Role of green hydrogen in synthetic methanol production pathways

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Hydrogen Background and Production Goals

Green hydrogen represents a revolutionary approach to clean energy production, derived from water electrolysis powered by renewable electricity sources such as wind, solar, or hydroelectric power. Unlike grey hydrogen (produced from natural gas) or blue hydrogen (produced with carbon capture), green hydrogen generates zero carbon emissions during production, positioning it as a cornerstone technology for global decarbonization efforts. The concept has evolved significantly since the early 2000s, with technological advancements dramatically reducing production costs from over $10/kg to approaching $4-5/kg in optimal locations by 2023.

The primary technical goal for green hydrogen in synthetic methanol production is to replace fossil fuel-based hydrogen as a key feedstock. Conventional methanol synthesis combines hydrogen with carbon dioxide or carbon monoxide under high pressure and temperature conditions with metal catalysts. By substituting green hydrogen, the production pathway can achieve near-carbon neutrality when combined with captured CO2, creating a circular carbon economy model.

Current production goals focus on scaling electrolysis technology to industrial levels while simultaneously reducing costs to make green hydrogen economically competitive with fossil-based alternatives. The International Energy Agency (IEA) and International Renewable Energy Agency (IRENA) have established ambitious targets of reducing green hydrogen costs to $1-2/kg by 2030 and below $1/kg by 2050, which would make synthetic methanol production via green hydrogen economically viable without subsidies.

Efficiency improvements represent another critical goal, with current electrolysis systems operating at 60-80% efficiency. Research aims to push this boundary toward 85-90% while extending electrolyzer lifespans from current 40,000-60,000 hours to over 80,000 hours, reducing replacement frequency and operational costs in industrial settings.

Water consumption presents an additional challenge, with current technologies requiring approximately 9 liters of purified water to produce 1 kg of hydrogen. Developing electrolysis systems that can operate with seawater or wastewater would significantly enhance sustainability and deployment potential in water-scarce regions.

The integration of green hydrogen production with variable renewable energy sources constitutes another key objective. Developing electrolyzers capable of operating efficiently under fluctuating power inputs would enable direct coupling with renewable generation, eliminating the need for battery storage intermediaries and further reducing system costs. This flexibility would also allow hydrogen production facilities to provide grid balancing services, creating additional revenue streams while supporting broader renewable energy integration.

The primary technical goal for green hydrogen in synthetic methanol production is to replace fossil fuel-based hydrogen as a key feedstock. Conventional methanol synthesis combines hydrogen with carbon dioxide or carbon monoxide under high pressure and temperature conditions with metal catalysts. By substituting green hydrogen, the production pathway can achieve near-carbon neutrality when combined with captured CO2, creating a circular carbon economy model.

Current production goals focus on scaling electrolysis technology to industrial levels while simultaneously reducing costs to make green hydrogen economically competitive with fossil-based alternatives. The International Energy Agency (IEA) and International Renewable Energy Agency (IRENA) have established ambitious targets of reducing green hydrogen costs to $1-2/kg by 2030 and below $1/kg by 2050, which would make synthetic methanol production via green hydrogen economically viable without subsidies.

Efficiency improvements represent another critical goal, with current electrolysis systems operating at 60-80% efficiency. Research aims to push this boundary toward 85-90% while extending electrolyzer lifespans from current 40,000-60,000 hours to over 80,000 hours, reducing replacement frequency and operational costs in industrial settings.

Water consumption presents an additional challenge, with current technologies requiring approximately 9 liters of purified water to produce 1 kg of hydrogen. Developing electrolysis systems that can operate with seawater or wastewater would significantly enhance sustainability and deployment potential in water-scarce regions.

The integration of green hydrogen production with variable renewable energy sources constitutes another key objective. Developing electrolyzers capable of operating efficiently under fluctuating power inputs would enable direct coupling with renewable generation, eliminating the need for battery storage intermediaries and further reducing system costs. This flexibility would also allow hydrogen production facilities to provide grid balancing services, creating additional revenue streams while supporting broader renewable energy integration.

Market Analysis for Synthetic Methanol Demand

The global synthetic methanol market is experiencing significant growth, driven by increasing demand across multiple sectors. Currently, the market size is valued at approximately 30 billion USD, with projections indicating a compound annual growth rate of 5-6% through 2030. This growth trajectory is supported by methanol's versatility as both a chemical feedstock and potential clean fuel alternative.

Traditional industries such as construction, automotive, and electronics continue to drive substantial demand for methanol-derived products including formaldehyde, acetic acid, and various solvents. However, emerging applications in the energy sector are creating new market opportunities, particularly as countries seek to reduce carbon emissions and develop alternative fuel pathways.

The transportation sector represents a particularly promising growth area for synthetic methanol demand. Maritime shipping is increasingly exploring methanol as a low-carbon fuel alternative to meet stringent International Maritime Organization (IMO) emissions regulations. Several major shipping companies have already commissioned methanol-powered vessels, signaling a potential shift in the industry. Similarly, methanol fuel cells for vehicles and portable power applications are gaining traction in markets focused on decarbonization.

Chemical production remains the dominant application segment, accounting for over 60% of global methanol consumption. Formaldehyde production alone consumes approximately 30% of global methanol supply, while methanol-to-olefins (MTO) technology has emerged as a significant growth driver, particularly in China where coal-to-methanol-to-olefins pathways have been extensively developed.

Regionally, Asia-Pacific dominates the synthetic methanol market, with China accounting for nearly half of global consumption. Europe and North America follow as significant markets, with Europe showing particularly strong interest in green methanol pathways due to stringent environmental regulations and ambitious climate targets.

The integration of green hydrogen into methanol synthesis pathways is creating a premium market segment for "green methanol" with substantially lower carbon footprints. While currently representing less than 1% of the global methanol market, green methanol demand is projected to grow at 25-30% annually as industries seek to decarbonize their supply chains and meet sustainability commitments.

Price sensitivity remains a critical factor in market adoption, with conventional methanol typically priced between 300-400 USD per ton, while green methanol currently commands prices of 800-1200 USD per ton. This price differential highlights the importance of cost reduction in green hydrogen production to enable broader market penetration of sustainable synthetic methanol pathways.

Traditional industries such as construction, automotive, and electronics continue to drive substantial demand for methanol-derived products including formaldehyde, acetic acid, and various solvents. However, emerging applications in the energy sector are creating new market opportunities, particularly as countries seek to reduce carbon emissions and develop alternative fuel pathways.

The transportation sector represents a particularly promising growth area for synthetic methanol demand. Maritime shipping is increasingly exploring methanol as a low-carbon fuel alternative to meet stringent International Maritime Organization (IMO) emissions regulations. Several major shipping companies have already commissioned methanol-powered vessels, signaling a potential shift in the industry. Similarly, methanol fuel cells for vehicles and portable power applications are gaining traction in markets focused on decarbonization.

Chemical production remains the dominant application segment, accounting for over 60% of global methanol consumption. Formaldehyde production alone consumes approximately 30% of global methanol supply, while methanol-to-olefins (MTO) technology has emerged as a significant growth driver, particularly in China where coal-to-methanol-to-olefins pathways have been extensively developed.

Regionally, Asia-Pacific dominates the synthetic methanol market, with China accounting for nearly half of global consumption. Europe and North America follow as significant markets, with Europe showing particularly strong interest in green methanol pathways due to stringent environmental regulations and ambitious climate targets.

The integration of green hydrogen into methanol synthesis pathways is creating a premium market segment for "green methanol" with substantially lower carbon footprints. While currently representing less than 1% of the global methanol market, green methanol demand is projected to grow at 25-30% annually as industries seek to decarbonize their supply chains and meet sustainability commitments.

Price sensitivity remains a critical factor in market adoption, with conventional methanol typically priced between 300-400 USD per ton, while green methanol currently commands prices of 800-1200 USD per ton. This price differential highlights the importance of cost reduction in green hydrogen production to enable broader market penetration of sustainable synthetic methanol pathways.

Current Challenges in Green Hydrogen-Based Methanol Synthesis

Despite the promising potential of green hydrogen in methanol synthesis, several significant challenges impede its widespread implementation. The primary obstacle remains the high production cost of green hydrogen, currently ranging from $4-6/kg compared to $1-2/kg for gray hydrogen derived from fossil fuels. This cost differential creates a substantial economic barrier for commercial-scale adoption of green hydrogen-based methanol production pathways.

Energy efficiency presents another critical challenge. The electrolysis process for green hydrogen production typically achieves only 60-80% efficiency, resulting in considerable energy losses. When integrated into methanol synthesis, these inefficiencies compound, reducing the overall process economics and sustainability benefits.

Infrastructure limitations further constrain implementation. Green hydrogen requires specialized storage, transportation, and handling systems due to its low volumetric energy density and material compatibility issues. The current global infrastructure is predominantly designed for fossil fuel-based systems, necessitating significant capital investments for transition to hydrogen-compatible facilities.

Technical challenges in the catalytic conversion process also persist. Current catalysts for CO2 hydrogenation to methanol exhibit limited selectivity and require high pressure (50-100 bar) and moderate temperature (200-300°C) conditions, increasing operational complexity and energy requirements. Catalyst deactivation due to impurities in industrial CO2 streams remains problematic, reducing catalyst lifespan and increasing replacement frequency.

System integration complexities arise when combining renewable electricity generation, electrolysis, and methanol synthesis. Intermittency of renewable energy sources creates operational challenges for electrolyzers designed for continuous operation, necessitating either energy storage solutions or hybrid systems, both adding cost and complexity.

Regulatory frameworks and carbon pricing mechanisms remain underdeveloped in many regions, failing to adequately value the environmental benefits of green hydrogen-based methanol over fossil-derived alternatives. Without supportive policies that internalize environmental externalities, the economic case for green pathways remains challenging.

Scale-up issues present additional barriers, as most successful demonstrations have occurred at pilot scale (1-10 MW electrolyzers), while commercial viability requires much larger installations (100+ MW). The technical and financial risks associated with scaling these technologies create hesitancy among potential investors and industrial adopters.

Energy efficiency presents another critical challenge. The electrolysis process for green hydrogen production typically achieves only 60-80% efficiency, resulting in considerable energy losses. When integrated into methanol synthesis, these inefficiencies compound, reducing the overall process economics and sustainability benefits.

Infrastructure limitations further constrain implementation. Green hydrogen requires specialized storage, transportation, and handling systems due to its low volumetric energy density and material compatibility issues. The current global infrastructure is predominantly designed for fossil fuel-based systems, necessitating significant capital investments for transition to hydrogen-compatible facilities.

Technical challenges in the catalytic conversion process also persist. Current catalysts for CO2 hydrogenation to methanol exhibit limited selectivity and require high pressure (50-100 bar) and moderate temperature (200-300°C) conditions, increasing operational complexity and energy requirements. Catalyst deactivation due to impurities in industrial CO2 streams remains problematic, reducing catalyst lifespan and increasing replacement frequency.

System integration complexities arise when combining renewable electricity generation, electrolysis, and methanol synthesis. Intermittency of renewable energy sources creates operational challenges for electrolyzers designed for continuous operation, necessitating either energy storage solutions or hybrid systems, both adding cost and complexity.

Regulatory frameworks and carbon pricing mechanisms remain underdeveloped in many regions, failing to adequately value the environmental benefits of green hydrogen-based methanol over fossil-derived alternatives. Without supportive policies that internalize environmental externalities, the economic case for green pathways remains challenging.

Scale-up issues present additional barriers, as most successful demonstrations have occurred at pilot scale (1-10 MW electrolyzers), while commercial viability requires much larger installations (100+ MW). The technical and financial risks associated with scaling these technologies create hesitancy among potential investors and industrial adopters.

Current Methanol Synthesis Pathways Using Green Hydrogen

01 Production methods for green hydrogen

Various methods for producing green hydrogen using renewable energy sources are described. These methods primarily focus on water electrolysis powered by renewable electricity such as solar, wind, or hydroelectric power. The electrolysis process splits water molecules into hydrogen and oxygen without generating carbon emissions. Advanced electrolysis technologies including proton exchange membrane (PEM), alkaline, and solid oxide electrolyzers are employed to improve efficiency and reduce production costs.- Production methods for green hydrogen: Various methods for producing green hydrogen using renewable energy sources. These methods primarily focus on water electrolysis powered by renewable electricity such as solar, wind, or hydroelectric power. The electrolysis process splits water molecules into hydrogen and oxygen without generating carbon emissions. Advanced electrolysis technologies including proton exchange membrane (PEM), alkaline, and solid oxide electrolyzers are employed to improve efficiency and reduce production costs.

- Storage and transportation solutions: Innovative technologies for storing and transporting green hydrogen safely and efficiently. These include compression and liquefaction methods, chemical carriers like ammonia or liquid organic hydrogen carriers (LOHC), and advanced materials for hydrogen containment. Pipeline infrastructure adaptations and specialized vessels for maritime hydrogen transport are also being developed to enable the creation of a global green hydrogen supply chain.

- Integration with renewable energy systems: Systems and methods for integrating green hydrogen production with renewable energy sources. These technologies focus on optimizing the coupling between intermittent renewable energy generation and hydrogen production facilities. Smart grid solutions, energy management systems, and hybrid power plants that combine solar/wind with hydrogen production and storage are being developed to enhance grid stability and maximize renewable energy utilization.

- Industrial applications and fuel cells: Applications of green hydrogen in industrial processes and fuel cell technologies. These include using green hydrogen as a feedstock for chemical production, as a reducing agent in steel manufacturing, and as a clean fuel for high-temperature industrial processes. Advanced fuel cell designs for stationary power generation and transportation applications are also being developed to efficiently convert hydrogen back into electricity with only water as a byproduct.

- Catalysts and efficiency improvements: Novel catalysts and materials to improve the efficiency of green hydrogen production and utilization. These innovations focus on developing non-precious metal catalysts, nanostructured materials, and advanced electrode designs to enhance electrolysis performance while reducing costs. Efficiency improvements in hydrogen conversion processes, purification methods, and system integration are also being pursued to make green hydrogen economically competitive with fossil fuel alternatives.

02 Storage and transportation solutions

Technologies for efficient storage and transportation of green hydrogen are essential for its widespread adoption. These include compression and liquefaction methods, chemical carriers like ammonia or liquid organic hydrogen carriers (LOHC), and advanced materials for hydrogen storage such as metal hydrides and carbon-based materials. Pipeline infrastructure adaptations and specialized containers for hydrogen transport are also covered to ensure safe and cost-effective delivery from production sites to end users.Expand Specific Solutions03 Integration with renewable energy systems

Systems and methods for integrating green hydrogen production with renewable energy sources are described. These include hybrid power plants combining solar/wind generation with hydrogen production facilities, smart grid technologies for optimizing hydrogen production based on renewable energy availability, and energy management systems that balance electricity generation and hydrogen production. Such integration helps address the intermittency issues of renewable energy by using excess electricity for hydrogen production during peak generation periods.Expand Specific Solutions04 Industrial applications and end-use technologies

Various industrial applications and end-use technologies for green hydrogen are covered, including fuel cells for transportation and stationary power generation, hydrogen combustion technologies for industrial heat, and chemical processes using hydrogen as a feedstock. These applications span across sectors such as steel manufacturing, ammonia production, refining, and transportation. The technologies focus on maximizing efficiency while minimizing emissions when utilizing green hydrogen as an energy carrier or industrial input.Expand Specific Solutions05 Economic and efficiency improvements

Innovations aimed at improving the economic viability and efficiency of green hydrogen production and utilization are described. These include catalyst developments to reduce precious metal requirements in electrolyzers, system design optimizations to increase energy efficiency, and process innovations to lower capital and operational costs. Scale-up technologies and manufacturing improvements are also covered to enable mass production and achieve cost parity with conventional hydrogen production methods.Expand Specific Solutions

Key Industry Players in Green Hydrogen and Methanol Markets

The green hydrogen market in synthetic methanol production is in an early growth phase, characterized by increasing investments and research activities. The market size is expanding rapidly, driven by decarbonization goals and renewable energy integration, though still representing a small fraction of the overall methanol industry. Technologically, the field shows varying maturity levels across different players. Research institutions like IIT Guwahati, Oxford University Innovation, and University of Queensland are advancing fundamental research, while industrial leaders such as Air Liquide, Saudi Aramco, Phillips 66, and Sinopec are scaling up pilot projects. Companies like New Wave Hydrogen and WasteFuel Global are developing innovative approaches, while established firms like Johnson Matthey Davy Technologies and FEV Group provide engineering expertise to bridge research-to-commercial gaps in this emerging green chemistry sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated green hydrogen-to-methanol production system that leverages their extensive experience in conventional methanol synthesis. Their technology utilizes advanced alkaline electrolysis units powered by renewable electricity, coupled with proprietary copper-zinc-aluminum catalysts specifically optimized for CO2 hydrogenation to methanol. Sinopec's process incorporates innovative pressure swing adsorption systems that enable efficient hydrogen purification while minimizing energy consumption. The company has implemented a demonstration facility in Qilu, China that produces approximately 50,000 tons of green methanol annually using hydrogen from renewable sources and captured CO2 from their refinery operations. Their system features advanced heat integration that recovers approximately 60% of process heat, significantly improving overall energy efficiency. Sinopec has also developed specialized reactor designs that enhance mass transfer between hydrogen and CO2, increasing single-pass conversion rates by up to 15% compared to conventional reactors.

Strengths: Extensive experience in large-scale methanol production and distribution; established infrastructure that can be leveraged for green methanol deployment; proprietary catalyst technology with enhanced stability and selectivity. Weaknesses: Current technology still heavily dependent on low-cost electricity to be economically viable; limited experience with fluctuating renewable energy integration; technology optimization primarily focused on Chinese market conditions.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a comprehensive green hydrogen-to-methanol pathway that leverages their extensive experience in carbon management and hydrogen production. Their technology integrates solar-powered electrolysis with advanced methanol synthesis processes specifically designed for arid climate conditions. The company's approach includes innovative water management systems that minimize freshwater consumption through closed-loop recycling and desalination integration. Aramco's process features proprietary copper-zinc oxide catalysts with enhanced resistance to sulfur poisoning, allowing for greater flexibility in CO2 source selection. Their system incorporates advanced thermal management that utilizes concentrated solar power for process heating, reducing the overall electricity demand for hydrogen production by approximately 25%. The company has implemented a demonstration facility in Saudi Arabia that produces 10,000 tons of green methanol annually using exclusively renewable energy sources. Aramco's technology also includes sophisticated process control systems that optimize hydrogen production in response to solar irradiance variations, maximizing system efficiency across diurnal cycles.

Strengths: Abundant access to solar resources for renewable hydrogen production; extensive experience in large-scale gas processing and catalytic systems; integrated approach to water management critical for desert environments. Weaknesses: Technology heavily optimized for specific geographic conditions; limited experience with integration into existing chemical value chains outside the Middle East; significant capital requirements for full-scale deployment.

Critical Technologies for Green Hydrogen-to-Methanol Conversion

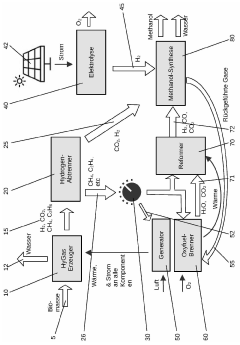

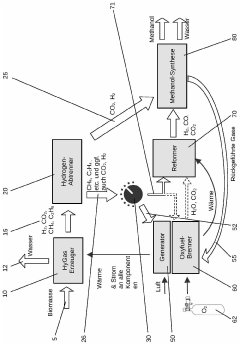

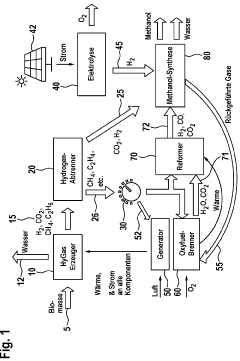

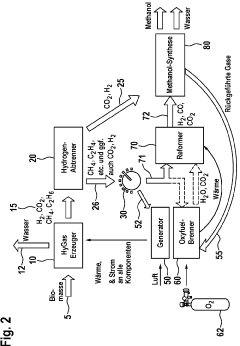

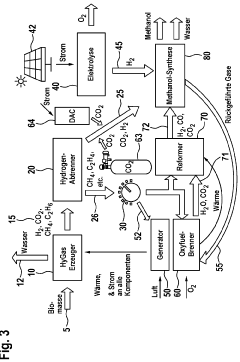

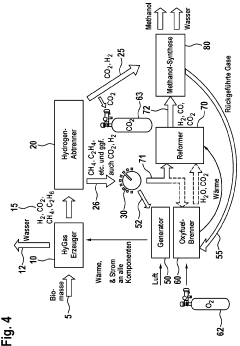

methanol production from biomass and green hydrogen

PatentInactiveDE102022115977A1

Innovation

- A dual operating mode system is implemented where sufficient green electricity is used for electrolytic hydrogen production, and when it's unavailable, residual gases from biogas separation are utilized to generate electricity, optimizing methanol synthesis by recycling unconverted materials and using oxyfuel burners and reformers to produce further synthesis gas.

Methanol production from biomass and green hydrogen

PatentWO2024002419A1

Innovation

- Dual operating mode system that adapts to hydrogen availability: main mode using electrolysis-derived hydrogen when sufficient electricity is available, and secondary mode utilizing residual gas from biogas separation when electricity is limited.

- Circular resource utilization by repurposing residual gas from biogas separation to power the methanol production process during limited electricity availability, creating a self-sustaining production system.

- Integration of biomass-derived synthesis gas with green hydrogen for methanol production, combining biogenic carbon sources with renewable hydrogen to create a more sustainable methanol production pathway.

Carbon Capture Integration in Methanol Synthesis

Carbon capture technology plays a pivotal role in the integration of green hydrogen for synthetic methanol production pathways. The synthesis of methanol traditionally relies on fossil-based hydrogen and carbon sources, resulting in significant carbon emissions. However, the incorporation of carbon capture systems creates a sustainable circular carbon economy when combined with green hydrogen.

Carbon capture can be implemented at various stages of the methanol synthesis process. Pre-combustion capture involves removing CO2 before combustion occurs, while post-combustion capture extracts CO2 from flue gases. Oxy-fuel combustion, another approach, uses pure oxygen for combustion, producing a concentrated CO2 stream that is easier to capture. Each method offers distinct advantages depending on the specific methanol production configuration.

When integrated with green hydrogen production, carbon capture technologies enable the creation of carbon-neutral or even carbon-negative methanol. The captured CO2 serves as a feedstock that, when combined with green hydrogen, produces methanol through catalytic hydrogenation processes. This integration pathway significantly reduces the carbon footprint compared to conventional methanol production methods.

Recent technological advancements have improved the efficiency of carbon capture in methanol synthesis. Novel sorbents and membranes with enhanced CO2 selectivity have reduced energy penalties associated with capture processes. Additionally, process intensification techniques have optimized heat integration between carbon capture units and methanol synthesis reactors, improving overall system efficiency.

Economic analyses indicate that while carbon capture integration increases capital expenditure by 15-30%, the long-term benefits include reduced carbon taxes and access to premium markets for low-carbon methanol products. The levelized cost of methanol production with integrated carbon capture ranges from $450-650 per ton, depending on the capture technology employed and regional energy prices.

Several demonstration projects worldwide showcase successful integration of carbon capture in green methanol pathways. Notable examples include Carbon Recycling International's George Olah plant in Iceland, which utilizes geothermal energy for hydrogen production and captured CO2 from industrial sources. Similarly, the MefCO2 project in Germany demonstrates the technical feasibility of converting captured CO2 from power plants into methanol using renewable hydrogen.

Future developments focus on improving energy efficiency of integrated systems and reducing capital costs through modular designs and advanced materials. Research is also exploring direct air capture integration with methanol synthesis to create truly carbon-negative fuel pathways when powered by renewable energy sources.

Carbon capture can be implemented at various stages of the methanol synthesis process. Pre-combustion capture involves removing CO2 before combustion occurs, while post-combustion capture extracts CO2 from flue gases. Oxy-fuel combustion, another approach, uses pure oxygen for combustion, producing a concentrated CO2 stream that is easier to capture. Each method offers distinct advantages depending on the specific methanol production configuration.

When integrated with green hydrogen production, carbon capture technologies enable the creation of carbon-neutral or even carbon-negative methanol. The captured CO2 serves as a feedstock that, when combined with green hydrogen, produces methanol through catalytic hydrogenation processes. This integration pathway significantly reduces the carbon footprint compared to conventional methanol production methods.

Recent technological advancements have improved the efficiency of carbon capture in methanol synthesis. Novel sorbents and membranes with enhanced CO2 selectivity have reduced energy penalties associated with capture processes. Additionally, process intensification techniques have optimized heat integration between carbon capture units and methanol synthesis reactors, improving overall system efficiency.

Economic analyses indicate that while carbon capture integration increases capital expenditure by 15-30%, the long-term benefits include reduced carbon taxes and access to premium markets for low-carbon methanol products. The levelized cost of methanol production with integrated carbon capture ranges from $450-650 per ton, depending on the capture technology employed and regional energy prices.

Several demonstration projects worldwide showcase successful integration of carbon capture in green methanol pathways. Notable examples include Carbon Recycling International's George Olah plant in Iceland, which utilizes geothermal energy for hydrogen production and captured CO2 from industrial sources. Similarly, the MefCO2 project in Germany demonstrates the technical feasibility of converting captured CO2 from power plants into methanol using renewable hydrogen.

Future developments focus on improving energy efficiency of integrated systems and reducing capital costs through modular designs and advanced materials. Research is also exploring direct air capture integration with methanol synthesis to create truly carbon-negative fuel pathways when powered by renewable energy sources.

Economic Viability and Policy Frameworks

The economic viability of green hydrogen in synthetic methanol production remains a significant challenge despite its environmental benefits. Current production costs for green hydrogen range from $4-6 per kg, substantially higher than gray hydrogen at $1-2 per kg. This cost differential creates a considerable barrier to widespread adoption in methanol synthesis, where hydrogen represents approximately 60-70% of production costs.

Capital expenditure requirements for electrolysis facilities present another economic hurdle. A typical 100 MW electrolyzer installation requires investments of $100-150 million, with additional costs for integration with methanol synthesis plants. Return on investment periods often extend beyond 10 years without supportive policy frameworks, deterring many potential investors.

Policy support mechanisms have emerged as critical enablers for green hydrogen-based methanol production. Carbon pricing mechanisms, including emissions trading systems and carbon taxes implemented in the EU, Canada, and parts of Asia, help narrow the cost gap between conventional and green methanol pathways. The EU's Carbon Border Adjustment Mechanism further strengthens these incentives by applying carbon pricing to imports.

Direct subsidies and production incentives have proven effective in several regions. The US Inflation Reduction Act offers production tax credits of up to $3 per kg for green hydrogen, significantly improving project economics. Similar schemes in Germany, Japan, and South Korea provide capital grants covering 30-50% of electrolyzer costs or operational subsidies based on hydrogen production volumes.

Regulatory frameworks mandating renewable content in transportation fuels and chemicals create guaranteed markets for green methanol. The EU's ReFuelEU Aviation initiative and maritime fuel regulations establish growing demand pools, while chemical sector regulations in several countries require minimum renewable content in methanol-derived products.

International cooperation frameworks are emerging to standardize green hydrogen certification and facilitate global trade. The International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) is developing harmonized certification schemes, while bilateral agreements between hydrogen-producing and consuming nations address trade barriers and technical standards.

Economic modeling suggests that with continued technology improvements and supportive policies, green hydrogen-based methanol could achieve cost parity with conventional pathways in select markets by 2030, with broader competitiveness following by 2035-2040. This timeline aligns with many national decarbonization strategies, positioning green methanol as a viable component of medium-term climate action plans.

Capital expenditure requirements for electrolysis facilities present another economic hurdle. A typical 100 MW electrolyzer installation requires investments of $100-150 million, with additional costs for integration with methanol synthesis plants. Return on investment periods often extend beyond 10 years without supportive policy frameworks, deterring many potential investors.

Policy support mechanisms have emerged as critical enablers for green hydrogen-based methanol production. Carbon pricing mechanisms, including emissions trading systems and carbon taxes implemented in the EU, Canada, and parts of Asia, help narrow the cost gap between conventional and green methanol pathways. The EU's Carbon Border Adjustment Mechanism further strengthens these incentives by applying carbon pricing to imports.

Direct subsidies and production incentives have proven effective in several regions. The US Inflation Reduction Act offers production tax credits of up to $3 per kg for green hydrogen, significantly improving project economics. Similar schemes in Germany, Japan, and South Korea provide capital grants covering 30-50% of electrolyzer costs or operational subsidies based on hydrogen production volumes.

Regulatory frameworks mandating renewable content in transportation fuels and chemicals create guaranteed markets for green methanol. The EU's ReFuelEU Aviation initiative and maritime fuel regulations establish growing demand pools, while chemical sector regulations in several countries require minimum renewable content in methanol-derived products.

International cooperation frameworks are emerging to standardize green hydrogen certification and facilitate global trade. The International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) is developing harmonized certification schemes, while bilateral agreements between hydrogen-producing and consuming nations address trade barriers and technical standards.

Economic modeling suggests that with continued technology improvements and supportive policies, green hydrogen-based methanol could achieve cost parity with conventional pathways in select markets by 2030, with broader competitiveness following by 2035-2040. This timeline aligns with many national decarbonization strategies, positioning green methanol as a viable component of medium-term climate action plans.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!