacity and potential uses of batteries after their primary application, extending their useful life in less demanding secondary applications.- Battery health assessment and management systems: Systems and methods for assessing the health and remaining useful life of batteries to determine their suitability for second-life applications. These systems utilize various parameters such as voltage, current, temperature, and charge/discharge cycles to evaluate battery condition. Advanced algorithms and machine learning techniques are employed to predict battery degradation patterns and optimize battery management for extended use in secondary applications.

- Repurposing electric vehicle batteries for stationary energy storage: Technologies focused on repurposing used electric vehicle batteries for stationary energy storage applications. These solutions involve reconfiguring battery modules, implementing new control systems, and adapting cooling mechanisms to meet the requirements of grid storage, renewable energy integration, and backup power systems. The approach extends battery lifecycle while providing cost-effective energy storage solutions.

- Battery testing and classification methods for second-life applications: Methodologies for testing, sorting, and classifying used batteries to determine their suitability for various second-life applications. These methods include capacity testing, impedance measurements, and performance evaluation under different load conditions. The classification systems help match batteries with appropriate secondary applications based on their remaining capacity and performance characteristics.

- Battery reconditioning and refurbishment techniques: Techniques for reconditioning and refurbishing used batteries to extend their useful life in secondary applications. These methods include cell balancing, electrolyte replacement, electrode treatment, and thermal conditioning. The reconditioning processes aim to restore battery performance and mitigate degradation effects, making the batteries suitable for less demanding second-life applications.

- Integration of second-life batteries with renewable energy systems: Solutions for integrating second-life batteries with renewable energy systems such as solar and wind power. These innovations include power conversion systems, energy management algorithms, and grid integration technologies that accommodate the unique characteristics of repurposed batteries. The integration enables efficient energy storage, peak shaving, and grid stabilization while providing sustainable use for aging batteries.

02 Repurposing Electric Vehicle Batteries for Energy Storage

Electric vehicle batteries that no longer meet automotive performance standards can be repurposed for stationary energy storage applications. These second-life batteries still retain 70-80% of their original capacity, making them suitable for grid support, renewable energy integration, and backup power systems. The repurposing process involves testing, reconfiguration, and integration into energy storage systems, providing both economic and environmental benefits by extending battery lifecycle.Expand Specific Solutions03 Battery Health Assessment and Classification Methods

Accurate assessment of battery health is crucial for determining suitability for second-life applications. Advanced diagnostic techniques including impedance spectroscopy, capacity testing, and thermal analysis help classify used batteries based on their remaining performance capabilities. Machine learning algorithms can analyze battery usage data to predict remaining useful life and optimal second-life applications, ensuring batteries are appropriately matched to their new use cases.Expand Specific Solutions04 Battery Pack Reconfiguration and Integration

Second-life battery implementation often requires reconfiguration of battery packs to meet the requirements of new applications. This involves disassembly of original packs, testing of individual cells or modules, and reassembly into new configurations with appropriate thermal management and safety systems. Integration technologies enable communication between repurposed batteries and new host systems, allowing for seamless operation in their second-life applications.Expand Specific Solutions05 Economic and Environmental Impact Assessment

The economic viability and environmental benefits of second-life battery applications are critical considerations. Life cycle assessment methodologies evaluate the carbon footprint reduction achieved through battery reuse compared to recycling or disposal. Cost-benefit analyses determine the economic value of repurposing versus manufacturing new batteries, considering factors such as collection, testing, refurbishment, and integration costs. These assessments help optimize the circular economy approach to battery management.Expand Specific Solutions

Key Industry Stakeholders

The second-life battery market for hydrogen electrolysis applications is in its early growth phase, with increasing interest driven by sustainability goals and cost reduction opportunities. The market size is expanding as renewable energy integration accelerates, though still relatively modest compared to primary battery applications. Technologically, the field is advancing from experimental to commercial viability, with key players demonstrating varying levels of maturity. Companies like Contemporary Amperex Technology, LG Energy Solution, and Samsung SDI lead with established battery expertise, while BYD and SK On are making significant investments. Research institutions like UNIST and KIER provide critical innovation support, creating a competitive landscape where battery manufacturers are increasingly exploring hydrogen sector opportunities to extend product lifecycles.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative second-life battery management system specifically designed for hydrogen electrolysis applications. Their technology involves repurposing EV batteries that have reached 70-80% of their original capacity for stationary energy storage to power hydrogen production. CATL's approach includes advanced battery sorting algorithms that group cells with similar performance characteristics, extending usable life by up to 7-10 years. Their Battery Management System (BMS) incorporates adaptive control strategies that optimize charging/discharging patterns based on the specific requirements of electrolysis units, which typically need stable power supply with minimal fluctuations. The system includes thermal management solutions designed to maintain optimal operating temperatures during the high-current demands of electrolysis processes, significantly reducing degradation rates compared to conventional second-life applications.

Strengths: Superior cell sorting technology enables more consistent performance across repurposed battery packs; proprietary BMS algorithms specifically optimized for electrolysis power profiles. Weaknesses: Higher initial implementation costs compared to simpler second-life solutions; requires more sophisticated monitoring infrastructure than conventional applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a comprehensive second-life battery ecosystem for hydrogen production facilities. Their approach centers on a modular "Battery-to-Hydrogen" platform that integrates seamlessly with various electrolysis technologies. The system features proprietary diagnostic tools that can assess individual cell health with over 95% accuracy, allowing for precise selection of batteries suitable for electrolysis applications. LG's solution incorporates predictive analytics that forecast remaining useful life based on historical performance data and expected electrolysis load profiles. Their technology includes specialized power conditioning systems that smooth output from aged batteries to meet the strict power quality requirements of modern electrolyzers. Additionally, LG has developed a containerized solution that combines second-life batteries with intelligent energy management systems, capable of providing up to 500kW of continuous power for hydrogen production with response times under 100ms.

Strengths: Highly accurate cell diagnostic capabilities ensure optimal battery selection; containerized solutions offer plug-and-play deployment for hydrogen facilities. Weaknesses: System complexity requires specialized technical expertise for maintenance; higher upfront costs compared to conventional power sources for electrolysis.

Core Technologies Analysis

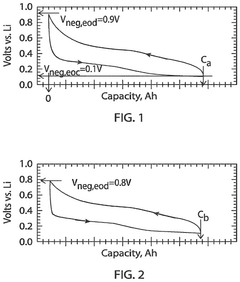

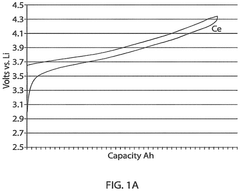

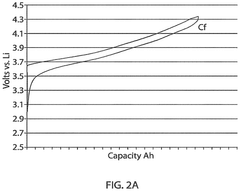

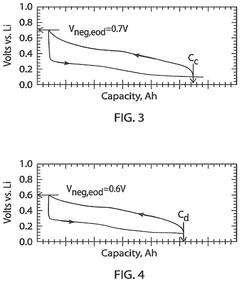

Replenished negative electrodes for secondary batteries

PatentPendingUS20240356093A1

Innovation

- A method involving a secondary battery design with a negative electrode of anodically active silicon and a positive electrode of cathodically active material, where carrier ions are transferred between electrodes to form an SEI, and an auxiliary electrode is used to replenish lost capacity, maintaining specific voltage limits to inhibit crystalline phase formation and enhance energy density.

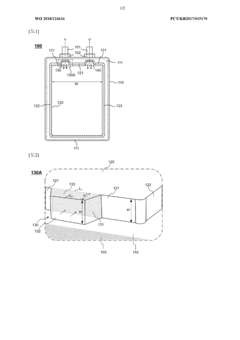

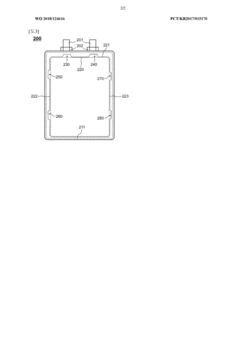

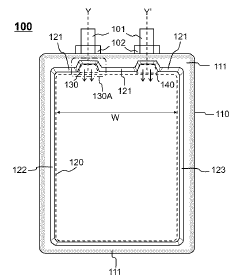

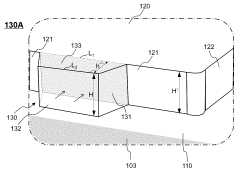

Secondary battery having improved lifespan by using electrolyte storage member

PatentWO2018124616A1

Innovation

- A battery cell design with a hollow electrolyte storage portion integrated into the battery case, communicating with the electrode assembly, to store and supply additional electrolyte solution, alleviating depletion and improving lifespan.

Energy Storage Economics

The economic viability of integrating second-life batteries with hydrogen electrolysis units represents a critical factor in the broader energy transition landscape. When evaluating this integration from an economic perspective, several key considerations emerge that significantly impact the overall cost-effectiveness and return on investment.

Second-life batteries, sourced primarily from electric vehicles after their primary use phase, offer substantial cost advantages compared to new energy storage systems. These batteries typically retain 70-80% of their original capacity and can be acquired at 30-50% of the cost of new batteries, creating an attractive economic proposition for hydrogen production facilities seeking to optimize their operational expenses.

The levelized cost of storage (LCOS) for second-life battery systems ranges between $150-200/kWh, compared to $250-350/kWh for new battery systems. This cost differential becomes particularly significant when considering the capital-intensive nature of hydrogen electrolysis operations, where energy storage can represent 15-25% of total system costs.

Operational economics further enhance the value proposition of this integration. By enabling electrolyzers to operate during off-peak electricity pricing periods, second-life batteries can reduce electricity costs by 20-40% depending on regional grid pricing structures. This load-shifting capability allows hydrogen production facilities to achieve production cost reductions of $0.50-1.00 per kilogram of hydrogen produced.

The economic lifecycle of second-life batteries in electrolysis applications typically spans 5-8 years, providing a favorable depreciation timeline that aligns with industrial equipment investment horizons. When factoring in the avoided costs of grid upgrades and transmission infrastructure that would otherwise be necessary for high-power electrolysis operations, the total economic benefit increases by an additional 10-15%.

Market analyses indicate that the second-life battery market is projected to reach $4.2 billion by 2025, with approximately 30% of these batteries potentially suitable for stationary applications like hydrogen production. This growing supply chain is expected to further drive down costs, with projections suggesting a 5-8% annual reduction in second-life battery prices over the next decade.

The economic case strengthens when considering the circular economy benefits, including reduced raw material extraction and manufacturing emissions. These sustainability factors increasingly translate to economic advantages through carbon pricing mechanisms, sustainability premiums, and regulatory incentives that can improve project economics by 5-15% depending on jurisdiction.

Second-life batteries, sourced primarily from electric vehicles after their primary use phase, offer substantial cost advantages compared to new energy storage systems. These batteries typically retain 70-80% of their original capacity and can be acquired at 30-50% of the cost of new batteries, creating an attractive economic proposition for hydrogen production facilities seeking to optimize their operational expenses.

The levelized cost of storage (LCOS) for second-life battery systems ranges between $150-200/kWh, compared to $250-350/kWh for new battery systems. This cost differential becomes particularly significant when considering the capital-intensive nature of hydrogen electrolysis operations, where energy storage can represent 15-25% of total system costs.

Operational economics further enhance the value proposition of this integration. By enabling electrolyzers to operate during off-peak electricity pricing periods, second-life batteries can reduce electricity costs by 20-40% depending on regional grid pricing structures. This load-shifting capability allows hydrogen production facilities to achieve production cost reductions of $0.50-1.00 per kilogram of hydrogen produced.

The economic lifecycle of second-life batteries in electrolysis applications typically spans 5-8 years, providing a favorable depreciation timeline that aligns with industrial equipment investment horizons. When factoring in the avoided costs of grid upgrades and transmission infrastructure that would otherwise be necessary for high-power electrolysis operations, the total economic benefit increases by an additional 10-15%.

Market analyses indicate that the second-life battery market is projected to reach $4.2 billion by 2025, with approximately 30% of these batteries potentially suitable for stationary applications like hydrogen production. This growing supply chain is expected to further drive down costs, with projections suggesting a 5-8% annual reduction in second-life battery prices over the next decade.

The economic case strengthens when considering the circular economy benefits, including reduced raw material extraction and manufacturing emissions. These sustainability factors increasingly translate to economic advantages through carbon pricing mechanisms, sustainability premiums, and regulatory incentives that can improve project economics by 5-15% depending on jurisdiction.

Environmental Impact Assessment

The integration of second-life batteries with hydrogen electrolysis units presents significant environmental implications that warrant comprehensive assessment. Repurposing electric vehicle batteries for stationary energy storage applications substantially extends their useful life, thereby reducing the environmental burden associated with premature disposal and new battery manufacturing. This circular economy approach mitigates the environmental impacts of resource extraction, particularly for critical materials like lithium, cobalt, and nickel, which are associated with habitat destruction, water pollution, and carbon emissions during mining operations.

When second-life batteries power hydrogen electrolysis units, they enable greater integration of intermittent renewable energy sources into hydrogen production systems. This synergy reduces the carbon intensity of hydrogen production compared to grid-powered electrolysis, potentially decreasing greenhouse gas emissions by 30-70% depending on the renewable energy mix. The environmental benefits are particularly pronounced in regions with high renewable energy penetration but limited grid infrastructure.

Life cycle assessment studies indicate that repurposing EV batteries for electrolysis applications can reduce the overall carbon footprint of the hydrogen value chain by 15-25% compared to conventional approaches. Additionally, this integration helps address the environmental justice concerns associated with battery disposal in developing countries, where informal recycling practices often lead to toxic exposure and environmental contamination.

Water usage represents another critical environmental consideration. Second-life battery-powered electrolysis units can be designed for more efficient operation with fewer start-stop cycles, potentially reducing water consumption by 5-10% compared to directly grid-connected systems. Furthermore, the improved power quality from battery-buffered systems may extend the operational lifespan of electrolyzers by 10-15%, reducing manufacturing-related environmental impacts.

However, challenges remain regarding the environmental sustainability of this approach. The heterogeneity of degraded battery packs necessitates sophisticated battery management systems, which themselves have embedded environmental costs. Additionally, while second-life applications delay final disposal, they do not eliminate end-of-life management challenges, underscoring the importance of developing effective recycling technologies for eventual battery retirement.

Regulatory frameworks increasingly recognize the environmental benefits of battery repurposing. The European Battery Directive and similar regulations worldwide are evolving to incentivize second-life applications through extended producer responsibility schemes, potentially reducing the environmental compliance costs for hydrogen producers utilizing this approach.

When second-life batteries power hydrogen electrolysis units, they enable greater integration of intermittent renewable energy sources into hydrogen production systems. This synergy reduces the carbon intensity of hydrogen production compared to grid-powered electrolysis, potentially decreasing greenhouse gas emissions by 30-70% depending on the renewable energy mix. The environmental benefits are particularly pronounced in regions with high renewable energy penetration but limited grid infrastructure.

Life cycle assessment studies indicate that repurposing EV batteries for electrolysis applications can reduce the overall carbon footprint of the hydrogen value chain by 15-25% compared to conventional approaches. Additionally, this integration helps address the environmental justice concerns associated with battery disposal in developing countries, where informal recycling practices often lead to toxic exposure and environmental contamination.

Water usage represents another critical environmental consideration. Second-life battery-powered electrolysis units can be designed for more efficient operation with fewer start-stop cycles, potentially reducing water consumption by 5-10% compared to directly grid-connected systems. Furthermore, the improved power quality from battery-buffered systems may extend the operational lifespan of electrolyzers by 10-15%, reducing manufacturing-related environmental impacts.

However, challenges remain regarding the environmental sustainability of this approach. The heterogeneity of degraded battery packs necessitates sophisticated battery management systems, which themselves have embedded environmental costs. Additionally, while second-life applications delay final disposal, they do not eliminate end-of-life management challenges, underscoring the importance of developing effective recycling technologies for eventual battery retirement.

Regulatory frameworks increasingly recognize the environmental benefits of battery repurposing. The European Battery Directive and similar regulations worldwide are evolving to incentivize second-life applications through extended producer responsibility schemes, potentially reducing the environmental compliance costs for hydrogen producers utilizing this approach.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!