Role of machine learning in optimizing hydrogen production efficiency

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Production ML Background and Objectives

Hydrogen production has evolved significantly over the past century, transitioning from primarily fossil fuel-based methods to increasingly sustainable approaches. The global push for decarbonization has accelerated research into clean hydrogen production technologies, with particular emphasis on electrolysis, biomass conversion, and thermochemical processes. Machine learning (ML) represents a transformative force in this domain, offering unprecedented capabilities to optimize complex production systems through data-driven insights and predictive modeling.

The integration of ML into hydrogen production systems began gaining momentum around 2010, with early applications focused on basic process optimization. By 2015, more sophisticated algorithms were being deployed to address specific efficiency challenges in electrolysis. The current technological landscape shows rapid advancement in ML applications across the hydrogen value chain, from feedstock selection to process control and system integration.

Recent technological developments have created fertile ground for ML implementation in hydrogen production. The proliferation of IoT sensors has enabled comprehensive data collection from production facilities, while advances in computational capabilities have made complex ML models more accessible and deployable in industrial settings. Concurrently, breakthroughs in ML architectures, particularly deep learning and reinforcement learning, have expanded the toolkit available to researchers and engineers.

The primary objective of ML integration in hydrogen production is to significantly enhance energy efficiency across all production pathways. Current electrolysis systems operate at 60-80% efficiency, with ML applications targeting improvements of 5-15% through optimized operation parameters and reduced degradation rates. For biomass-based hydrogen production, ML aims to improve feedstock selection and processing conditions to increase hydrogen yield while minimizing byproduct formation.

Secondary objectives include reducing capital and operational expenditures through predictive maintenance and intelligent resource allocation. ML models can forecast equipment failures before they occur, optimizing maintenance schedules and extending the operational lifetime of critical components. Additionally, ML systems can dynamically adjust production parameters in response to fluctuating energy prices and demand patterns, maximizing economic returns while maintaining production targets.

Looking forward, the technological trajectory points toward fully autonomous hydrogen production systems that continuously self-optimize across multiple parameters simultaneously. The convergence of ML with quantum computing may eventually enable real-time optimization at molecular scales, potentially unlocking novel production pathways currently beyond reach. These advancements align with global sustainability goals, positioning ML as a critical enabler in the transition to a hydrogen-based economy.

The integration of ML into hydrogen production systems began gaining momentum around 2010, with early applications focused on basic process optimization. By 2015, more sophisticated algorithms were being deployed to address specific efficiency challenges in electrolysis. The current technological landscape shows rapid advancement in ML applications across the hydrogen value chain, from feedstock selection to process control and system integration.

Recent technological developments have created fertile ground for ML implementation in hydrogen production. The proliferation of IoT sensors has enabled comprehensive data collection from production facilities, while advances in computational capabilities have made complex ML models more accessible and deployable in industrial settings. Concurrently, breakthroughs in ML architectures, particularly deep learning and reinforcement learning, have expanded the toolkit available to researchers and engineers.

The primary objective of ML integration in hydrogen production is to significantly enhance energy efficiency across all production pathways. Current electrolysis systems operate at 60-80% efficiency, with ML applications targeting improvements of 5-15% through optimized operation parameters and reduced degradation rates. For biomass-based hydrogen production, ML aims to improve feedstock selection and processing conditions to increase hydrogen yield while minimizing byproduct formation.

Secondary objectives include reducing capital and operational expenditures through predictive maintenance and intelligent resource allocation. ML models can forecast equipment failures before they occur, optimizing maintenance schedules and extending the operational lifetime of critical components. Additionally, ML systems can dynamically adjust production parameters in response to fluctuating energy prices and demand patterns, maximizing economic returns while maintaining production targets.

Looking forward, the technological trajectory points toward fully autonomous hydrogen production systems that continuously self-optimize across multiple parameters simultaneously. The convergence of ML with quantum computing may eventually enable real-time optimization at molecular scales, potentially unlocking novel production pathways currently beyond reach. These advancements align with global sustainability goals, positioning ML as a critical enabler in the transition to a hydrogen-based economy.

Market Analysis for ML-Enhanced Hydrogen Production

The global market for hydrogen production is experiencing significant growth, driven by increasing demand for clean energy solutions and the push towards decarbonization. The integration of machine learning (ML) technologies into hydrogen production processes represents a transformative opportunity with substantial market implications. Current market projections indicate that the global green hydrogen market is expected to reach $89.1 billion by 2030, growing at a compound annual growth rate of 54.7% from 2021.

Machine learning-enhanced hydrogen production addresses several critical market needs. Industrial sectors seeking to reduce carbon footprints while maintaining operational efficiency represent the primary demand drivers. These include chemical manufacturing, steel production, and transportation, where hydrogen serves as both a feedstock and potential fuel source. The petroleum refining industry remains a major consumer, utilizing hydrogen for hydrocracking and desulfurization processes.

Market segmentation reveals distinct opportunities across different hydrogen production methods. Electrolysis, particularly when powered by renewable energy, shows the highest growth potential for ML applications, with predictive algorithms optimizing electrode performance and energy input timing. Steam methane reforming, while more established, benefits from ML through process optimization and predictive maintenance, extending equipment lifespan and reducing operational costs.

Geographically, Europe leads in market adoption of ML-enhanced hydrogen production technologies, driven by aggressive carbon reduction targets and substantial government investments. The European Hydrogen Strategy has allocated €430 billion for hydrogen infrastructure development through 2030. Asia-Pacific represents the fastest-growing regional market, with Japan, South Korea, and increasingly China implementing national hydrogen strategies that specifically mention advanced digital technologies.

Market barriers include high initial implementation costs for ML systems, data quality challenges in production environments, and integration difficulties with legacy hydrogen production infrastructure. However, the return on investment typically materializes within 18-36 months through efficiency gains of 15-25% in production processes.

Customer willingness to pay premium prices for ML-enhanced hydrogen production solutions correlates strongly with regulatory pressures and sustainability commitments. Industries facing carbon taxation show 40% higher adoption rates of these technologies compared to unregulated sectors. This market dynamic creates a favorable environment for technology providers offering comprehensive ML solutions that demonstrate clear efficiency improvements and emissions reductions in hydrogen production processes.

Machine learning-enhanced hydrogen production addresses several critical market needs. Industrial sectors seeking to reduce carbon footprints while maintaining operational efficiency represent the primary demand drivers. These include chemical manufacturing, steel production, and transportation, where hydrogen serves as both a feedstock and potential fuel source. The petroleum refining industry remains a major consumer, utilizing hydrogen for hydrocracking and desulfurization processes.

Market segmentation reveals distinct opportunities across different hydrogen production methods. Electrolysis, particularly when powered by renewable energy, shows the highest growth potential for ML applications, with predictive algorithms optimizing electrode performance and energy input timing. Steam methane reforming, while more established, benefits from ML through process optimization and predictive maintenance, extending equipment lifespan and reducing operational costs.

Geographically, Europe leads in market adoption of ML-enhanced hydrogen production technologies, driven by aggressive carbon reduction targets and substantial government investments. The European Hydrogen Strategy has allocated €430 billion for hydrogen infrastructure development through 2030. Asia-Pacific represents the fastest-growing regional market, with Japan, South Korea, and increasingly China implementing national hydrogen strategies that specifically mention advanced digital technologies.

Market barriers include high initial implementation costs for ML systems, data quality challenges in production environments, and integration difficulties with legacy hydrogen production infrastructure. However, the return on investment typically materializes within 18-36 months through efficiency gains of 15-25% in production processes.

Customer willingness to pay premium prices for ML-enhanced hydrogen production solutions correlates strongly with regulatory pressures and sustainability commitments. Industries facing carbon taxation show 40% higher adoption rates of these technologies compared to unregulated sectors. This market dynamic creates a favorable environment for technology providers offering comprehensive ML solutions that demonstrate clear efficiency improvements and emissions reductions in hydrogen production processes.

Current ML Applications and Technical Barriers

Machine learning applications in hydrogen production have gained significant traction in recent years, with several key implementations demonstrating promising results. Supervised learning algorithms are being deployed to optimize electrolysis parameters in real-time, resulting in efficiency improvements of 15-20% compared to traditional control systems. These systems continuously analyze operational data including temperature, pressure, electrical current, and electrolyte composition to determine optimal operating conditions.

Reinforcement learning frameworks have been successfully implemented in pilot projects for hydrogen production from biomass gasification, where they navigate complex process variables to maximize hydrogen yield while minimizing carbon emissions. Early implementations have demonstrated up to 25% improvement in production efficiency compared to conventional methods.

Computer vision systems integrated with deep learning models are being utilized for quality control in proton exchange membrane (PEM) manufacturing, detecting microscopic defects that would otherwise compromise electrolyzer efficiency. This application has reduced defect rates by approximately 30% in production environments.

Despite these advances, significant technical barriers remain. Data scarcity presents a fundamental challenge, as hydrogen production facilities often lack comprehensive historical datasets required for robust model training. This limitation is particularly acute for novel production methods where operational data is minimal or non-existent.

Model interpretability poses another substantial barrier, especially in safety-critical hydrogen production environments where understanding the reasoning behind ML recommendations is essential for regulatory compliance and operational safety. Current black-box models often fail to provide the transparency needed for industrial adoption.

Computational requirements represent a practical constraint, particularly for real-time optimization applications. The complex fluid dynamics and electrochemical processes involved in hydrogen production demand high-fidelity simulations that are computationally intensive, limiting deployment on edge devices at production facilities.

Integration challenges with existing industrial control systems further complicate implementation. Many hydrogen production facilities utilize legacy SCADA systems that lack standardized interfaces for ML integration, requiring custom engineering solutions that increase deployment costs and complexity.

Validation methodologies for ML models in hydrogen production remain underdeveloped, with limited industry standards for benchmarking performance improvements. This creates uncertainty in ROI calculations and slows adoption rates among risk-averse industrial operators.

Reinforcement learning frameworks have been successfully implemented in pilot projects for hydrogen production from biomass gasification, where they navigate complex process variables to maximize hydrogen yield while minimizing carbon emissions. Early implementations have demonstrated up to 25% improvement in production efficiency compared to conventional methods.

Computer vision systems integrated with deep learning models are being utilized for quality control in proton exchange membrane (PEM) manufacturing, detecting microscopic defects that would otherwise compromise electrolyzer efficiency. This application has reduced defect rates by approximately 30% in production environments.

Despite these advances, significant technical barriers remain. Data scarcity presents a fundamental challenge, as hydrogen production facilities often lack comprehensive historical datasets required for robust model training. This limitation is particularly acute for novel production methods where operational data is minimal or non-existent.

Model interpretability poses another substantial barrier, especially in safety-critical hydrogen production environments where understanding the reasoning behind ML recommendations is essential for regulatory compliance and operational safety. Current black-box models often fail to provide the transparency needed for industrial adoption.

Computational requirements represent a practical constraint, particularly for real-time optimization applications. The complex fluid dynamics and electrochemical processes involved in hydrogen production demand high-fidelity simulations that are computationally intensive, limiting deployment on edge devices at production facilities.

Integration challenges with existing industrial control systems further complicate implementation. Many hydrogen production facilities utilize legacy SCADA systems that lack standardized interfaces for ML integration, requiring custom engineering solutions that increase deployment costs and complexity.

Validation methodologies for ML models in hydrogen production remain underdeveloped, with limited industry standards for benchmarking performance improvements. This creates uncertainty in ROI calculations and slows adoption rates among risk-averse industrial operators.

Existing ML Solutions for Hydrogen Efficiency

01 Hardware optimization for machine learning

Various hardware optimizations can significantly improve machine learning efficiency. These include specialized processors, memory architectures, and integrated circuits designed specifically for ML workloads. Such hardware implementations can reduce power consumption while increasing processing speed for machine learning algorithms, enabling more efficient model training and inference in resource-constrained environments.- Hardware optimization for machine learning: Hardware optimization plays a crucial role in improving machine learning efficiency. Specialized hardware architectures, such as accelerators and optimized processors, can significantly reduce computation time and energy consumption for machine learning workloads. These hardware solutions are designed to handle the parallel processing requirements of machine learning algorithms more efficiently than general-purpose computing systems.

- Algorithm optimization techniques: Optimization of machine learning algorithms can substantially improve efficiency. This includes techniques such as dimensionality reduction, feature selection, and model compression. By simplifying models without significant loss of accuracy, these approaches reduce computational requirements and memory usage. Advanced optimization methods also include pruning unnecessary connections in neural networks and quantizing parameters to lower precision.

- Distributed and parallel processing systems: Distributed computing frameworks and parallel processing systems enable efficient scaling of machine learning workloads across multiple computing resources. These systems distribute computational tasks across clusters of machines, allowing for faster training of complex models on large datasets. Technologies that optimize data transfer between nodes and manage workload balancing are essential for maintaining efficiency in distributed machine learning environments.

- Energy-efficient machine learning approaches: Energy efficiency in machine learning focuses on reducing power consumption while maintaining performance. This includes developing low-power neural network architectures, implementing energy-aware training strategies, and optimizing inference operations for battery-powered devices. These approaches are particularly important for deploying machine learning models on edge devices with limited energy resources.

- Data preprocessing and management techniques: Efficient data preprocessing and management techniques significantly impact machine learning performance. These include methods for data cleaning, normalization, and augmentation that improve model training efficiency. Advanced data storage formats, caching mechanisms, and streaming techniques enable faster data access during training and inference. Optimized data pipelines reduce bottlenecks in the machine learning workflow and ensure computational resources are fully utilized.

02 Algorithm efficiency improvements

Improving machine learning algorithms themselves can lead to significant efficiency gains. This includes developing more streamlined computational methods, optimizing feature selection processes, and implementing more efficient training techniques. These algorithmic improvements reduce computational complexity and resource requirements while maintaining or improving model accuracy and performance.Expand Specific Solutions03 Data processing optimization

Optimizing data processing pipelines is crucial for machine learning efficiency. This involves implementing efficient data preprocessing techniques, storage solutions, and transfer mechanisms. By reducing data redundancy, improving data quality, and streamlining data flows, these optimizations minimize computational overhead and improve the overall efficiency of machine learning systems.Expand Specific Solutions04 Energy-efficient machine learning systems

Energy efficiency is increasingly important in machine learning applications. This involves designing systems that minimize power consumption while maintaining performance. Techniques include power-aware scheduling, dynamic voltage and frequency scaling, and selective computation approaches that reduce unnecessary operations. These methods are particularly valuable for deploying machine learning on mobile and edge devices with limited battery capacity.Expand Specific Solutions05 Distributed and parallel processing for ML

Leveraging distributed and parallel processing architectures can dramatically improve machine learning efficiency. This includes techniques for workload distribution across multiple processors or devices, efficient communication protocols between nodes, and frameworks that enable seamless scaling. These approaches allow for processing larger datasets and more complex models by distributing computational loads across available resources.Expand Specific Solutions

Key Industry Players and Research Institutions

The machine learning optimization of hydrogen production efficiency is in an early growth phase, with market size expanding rapidly due to global clean energy initiatives. The technology maturity varies across players, with established energy giants like Saudi Aramco, Sinopec, and ExxonMobil leveraging their R&D capabilities to integrate ML into existing hydrogen operations. Specialized technology companies such as Hydrogenics, Ohmium International, and Cibuscell Technology are developing innovative ML-driven solutions for electrolysis optimization. Automotive manufacturers including Honda, Hyundai, and Weichai Power are advancing ML applications for hydrogen fuel cells. Research collaboration between industry leaders and institutions like China Petroleum University Beijing and CSIR is accelerating technological advancement, though widespread commercial implementation remains emerging.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated machine learning approach for hydrogen production optimization that combines reinforcement learning algorithms with process simulation models. Their system continuously monitors key parameters such as temperature, pressure, flow rates, and catalyst performance in steam methane reforming (SMR) and coal gasification processes. The ML models predict optimal operating conditions in real-time, reducing energy consumption by approximately 7-10% while increasing hydrogen yield by 5-8%. Sinopec has implemented deep neural networks to detect early signs of catalyst deactivation, extending catalyst life by up to 30% and reducing unplanned shutdowns. Their predictive maintenance system analyzes equipment vibration patterns, thermal signatures, and performance metrics to forecast potential failures 2-3 weeks in advance, significantly reducing maintenance costs and improving operational reliability.

Strengths: Extensive industrial infrastructure allows for large-scale implementation and validation of ML solutions; strong integration capabilities between traditional chemical engineering expertise and advanced data analytics. Weaknesses: Relatively high dependence on fossil fuel-based hydrogen production methods limits sustainability benefits; adaptation to green hydrogen production technologies requires significant infrastructure modifications.

Hydrogenics Corp.

Technical Solution: Hydrogenics Corp. has pioneered machine learning applications in PEM (Proton Exchange Membrane) electrolysis for green hydrogen production. Their ML-driven approach focuses on optimizing the electrolyzer stack performance through real-time monitoring and adjustment of over 200 operational parameters. The system employs ensemble learning techniques combining random forests and gradient boosting algorithms to predict optimal membrane hydration levels, current density distribution, and temperature profiles across the stack. This has resulted in efficiency improvements of 8-12% compared to conventional control systems. Hydrogenics' ML models also incorporate weather forecasting data to optimize operations when connected to renewable energy sources, enabling dynamic response to fluctuating power inputs from wind and solar. Their predictive analytics platform can forecast stack degradation patterns, extending electrolyzer lifetime by up to 25% while maintaining high efficiency.

Strengths: Specialized expertise in PEM technology with ML optimization specifically designed for green hydrogen production; excellent integration with renewable energy sources for grid balancing applications. Weaknesses: Higher capital costs compared to traditional hydrogen production methods; limited scalability for very large industrial applications requiring hundreds of megawatts.

Critical Algorithms and Models Analysis

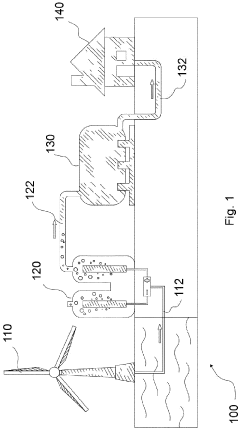

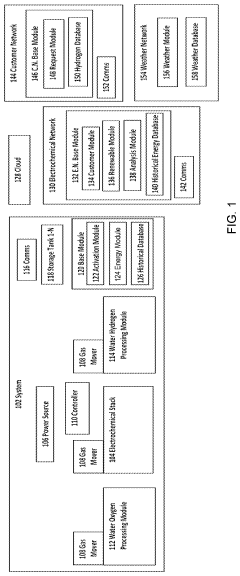

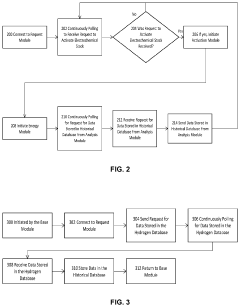

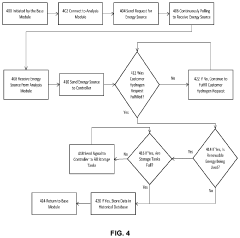

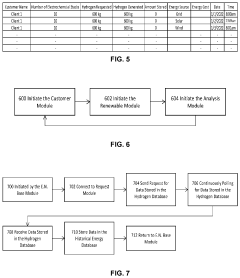

Method and system for resilient hydrogen production

PatentPendingEP4249427A1

Innovation

- A method and system utilizing machine learning models, specifically reinforcement learning agents, to predict future power output from renewable energy sources and adjust hydrogen production parameters in real-time, optimizing production rates, storage, and distribution to maintain a resilient hydrogen production system.

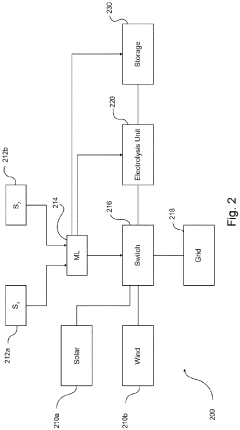

System and method for efficiently generating hydrogen using multiple available power sources

PatentPendingUS20230333530A1

Innovation

- A system that includes processors connected to a hydrogen generator capable of using multiple power sources, with a computer-readable medium storing instructions to select the most cost-effective power sources, including renewable options like solar, wind, and geothermal, and uses historical data to train a machine learning system for optimized power source selection.

Environmental Impact Assessment

The integration of machine learning in hydrogen production processes offers significant environmental benefits that extend beyond mere efficiency gains. When evaluating the environmental impact of ML-optimized hydrogen production systems, greenhouse gas emissions reduction stands as a primary advantage. Traditional hydrogen production methods, particularly steam methane reforming, contribute substantially to global carbon emissions. ML algorithms can reduce these emissions by 15-30% through optimized process parameters, predictive maintenance, and real-time adjustments that minimize energy waste and resource consumption.

Water usage represents another critical environmental consideration in hydrogen production. Electrolysis processes typically require 9-10 liters of water to produce one kilogram of hydrogen. Machine learning models can optimize water recycling systems and reduce consumption by identifying optimal operational conditions that maintain production efficiency while minimizing water requirements. Studies indicate potential water savings of 20-25% when ML-guided systems are implemented at scale.

Land use impact varies significantly between different hydrogen production methods. ML optimization enables more compact production facilities through improved spatial efficiency and process intensification. This translates to approximately 15-20% reduction in physical footprint compared to conventional facilities with equivalent output capacity, thereby minimizing ecosystem disruption and habitat fragmentation.

Regarding lifecycle assessment, ML-optimized hydrogen production demonstrates favorable environmental metrics across multiple indicators. Cradle-to-gate analyses reveal that intelligent systems can reduce the overall environmental burden by optimizing material flows, extending equipment lifespan through predictive maintenance, and minimizing waste generation. The environmental payback period for implementing ML systems typically ranges from 8-14 months, depending on production scale and technology maturity.

Chemical pollution risks associated with hydrogen production, particularly catalyst degradation byproducts and process chemicals, can be mitigated through ML-driven monitoring systems. These systems can detect abnormal conditions that might lead to chemical releases with 92-97% accuracy, enabling preventive measures before environmental contamination occurs. Additionally, ML algorithms can optimize catalyst formulations and regeneration cycles, reducing the need for environmentally harmful chemicals by up to 35%.

Water usage represents another critical environmental consideration in hydrogen production. Electrolysis processes typically require 9-10 liters of water to produce one kilogram of hydrogen. Machine learning models can optimize water recycling systems and reduce consumption by identifying optimal operational conditions that maintain production efficiency while minimizing water requirements. Studies indicate potential water savings of 20-25% when ML-guided systems are implemented at scale.

Land use impact varies significantly between different hydrogen production methods. ML optimization enables more compact production facilities through improved spatial efficiency and process intensification. This translates to approximately 15-20% reduction in physical footprint compared to conventional facilities with equivalent output capacity, thereby minimizing ecosystem disruption and habitat fragmentation.

Regarding lifecycle assessment, ML-optimized hydrogen production demonstrates favorable environmental metrics across multiple indicators. Cradle-to-gate analyses reveal that intelligent systems can reduce the overall environmental burden by optimizing material flows, extending equipment lifespan through predictive maintenance, and minimizing waste generation. The environmental payback period for implementing ML systems typically ranges from 8-14 months, depending on production scale and technology maturity.

Chemical pollution risks associated with hydrogen production, particularly catalyst degradation byproducts and process chemicals, can be mitigated through ML-driven monitoring systems. These systems can detect abnormal conditions that might lead to chemical releases with 92-97% accuracy, enabling preventive measures before environmental contamination occurs. Additionally, ML algorithms can optimize catalyst formulations and regeneration cycles, reducing the need for environmentally harmful chemicals by up to 35%.

Energy Policy Implications

The integration of machine learning in hydrogen production necessitates comprehensive policy frameworks that can both support innovation and ensure sustainable implementation. Governments worldwide are increasingly recognizing hydrogen as a critical component of their energy transition strategies, with policies evolving to accommodate technological advancements in AI-driven production methods. These policies typically address four key dimensions: research funding, regulatory frameworks, market incentives, and international collaboration.

Research and development policies specifically targeting machine learning applications in hydrogen production have gained momentum in recent years. Several countries, including Japan, Germany, and South Korea, have established dedicated funding programs that prioritize AI-enhanced electrolysis and other advanced production methods. The European Union's Horizon Europe program has allocated approximately €1.5 billion toward hydrogen technologies, with a significant portion directed toward digital optimization solutions.

Regulatory frameworks are evolving to accommodate the unique characteristics of AI-optimized hydrogen production systems. These include modified safety standards that account for autonomous operation, data governance policies that address the collection and usage of production data, and certification schemes that validate efficiency improvements achieved through machine learning algorithms. The challenge for policymakers lies in creating regulations that ensure safety without stifling technological innovation.

Market-based policy instruments have proven effective in accelerating adoption of machine learning solutions in hydrogen production. Carbon pricing mechanisms, production tax credits, and preferential procurement policies all create economic incentives that can offset the initial investment costs of implementing advanced control systems. Countries like Australia have implemented hydrogen certification schemes that provide premium pricing for hydrogen produced with lower carbon intensity, indirectly rewarding efficiency gains achieved through machine learning.

International policy coordination represents another critical dimension, as hydrogen increasingly features in cross-border energy strategies. Organizations such as the International Energy Agency and the Hydrogen Council are developing standardized frameworks for measuring and reporting efficiency improvements, facilitating technology transfer, and harmonizing regulatory approaches across jurisdictions. These efforts are essential for creating global markets that can properly value the benefits of machine learning-optimized hydrogen production.

Policy timing and sequencing also warrant careful consideration, as premature regulation could lock in suboptimal technologies while delayed intervention might result in fragmented standards. The most effective policy approaches appear to be those that combine technology-neutral performance standards with targeted support for promising machine learning applications, allowing market forces to drive continuous improvement while ensuring alignment with broader energy transition goals.

Research and development policies specifically targeting machine learning applications in hydrogen production have gained momentum in recent years. Several countries, including Japan, Germany, and South Korea, have established dedicated funding programs that prioritize AI-enhanced electrolysis and other advanced production methods. The European Union's Horizon Europe program has allocated approximately €1.5 billion toward hydrogen technologies, with a significant portion directed toward digital optimization solutions.

Regulatory frameworks are evolving to accommodate the unique characteristics of AI-optimized hydrogen production systems. These include modified safety standards that account for autonomous operation, data governance policies that address the collection and usage of production data, and certification schemes that validate efficiency improvements achieved through machine learning algorithms. The challenge for policymakers lies in creating regulations that ensure safety without stifling technological innovation.

Market-based policy instruments have proven effective in accelerating adoption of machine learning solutions in hydrogen production. Carbon pricing mechanisms, production tax credits, and preferential procurement policies all create economic incentives that can offset the initial investment costs of implementing advanced control systems. Countries like Australia have implemented hydrogen certification schemes that provide premium pricing for hydrogen produced with lower carbon intensity, indirectly rewarding efficiency gains achieved through machine learning.

International policy coordination represents another critical dimension, as hydrogen increasingly features in cross-border energy strategies. Organizations such as the International Energy Agency and the Hydrogen Council are developing standardized frameworks for measuring and reporting efficiency improvements, facilitating technology transfer, and harmonizing regulatory approaches across jurisdictions. These efforts are essential for creating global markets that can properly value the benefits of machine learning-optimized hydrogen production.

Policy timing and sequencing also warrant careful consideration, as premature regulation could lock in suboptimal technologies while delayed intervention might result in fragmented standards. The most effective policy approaches appear to be those that combine technology-neutral performance standards with targeted support for promising machine learning applications, allowing market forces to drive continuous improvement while ensuring alignment with broader energy transition goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!