Integration of offshore wind with large-scale green hydrogen production

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Offshore Wind-Hydrogen Integration Background and Objectives

The integration of offshore wind with large-scale green hydrogen production represents a transformative approach to renewable energy utilization and decarbonization. This technological convergence has evolved significantly over the past decade, driven by the urgent need to reduce carbon emissions and the growing recognition of hydrogen's potential as a clean energy carrier. Initially, offshore wind development focused primarily on electricity generation for grid integration, while hydrogen production remained largely dependent on fossil fuel-based methods. However, the technological landscape has shifted dramatically as both sectors have matured.

The evolution of offshore wind technology has been characterized by increasing turbine sizes, improved reliability, and declining costs. From the early 2-3 MW turbines deployed in shallow waters, the industry has progressed to 15+ MW giants capable of operating in deeper waters through floating foundations. Concurrently, electrolysis technology for hydrogen production has advanced from small-scale demonstrations to industrial-scale applications, with significant improvements in efficiency, durability, and cost-effectiveness.

The convergence of these technologies presents a compelling opportunity to address several critical challenges in the energy transition. Offshore wind farms often face grid connection constraints and curtailment issues during periods of excess generation. By integrating hydrogen production capabilities, excess electricity can be converted to hydrogen, effectively storing energy that would otherwise be wasted and providing a solution to wind power's inherent intermittency.

The primary objective of offshore wind-hydrogen integration is to establish economically viable pathways for large-scale green hydrogen production using offshore wind resources. This involves developing technical solutions for efficient energy conversion, addressing the logistical challenges of offshore hydrogen production, and creating appropriate infrastructure for hydrogen transport and storage. The ultimate goal is to create a sustainable supply chain that can deliver cost-competitive green hydrogen to various end-use sectors, including industry, transportation, and power generation.

Secondary objectives include optimizing system design to maximize economic returns, minimizing environmental impacts, and developing regulatory frameworks that support this emerging industry. The integration also aims to enhance energy security by reducing dependence on imported fossil fuels and creating new economic opportunities in coastal regions through the development of hydrogen hubs and associated industries.

The technological trajectory suggests a phased approach, beginning with onshore electrolysis powered by offshore wind, progressing to nearshore integrated systems, and ultimately moving toward fully offshore hydrogen production facilities. This evolution aligns with broader energy transition goals and positions offshore wind-hydrogen integration as a cornerstone of future decarbonization strategies.

The evolution of offshore wind technology has been characterized by increasing turbine sizes, improved reliability, and declining costs. From the early 2-3 MW turbines deployed in shallow waters, the industry has progressed to 15+ MW giants capable of operating in deeper waters through floating foundations. Concurrently, electrolysis technology for hydrogen production has advanced from small-scale demonstrations to industrial-scale applications, with significant improvements in efficiency, durability, and cost-effectiveness.

The convergence of these technologies presents a compelling opportunity to address several critical challenges in the energy transition. Offshore wind farms often face grid connection constraints and curtailment issues during periods of excess generation. By integrating hydrogen production capabilities, excess electricity can be converted to hydrogen, effectively storing energy that would otherwise be wasted and providing a solution to wind power's inherent intermittency.

The primary objective of offshore wind-hydrogen integration is to establish economically viable pathways for large-scale green hydrogen production using offshore wind resources. This involves developing technical solutions for efficient energy conversion, addressing the logistical challenges of offshore hydrogen production, and creating appropriate infrastructure for hydrogen transport and storage. The ultimate goal is to create a sustainable supply chain that can deliver cost-competitive green hydrogen to various end-use sectors, including industry, transportation, and power generation.

Secondary objectives include optimizing system design to maximize economic returns, minimizing environmental impacts, and developing regulatory frameworks that support this emerging industry. The integration also aims to enhance energy security by reducing dependence on imported fossil fuels and creating new economic opportunities in coastal regions through the development of hydrogen hubs and associated industries.

The technological trajectory suggests a phased approach, beginning with onshore electrolysis powered by offshore wind, progressing to nearshore integrated systems, and ultimately moving toward fully offshore hydrogen production facilities. This evolution aligns with broader energy transition goals and positions offshore wind-hydrogen integration as a cornerstone of future decarbonization strategies.

Market Analysis for Green Hydrogen from Offshore Wind

The global green hydrogen market is experiencing unprecedented growth, driven by the urgent need for decarbonization across industries. Current market valuations place the green hydrogen sector at approximately $2.5 billion as of 2022, with projections indicating a compound annual growth rate exceeding 39% through 2030. This remarkable expansion is particularly evident in regions with ambitious climate targets, such as the European Union, where the REPowerEU plan aims to produce 10 million tonnes of domestic renewable hydrogen by 2030.

Offshore wind presents a compelling energy source for green hydrogen production due to its higher capacity factors compared to onshore alternatives. Wind farms in offshore environments typically achieve 40-55% capacity factors, significantly outperforming the 25-35% common for onshore installations. This enhanced reliability translates directly to more consistent hydrogen production operations and improved electrolyzer utilization rates.

Market demand for green hydrogen from offshore wind spans multiple sectors. Heavy industry represents the largest potential market, with steel manufacturing alone requiring approximately 71 million tonnes of hydrogen annually if fully converted to hydrogen-based production. Maritime shipping constitutes another significant demand center, with major shipping companies already investing in hydrogen-powered vessel development and port infrastructure.

Energy storage applications are gaining traction as grid operators seek solutions for seasonal storage challenges that batteries cannot address. The ability to convert excess offshore wind power during high-production periods into storable hydrogen represents a valuable grid balancing mechanism worth an estimated $13 billion by 2030.

Geographic market distribution shows particular strength in Northern Europe, where countries bordering the North Sea have established the North Sea Energy Cooperation to coordinate offshore wind and hydrogen development. Similar initiatives are emerging in East Asia, particularly Japan and South Korea, where limited land availability makes offshore solutions especially attractive.

Price sensitivity remains a critical market factor. Current green hydrogen production costs range from $3-8 per kilogram, with offshore wind-powered production typically falling in the higher end of this spectrum due to increased infrastructure requirements. However, technology learning curves suggest potential cost reductions of 40-60% by 2030 as electrolyzer technologies mature and offshore wind costs continue to decline.

Market barriers include significant upfront capital requirements, with integrated offshore wind and hydrogen projects typically requiring investments of $1-2 billion. Regulatory frameworks remain underdeveloped in most jurisdictions, creating uncertainty for investors and project developers seeking clear market signals and support mechanisms.

Offshore wind presents a compelling energy source for green hydrogen production due to its higher capacity factors compared to onshore alternatives. Wind farms in offshore environments typically achieve 40-55% capacity factors, significantly outperforming the 25-35% common for onshore installations. This enhanced reliability translates directly to more consistent hydrogen production operations and improved electrolyzer utilization rates.

Market demand for green hydrogen from offshore wind spans multiple sectors. Heavy industry represents the largest potential market, with steel manufacturing alone requiring approximately 71 million tonnes of hydrogen annually if fully converted to hydrogen-based production. Maritime shipping constitutes another significant demand center, with major shipping companies already investing in hydrogen-powered vessel development and port infrastructure.

Energy storage applications are gaining traction as grid operators seek solutions for seasonal storage challenges that batteries cannot address. The ability to convert excess offshore wind power during high-production periods into storable hydrogen represents a valuable grid balancing mechanism worth an estimated $13 billion by 2030.

Geographic market distribution shows particular strength in Northern Europe, where countries bordering the North Sea have established the North Sea Energy Cooperation to coordinate offshore wind and hydrogen development. Similar initiatives are emerging in East Asia, particularly Japan and South Korea, where limited land availability makes offshore solutions especially attractive.

Price sensitivity remains a critical market factor. Current green hydrogen production costs range from $3-8 per kilogram, with offshore wind-powered production typically falling in the higher end of this spectrum due to increased infrastructure requirements. However, technology learning curves suggest potential cost reductions of 40-60% by 2030 as electrolyzer technologies mature and offshore wind costs continue to decline.

Market barriers include significant upfront capital requirements, with integrated offshore wind and hydrogen projects typically requiring investments of $1-2 billion. Regulatory frameworks remain underdeveloped in most jurisdictions, creating uncertainty for investors and project developers seeking clear market signals and support mechanisms.

Technical Barriers and Global Development Status

The integration of offshore wind with large-scale green hydrogen production faces significant technical barriers despite its promising potential. Currently, the most pressing challenge is the efficiency loss in the energy conversion chain. The electricity-to-hydrogen conversion process via electrolysis typically achieves only 60-75% efficiency, resulting in substantial energy losses when converting wind power to hydrogen. This inefficiency is further compounded by the intermittent nature of wind resources, requiring sophisticated energy management systems or substantial storage capacity.

Offshore electrolysis presents unique engineering challenges, including the need for seawater desalination before electrolysis, corrosion-resistant materials for marine environments, and compact system designs suitable for limited platform space. The transportation of produced hydrogen also remains problematic, with pipeline infrastructure being costly and technically complex to install undersea, while compression or liquefaction for shipping increases both energy consumption and system complexity.

From a global development perspective, several regions are making significant strides in this field. The North Sea region leads development efforts, with countries like Germany, Netherlands, Denmark, and the UK investing heavily in offshore wind-hydrogen projects. The NortH2 project in the Netherlands aims to develop 10 GW of offshore wind capacity dedicated to green hydrogen production by 2040. Similarly, Germany's AquaVentus initiative targets 10 GW of offshore electrolysis capacity by 2035.

Asia-Pacific countries, particularly Japan, South Korea, and Australia, are also advancing rapidly. Japan's Hydrogen Energy Supply Chain project demonstrates the feasibility of international hydrogen shipping, while Australia leverages its abundant renewable resources for export-oriented hydrogen production. China has recently announced ambitious plans to develop offshore wind-hydrogen integration in its coastal provinces.

The United States is accelerating its efforts through the Department of Energy's Hydrogen Shot initiative, which aims to reduce clean hydrogen costs by 80% within a decade. Several pilot projects along the East and West coasts are exploring offshore wind-hydrogen synergies.

Current technology readiness levels (TRLs) vary across the integration chain. While offshore wind technology is relatively mature (TRL 8-9), offshore electrolysis systems remain at demonstration phase (TRL 6-7). Integrated systems combining both technologies are still in early pilot stages (TRL 4-5), indicating significant room for technological advancement before commercial-scale deployment becomes widespread.

Offshore electrolysis presents unique engineering challenges, including the need for seawater desalination before electrolysis, corrosion-resistant materials for marine environments, and compact system designs suitable for limited platform space. The transportation of produced hydrogen also remains problematic, with pipeline infrastructure being costly and technically complex to install undersea, while compression or liquefaction for shipping increases both energy consumption and system complexity.

From a global development perspective, several regions are making significant strides in this field. The North Sea region leads development efforts, with countries like Germany, Netherlands, Denmark, and the UK investing heavily in offshore wind-hydrogen projects. The NortH2 project in the Netherlands aims to develop 10 GW of offshore wind capacity dedicated to green hydrogen production by 2040. Similarly, Germany's AquaVentus initiative targets 10 GW of offshore electrolysis capacity by 2035.

Asia-Pacific countries, particularly Japan, South Korea, and Australia, are also advancing rapidly. Japan's Hydrogen Energy Supply Chain project demonstrates the feasibility of international hydrogen shipping, while Australia leverages its abundant renewable resources for export-oriented hydrogen production. China has recently announced ambitious plans to develop offshore wind-hydrogen integration in its coastal provinces.

The United States is accelerating its efforts through the Department of Energy's Hydrogen Shot initiative, which aims to reduce clean hydrogen costs by 80% within a decade. Several pilot projects along the East and West coasts are exploring offshore wind-hydrogen synergies.

Current technology readiness levels (TRLs) vary across the integration chain. While offshore wind technology is relatively mature (TRL 8-9), offshore electrolysis systems remain at demonstration phase (TRL 6-7). Integrated systems combining both technologies are still in early pilot stages (TRL 4-5), indicating significant room for technological advancement before commercial-scale deployment becomes widespread.

Current Integration Solutions and Architectures

01 Offshore wind-hydrogen integrated systems

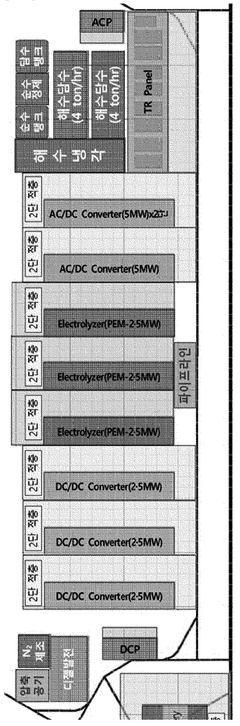

Integrated systems that combine offshore wind power generation with hydrogen production facilities. These systems utilize excess electricity from wind turbines to power electrolyzers that split water into hydrogen and oxygen. The integration allows for efficient energy conversion and storage, helping to address the intermittency issues of wind power while producing green hydrogen that can be transported to shore or used for various applications.- Offshore wind-hydrogen integrated systems: Integrated systems that combine offshore wind farms with hydrogen production facilities enable direct conversion of wind energy to green hydrogen. These systems typically include wind turbines, electrolyzers, hydrogen storage, and transportation infrastructure designed to operate in marine environments. The integration optimizes energy utilization by converting excess wind power to hydrogen during peak production periods, addressing intermittency issues of renewable energy sources.

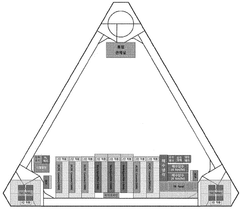

- Floating platforms for combined wind and hydrogen production: Specialized floating platforms designed to house both wind turbines and hydrogen production equipment enable offshore green hydrogen generation in deep waters. These platforms incorporate stabilization systems to withstand marine conditions while supporting electrolysis operations. The floating design allows for deployment in locations with optimal wind resources regardless of water depth, and can include integrated storage solutions for the produced hydrogen.

- Hydrogen storage and transportation from offshore facilities: Systems for storing and transporting hydrogen produced at offshore wind facilities include specialized containers, pipeline networks, and carrier vessels. These solutions address the challenges of safely storing hydrogen in marine environments and efficiently transporting it to shore or directly to end users. Some systems incorporate compression or liquefaction technologies to increase storage density, while others utilize chemical carriers like ammonia or liquid organic hydrogen carriers.

- Grid-independent offshore energy systems: Self-contained offshore energy systems that operate independently from the mainland electrical grid combine wind power generation with hydrogen production as an energy storage medium. These systems can power remote offshore operations or island communities without requiring undersea power cables. The hydrogen produced serves as both energy storage and exportable fuel, providing flexibility in energy management and creating additional revenue streams beyond electricity sales.

- Seawater electrolysis for offshore hydrogen production: Specialized electrolysis systems designed to use seawater as a feedstock for hydrogen production at offshore wind facilities eliminate the need to transport fresh water to remote locations. These systems incorporate filtration and desalination technologies to prepare seawater for electrolysis, along with corrosion-resistant materials suitable for the marine environment. Some designs integrate with cooling systems that utilize seawater to improve overall efficiency of the hydrogen production process.

02 Floating platforms for combined wind and hydrogen production

Specialized floating structures designed to support both wind turbines and hydrogen production equipment in deep-sea environments. These platforms enable the deployment of renewable energy systems in locations with optimal wind conditions that are too deep for fixed foundations. The floating platforms incorporate stabilization systems, hydrogen storage solutions, and may include facilities for hydrogen compression or liquefaction to facilitate transportation.Expand Specific Solutions03 Hydrogen storage and transportation from offshore facilities

Methods and systems for storing hydrogen produced offshore and transporting it to onshore facilities. This includes technologies for hydrogen compression, liquefaction, or conversion to carrier compounds like ammonia or liquid organic hydrogen carriers. The systems may incorporate pipelines, specialized vessels, or containerized solutions to efficiently move the produced hydrogen to end-users while maintaining safety and minimizing losses.Expand Specific Solutions04 Control systems for optimizing offshore wind-hydrogen production

Advanced control and management systems that optimize the operation of integrated offshore wind and hydrogen production facilities. These systems balance power distribution between grid export and hydrogen production based on electricity demand, grid conditions, and hydrogen market prices. They incorporate predictive algorithms, real-time monitoring, and automated decision-making to maximize efficiency and economic returns while ensuring system stability and safety.Expand Specific Solutions05 Grid integration and energy management for offshore hydrogen systems

Technologies that enable the integration of offshore wind-hydrogen systems with existing power grids and energy markets. These solutions address challenges related to grid stability, power quality, and market participation. They include power electronics for grid connection, energy management systems that respond to market signals, and hybrid approaches that combine hydrogen production with battery storage or other technologies to provide grid services while producing clean hydrogen.Expand Specific Solutions

Leading Companies and Competitive Landscape

The offshore wind and green hydrogen integration market is in an early growth phase, characterized by increasing commercial deployments following successful pilot projects. The global market is projected to reach significant scale by 2030, driven by decarbonization targets and energy security concerns. Technologically, the field is advancing rapidly with varying maturity levels across the value chain. Leading players include Siemens Energy, which offers integrated solutions combining wind turbines and electrolyzers; RWE, developing large-scale offshore wind-hydrogen projects; and oil majors like CNOOC and Saudi Aramco diversifying into this space. Academic institutions (Zhejiang University, Dalian University of Technology) are advancing fundamental research, while specialized firms like Aker Solutions and ABB provide critical system integration expertise. The ecosystem reflects a mix of established energy companies and new entrants collaborating to overcome technical and economic challenges.

Siemens Gamesa Renewable Energy AS

Technical Solution: Siemens Gamesa has developed an integrated offshore wind-to-hydrogen solution called "SG 14-222 DD + Electrolysis" that combines their 14MW offshore wind turbines with scalable electrolyzer systems. Their approach features direct integration of electrolyzers with wind turbines, eliminating the need for grid connection and reducing transmission losses. The system incorporates advanced power electronics to handle the variable power output from wind turbines, enabling efficient hydrogen production even during fluctuating wind conditions. Their solution includes a modular design that allows for scalable hydrogen production capacity from megawatt to gigawatt scale, with integrated storage solutions to manage intermittency. Siemens Gamesa's technology also features advanced control systems that optimize hydrogen production based on wind forecasts, electricity prices, and hydrogen demand patterns, maximizing operational efficiency and economic returns.

Strengths: Vertical integration capabilities combining wind turbine expertise with hydrogen production technology; established global supply chain and manufacturing infrastructure; proven track record in offshore wind deployment. Weaknesses: Higher initial capital costs compared to conventional energy systems; technology still in early commercial deployment phase; dependence on favorable regulatory frameworks for large-scale adoption.

RWE Offshore Wind GmbH

Technical Solution: RWE Offshore Wind has pioneered the AquaVentus initiative, a comprehensive offshore wind-to-hydrogen ecosystem in the North Sea. Their technical approach involves deploying dedicated offshore wind farms with integrated hydrogen production facilities, utilizing a network of hydrogen pipelines to transport the green hydrogen to shore. The system incorporates advanced PEM (Proton Exchange Membrane) electrolyzers specifically designed to handle the dynamic power output from offshore wind farms. RWE's solution features innovative offshore platforms that house both electrical equipment and hydrogen production facilities, optimizing space utilization and reducing infrastructure costs. Their technology includes sophisticated control systems that balance hydrogen production with grid demands, allowing for flexible operation based on market conditions. RWE has also developed specialized offshore hydrogen storage solutions to manage production fluctuations and ensure consistent supply to customers.

Strengths: Extensive experience in developing and operating large-scale offshore wind projects; strong financial capacity to support capital-intensive hydrogen projects; established relationships with industrial hydrogen consumers. Weaknesses: Limited experience with hydrogen production at commercial scale; challenges in developing cost-effective offshore hydrogen transport infrastructure; higher production costs compared to conventional hydrogen.

Key Patents and Innovations in Offshore Electrolysis

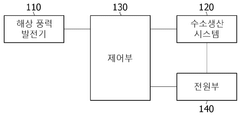

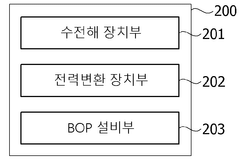

Offshore green hydrogen production system integrated with floating offshore wind power

PatentWO2025058260A1

Innovation

- A floating offshore wind power integrated marine green hydrogen production system, which includes an offshore wind generator, a hydrogen production system using seawater, a controller for system management, and a power supply unit to convert and distribute energy efficiently.

Economic Feasibility and Cost Reduction Pathways

The economic feasibility of integrating offshore wind with large-scale green hydrogen production remains a significant challenge despite the promising environmental benefits. Current levelized cost of hydrogen (LCOH) from offshore wind-powered electrolysis ranges between $4-6/kg, substantially higher than conventional grey hydrogen production methods ($1-2/kg). This cost differential presents a major barrier to widespread commercial adoption without policy support or carbon pricing mechanisms.

Capital expenditure represents approximately 60-70% of total costs in offshore wind-hydrogen systems. Electrolyzers account for 30-40% of initial investment, while offshore wind infrastructure contributes 45-55%. Balance of plant components, including compression, storage, and transmission systems, comprise the remaining 15-20% of capital costs. Operating expenses, though lower than capital costs, include significant maintenance requirements due to the harsh marine environment.

Several cost reduction pathways show promise for improving economic viability. Technological advancements in electrolyzer efficiency could reduce electricity consumption from current 50-55 kWh/kg H₂ to theoretical minimums closer to 39 kWh/kg H₂. Manufacturing scale-up is expected to reduce electrolyzer costs by 60-75% by 2030 through economies of scale and learning curve effects.

Offshore wind costs continue to decline through larger turbine sizes, improved capacity factors, and optimized installation techniques. Integration synergies offer additional savings through shared infrastructure, reduced curtailment, and optimized system design. Co-location of production facilities can eliminate costly transmission infrastructure while enabling more consistent hydrogen production.

Policy mechanisms will play a crucial role in bridging the economic gap during early market development. Carbon pricing, production tax credits, and hydrogen-specific incentives can significantly improve project economics. The EU Hydrogen Strategy and various national hydrogen roadmaps have established frameworks for such support mechanisms, though implementation remains inconsistent across regions.

Achieving cost parity with conventional hydrogen production methods will likely require a combination of technological improvements, scale economies, and supportive policy frameworks. Analysis suggests that under favorable conditions, green hydrogen from offshore wind could reach $2-3/kg by 2030 and potentially approach $1.5-2/kg by 2040, making it competitive with both blue and grey hydrogen production methods.

Capital expenditure represents approximately 60-70% of total costs in offshore wind-hydrogen systems. Electrolyzers account for 30-40% of initial investment, while offshore wind infrastructure contributes 45-55%. Balance of plant components, including compression, storage, and transmission systems, comprise the remaining 15-20% of capital costs. Operating expenses, though lower than capital costs, include significant maintenance requirements due to the harsh marine environment.

Several cost reduction pathways show promise for improving economic viability. Technological advancements in electrolyzer efficiency could reduce electricity consumption from current 50-55 kWh/kg H₂ to theoretical minimums closer to 39 kWh/kg H₂. Manufacturing scale-up is expected to reduce electrolyzer costs by 60-75% by 2030 through economies of scale and learning curve effects.

Offshore wind costs continue to decline through larger turbine sizes, improved capacity factors, and optimized installation techniques. Integration synergies offer additional savings through shared infrastructure, reduced curtailment, and optimized system design. Co-location of production facilities can eliminate costly transmission infrastructure while enabling more consistent hydrogen production.

Policy mechanisms will play a crucial role in bridging the economic gap during early market development. Carbon pricing, production tax credits, and hydrogen-specific incentives can significantly improve project economics. The EU Hydrogen Strategy and various national hydrogen roadmaps have established frameworks for such support mechanisms, though implementation remains inconsistent across regions.

Achieving cost parity with conventional hydrogen production methods will likely require a combination of technological improvements, scale economies, and supportive policy frameworks. Analysis suggests that under favorable conditions, green hydrogen from offshore wind could reach $2-3/kg by 2030 and potentially approach $1.5-2/kg by 2040, making it competitive with both blue and grey hydrogen production methods.

Regulatory Framework and Policy Incentives

The regulatory landscape for integrating offshore wind with large-scale green hydrogen production is evolving rapidly across different jurisdictions. In the European Union, the Renewable Energy Directive (RED II) and the European Green Deal provide foundational frameworks that support this integration, establishing targets for renewable hydrogen production and creating mechanisms for cross-border cooperation. These regulations are complemented by the EU Hydrogen Strategy, which aims to install at least 40GW of renewable hydrogen electrolyzers by 2030, with specific provisions for offshore wind integration.

In the United States, the Inflation Reduction Act of 2022 has introduced significant tax incentives for clean hydrogen production, offering up to $3 per kilogram for green hydrogen with the lowest carbon intensity. This is coupled with the Offshore Wind Development regulatory framework, which streamlines permitting processes for projects that combine offshore wind farms with hydrogen production facilities.

Financial incentives play a crucial role in accelerating technology adoption. Several countries have implemented direct subsidies for green hydrogen projects, particularly those utilizing offshore wind energy. For instance, Germany's H2Global initiative provides a €900 million funding mechanism specifically designed to bridge the cost gap between green hydrogen production and market prices, with preferential treatment for offshore wind-hydrogen integration projects.

Carbon pricing mechanisms are increasingly being leveraged to enhance the economic viability of green hydrogen from offshore wind. The EU Emissions Trading System (ETS) and similar schemes in other regions create economic advantages for low-carbon technologies by imposing costs on fossil fuel alternatives. Recent reforms to these systems have strengthened price signals, making green hydrogen more competitive against conventional hydrogen production methods.

Regulatory sandboxes have emerged as innovative policy tools to facilitate technological experimentation. Countries including the UK, Denmark, and the Netherlands have established special regulatory zones where integrated offshore wind and hydrogen projects can operate under modified rules, allowing developers to test novel business models and technical configurations without facing the full burden of existing regulations.

International standardization efforts are also underway to address technical barriers. Organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are developing standards for hydrogen production, storage, and transport that specifically consider the unique characteristics of offshore wind-hydrogen systems, facilitating global market development and technology transfer.

In the United States, the Inflation Reduction Act of 2022 has introduced significant tax incentives for clean hydrogen production, offering up to $3 per kilogram for green hydrogen with the lowest carbon intensity. This is coupled with the Offshore Wind Development regulatory framework, which streamlines permitting processes for projects that combine offshore wind farms with hydrogen production facilities.

Financial incentives play a crucial role in accelerating technology adoption. Several countries have implemented direct subsidies for green hydrogen projects, particularly those utilizing offshore wind energy. For instance, Germany's H2Global initiative provides a €900 million funding mechanism specifically designed to bridge the cost gap between green hydrogen production and market prices, with preferential treatment for offshore wind-hydrogen integration projects.

Carbon pricing mechanisms are increasingly being leveraged to enhance the economic viability of green hydrogen from offshore wind. The EU Emissions Trading System (ETS) and similar schemes in other regions create economic advantages for low-carbon technologies by imposing costs on fossil fuel alternatives. Recent reforms to these systems have strengthened price signals, making green hydrogen more competitive against conventional hydrogen production methods.

Regulatory sandboxes have emerged as innovative policy tools to facilitate technological experimentation. Countries including the UK, Denmark, and the Netherlands have established special regulatory zones where integrated offshore wind and hydrogen projects can operate under modified rules, allowing developers to test novel business models and technical configurations without facing the full burden of existing regulations.

International standardization efforts are also underway to address technical barriers. Organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are developing standards for hydrogen production, storage, and transport that specifically consider the unique characteristics of offshore wind-hydrogen systems, facilitating global market development and technology transfer.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!