Comparative energy efficiency of hydrogen liquefaction processes

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Liquefaction Technology Background and Objectives

Hydrogen liquefaction represents a critical technology in the global transition toward clean energy systems. The process of converting gaseous hydrogen to its liquid state at cryogenic temperatures (-253°C or 20K) has evolved significantly since its first commercial implementation in the 1950s. This technology enables high-density storage and long-distance transportation of hydrogen, addressing key challenges in the hydrogen value chain.

The evolution of hydrogen liquefaction technology has been marked by continuous improvements in energy efficiency and process optimization. Early systems required approximately 15-20 kWh/kg of energy, whereas modern advanced systems have reduced this requirement to 10-12 kWh/kg. Despite these improvements, liquefaction remains energy-intensive, consuming approximately 30-40% of hydrogen's energy content.

Current technological development focuses on reducing the significant energy penalty associated with liquefaction while increasing production capacity. The theoretical minimum work required for hydrogen liquefaction is approximately 3.9 kWh/kg, indicating substantial room for efficiency improvements in existing processes.

Market drivers for hydrogen liquefaction technology include the growing demand for clean energy carriers, the expansion of hydrogen mobility applications, and the need for efficient long-distance hydrogen transport. As hydrogen economies scale globally, liquefaction becomes increasingly important for connecting production sites with end-use markets across continental distances.

The primary technical objectives in hydrogen liquefaction research include: reducing specific energy consumption to below 6 kWh/kg; increasing single-train capacity beyond 50 tons per day; improving system reliability and availability; and developing more compact, modular designs suitable for distributed energy systems.

Comparative analysis of different liquefaction processes reveals varying approaches to the fundamental thermodynamic challenge of cooling hydrogen to its boiling point while managing the ortho-to-para hydrogen conversion. The Claude cycle, modified Claude cycle, Brayton cycle, and various hybrid systems represent the main process architectures, each with distinct energy efficiency profiles.

Recent technological breakthroughs include the development of magnetocaloric liquefaction, advanced turboexpander designs, and integrated heat recovery systems. These innovations aim to close the gap between current performance and theoretical efficiency limits, potentially revolutionizing the economics of liquid hydrogen as an energy carrier.

The strategic importance of hydrogen liquefaction extends beyond technical considerations to encompass broader energy security, decarbonization, and industrial competitiveness objectives. As nations develop hydrogen strategies, liquefaction technology represents a critical enabler for realizing the full potential of hydrogen in the global energy transition.

The evolution of hydrogen liquefaction technology has been marked by continuous improvements in energy efficiency and process optimization. Early systems required approximately 15-20 kWh/kg of energy, whereas modern advanced systems have reduced this requirement to 10-12 kWh/kg. Despite these improvements, liquefaction remains energy-intensive, consuming approximately 30-40% of hydrogen's energy content.

Current technological development focuses on reducing the significant energy penalty associated with liquefaction while increasing production capacity. The theoretical minimum work required for hydrogen liquefaction is approximately 3.9 kWh/kg, indicating substantial room for efficiency improvements in existing processes.

Market drivers for hydrogen liquefaction technology include the growing demand for clean energy carriers, the expansion of hydrogen mobility applications, and the need for efficient long-distance hydrogen transport. As hydrogen economies scale globally, liquefaction becomes increasingly important for connecting production sites with end-use markets across continental distances.

The primary technical objectives in hydrogen liquefaction research include: reducing specific energy consumption to below 6 kWh/kg; increasing single-train capacity beyond 50 tons per day; improving system reliability and availability; and developing more compact, modular designs suitable for distributed energy systems.

Comparative analysis of different liquefaction processes reveals varying approaches to the fundamental thermodynamic challenge of cooling hydrogen to its boiling point while managing the ortho-to-para hydrogen conversion. The Claude cycle, modified Claude cycle, Brayton cycle, and various hybrid systems represent the main process architectures, each with distinct energy efficiency profiles.

Recent technological breakthroughs include the development of magnetocaloric liquefaction, advanced turboexpander designs, and integrated heat recovery systems. These innovations aim to close the gap between current performance and theoretical efficiency limits, potentially revolutionizing the economics of liquid hydrogen as an energy carrier.

The strategic importance of hydrogen liquefaction extends beyond technical considerations to encompass broader energy security, decarbonization, and industrial competitiveness objectives. As nations develop hydrogen strategies, liquefaction technology represents a critical enabler for realizing the full potential of hydrogen in the global energy transition.

Market Analysis for Liquid Hydrogen Demand

The global liquid hydrogen market is experiencing significant growth driven by increasing demand across multiple sectors. The transportation sector represents the largest market segment, with hydrogen fuel cell vehicles gaining traction as a zero-emission alternative to conventional vehicles. Major automotive manufacturers including Toyota, Hyundai, and Honda have commercially launched hydrogen fuel cell vehicles, while heavy-duty applications such as trucks, buses, and trains are emerging as promising markets due to hydrogen's advantages in range and refueling time compared to battery electric alternatives.

The aerospace industry constitutes another substantial demand driver, with liquid hydrogen serving as a high-performance rocket propellant. Space agencies and private companies like NASA, SpaceX, and Blue Origin utilize liquid hydrogen for launch vehicles, creating consistent demand in this specialized sector. The growing commercial space industry is expected to further increase consumption in coming years.

Industrial applications represent a stable and growing market segment. Petroleum refining, metal processing, glass manufacturing, and electronics production all utilize hydrogen in various processes. As industries seek to decarbonize, many are exploring hydrogen as a replacement for fossil fuels in high-temperature industrial processes, potentially creating substantial new demand.

Energy storage applications are emerging as a particularly promising growth area. Liquid hydrogen offers advantages for long-duration energy storage, addressing intermittency challenges associated with renewable energy sources. Several pilot projects are underway globally to demonstrate hydrogen's viability for grid-scale energy storage, seasonal storage, and backup power applications.

Regionally, Asia-Pacific currently leads global demand, with Japan and South Korea implementing ambitious hydrogen strategies. Europe follows closely with strong policy support, particularly in Germany, France, and the Netherlands. North America shows growing interest, especially in California and Canada, while emerging economies are beginning to develop hydrogen roadmaps.

Market forecasts indicate the global liquid hydrogen market will grow at a compound annual growth rate of 5.8% through 2030, reaching approximately 650,000 tons annually. This growth trajectory is supported by declining production costs, expanding infrastructure, and strengthening policy frameworks worldwide. The energy transition imperative is accelerating adoption across sectors, with hydrogen increasingly viewed as essential for achieving net-zero emissions targets in hard-to-abate sectors.

The aerospace industry constitutes another substantial demand driver, with liquid hydrogen serving as a high-performance rocket propellant. Space agencies and private companies like NASA, SpaceX, and Blue Origin utilize liquid hydrogen for launch vehicles, creating consistent demand in this specialized sector. The growing commercial space industry is expected to further increase consumption in coming years.

Industrial applications represent a stable and growing market segment. Petroleum refining, metal processing, glass manufacturing, and electronics production all utilize hydrogen in various processes. As industries seek to decarbonize, many are exploring hydrogen as a replacement for fossil fuels in high-temperature industrial processes, potentially creating substantial new demand.

Energy storage applications are emerging as a particularly promising growth area. Liquid hydrogen offers advantages for long-duration energy storage, addressing intermittency challenges associated with renewable energy sources. Several pilot projects are underway globally to demonstrate hydrogen's viability for grid-scale energy storage, seasonal storage, and backup power applications.

Regionally, Asia-Pacific currently leads global demand, with Japan and South Korea implementing ambitious hydrogen strategies. Europe follows closely with strong policy support, particularly in Germany, France, and the Netherlands. North America shows growing interest, especially in California and Canada, while emerging economies are beginning to develop hydrogen roadmaps.

Market forecasts indicate the global liquid hydrogen market will grow at a compound annual growth rate of 5.8% through 2030, reaching approximately 650,000 tons annually. This growth trajectory is supported by declining production costs, expanding infrastructure, and strengthening policy frameworks worldwide. The energy transition imperative is accelerating adoption across sectors, with hydrogen increasingly viewed as essential for achieving net-zero emissions targets in hard-to-abate sectors.

Current Challenges in Hydrogen Liquefaction Efficiency

Despite significant advancements in hydrogen liquefaction technology, the industry continues to face substantial challenges in achieving optimal energy efficiency. Current commercial hydrogen liquefaction plants operate at efficiency levels of only 30-35%, representing a significant gap from theoretical limits and resulting in high operational costs that impede widespread hydrogen adoption as an energy carrier.

The fundamental thermodynamic challenge stems from hydrogen's low inversion temperature (approximately 202 K), which necessitates complex multi-stage cooling processes. Unlike natural gas liquefaction, hydrogen requires pre-cooling with liquid nitrogen followed by further cooling through expansion processes, creating inherent inefficiencies at each stage of heat transfer and expansion.

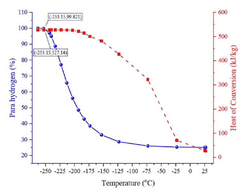

Ortho-para hydrogen conversion presents another major efficiency hurdle. During liquefaction, hydrogen must convert from its room temperature equilibrium state (75% ortho, 25% para) to almost pure para-hydrogen (>95%) at liquefaction temperatures to prevent boil-off losses during storage. This exothermic conversion releases substantial heat (523 kJ/kg) that must be removed during the cooling process, significantly increasing the energy requirement of liquefaction systems.

Heat leak and insulation inefficiencies constitute persistent technical challenges. Even with advanced vacuum-insulated systems, cryogenic temperatures of liquid hydrogen (20 K) create steep temperature gradients that drive continuous heat ingress. Current materials and insulation technologies struggle to maintain the ultra-low temperatures required without substantial energy expenditure for continuous cooling.

Scale limitations further compound efficiency problems. Most existing hydrogen liquefaction plants operate at relatively small capacities (5-10 tonnes/day), whereas efficiency improvements typically manifest at larger scales. The capital investment required for larger plants remains prohibitive without guaranteed market demand, creating a challenging economic cycle that impedes efficiency improvements.

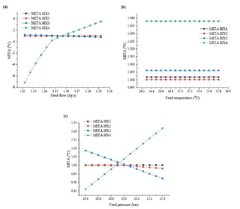

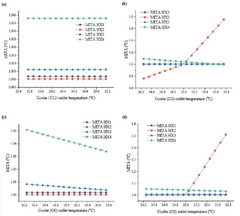

Equipment inefficiencies in compressors, expanders, and heat exchangers contribute significantly to overall system losses. Current compressor technologies achieve isentropic efficiencies of only 65-75%, while expanders typically operate at 75-85% efficiency. These component-level inefficiencies cascade throughout the system, substantially reducing overall process performance.

Intermittent operation capabilities represent an emerging challenge as hydrogen production increasingly couples with renewable energy sources. Traditional liquefaction plants are designed for continuous operation, and their efficiency decreases dramatically during load changes or start-stop cycles, creating a mismatch with the variable nature of renewable energy production.

The fundamental thermodynamic challenge stems from hydrogen's low inversion temperature (approximately 202 K), which necessitates complex multi-stage cooling processes. Unlike natural gas liquefaction, hydrogen requires pre-cooling with liquid nitrogen followed by further cooling through expansion processes, creating inherent inefficiencies at each stage of heat transfer and expansion.

Ortho-para hydrogen conversion presents another major efficiency hurdle. During liquefaction, hydrogen must convert from its room temperature equilibrium state (75% ortho, 25% para) to almost pure para-hydrogen (>95%) at liquefaction temperatures to prevent boil-off losses during storage. This exothermic conversion releases substantial heat (523 kJ/kg) that must be removed during the cooling process, significantly increasing the energy requirement of liquefaction systems.

Heat leak and insulation inefficiencies constitute persistent technical challenges. Even with advanced vacuum-insulated systems, cryogenic temperatures of liquid hydrogen (20 K) create steep temperature gradients that drive continuous heat ingress. Current materials and insulation technologies struggle to maintain the ultra-low temperatures required without substantial energy expenditure for continuous cooling.

Scale limitations further compound efficiency problems. Most existing hydrogen liquefaction plants operate at relatively small capacities (5-10 tonnes/day), whereas efficiency improvements typically manifest at larger scales. The capital investment required for larger plants remains prohibitive without guaranteed market demand, creating a challenging economic cycle that impedes efficiency improvements.

Equipment inefficiencies in compressors, expanders, and heat exchangers contribute significantly to overall system losses. Current compressor technologies achieve isentropic efficiencies of only 65-75%, while expanders typically operate at 75-85% efficiency. These component-level inefficiencies cascade throughout the system, substantially reducing overall process performance.

Intermittent operation capabilities represent an emerging challenge as hydrogen production increasingly couples with renewable energy sources. Traditional liquefaction plants are designed for continuous operation, and their efficiency decreases dramatically during load changes or start-stop cycles, creating a mismatch with the variable nature of renewable energy production.

Comparative Analysis of Current Liquefaction Methods

01 Cryogenic cooling systems for hydrogen liquefaction

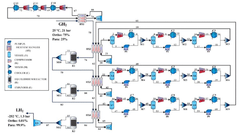

Advanced cryogenic cooling systems are essential for efficient hydrogen liquefaction. These systems utilize multi-stage cooling processes to gradually reduce hydrogen temperature to its liquefaction point (-253°C). By optimizing heat exchangers, refrigeration cycles, and insulation materials, these systems minimize energy losses during the extreme cooling process. Recent innovations include cascade refrigeration systems and the use of helium as an intermediate cooling medium to improve overall energy efficiency.- Cryogenic cooling and refrigeration cycles: Advanced cryogenic cooling techniques are essential for efficient hydrogen liquefaction. These processes typically employ multi-stage refrigeration cycles with optimized heat exchangers to gradually reduce hydrogen temperature to its liquefaction point (-253°C). By implementing cascaded cooling systems and specialized refrigerants, these methods minimize energy losses during the extreme temperature reduction required for hydrogen liquefaction, significantly improving the overall energy efficiency of the process.

- Heat integration and energy recovery systems: Heat integration strategies play a crucial role in improving hydrogen liquefaction efficiency. These approaches involve capturing and reusing cold energy from various process streams, implementing waste heat recovery systems, and optimizing thermal exchange networks. Advanced heat exchangers and cold recovery techniques allow for the recycling of cooling energy from the liquefied hydrogen and other process streams, significantly reducing the external energy input required for the liquefaction process.

- Ortho-para hydrogen conversion optimization: Efficient management of ortho-para hydrogen conversion is critical for energy-efficient liquefaction. Since the conversion from ortho to para hydrogen is exothermic and occurs during cooling, controlled catalytic conversion at strategic temperature stages can significantly reduce the energy requirements of the overall process. Advanced catalysts and optimized conversion timing help manage this transition efficiently, preventing energy losses that would otherwise occur from spontaneous conversion during storage.

- Novel compression and expansion technologies: Innovative compression and expansion technologies enhance the energy efficiency of hydrogen liquefaction processes. These include advanced turboexpanders, magnetic refrigeration systems, and high-efficiency compressors with improved isentropic efficiency. By minimizing entropy generation during compression and maximizing energy recovery during expansion stages, these technologies significantly reduce the power consumption required for hydrogen liquefaction, leading to more economically viable production of liquid hydrogen.

- Process integration with renewable energy sources: Integration of hydrogen liquefaction processes with renewable energy sources offers significant efficiency improvements. These systems synchronize liquefaction operations with the availability of renewable electricity, utilize electrolysis heat for process needs, and implement energy storage solutions to manage intermittency. Smart control systems optimize the operation based on energy availability, while hybrid approaches combine different renewable sources to ensure continuous operation with minimal fossil fuel backup, substantially reducing the carbon footprint of hydrogen liquefaction.

02 Heat recovery and integration techniques

Heat recovery and integration techniques significantly improve the energy efficiency of hydrogen liquefaction processes. These methods capture and reuse waste heat from various stages of the liquefaction process, reducing the overall energy consumption. Advanced heat exchangers, regenerative cooling systems, and thermal integration with other industrial processes help minimize energy losses. Innovations in this area focus on optimizing heat transfer between process streams and utilizing cold energy from the liquefied hydrogen during regasification.Expand Specific Solutions03 Catalytic and ortho-para hydrogen conversion

The conversion between ortho and para hydrogen states is crucial for energy-efficient liquefaction. Natural hydrogen exists as 75% ortho-hydrogen, which must be converted to para-hydrogen during liquefaction to prevent energy losses from spontaneous conversion. Catalytic conversion systems using materials such as iron oxide, activated alumina, or rare earth compounds facilitate this transition at higher temperatures, reducing the overall energy requirements. Optimizing the timing and temperature of this conversion within the liquefaction process significantly improves energy efficiency.Expand Specific Solutions04 Pressure optimization and expansion work recovery

Pressure management and expansion work recovery systems are vital for energy-efficient hydrogen liquefaction. These systems utilize controlled pressure drops through expansion devices to generate cooling effects while recovering mechanical energy. Turboexpanders, expansion engines, and hydraulic energy recovery systems convert pressure energy into useful work, reducing the external power requirements. Advanced pressure cycle designs optimize the balance between compression work input and expansion work recovery, significantly improving the overall energy efficiency of the liquefaction process.Expand Specific Solutions05 Novel refrigeration cycles and mixed refrigerant systems

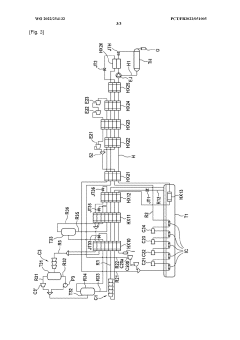

Innovative refrigeration cycles and mixed refrigerant systems offer substantial improvements in hydrogen liquefaction efficiency. These systems use carefully optimized mixtures of gases (such as nitrogen, helium, neon, and hydrocarbons) as refrigerants to better match the cooling curve of hydrogen. Claude cycles, modified Brayton cycles, and hybrid systems combine different thermodynamic approaches to minimize irreversibilities. Recent developments include auto-cascade systems and dual-refrigerant cycles that reduce compression work requirements and improve heat transfer characteristics throughout the liquefaction process.Expand Specific Solutions

Key Industry Players in Hydrogen Liquefaction

The hydrogen liquefaction process market is currently in a growth phase, with increasing demand driven by clean energy transitions. The global market size is expanding rapidly, projected to reach significant scale as hydrogen economies develop worldwide. Technologically, the field shows varying maturity levels, with established industrial gas companies like Air Liquide, Linde AG, and Air Products & Chemicals leading innovation in energy-efficient liquefaction processes. Chinese entities including CNOOC, CNPC, and specialized firms like Beijing Sinoscience Fullcryo Technology are rapidly advancing their capabilities. Research institutions such as Korea Institute of Energy Research and Technical Institute of Physics & Chemistry CAS collaborate with equipment manufacturers like Chart Energy & Chemicals and Cosmodyne to improve efficiency metrics. The competitive landscape features both traditional industrial gas giants and emerging specialized hydrogen technology providers focused on reducing the energy-intensive nature of hydrogen liquefaction.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced hydrogen liquefaction processes focusing on energy efficiency improvements through their proprietary Turbo-Brayton cycle technology. Their system incorporates multi-stage compression with intercooling, optimized heat exchangers, and an integrated refrigeration system that utilizes helium as the working fluid. The company's latest liquefaction plants achieve energy consumption rates of approximately 10-12 kWh/kg of liquid hydrogen, representing a significant improvement over conventional systems that typically require 12-15 kWh/kg. Air Liquide's process incorporates active magnetic bearings in their turboexpanders to minimize mechanical losses and employs advanced ortho-para hydrogen conversion catalysts integrated throughout the cooling process to manage the exothermic conversion efficiently. Their technology also features adaptive control systems that optimize process parameters based on operating conditions and hydrogen feed purity, further enhancing energy efficiency across varying production volumes.

Strengths: Industry-leading energy efficiency metrics with proven large-scale implementation capabilities. Their integrated ortho-para conversion approach minimizes energy penalties associated with this necessary conversion process. Weaknesses: Higher capital costs compared to conventional systems, and the technology requires specialized expertise for operation and maintenance. The helium-based refrigeration cycle adds complexity and potential supply chain vulnerabilities.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has pioneered the development of energy-efficient hydrogen liquefaction through their proprietary AP-X™ process technology. This system employs a mixed refrigerant cycle combined with nitrogen expander technology to achieve energy consumption figures of approximately 10-11 kWh/kg of liquid hydrogen. Their process incorporates specialized plate-fin heat exchangers with enhanced surface geometries that minimize temperature differences and reduce exergy losses throughout the cooling cascade. Air Products' technology features a unique approach to ortho-para hydrogen conversion using a distributed catalyst system that strategically manages the exothermic reaction heat at multiple temperature levels, reducing the overall energy penalty. The company has implemented advanced process integration techniques that recover waste heat from various process streams and utilize it for preheating or other auxiliary processes. Their systems also incorporate sophisticated load-following capabilities that maintain efficiency across production ranges from 30-100% of nameplate capacity, addressing one of the traditional challenges in hydrogen liquefaction operations.

Strengths: Highly optimized heat integration resulting in superior energy efficiency metrics and operational flexibility across varying production rates. Their mixed refrigerant approach provides excellent temperature matching in heat exchangers. Weaknesses: Complex refrigerant management systems require precise control and specialized maintenance. The technology has higher upfront capital costs compared to simpler Claude cycle systems.

Critical Patents and Innovations in Energy-Efficient Liquefaction

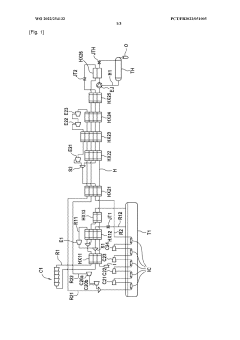

Enhanced hydrogen liquefaction process using carbon dioxide precooled loop

PatentActiveKR1020230107424A

Innovation

- A staged cooling process is implemented using carbon dioxide as a refrigerant in two pre-cooling cycles and mixed refrigerants in subsequent cooling and liquefaction cycles, dividing the pre-cooling section into sub-cycles to optimize energy efficiency and reduce complexity.

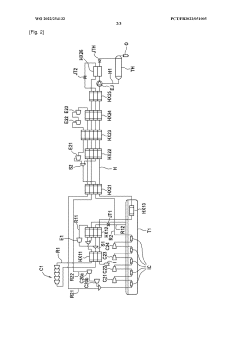

Method and plant for hydrogen liquefaction

PatentWO2022254132A1

Innovation

- A hydrogen liquefaction process with a pre-cooling step using a first refrigerant and a cooling step using a second refrigerant, where both refrigerants undergo compression and expansion in multiple stages to maintain the second refrigerant's temperature below 150 K, utilizing nitrogen and/or argon as the first refrigerant and hydrogen, neon, or helium as the second refrigerant, and incorporating adiabatic expansion to achieve high energy efficiency.

Economic Viability of Different Liquefaction Technologies

The economic viability of hydrogen liquefaction technologies is fundamentally tied to their energy efficiency, capital expenditure requirements, and operational costs. Current commercial hydrogen liquefaction processes consume approximately 10-13 kWh/kg H₂, representing 30-40% of the energy content of hydrogen itself. This significant energy penalty directly impacts the final cost of liquid hydrogen, making efficiency improvements critical for market competitiveness.

Claude-Linde cycle technologies, widely deployed in existing facilities, offer reliability but at relatively high energy costs. Their economic assessment reveals capital costs ranging from $50-100 million for medium-scale plants (5-10 tonnes/day), with energy costs constituting 70-80% of operational expenses. The levelized cost of liquefaction using these conventional systems typically ranges from $1.50-2.50 per kg of hydrogen.

Advanced helium-refrigerated systems demonstrate improved efficiency metrics, potentially reducing energy consumption to 6-8 kWh/kg H₂. Economic modeling suggests these systems could lower operational costs by 25-30% compared to conventional approaches, though they require 15-20% higher initial capital investment. The payback period for this additional investment typically ranges from 3-5 years depending on electricity prices and utilization rates.

Magnetocaloric liquefaction technologies, while still in development stages, show promising economic projections. Early techno-economic analyses indicate potential energy consumption reductions to 4-6 kWh/kg H₂, which could translate to 40-50% operational cost savings. However, current capital costs remain prohibitively high, with estimates suggesting a 2-3x premium over conventional systems, limiting near-term commercial viability despite favorable long-term economics.

Scale economies significantly impact liquefaction costs across all technologies. Small-scale plants (<1 tonne/day) typically face liquefaction costs of $3-5/kg H₂, while large-scale facilities (>50 tonnes/day) can achieve costs below $1/kg H₂. This scale dependency creates market entry barriers but also presents opportunities for centralized production models.

Electricity pricing volatility represents a critical economic risk factor. Sensitivity analyses demonstrate that a $0.01/kWh change in electricity prices translates to approximately $0.10-0.13/kg change in hydrogen liquefaction costs. This relationship underscores the strategic advantage of locating liquefaction facilities in regions with access to low-cost, stable renewable electricity sources to ensure long-term economic viability.

Future economic competitiveness will likely depend on technological innovations that reduce both capital and operational expenses, with industry projections suggesting that achieving liquefaction costs below $1/kg H₂ represents the threshold for widespread market adoption across multiple sectors.

Claude-Linde cycle technologies, widely deployed in existing facilities, offer reliability but at relatively high energy costs. Their economic assessment reveals capital costs ranging from $50-100 million for medium-scale plants (5-10 tonnes/day), with energy costs constituting 70-80% of operational expenses. The levelized cost of liquefaction using these conventional systems typically ranges from $1.50-2.50 per kg of hydrogen.

Advanced helium-refrigerated systems demonstrate improved efficiency metrics, potentially reducing energy consumption to 6-8 kWh/kg H₂. Economic modeling suggests these systems could lower operational costs by 25-30% compared to conventional approaches, though they require 15-20% higher initial capital investment. The payback period for this additional investment typically ranges from 3-5 years depending on electricity prices and utilization rates.

Magnetocaloric liquefaction technologies, while still in development stages, show promising economic projections. Early techno-economic analyses indicate potential energy consumption reductions to 4-6 kWh/kg H₂, which could translate to 40-50% operational cost savings. However, current capital costs remain prohibitively high, with estimates suggesting a 2-3x premium over conventional systems, limiting near-term commercial viability despite favorable long-term economics.

Scale economies significantly impact liquefaction costs across all technologies. Small-scale plants (<1 tonne/day) typically face liquefaction costs of $3-5/kg H₂, while large-scale facilities (>50 tonnes/day) can achieve costs below $1/kg H₂. This scale dependency creates market entry barriers but also presents opportunities for centralized production models.

Electricity pricing volatility represents a critical economic risk factor. Sensitivity analyses demonstrate that a $0.01/kWh change in electricity prices translates to approximately $0.10-0.13/kg change in hydrogen liquefaction costs. This relationship underscores the strategic advantage of locating liquefaction facilities in regions with access to low-cost, stable renewable electricity sources to ensure long-term economic viability.

Future economic competitiveness will likely depend on technological innovations that reduce both capital and operational expenses, with industry projections suggesting that achieving liquefaction costs below $1/kg H₂ represents the threshold for widespread market adoption across multiple sectors.

Environmental Impact and Sustainability Considerations

The environmental impact of hydrogen liquefaction processes represents a critical dimension in evaluating their overall sustainability. Current liquefaction technologies consume substantial amounts of energy, with typical plants requiring between 10-13 kWh/kg H₂, contributing significantly to indirect greenhouse gas emissions when powered by non-renewable sources. The carbon footprint of hydrogen liquefaction varies dramatically depending on the energy source, with coal-powered processes generating approximately 25-30 kg CO₂/kg H₂, while renewable-powered systems can approach near-zero emissions.

Water consumption presents another environmental consideration, particularly in large-scale operations where cooling systems may require substantial water resources. Advanced liquefaction processes incorporating closed-loop cooling systems have demonstrated potential water savings of 30-45% compared to conventional methods, though implementation costs remain a barrier to widespread adoption.

Refrigerant selection significantly impacts the environmental profile of liquefaction systems. Traditional processes often utilize hydrofluorocarbons (HFCs) with high global warming potential (GWP), while newer systems increasingly employ natural refrigerants like helium and nitrogen with minimal environmental impact. The Claude cycle, for instance, uses exclusively helium and hydrogen as working fluids, eliminating concerns about refrigerant leakage contributing to climate change.

Life cycle assessment (LCA) studies indicate that the environmental burden of hydrogen liquefaction infrastructure construction represents only 5-8% of lifetime emissions, with operational energy consumption dominating the environmental footprint. This underscores the importance of energy efficiency improvements in reducing overall environmental impact.

From a sustainability perspective, integration with renewable energy sources offers the most promising pathway toward environmentally benign hydrogen liquefaction. Systems designed with variable operation capabilities can synchronize with intermittent renewable generation, though this introduces efficiency penalties of 10-15% compared to steady-state operation. Recent pilot projects combining wind power with hydrogen liquefaction have demonstrated carbon intensity reductions of up to 85% compared to grid-powered alternatives.

The circular economy potential of hydrogen liquefaction facilities remains largely unexplored, though waste heat recovery systems have shown promise in improving overall system efficiency by 15-20% while reducing thermal pollution. Additionally, the potential for co-location with industrial facilities that can utilize waste cold energy presents opportunities for further sustainability improvements, with early implementations demonstrating energy savings of 8-12% across integrated systems.

Water consumption presents another environmental consideration, particularly in large-scale operations where cooling systems may require substantial water resources. Advanced liquefaction processes incorporating closed-loop cooling systems have demonstrated potential water savings of 30-45% compared to conventional methods, though implementation costs remain a barrier to widespread adoption.

Refrigerant selection significantly impacts the environmental profile of liquefaction systems. Traditional processes often utilize hydrofluorocarbons (HFCs) with high global warming potential (GWP), while newer systems increasingly employ natural refrigerants like helium and nitrogen with minimal environmental impact. The Claude cycle, for instance, uses exclusively helium and hydrogen as working fluids, eliminating concerns about refrigerant leakage contributing to climate change.

Life cycle assessment (LCA) studies indicate that the environmental burden of hydrogen liquefaction infrastructure construction represents only 5-8% of lifetime emissions, with operational energy consumption dominating the environmental footprint. This underscores the importance of energy efficiency improvements in reducing overall environmental impact.

From a sustainability perspective, integration with renewable energy sources offers the most promising pathway toward environmentally benign hydrogen liquefaction. Systems designed with variable operation capabilities can synchronize with intermittent renewable generation, though this introduces efficiency penalties of 10-15% compared to steady-state operation. Recent pilot projects combining wind power with hydrogen liquefaction have demonstrated carbon intensity reductions of up to 85% compared to grid-powered alternatives.

The circular economy potential of hydrogen liquefaction facilities remains largely unexplored, though waste heat recovery systems have shown promise in improving overall system efficiency by 15-20% while reducing thermal pollution. Additionally, the potential for co-location with industrial facilities that can utilize waste cold energy presents opportunities for further sustainability improvements, with early implementations demonstrating energy savings of 8-12% across integrated systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!