Safety case studies of large-scale electrolyzer installations

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyzer Safety Background and Objectives

Hydrogen production through water electrolysis has emerged as a cornerstone technology in the global transition towards sustainable energy systems. Large-scale electrolyzer installations represent a critical infrastructure component for green hydrogen production, yet they present unique safety challenges that must be thoroughly understood and addressed. The evolution of electrolyzer technology has progressed significantly from small laboratory-scale systems to industrial-scale installations capable of producing tons of hydrogen daily.

The safety considerations for electrolyzers have evolved alongside technological advancements, with early systems focusing primarily on basic electrical safety and hydrogen containment. Modern large-scale installations now require comprehensive safety frameworks addressing multiple risk dimensions including pressure management, gas detection, electrical safety, and system integration with renewable energy sources.

Current technological trends indicate a rapid scaling of electrolyzer systems, with individual installations growing from megawatt to multi-gigawatt capacity. This scaling introduces new safety challenges related to the concentration of hazards, increased system complexity, and the need for robust safety management systems capable of handling larger volumes of hydrogen and oxygen production.

The primary objective of examining safety case studies of large-scale electrolyzer installations is to identify recurring safety challenges, successful mitigation strategies, and lessons learned from incidents or near-misses. By analyzing real-world implementations, we aim to establish a knowledge base that can inform future installations and regulatory frameworks, ultimately accelerating the safe deployment of hydrogen production infrastructure.

Another critical goal is to develop standardized safety assessment methodologies specifically tailored to large-scale electrolyzers, as current standards often derive from smaller systems or adjacent industries. These methodologies must address the unique characteristics of different electrolyzer technologies (alkaline, PEM, solid oxide) and their specific safety profiles.

The technical evolution pathway suggests that future electrolyzer installations will continue to increase in scale while becoming more integrated with variable renewable energy sources. This integration introduces additional operational complexities and safety considerations related to dynamic operation, rapid power fluctuations, and system responsiveness that must be anticipated and managed.

Ultimately, establishing robust safety frameworks for large-scale electrolyzers is not merely a technical requirement but a prerequisite for public acceptance and regulatory approval of hydrogen as a mainstream energy carrier. The lessons derived from existing installations will be instrumental in shaping both technical standards and public perception of hydrogen safety.

The safety considerations for electrolyzers have evolved alongside technological advancements, with early systems focusing primarily on basic electrical safety and hydrogen containment. Modern large-scale installations now require comprehensive safety frameworks addressing multiple risk dimensions including pressure management, gas detection, electrical safety, and system integration with renewable energy sources.

Current technological trends indicate a rapid scaling of electrolyzer systems, with individual installations growing from megawatt to multi-gigawatt capacity. This scaling introduces new safety challenges related to the concentration of hazards, increased system complexity, and the need for robust safety management systems capable of handling larger volumes of hydrogen and oxygen production.

The primary objective of examining safety case studies of large-scale electrolyzer installations is to identify recurring safety challenges, successful mitigation strategies, and lessons learned from incidents or near-misses. By analyzing real-world implementations, we aim to establish a knowledge base that can inform future installations and regulatory frameworks, ultimately accelerating the safe deployment of hydrogen production infrastructure.

Another critical goal is to develop standardized safety assessment methodologies specifically tailored to large-scale electrolyzers, as current standards often derive from smaller systems or adjacent industries. These methodologies must address the unique characteristics of different electrolyzer technologies (alkaline, PEM, solid oxide) and their specific safety profiles.

The technical evolution pathway suggests that future electrolyzer installations will continue to increase in scale while becoming more integrated with variable renewable energy sources. This integration introduces additional operational complexities and safety considerations related to dynamic operation, rapid power fluctuations, and system responsiveness that must be anticipated and managed.

Ultimately, establishing robust safety frameworks for large-scale electrolyzers is not merely a technical requirement but a prerequisite for public acceptance and regulatory approval of hydrogen as a mainstream energy carrier. The lessons derived from existing installations will be instrumental in shaping both technical standards and public perception of hydrogen safety.

Market Analysis for Large-Scale Hydrogen Production

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and clean energy transition. Current market valuations place the hydrogen production sector at approximately $130 billion annually, with projections indicating potential growth to $500 billion by 2030 if current investment trends continue. Green hydrogen, produced specifically through electrolysis powered by renewable energy, represents the fastest-growing segment within this market.

Demand patterns show significant regional variations, with Europe, Japan, South Korea, and increasingly China leading adoption rates. The European Union's Hydrogen Strategy targets 40GW of electrolyzer capacity by 2030, representing a forty-fold increase from current levels. Industrial applications currently dominate market demand, with refineries, ammonia production, and steel manufacturing collectively accounting for over 70% of hydrogen consumption.

Market analysis reveals that large-scale electrolyzer installations (>10MW) are becoming increasingly economically viable as economies of scale drive down costs. Current levelized cost of hydrogen (LCOH) from large-scale electrolysis ranges between $4-6/kg, with industry projections suggesting potential reduction to $2-3/kg by 2025 and potentially below $2/kg by 2030 as technology matures and deployment scales.

Investment flows into the sector have been substantial, with over $300 billion in announced investments for hydrogen projects globally through 2030. Venture capital and private equity funding for electrolyzer technologies increased by 145% in 2021 compared to the previous year, indicating strong market confidence in the technology's commercial potential.

Supply chain analysis indicates potential bottlenecks in critical materials for electrolyzer manufacturing, particularly platinum group metals for PEM electrolyzers and specialized ceramics for solid oxide systems. These constraints may impact scaling capabilities in the short term but are driving innovation in material science and alternative catalyst development.

Customer segmentation shows diversification beyond traditional industrial users, with emerging applications in transportation (particularly heavy-duty vehicles and maritime shipping), energy storage, and grid balancing services. These new market segments are expected to account for approximately 25% of hydrogen demand by 2030, compared to less than 5% today.

Regulatory frameworks are evolving rapidly across major markets, with carbon pricing mechanisms, renewable energy mandates, and direct hydrogen production subsidies creating favorable economics for large-scale electrolyzer deployments. The implementation of certification schemes for low-carbon hydrogen is also emerging as a critical market enabler, allowing premium pricing for green hydrogen products.

Demand patterns show significant regional variations, with Europe, Japan, South Korea, and increasingly China leading adoption rates. The European Union's Hydrogen Strategy targets 40GW of electrolyzer capacity by 2030, representing a forty-fold increase from current levels. Industrial applications currently dominate market demand, with refineries, ammonia production, and steel manufacturing collectively accounting for over 70% of hydrogen consumption.

Market analysis reveals that large-scale electrolyzer installations (>10MW) are becoming increasingly economically viable as economies of scale drive down costs. Current levelized cost of hydrogen (LCOH) from large-scale electrolysis ranges between $4-6/kg, with industry projections suggesting potential reduction to $2-3/kg by 2025 and potentially below $2/kg by 2030 as technology matures and deployment scales.

Investment flows into the sector have been substantial, with over $300 billion in announced investments for hydrogen projects globally through 2030. Venture capital and private equity funding for electrolyzer technologies increased by 145% in 2021 compared to the previous year, indicating strong market confidence in the technology's commercial potential.

Supply chain analysis indicates potential bottlenecks in critical materials for electrolyzer manufacturing, particularly platinum group metals for PEM electrolyzers and specialized ceramics for solid oxide systems. These constraints may impact scaling capabilities in the short term but are driving innovation in material science and alternative catalyst development.

Customer segmentation shows diversification beyond traditional industrial users, with emerging applications in transportation (particularly heavy-duty vehicles and maritime shipping), energy storage, and grid balancing services. These new market segments are expected to account for approximately 25% of hydrogen demand by 2030, compared to less than 5% today.

Regulatory frameworks are evolving rapidly across major markets, with carbon pricing mechanisms, renewable energy mandates, and direct hydrogen production subsidies creating favorable economics for large-scale electrolyzer deployments. The implementation of certification schemes for low-carbon hydrogen is also emerging as a critical market enabler, allowing premium pricing for green hydrogen products.

Current Safety Challenges in Industrial Electrolyzers

Despite significant advancements in electrolyzer technology, large-scale industrial installations continue to face substantial safety challenges. Hydrogen's wide flammability range (4-75% in air) and low ignition energy (0.02mJ) create inherent risks in production environments. Recent incidents at hydrogen facilities in Norway (2019) and South Korea (2018) highlight the potential consequences of safety failures, resulting in significant damage and operational disruptions.

Pressure management remains a critical concern in industrial electrolyzers. Systems operating at 30+ bar face risks of mechanical failure, with pressure differentials between anode and cathode compartments potentially causing membrane ruptures and dangerous gas mixing. The 2020 incident at a European green hydrogen facility demonstrated how pressure control system failures can lead to catastrophic events.

Gas purity monitoring presents ongoing challenges, particularly for PEM and alkaline electrolyzers. Cross-contamination between hydrogen and oxygen streams creates explosive conditions, with the safety threshold typically set at <2% H₂ in O₂. Current detection systems often struggle with response time limitations, creating vulnerability windows during rapid operational changes or system upsets.

Thermal management issues persist in large-scale installations. Heat distribution irregularities across cell stacks can create hotspots exceeding 90°C in PEM systems, potentially degrading membranes and catalysts while increasing gas permeation rates. The 2021 incident at an Australian 10MW facility demonstrated how thermal runaway conditions can escalate rapidly.

Electrical safety challenges are amplified in megawatt-scale systems operating at high current densities (1-2 A/cm²). Insulation failures, ground faults, and DC arcing risks increase with system scale. The incident at a Canadian demonstration plant in 2022 illustrated how electrical faults can cascade into broader safety events.

Material compatibility issues continue to emerge as electrolyzers scale up. Hydrogen embrittlement affects steel components, while KOH electrolyte in alkaline systems presents corrosion challenges. Long-term degradation mechanisms remain inadequately characterized at industrial scales, creating uncertainty about component lifespans and failure modes.

Emergency shutdown systems face reliability challenges in large installations, where rapid depressurization and purging of multiple stacks must occur simultaneously. The 2019 incident at a European industrial site revealed coordination failures between detection systems and shutdown protocols, extending exposure to hazardous conditions.

Human Engineering Reliability Analysis (HERA) studies indicate that operator error contributes to approximately 22% of safety incidents in complex electrolyzer installations, highlighting the need for improved interfaces and training protocols as systems grow increasingly complex.

Pressure management remains a critical concern in industrial electrolyzers. Systems operating at 30+ bar face risks of mechanical failure, with pressure differentials between anode and cathode compartments potentially causing membrane ruptures and dangerous gas mixing. The 2020 incident at a European green hydrogen facility demonstrated how pressure control system failures can lead to catastrophic events.

Gas purity monitoring presents ongoing challenges, particularly for PEM and alkaline electrolyzers. Cross-contamination between hydrogen and oxygen streams creates explosive conditions, with the safety threshold typically set at <2% H₂ in O₂. Current detection systems often struggle with response time limitations, creating vulnerability windows during rapid operational changes or system upsets.

Thermal management issues persist in large-scale installations. Heat distribution irregularities across cell stacks can create hotspots exceeding 90°C in PEM systems, potentially degrading membranes and catalysts while increasing gas permeation rates. The 2021 incident at an Australian 10MW facility demonstrated how thermal runaway conditions can escalate rapidly.

Electrical safety challenges are amplified in megawatt-scale systems operating at high current densities (1-2 A/cm²). Insulation failures, ground faults, and DC arcing risks increase with system scale. The incident at a Canadian demonstration plant in 2022 illustrated how electrical faults can cascade into broader safety events.

Material compatibility issues continue to emerge as electrolyzers scale up. Hydrogen embrittlement affects steel components, while KOH electrolyte in alkaline systems presents corrosion challenges. Long-term degradation mechanisms remain inadequately characterized at industrial scales, creating uncertainty about component lifespans and failure modes.

Emergency shutdown systems face reliability challenges in large installations, where rapid depressurization and purging of multiple stacks must occur simultaneously. The 2019 incident at a European industrial site revealed coordination failures between detection systems and shutdown protocols, extending exposure to hazardous conditions.

Human Engineering Reliability Analysis (HERA) studies indicate that operator error contributes to approximately 22% of safety incidents in complex electrolyzer installations, highlighting the need for improved interfaces and training protocols as systems grow increasingly complex.

Existing Safety Protocols and Risk Mitigation Strategies

01 Safety monitoring systems for large-scale electrolyzers

Advanced monitoring systems are essential for ensuring the safe operation of large-scale electrolyzer installations. These systems continuously track critical parameters such as pressure, temperature, gas concentration, and electrical current to detect abnormal conditions. Real-time monitoring allows for immediate response to potential hazards, with automated shutdown procedures that can be triggered when safety thresholds are exceeded. Integration with central control systems enables comprehensive oversight of the entire installation.- Hydrogen safety systems for large electrolyzers: Large-scale electrolyzer installations require comprehensive hydrogen safety systems to prevent accidents. These systems include hydrogen leak detection, automatic shutdown mechanisms, and proper ventilation to prevent the accumulation of explosive gas mixtures. Safety systems are designed to monitor hydrogen concentration levels continuously and trigger alarms or emergency shutdowns when dangerous conditions are detected, thereby minimizing explosion risks in industrial hydrogen production facilities.

- Pressure management and control systems: Effective pressure management is critical for safe operation of large-scale electrolyzers. These installations incorporate pressure relief valves, pressure monitoring sensors, and automated control systems to maintain optimal operating pressures. The pressure control systems prevent overpressurization scenarios that could lead to mechanical failures or hydrogen leaks. Advanced pressure management solutions include multi-stage pressure reduction and intelligent pressure balancing across electrolyzer stacks to ensure stable and safe operation.

- Electrical safety and power management: Large electrolyzer installations require sophisticated electrical safety systems due to their high power consumption. These include electrical isolation mechanisms, ground fault detection, surge protection, and emergency power cutoff systems. Power management solutions monitor electrical parameters in real-time to detect anomalies and prevent electrical hazards. Redundant safety circuits and insulation monitoring devices are implemented to protect both equipment and personnel from electrical accidents in these high-voltage environments.

- Cooling and thermal management systems: Thermal management is essential for safe operation of large-scale electrolyzers, which generate significant heat during operation. Advanced cooling systems utilize water circulation, heat exchangers, and temperature monitoring to maintain optimal operating temperatures. These systems prevent overheating that could damage components or create unsafe conditions. Thermal management solutions include automated temperature control mechanisms that adjust cooling intensity based on real-time temperature measurements across different sections of the electrolyzer installation.

- Integrated safety monitoring and control architecture: Large electrolyzer installations employ comprehensive safety architectures that integrate multiple monitoring and control systems. These architectures include centralized control rooms, distributed sensor networks, and automated safety protocols. Advanced systems utilize industrial IoT technologies to provide real-time monitoring, predictive maintenance, and remote operation capabilities. The integrated approach ensures coordinated responses to safety incidents, with redundant safety layers and fail-safe mechanisms that maintain protection even when individual components fail.

02 Hydrogen leak detection and management

Hydrogen leak detection is critical for large-scale electrolyzer safety due to hydrogen's flammability and explosive potential. Modern installations incorporate multiple detection methods including gas sensors strategically placed throughout the facility, pressure monitoring systems, and infrared imaging technology. These systems are designed to detect even small leaks before they become hazardous. Upon detection, automated ventilation systems activate to disperse hydrogen concentrations, while alarm systems alert operators to take appropriate action.Expand Specific Solutions03 Pressure regulation and relief systems

Pressure management is fundamental to electrolyzer safety as these systems operate under significant pressure. Advanced pressure regulation systems maintain optimal operating conditions while preventing dangerous overpressure situations. Multiple layers of protection include primary pressure regulators, secondary relief valves, and emergency pressure release mechanisms. These systems are designed to automatically respond to pressure anomalies, venting excess pressure through designated pathways to prevent equipment damage and potential explosions.Expand Specific Solutions04 Electrical safety and power management

Electrical safety is paramount in large-scale electrolyzer installations that consume significant electrical power. Comprehensive electrical safety systems include isolation mechanisms, ground fault detection, surge protection, and emergency power disconnection capabilities. Power management systems monitor electrical parameters to prevent overloads and ensure stable operation. Redundant safety circuits provide backup protection, while specialized insulation and grounding systems minimize risks of electrical hazards to both equipment and personnel.Expand Specific Solutions05 Emergency shutdown and response protocols

Comprehensive emergency shutdown systems are critical safety components in large-scale electrolyzer installations. These systems feature multiple activation methods including automated triggers based on sensor data, manual emergency stops accessible throughout the facility, and remote shutdown capabilities. Shutdown protocols follow a carefully designed sequence to safely de-energize equipment, isolate hazardous materials, and bring the system to a secure state. Integration with facility-wide emergency response systems ensures coordinated actions during incidents, while regular testing and drills maintain operational readiness.Expand Specific Solutions

Leading Manufacturers and Operators in Electrolyzer Industry

The safety landscape of large-scale electrolyzer installations is evolving rapidly as the hydrogen economy transitions from early adoption to commercial scaling. The market is projected to grow significantly, driven by decarbonization initiatives worldwide. From a technological maturity perspective, established industrial players like ThyssenKrupp Uhde Chlorine Engineers, Linde GmbH, and Air Liquide SA bring decades of experience in industrial electrolysis safety, while newer entrants such as Siemens Energy and LG Energy Solution are advancing innovative safety protocols. Companies like Recherche 2000 have pioneered monitoring systems specifically for electrolyzer safety, with their EMOS system becoming an industry benchmark. The competitive landscape is characterized by collaboration between traditional chemical engineering firms and technology companies to address the unique safety challenges of scaling hydrogen production infrastructure.

ThyssenKrupp Uhde Chlorine Engineers GmbH

Technical Solution: ThyssenKrupp Uhde Chlorine Engineers (now thyssenkrupp nucera) has developed advanced alkaline water electrolysis (AWE) technology for large-scale hydrogen production. Their 20MW single skid electrolyzer modules can be combined to create installations exceeding 100MW capacity. The company has implemented comprehensive safety protocols including automated monitoring systems that detect hydrogen leaks, pressure anomalies, and electrolyte imbalances. Their safety case studies demonstrate successful implementation of hazardous area classifications according to IEC standards, with specific focus on hydrogen's wide flammability range (4-75% in air). Their installations feature multiple redundant emergency shutdown systems and utilize specialized materials resistant to hydrogen embrittlement. Recent safety improvements include advanced membrane technology that prevents cross-contamination between hydrogen and oxygen production chambers, significantly reducing explosion risks in large-scale operations.

Strengths: Industry-leading experience with multiple large-scale installations globally; proprietary membrane technology reducing cross-contamination risks; modular design allowing for safer maintenance procedures. Weaknesses: Higher initial capital costs compared to some competitors; requires specialized maintenance expertise; safety systems add complexity to operations.

Linde GmbH

Technical Solution: Linde has pioneered comprehensive safety frameworks for industrial-scale PEM and alkaline electrolyzers, with installations exceeding 10MW capacity. Their approach integrates multi-layered safety systems including proprietary gas detection technology capable of identifying hydrogen concentrations as low as 0.1% in ambient air. Linde's safety case studies document implementation of HAZOP (Hazard and Operability) and LOPA (Layer of Protection Analysis) methodologies specifically adapted for large electrolyzer installations. Their systems incorporate automated ventilation controls that activate at predefined hydrogen concentration thresholds, preventing accumulation in confined spaces. Linde has developed specialized purging protocols using inert gases to safely commission and decommission large electrolyzers, addressing the particular challenges of hydrogen's low ignition energy (0.02mJ). Their installations feature advanced thermal management systems that prevent hotspots and potential ignition sources, with documented safety performance across multiple climate conditions.

Strengths: Extensive experience in industrial gas safety beyond just electrolysis; integrated approach combining gas production, storage and distribution safety; proprietary detection technology with exceptional sensitivity. Weaknesses: Solutions often require significant physical space for safety systems; higher operational costs due to comprehensive monitoring requirements; some safety protocols may reduce operational flexibility.

Critical Incident Analysis and Lessons Learned

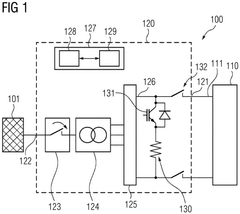

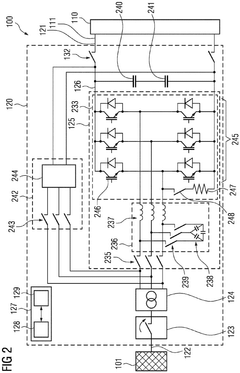

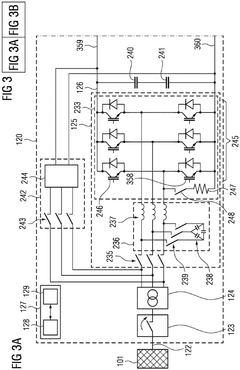

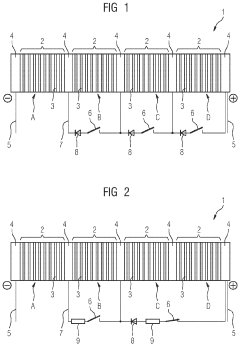

Fast de-energizable power supply for an electrolysis system

PatentPendingEP4525247A1

Innovation

- A fast de-energizable power supply system that includes an AC power input, a DC power output, an AC-DC converter, a controller unit for generating discharge control signals, and active switching devices to enable discharging current flow through discharge resistors, ensuring rapid and controlled de-energization of the electrolysis system.

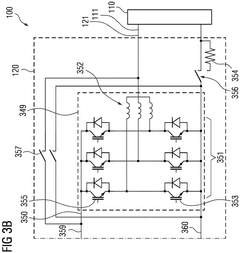

Electrolysis system for breaking down water into hydrogen and oxygen, and a method for operating the electrolysis system

PatentActiveUS20230031617A1

Innovation

- An electrolysis system with at least two electrolysis modules, each comprising multiple cells separated by a proton-exchange membrane, where a direct current-capable switching apparatus is connected in parallel to allow bridging of modules during low power, maintaining high current density and preventing partial-load operation of individual modules, thus preventing cooldown and aging.

Regulatory Compliance Framework for Hydrogen Production

The regulatory landscape for hydrogen production through electrolysis is complex and multifaceted, requiring careful navigation by industry stakeholders. At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have developed standards specifically addressing hydrogen technologies, including ISO 22734 for water electrolysis applications and IEC 62282 series for fuel cell technologies.

National regulatory frameworks vary significantly across regions, with the European Union leading through its comprehensive Hydrogen Strategy and the Renewable Energy Directive II (RED II), which establishes sustainability criteria for hydrogen production. The EU has also implemented the ATEX Directive (2014/34/EU) governing equipment in potentially explosive atmospheres, directly applicable to electrolyzer installations.

In the United States, regulatory oversight is distributed among federal agencies including the Department of Energy (DOE), Environmental Protection Agency (EPA), and Occupational Safety and Health Administration (OSHA). The recent Hydrogen Shot initiative aims to reduce clean hydrogen costs by 80% within a decade, supported by regulatory streamlining efforts.

Safety standards specifically for large-scale electrolyzers include NFPA 2 (Hydrogen Technologies Code), NFPA 55 (Compressed Gases and Cryogenic Fluids Code), and CGA G-5.5 (Hydrogen Vent Systems). These standards address critical aspects such as ventilation requirements, electrical classification, pressure vessel design, and emergency response protocols.

Permitting processes for large-scale electrolyzer installations typically involve environmental impact assessments, safety reviews, and compliance with local building codes. Case studies from existing installations in Germany, Japan, and Australia demonstrate that early engagement with regulatory authorities and transparent safety documentation significantly reduce approval timelines.

Emerging regulatory trends include the development of risk-based approaches to hydrogen facility safety, harmonization of international standards, and the integration of green hydrogen certification schemes. The HyLAW project in Europe has identified over 400 legal and administrative processes affecting hydrogen deployment, highlighting the need for regulatory simplification.

For manufacturers and operators, maintaining comprehensive safety management systems that address the unique hazards of hydrogen production is essential for regulatory compliance. This includes regular risk assessments, personnel training programs, and documented emergency response procedures that align with both prescriptive requirements and performance-based safety objectives.

National regulatory frameworks vary significantly across regions, with the European Union leading through its comprehensive Hydrogen Strategy and the Renewable Energy Directive II (RED II), which establishes sustainability criteria for hydrogen production. The EU has also implemented the ATEX Directive (2014/34/EU) governing equipment in potentially explosive atmospheres, directly applicable to electrolyzer installations.

In the United States, regulatory oversight is distributed among federal agencies including the Department of Energy (DOE), Environmental Protection Agency (EPA), and Occupational Safety and Health Administration (OSHA). The recent Hydrogen Shot initiative aims to reduce clean hydrogen costs by 80% within a decade, supported by regulatory streamlining efforts.

Safety standards specifically for large-scale electrolyzers include NFPA 2 (Hydrogen Technologies Code), NFPA 55 (Compressed Gases and Cryogenic Fluids Code), and CGA G-5.5 (Hydrogen Vent Systems). These standards address critical aspects such as ventilation requirements, electrical classification, pressure vessel design, and emergency response protocols.

Permitting processes for large-scale electrolyzer installations typically involve environmental impact assessments, safety reviews, and compliance with local building codes. Case studies from existing installations in Germany, Japan, and Australia demonstrate that early engagement with regulatory authorities and transparent safety documentation significantly reduce approval timelines.

Emerging regulatory trends include the development of risk-based approaches to hydrogen facility safety, harmonization of international standards, and the integration of green hydrogen certification schemes. The HyLAW project in Europe has identified over 400 legal and administrative processes affecting hydrogen deployment, highlighting the need for regulatory simplification.

For manufacturers and operators, maintaining comprehensive safety management systems that address the unique hazards of hydrogen production is essential for regulatory compliance. This includes regular risk assessments, personnel training programs, and documented emergency response procedures that align with both prescriptive requirements and performance-based safety objectives.

Environmental Impact Assessment of Electrolyzer Operations

The environmental impact assessment of large-scale electrolyzer installations reveals both significant benefits and potential concerns that require careful management. Hydrogen production through electrolysis offers a promising pathway to decarbonization when powered by renewable energy sources, substantially reducing greenhouse gas emissions compared to conventional hydrogen production methods. Case studies from installations in Europe and Australia demonstrate CO2 emission reductions of 70-95% when utilizing renewable electricity instead of grid electricity or fossil fuel-based processes.

Water consumption represents a critical environmental consideration, with industrial-scale electrolyzers requiring 9-10 liters of purified water to produce one kilogram of hydrogen. The Shell Rhineland Refinery electrolyzer project implemented a closed-loop water recycling system that reduced freshwater consumption by approximately 60%, establishing an important benchmark for water conservation in the industry.

Land use impacts vary significantly based on installation design and location. The 20MW HyGreen Provence project in France demonstrated effective land-use optimization by co-locating electrolyzer facilities with existing solar installations, minimizing additional land disturbance while maximizing renewable energy utilization. Conversely, the HyperHammerfest project in Norway highlighted challenges in sensitive ecological areas, necessitating comprehensive environmental mitigation strategies.

Noise pollution from electrolyzer operations has emerged as a localized concern, particularly in installations near residential areas. The H2Future project in Austria implemented acoustic enclosures and vibration dampening systems that successfully reduced operational noise levels by 15-20 decibels, bringing them within acceptable community standards. These engineering solutions demonstrate viable approaches to noise mitigation.

Chemical management presents another environmental consideration, particularly regarding electrolyte solutions and cooling systems. The GreenHydrogen Denmark installation pioneered the use of biodegradable alternatives to traditional chemical additives, reducing potential soil and groundwater contamination risks by an estimated 80% compared to conventional systems.

End-of-life considerations for electrolyzer components are increasingly addressed through circular economy approaches. The REFHYNE project at Shell's Rhineland Refinery incorporated a comprehensive decommissioning plan that aims to recycle over 90% of precious metals from catalyst materials and repurpose 75% of system components, establishing important precedents for sustainable lifecycle management in the industry.

Water consumption represents a critical environmental consideration, with industrial-scale electrolyzers requiring 9-10 liters of purified water to produce one kilogram of hydrogen. The Shell Rhineland Refinery electrolyzer project implemented a closed-loop water recycling system that reduced freshwater consumption by approximately 60%, establishing an important benchmark for water conservation in the industry.

Land use impacts vary significantly based on installation design and location. The 20MW HyGreen Provence project in France demonstrated effective land-use optimization by co-locating electrolyzer facilities with existing solar installations, minimizing additional land disturbance while maximizing renewable energy utilization. Conversely, the HyperHammerfest project in Norway highlighted challenges in sensitive ecological areas, necessitating comprehensive environmental mitigation strategies.

Noise pollution from electrolyzer operations has emerged as a localized concern, particularly in installations near residential areas. The H2Future project in Austria implemented acoustic enclosures and vibration dampening systems that successfully reduced operational noise levels by 15-20 decibels, bringing them within acceptable community standards. These engineering solutions demonstrate viable approaches to noise mitigation.

Chemical management presents another environmental consideration, particularly regarding electrolyte solutions and cooling systems. The GreenHydrogen Denmark installation pioneered the use of biodegradable alternatives to traditional chemical additives, reducing potential soil and groundwater contamination risks by an estimated 80% compared to conventional systems.

End-of-life considerations for electrolyzer components are increasingly addressed through circular economy approaches. The REFHYNE project at Shell's Rhineland Refinery incorporated a comprehensive decommissioning plan that aims to recycle over 90% of precious metals from catalyst materials and repurpose 75% of system components, establishing important precedents for sustainable lifecycle management in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!