Optimization of power-to-gas systems with green hydrogen

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power-to-Gas Technology Background and Objectives

Power-to-Gas (P2G) technology has emerged as a promising solution for energy storage and sector coupling in the transition toward renewable energy systems. The concept dates back to the 1980s, but significant development has occurred only in the past decade due to increasing renewable energy penetration and the need for long-term energy storage solutions. P2G involves converting electrical energy into chemical energy in the form of hydrogen or methane, which can be stored and transported using existing natural gas infrastructure.

The evolution of P2G technology has been marked by several key milestones, including the development of more efficient electrolyzers, advancements in catalytic methanation processes, and integration with renewable energy sources. Initially focused on utilizing excess electricity from intermittent renewables, P2G has evolved to become a central component of comprehensive energy transition strategies, particularly in countries with ambitious decarbonization goals.

Green hydrogen, produced through water electrolysis powered by renewable electricity, represents the cornerstone of sustainable P2G systems. Unlike grey or blue hydrogen, green hydrogen production generates zero carbon emissions, making it essential for truly sustainable energy systems. Recent technological improvements in electrolyzer efficiency, durability, and cost reduction have accelerated the viability of green hydrogen production at scale.

The primary technical objective of P2G optimization is to enhance system efficiency across the entire value chain, from electricity input to gas output. Current P2G systems typically achieve overall efficiencies of 30-65%, depending on whether the end product is hydrogen or synthetic methane. Significant research efforts are directed toward improving electrolyzer performance, optimizing system integration, and developing advanced control strategies to maximize efficiency and economic viability.

Additional objectives include reducing capital and operational costs, enhancing system flexibility to accommodate variable renewable energy inputs, and developing modular scalable solutions suitable for different deployment scenarios. Cost reduction pathways focus on electrolyzer technology advancement, system simplification, and economies of scale in manufacturing and deployment.

The long-term vision for P2G technology encompasses its role in enabling a fully renewable energy system by providing seasonal storage capabilities, facilitating sector coupling between electricity, gas, heat, and transportation, and supporting industrial decarbonization through green hydrogen utilization. As renewable energy penetration increases globally, the strategic importance of P2G as an enabling technology for energy system transformation continues to grow, driving research and development efforts toward optimized solutions.

The evolution of P2G technology has been marked by several key milestones, including the development of more efficient electrolyzers, advancements in catalytic methanation processes, and integration with renewable energy sources. Initially focused on utilizing excess electricity from intermittent renewables, P2G has evolved to become a central component of comprehensive energy transition strategies, particularly in countries with ambitious decarbonization goals.

Green hydrogen, produced through water electrolysis powered by renewable electricity, represents the cornerstone of sustainable P2G systems. Unlike grey or blue hydrogen, green hydrogen production generates zero carbon emissions, making it essential for truly sustainable energy systems. Recent technological improvements in electrolyzer efficiency, durability, and cost reduction have accelerated the viability of green hydrogen production at scale.

The primary technical objective of P2G optimization is to enhance system efficiency across the entire value chain, from electricity input to gas output. Current P2G systems typically achieve overall efficiencies of 30-65%, depending on whether the end product is hydrogen or synthetic methane. Significant research efforts are directed toward improving electrolyzer performance, optimizing system integration, and developing advanced control strategies to maximize efficiency and economic viability.

Additional objectives include reducing capital and operational costs, enhancing system flexibility to accommodate variable renewable energy inputs, and developing modular scalable solutions suitable for different deployment scenarios. Cost reduction pathways focus on electrolyzer technology advancement, system simplification, and economies of scale in manufacturing and deployment.

The long-term vision for P2G technology encompasses its role in enabling a fully renewable energy system by providing seasonal storage capabilities, facilitating sector coupling between electricity, gas, heat, and transportation, and supporting industrial decarbonization through green hydrogen utilization. As renewable energy penetration increases globally, the strategic importance of P2G as an enabling technology for energy system transformation continues to grow, driving research and development efforts toward optimized solutions.

Market Analysis for Green Hydrogen Energy Storage

The global market for green hydrogen energy storage is experiencing unprecedented growth, driven by the convergence of renewable energy expansion, decarbonization policies, and technological advancements in power-to-gas systems. Current market valuations place the green hydrogen storage sector at approximately $300 million in 2022, with projections indicating a compound annual growth rate of 12-15% through 2030, potentially reaching $1.2 billion by decade's end.

Energy storage represents a critical component in renewable energy integration, with green hydrogen emerging as a promising long-duration storage solution. Unlike battery technologies that typically provide 4-8 hours of storage, hydrogen systems can store energy for weeks or months, addressing seasonal fluctuations in renewable generation. This capability positions hydrogen storage as complementary rather than competitive with battery technologies in the broader energy storage ecosystem.

Regional market analysis reveals significant variations in adoption patterns. Europe leads the market with approximately 40% share, driven by ambitious hydrogen strategies in Germany, Netherlands, and France. The Asia-Pacific region follows at 30%, with Japan and South Korea making substantial investments in hydrogen infrastructure. North America accounts for 20% of the market, while the remaining 10% is distributed across other regions including Australia and the Middle East.

Demand segmentation shows utilities and grid operators constitute the largest customer segment (45%), seeking solutions for grid balancing and renewable integration. Industrial users represent 30% of demand, primarily for process heat and feedstock applications. Transportation applications account for 15%, while residential and commercial applications comprise the remaining 10%.

The economic proposition of hydrogen energy storage is strengthening as electrolyzer costs decline by approximately 60% over the past decade. However, levelized cost analysis indicates hydrogen storage remains 2-3 times more expensive than pumped hydro or compressed air energy storage for most applications, though this gap is narrowing rapidly with technological improvements and scale economies.

Market barriers include high capital costs, efficiency losses in the power-to-gas-to-power cycle (typically 30-45%), and infrastructure limitations. Despite these challenges, policy support through carbon pricing mechanisms, renewable energy mandates, and direct subsidies is creating favorable market conditions in many regions.

Forecasts suggest the inflection point for widespread commercial adoption will occur between 2025-2027, when electrolyzer costs are expected to fall below $500/kW and renewable electricity prices consistently reach under $30/MWh in major markets.

Energy storage represents a critical component in renewable energy integration, with green hydrogen emerging as a promising long-duration storage solution. Unlike battery technologies that typically provide 4-8 hours of storage, hydrogen systems can store energy for weeks or months, addressing seasonal fluctuations in renewable generation. This capability positions hydrogen storage as complementary rather than competitive with battery technologies in the broader energy storage ecosystem.

Regional market analysis reveals significant variations in adoption patterns. Europe leads the market with approximately 40% share, driven by ambitious hydrogen strategies in Germany, Netherlands, and France. The Asia-Pacific region follows at 30%, with Japan and South Korea making substantial investments in hydrogen infrastructure. North America accounts for 20% of the market, while the remaining 10% is distributed across other regions including Australia and the Middle East.

Demand segmentation shows utilities and grid operators constitute the largest customer segment (45%), seeking solutions for grid balancing and renewable integration. Industrial users represent 30% of demand, primarily for process heat and feedstock applications. Transportation applications account for 15%, while residential and commercial applications comprise the remaining 10%.

The economic proposition of hydrogen energy storage is strengthening as electrolyzer costs decline by approximately 60% over the past decade. However, levelized cost analysis indicates hydrogen storage remains 2-3 times more expensive than pumped hydro or compressed air energy storage for most applications, though this gap is narrowing rapidly with technological improvements and scale economies.

Market barriers include high capital costs, efficiency losses in the power-to-gas-to-power cycle (typically 30-45%), and infrastructure limitations. Despite these challenges, policy support through carbon pricing mechanisms, renewable energy mandates, and direct subsidies is creating favorable market conditions in many regions.

Forecasts suggest the inflection point for widespread commercial adoption will occur between 2025-2027, when electrolyzer costs are expected to fall below $500/kW and renewable electricity prices consistently reach under $30/MWh in major markets.

Current Challenges in Power-to-Gas Implementation

Despite the promising potential of power-to-gas (P2G) systems utilizing green hydrogen, several significant challenges currently impede widespread implementation. The intermittent nature of renewable energy sources creates operational difficulties for electrolyzers, which typically perform optimally under steady-state conditions. Frequent ramping up and down in response to fluctuating renewable generation reduces efficiency and accelerates component degradation, ultimately increasing operational costs and reducing system lifespan.

Economic viability remains a critical barrier, with high capital expenditure requirements for electrolyzers, hydrogen storage systems, and methanation reactors. Current levelized costs of green hydrogen production range from $4-6/kg, significantly higher than conventional hydrogen production methods. Without substantial cost reductions or policy support mechanisms, P2G systems struggle to compete in energy markets.

Technical efficiency limitations present another major challenge. The overall energy conversion efficiency of P2G systems typically ranges between 30-45% when considering the complete pathway from electricity to gas and back to electricity. These efficiency losses represent a substantial barrier to economic feasibility in competitive energy markets where every percentage point of efficiency directly impacts operational economics.

Infrastructure constraints further complicate implementation. Existing natural gas infrastructure requires modifications to accommodate hydrogen blending beyond certain thresholds (typically 5-20% by volume), while dedicated hydrogen infrastructure remains underdeveloped in most regions. The lack of standardized interfaces between power grids, gas networks, and hydrogen systems creates integration challenges that increase project complexity and costs.

Regulatory frameworks have not kept pace with technological developments, creating uncertainty for investors and project developers. Unclear classification of P2G facilities within energy system regulations, ambiguous ownership structures for cross-sector assets, and inconsistent carbon pricing mechanisms all contribute to market hesitation. Additionally, permitting processes designed for conventional energy systems often fail to address the unique characteristics of P2G installations.

Scale-up challenges persist as the industry transitions from demonstration projects to commercial-scale implementations. Manufacturing capacity for key components remains limited, creating supply chain bottlenecks and maintaining high equipment costs. The specialized knowledge required for system design, integration, and operation further constrains rapid deployment as the necessary workforce skills remain in short supply.

Economic viability remains a critical barrier, with high capital expenditure requirements for electrolyzers, hydrogen storage systems, and methanation reactors. Current levelized costs of green hydrogen production range from $4-6/kg, significantly higher than conventional hydrogen production methods. Without substantial cost reductions or policy support mechanisms, P2G systems struggle to compete in energy markets.

Technical efficiency limitations present another major challenge. The overall energy conversion efficiency of P2G systems typically ranges between 30-45% when considering the complete pathway from electricity to gas and back to electricity. These efficiency losses represent a substantial barrier to economic feasibility in competitive energy markets where every percentage point of efficiency directly impacts operational economics.

Infrastructure constraints further complicate implementation. Existing natural gas infrastructure requires modifications to accommodate hydrogen blending beyond certain thresholds (typically 5-20% by volume), while dedicated hydrogen infrastructure remains underdeveloped in most regions. The lack of standardized interfaces between power grids, gas networks, and hydrogen systems creates integration challenges that increase project complexity and costs.

Regulatory frameworks have not kept pace with technological developments, creating uncertainty for investors and project developers. Unclear classification of P2G facilities within energy system regulations, ambiguous ownership structures for cross-sector assets, and inconsistent carbon pricing mechanisms all contribute to market hesitation. Additionally, permitting processes designed for conventional energy systems often fail to address the unique characteristics of P2G installations.

Scale-up challenges persist as the industry transitions from demonstration projects to commercial-scale implementations. Manufacturing capacity for key components remains limited, creating supply chain bottlenecks and maintaining high equipment costs. The specialized knowledge required for system design, integration, and operation further constrains rapid deployment as the necessary workforce skills remain in short supply.

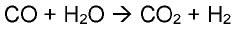

Current Power-to-Gas System Architectures

01 Electrolysis optimization for green hydrogen production

Optimization of electrolysis processes is crucial for efficient green hydrogen production in power-to-gas systems. This includes improving electrode materials, electrolyte compositions, and operating parameters such as temperature, pressure, and current density. Advanced electrolysis technologies like PEM (Proton Exchange Membrane) and alkaline electrolysis are being enhanced to increase efficiency and reduce energy consumption, which is essential for making green hydrogen production economically viable.- Electrolysis optimization for green hydrogen production: Various methods to optimize the electrolysis process for green hydrogen production in power-to-gas systems. This includes advanced electrode materials, improved membrane technologies, and optimized operating conditions such as temperature, pressure, and current density. These optimizations aim to increase efficiency, reduce energy consumption, and enhance the overall performance of electrolyzers used in green hydrogen production.

- Integration of renewable energy sources with power-to-gas systems: Techniques for effectively integrating intermittent renewable energy sources like solar and wind with power-to-gas systems. This includes smart grid integration, energy management systems, and storage solutions that help balance supply and demand fluctuations. The integration focuses on maximizing the utilization of renewable energy for hydrogen production while maintaining system stability and efficiency.

- System control and optimization algorithms: Advanced control strategies and optimization algorithms for power-to-gas systems using green hydrogen. These include machine learning approaches, model predictive control, and real-time optimization techniques that enhance system performance, reduce operational costs, and improve reliability. The algorithms help in dynamic adjustment of system parameters based on changing conditions and requirements.

- Hydrogen storage and distribution optimization: Methods for optimizing the storage and distribution of hydrogen in power-to-gas systems. This includes advanced compression techniques, novel storage materials, pipeline optimization, and efficient distribution networks. These optimizations aim to reduce energy losses during storage and transportation while ensuring the safety and reliability of the hydrogen supply chain.

- Methanation and synthetic fuel production optimization: Techniques for optimizing the conversion of hydrogen to methane or other synthetic fuels in power-to-gas systems. This includes catalyst development, reactor design improvements, and process integration strategies that enhance conversion efficiency and product quality. The optimization focuses on maximizing carbon utilization, improving reaction kinetics, and reducing energy requirements in the methanation process.

02 Integration of renewable energy sources with hydrogen systems

Effective integration of renewable energy sources such as solar, wind, and hydroelectric power with hydrogen production systems is key to optimizing power-to-gas operations. This involves developing smart grid technologies, energy management systems, and storage solutions that can handle the intermittent nature of renewable energy. Advanced control algorithms and forecasting tools help balance energy supply and demand, ensuring continuous hydrogen production despite fluctuations in renewable energy availability.Expand Specific Solutions03 Hydrogen storage and transportation optimization

Optimizing hydrogen storage and transportation is essential for efficient power-to-gas systems. This includes developing advanced materials for high-density storage, such as metal hydrides and carbon-based materials, as well as improving compression and liquefaction technologies. Pipeline infrastructure optimization, carrier materials like ammonia or liquid organic hydrogen carriers (LOHC), and modular storage solutions are being developed to enhance the safety, efficiency, and cost-effectiveness of hydrogen logistics.Expand Specific Solutions04 Methanation and synthetic fuel production processes

Converting hydrogen to methane or other synthetic fuels through methanation processes is a key aspect of power-to-gas systems. Optimization focuses on catalyst development, reactor design, and process integration to improve conversion efficiency and selectivity. Advanced control strategies and heat management techniques are being implemented to enhance the thermodynamics of these reactions. The integration of carbon capture technologies with methanation processes also enables more sustainable synthetic fuel production by utilizing captured CO2.Expand Specific Solutions05 System-level optimization and economic viability

System-level optimization addresses the overall efficiency, reliability, and economic viability of power-to-gas systems. This includes developing integrated energy models, lifecycle assessment methodologies, and techno-economic analyses to identify optimal system configurations. Advanced control systems, artificial intelligence, and machine learning algorithms are being employed to optimize operation parameters in real-time. Additionally, policy frameworks, market mechanisms, and business models are being developed to enhance the commercial feasibility of green hydrogen-based power-to-gas systems.Expand Specific Solutions

Key Industry Players in Green Hydrogen Sector

The power-to-gas systems with green hydrogen market is currently in an early growth phase, characterized by increasing commercial deployments beyond pilot projects. The global market size is projected to reach $10-15 billion by 2030, driven by decarbonization policies and renewable energy integration needs. Technologically, companies are at varying maturity levels: established industrial players like Linde, thyssenkrupp, and Mitsubishi Heavy Industries have advanced commercial-scale solutions, while Hydrogenics (now part of Cummins) and Plug Power are rapidly scaling their electrolysis technologies. Research institutions like Paul Scherrer Institut and IFP Energies Nouvelles are advancing next-generation technologies. State Grid companies in China are increasingly investing in large-scale demonstration projects, while European utilities are leading commercial implementations, creating a competitive landscape spanning multiple industrial sectors.

Hydrogenics Corp.

Technical Solution: Hydrogenics has developed advanced PEM (Proton Exchange Membrane) electrolysis technology for power-to-gas systems that efficiently converts renewable electricity into green hydrogen. Their HyLYZER® platform integrates seamlessly with renewable energy sources like wind and solar, enabling dynamic operation that can respond to fluctuating power inputs. The system achieves conversion efficiencies of up to 80% (HHV) and can ramp from 0-100% in less than 10 seconds, making it ideal for grid balancing applications. Hydrogenics' power-to-gas solutions include comprehensive energy management systems that optimize hydrogen production based on electricity prices, grid demands, and storage capacity. Their installations in Europe have demonstrated the ability to absorb multi-megawatt loads of excess renewable energy that would otherwise be curtailed, converting it to hydrogen for later use in multiple sectors including transportation, industry, and power generation.

Strengths: Rapid response capability allows for grid stabilization services and frequency regulation; modular design enables scalability from kilowatts to megawatts; proven technology with multiple commercial installations. Weaknesses: Higher capital costs compared to conventional hydrogen production; requires high-purity water inputs which adds to operational complexity; efficiency losses during conversion processes impact overall system economics.

Linde GmbH

Technical Solution: Linde has pioneered an integrated power-to-gas system called HYDROPRIME that optimizes green hydrogen production through advanced PEM electrolysis technology. Their system incorporates proprietary pressure management that enables direct compression of hydrogen during electrolysis, eliminating the need for separate mechanical compression and reducing energy consumption by approximately 30%. Linde's approach includes intelligent load management software that analyzes grid conditions, electricity pricing, and hydrogen demand in real-time to optimize operation schedules. The system achieves overall efficiencies of 70-75% from electricity to hydrogen, with their latest generation electrolyzers operating at current densities above 2 A/cm². Additionally, Linde has developed specialized purification and drying technologies that ensure the hydrogen meets industrial and mobility application standards (99.999% purity) with minimal energy input. Their installations typically include modular hydrogen storage solutions that can be scaled according to project requirements, enabling flexible operation despite intermittent renewable energy inputs.

Strengths: Comprehensive system integration expertise from electricity input to final hydrogen application; global service network supporting operational reliability; advanced process optimization algorithms that maximize economic performance. Weaknesses: Higher initial capital investment compared to conventional systems; technology still evolving with room for efficiency improvements; requires significant scale to achieve optimal economics.

Critical Electrolysis and Methanation Technologies

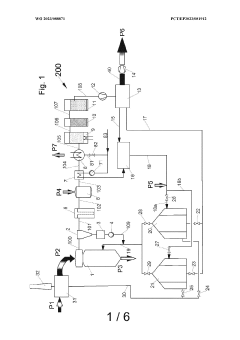

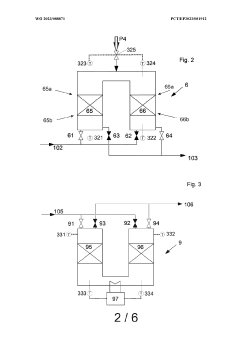

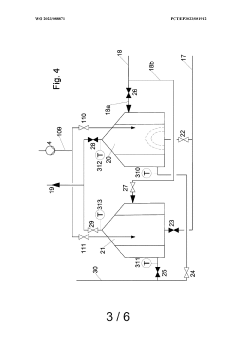

Method and device for generating hydrogen

PatentWO2023088871A1

Innovation

- A method and device utilizing allothermic gasification of biomass with heated steam for hydrogen production, where steam is reused to enhance efficiency, and a control system monitors and adjusts process parameters to maintain efficiency and output over time.

Regulatory Framework for Green Hydrogen

The regulatory landscape for green hydrogen is rapidly evolving globally as governments recognize its potential in decarbonization strategies. Currently, most regulatory frameworks are in nascent stages, with significant variations across regions. The European Union leads with its Hydrogen Strategy, which aims to install at least 6 GW of renewable hydrogen electrolyzers by 2024 and 40 GW by 2030, supported by the European Green Deal and Recovery Plan.

In the United States, regulatory approaches differ by state, with California pioneering through its Low Carbon Fuel Standard (LCFS) that incentivizes hydrogen production from renewable sources. The federal government has recently enhanced support through the Inflation Reduction Act, providing tax credits for clean hydrogen production based on carbon intensity metrics.

Asia-Pacific countries are also developing frameworks, with Japan's Strategic Roadmap for Hydrogen and Fuel Cells setting ambitious targets for cost reduction and supply chain development. Australia has established the National Hydrogen Strategy focusing on export opportunities, while South Korea's Hydrogen Economy Roadmap emphasizes fuel cell applications.

A critical regulatory challenge is the standardization of green hydrogen certification. The CertifHy project in Europe represents one of the first attempts to establish a comprehensive certification system, defining green hydrogen as produced from renewable energy with specific carbon emission thresholds.

Regulatory frameworks must address several key areas to optimize power-to-gas systems: grid connection rules for electrolyzers, permitting processes for hydrogen infrastructure, safety standards for storage and transport, and integration with existing natural gas regulations. The lack of harmonized international standards currently creates market fragmentation and investment uncertainty.

Carbon pricing mechanisms significantly impact the economic viability of green hydrogen projects. Regions with robust carbon markets or taxes provide indirect support by making fossil-based alternatives less competitive. However, the effectiveness varies widely based on carbon price levels and coverage.

Financial incentives represent another regulatory tool, with feed-in tariffs, tax exemptions, and direct subsidies being implemented in various jurisdictions. Germany's H2Global initiative exemplifies an innovative auction-based mechanism to bridge the cost gap between green hydrogen production and market prices.

Looking forward, regulatory convergence will be essential to facilitate international trade in green hydrogen. Emerging discussions on guarantees of origin, carbon border adjustment mechanisms, and international hydrogen standards will shape the global market development for power-to-gas systems utilizing green hydrogen.

In the United States, regulatory approaches differ by state, with California pioneering through its Low Carbon Fuel Standard (LCFS) that incentivizes hydrogen production from renewable sources. The federal government has recently enhanced support through the Inflation Reduction Act, providing tax credits for clean hydrogen production based on carbon intensity metrics.

Asia-Pacific countries are also developing frameworks, with Japan's Strategic Roadmap for Hydrogen and Fuel Cells setting ambitious targets for cost reduction and supply chain development. Australia has established the National Hydrogen Strategy focusing on export opportunities, while South Korea's Hydrogen Economy Roadmap emphasizes fuel cell applications.

A critical regulatory challenge is the standardization of green hydrogen certification. The CertifHy project in Europe represents one of the first attempts to establish a comprehensive certification system, defining green hydrogen as produced from renewable energy with specific carbon emission thresholds.

Regulatory frameworks must address several key areas to optimize power-to-gas systems: grid connection rules for electrolyzers, permitting processes for hydrogen infrastructure, safety standards for storage and transport, and integration with existing natural gas regulations. The lack of harmonized international standards currently creates market fragmentation and investment uncertainty.

Carbon pricing mechanisms significantly impact the economic viability of green hydrogen projects. Regions with robust carbon markets or taxes provide indirect support by making fossil-based alternatives less competitive. However, the effectiveness varies widely based on carbon price levels and coverage.

Financial incentives represent another regulatory tool, with feed-in tariffs, tax exemptions, and direct subsidies being implemented in various jurisdictions. Germany's H2Global initiative exemplifies an innovative auction-based mechanism to bridge the cost gap between green hydrogen production and market prices.

Looking forward, regulatory convergence will be essential to facilitate international trade in green hydrogen. Emerging discussions on guarantees of origin, carbon border adjustment mechanisms, and international hydrogen standards will shape the global market development for power-to-gas systems utilizing green hydrogen.

Economic Viability Assessment

The economic viability of power-to-gas (P2G) systems utilizing green hydrogen represents a critical factor in determining their widespread adoption and implementation. Current cost analyses indicate that green hydrogen production via electrolysis ranges between $4-6/kg, significantly higher than conventional grey hydrogen production methods at $1-2/kg. This cost differential presents a substantial barrier to market penetration without supportive policy frameworks.

Capital expenditure (CAPEX) for P2G systems remains high, with electrolyzer costs constituting approximately 40-60% of total system investment. However, projections suggest a 60-70% reduction in electrolyzer costs by 2030 due to technological advancements and economies of scale, potentially bringing green hydrogen production costs below $2/kg in optimal locations.

Operational expenditure (OPEX) is heavily influenced by electricity prices, which typically account for 60-80% of total production costs. Systems optimized to operate during periods of low electricity prices or excess renewable generation can achieve significantly improved economic performance. Analysis of various European markets demonstrates that facilities achieving 4,000+ full-load hours annually with electricity costs below $40/MWh can approach economic viability under current market conditions.

Revenue streams for P2G systems extend beyond hydrogen sales to include grid services, oxygen by-product commercialization, and heat recovery. Advanced business models incorporating multiple value streams show potential internal rates of return (IRR) of 8-15% in favorable regulatory environments. Sensitivity analysis reveals that electricity costs and capacity utilization factors represent the most significant variables affecting profitability.

Policy support mechanisms significantly impact economic viability. Carbon pricing mechanisms exceeding €100/tCO2, renewable energy subsidies, and hydrogen-specific incentives can collectively improve project economics by 20-40%. Several European countries have implemented hydrogen strategies with dedicated funding mechanisms, while the US Inflation Reduction Act provides production tax credits of up to $3/kg for green hydrogen.

Long-term economic projections indicate that P2G systems could achieve grid parity with conventional hydrogen production methods by 2025-2030 in regions with abundant renewable resources and supportive regulatory frameworks. This timeline may accelerate with technological breakthroughs in electrolysis efficiency or dramatic reductions in renewable electricity costs.

Capital expenditure (CAPEX) for P2G systems remains high, with electrolyzer costs constituting approximately 40-60% of total system investment. However, projections suggest a 60-70% reduction in electrolyzer costs by 2030 due to technological advancements and economies of scale, potentially bringing green hydrogen production costs below $2/kg in optimal locations.

Operational expenditure (OPEX) is heavily influenced by electricity prices, which typically account for 60-80% of total production costs. Systems optimized to operate during periods of low electricity prices or excess renewable generation can achieve significantly improved economic performance. Analysis of various European markets demonstrates that facilities achieving 4,000+ full-load hours annually with electricity costs below $40/MWh can approach economic viability under current market conditions.

Revenue streams for P2G systems extend beyond hydrogen sales to include grid services, oxygen by-product commercialization, and heat recovery. Advanced business models incorporating multiple value streams show potential internal rates of return (IRR) of 8-15% in favorable regulatory environments. Sensitivity analysis reveals that electricity costs and capacity utilization factors represent the most significant variables affecting profitability.

Policy support mechanisms significantly impact economic viability. Carbon pricing mechanisms exceeding €100/tCO2, renewable energy subsidies, and hydrogen-specific incentives can collectively improve project economics by 20-40%. Several European countries have implemented hydrogen strategies with dedicated funding mechanisms, while the US Inflation Reduction Act provides production tax credits of up to $3/kg for green hydrogen.

Long-term economic projections indicate that P2G systems could achieve grid parity with conventional hydrogen production methods by 2025-2030 in regions with abundant renewable resources and supportive regulatory frameworks. This timeline may accelerate with technological breakthroughs in electrolysis efficiency or dramatic reductions in renewable electricity costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!