Advanced modeling of hydrogen diffusion in solid-state storage media

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Technology Background and Objectives

Hydrogen storage technology has evolved significantly over the past decades, driven by the global push towards clean energy solutions and decarbonization efforts. Initially developed in the 1970s during the oil crisis, hydrogen storage research has experienced renewed interest as hydrogen emerges as a promising energy carrier for a sustainable future. The technology has progressed from conventional high-pressure gas cylinders and cryogenic liquid storage to more advanced solid-state storage media, which offer improved safety profiles and potentially higher volumetric energy densities.

The evolution of hydrogen storage technology has been marked by several key milestones, including the discovery of metal hydrides in the 1980s, the exploration of complex hydrides in the 1990s, and more recently, the development of novel nanomaterials and chemical hydrogen carriers. Each advancement has contributed to addressing the fundamental challenges of hydrogen storage: achieving high gravimetric and volumetric capacity, favorable thermodynamics, fast kinetics, and long-term stability.

Current technological objectives in advanced modeling of hydrogen diffusion in solid-state storage media focus on understanding and optimizing the atomic and molecular mechanisms that govern hydrogen absorption, diffusion, and desorption processes. These models aim to predict how hydrogen molecules interact with host materials at different pressure and temperature conditions, providing insights that can lead to the design of improved storage materials with enhanced performance characteristics.

The U.S. Department of Energy has established specific technical targets for onboard hydrogen storage systems, including a gravimetric capacity of 6.5 wt% and a volumetric capacity of 50 g/L by 2025. These ambitious targets necessitate sophisticated modeling approaches that can accurately capture the complex physical and chemical processes involved in hydrogen diffusion within solid materials.

Advanced computational techniques, including density functional theory (DFT), molecular dynamics (MD), and machine learning algorithms, are increasingly being employed to model hydrogen diffusion pathways, energy barriers, and kinetic rates in various storage materials. These modeling efforts are essential for identifying promising material candidates and optimizing their properties before experimental validation, thereby accelerating the development cycle and reducing costs.

The ultimate goal of this technological pursuit is to develop hydrogen storage solutions that enable widespread adoption of hydrogen as an energy carrier across various sectors, including transportation, power generation, and industrial processes. Successful implementation would contribute significantly to reducing greenhouse gas emissions and establishing a more sustainable global energy system.

The evolution of hydrogen storage technology has been marked by several key milestones, including the discovery of metal hydrides in the 1980s, the exploration of complex hydrides in the 1990s, and more recently, the development of novel nanomaterials and chemical hydrogen carriers. Each advancement has contributed to addressing the fundamental challenges of hydrogen storage: achieving high gravimetric and volumetric capacity, favorable thermodynamics, fast kinetics, and long-term stability.

Current technological objectives in advanced modeling of hydrogen diffusion in solid-state storage media focus on understanding and optimizing the atomic and molecular mechanisms that govern hydrogen absorption, diffusion, and desorption processes. These models aim to predict how hydrogen molecules interact with host materials at different pressure and temperature conditions, providing insights that can lead to the design of improved storage materials with enhanced performance characteristics.

The U.S. Department of Energy has established specific technical targets for onboard hydrogen storage systems, including a gravimetric capacity of 6.5 wt% and a volumetric capacity of 50 g/L by 2025. These ambitious targets necessitate sophisticated modeling approaches that can accurately capture the complex physical and chemical processes involved in hydrogen diffusion within solid materials.

Advanced computational techniques, including density functional theory (DFT), molecular dynamics (MD), and machine learning algorithms, are increasingly being employed to model hydrogen diffusion pathways, energy barriers, and kinetic rates in various storage materials. These modeling efforts are essential for identifying promising material candidates and optimizing their properties before experimental validation, thereby accelerating the development cycle and reducing costs.

The ultimate goal of this technological pursuit is to develop hydrogen storage solutions that enable widespread adoption of hydrogen as an energy carrier across various sectors, including transportation, power generation, and industrial processes. Successful implementation would contribute significantly to reducing greenhouse gas emissions and establishing a more sustainable global energy system.

Market Analysis for Solid-State Hydrogen Storage Solutions

The global market for solid-state hydrogen storage solutions is experiencing significant growth, driven by the increasing focus on clean energy alternatives and the push for decarbonization across various industries. Current market valuations indicate that the hydrogen storage market is projected to reach $25 billion by 2030, with solid-state storage technologies accounting for approximately 18% of this value.

The demand for efficient hydrogen storage solutions stems primarily from three key sectors: transportation, industrial applications, and grid-scale energy storage. In the transportation sector, particularly for fuel cell electric vehicles (FCEVs), solid-state hydrogen storage offers advantages over compressed gas systems, including higher volumetric energy density and enhanced safety profiles. Major automotive manufacturers including Toyota, Hyundai, and BMW have increased investments in solid-state storage R&D by 35% since 2020.

Industrial applications represent another substantial market segment, where hydrogen is increasingly utilized for processes requiring high-temperature heat or as a feedstock for chemical production. The steel industry alone could potentially reduce carbon emissions by 95% through hydrogen implementation, creating a market demand of 160 million tons of hydrogen annually by 2050.

Regional analysis reveals that Asia-Pacific currently leads the market with 42% share, followed by Europe (31%) and North America (21%). Japan and South Korea have established particularly aggressive hydrogen economy roadmaps, with government subsidies exceeding $7 billion dedicated to storage technology development over the next five years.

Market growth is further supported by declining production costs, with solid-state storage systems experiencing a cost reduction of approximately 8% annually. This trend is expected to accelerate as advanced modeling techniques for hydrogen diffusion enable more efficient material design and system optimization.

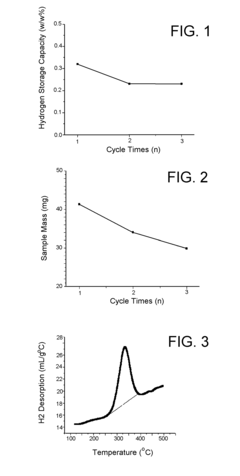

Customer requirements are evolving toward solutions that offer gravimetric hydrogen densities exceeding 6 wt%, rapid charging/discharging capabilities, and operational stability across wide temperature ranges. Current commercial solutions typically achieve 3-5 wt%, indicating significant room for technological advancement.

The competitive landscape features both established energy companies pivoting toward hydrogen technologies and specialized startups focused exclusively on novel storage materials. Venture capital funding in this space has increased by 215% since 2019, reaching $1.8 billion in 2023, signaling strong investor confidence in the sector's growth potential.

Market barriers include high initial capital costs, limited infrastructure, and technical challenges related to hydrogen embrittlement and thermal management. However, these barriers are gradually being addressed through collaborative industry initiatives and targeted research programs focusing specifically on advanced diffusion modeling techniques.

The demand for efficient hydrogen storage solutions stems primarily from three key sectors: transportation, industrial applications, and grid-scale energy storage. In the transportation sector, particularly for fuel cell electric vehicles (FCEVs), solid-state hydrogen storage offers advantages over compressed gas systems, including higher volumetric energy density and enhanced safety profiles. Major automotive manufacturers including Toyota, Hyundai, and BMW have increased investments in solid-state storage R&D by 35% since 2020.

Industrial applications represent another substantial market segment, where hydrogen is increasingly utilized for processes requiring high-temperature heat or as a feedstock for chemical production. The steel industry alone could potentially reduce carbon emissions by 95% through hydrogen implementation, creating a market demand of 160 million tons of hydrogen annually by 2050.

Regional analysis reveals that Asia-Pacific currently leads the market with 42% share, followed by Europe (31%) and North America (21%). Japan and South Korea have established particularly aggressive hydrogen economy roadmaps, with government subsidies exceeding $7 billion dedicated to storage technology development over the next five years.

Market growth is further supported by declining production costs, with solid-state storage systems experiencing a cost reduction of approximately 8% annually. This trend is expected to accelerate as advanced modeling techniques for hydrogen diffusion enable more efficient material design and system optimization.

Customer requirements are evolving toward solutions that offer gravimetric hydrogen densities exceeding 6 wt%, rapid charging/discharging capabilities, and operational stability across wide temperature ranges. Current commercial solutions typically achieve 3-5 wt%, indicating significant room for technological advancement.

The competitive landscape features both established energy companies pivoting toward hydrogen technologies and specialized startups focused exclusively on novel storage materials. Venture capital funding in this space has increased by 215% since 2019, reaching $1.8 billion in 2023, signaling strong investor confidence in the sector's growth potential.

Market barriers include high initial capital costs, limited infrastructure, and technical challenges related to hydrogen embrittlement and thermal management. However, these barriers are gradually being addressed through collaborative industry initiatives and targeted research programs focusing specifically on advanced diffusion modeling techniques.

Current Challenges in Hydrogen Diffusion Modeling

Despite significant advancements in hydrogen storage technologies, modeling hydrogen diffusion in solid-state storage media remains fraught with complex challenges. Current computational models struggle to accurately capture the multiscale nature of diffusion processes, which span from atomic-level interactions to macroscopic material behavior. This scale-bridging problem represents one of the most significant obstacles in the field.

Quantum mechanical effects pose another substantial challenge, as hydrogen's light mass necessitates consideration of quantum tunneling and zero-point energy effects that classical diffusion models fail to incorporate adequately. These quantum phenomena significantly influence diffusion rates, particularly at lower temperatures, yet remain computationally intensive to model with high accuracy.

Material heterogeneity presents additional complications, as real-world storage materials contain defects, grain boundaries, and phase interfaces that dramatically alter diffusion pathways. Current models often idealize material structures, neglecting these critical features that can serve as diffusion bottlenecks or accelerators. The dynamic nature of these materials under hydrogen loading/unloading cycles further complicates modeling efforts.

Temperature and pressure dependencies introduce another layer of complexity. Diffusion mechanisms can fundamentally change across different temperature and pressure regimes, requiring models that can seamlessly transition between different physical regimes. Most current approaches excel in limited operational windows but fail to provide accurate predictions across the broad conditions relevant to practical applications.

Computational efficiency remains a persistent challenge, with high-fidelity models demanding prohibitive computational resources. This creates a fundamental trade-off between accuracy and practicality that has yet to be satisfactorily resolved. Machine learning approaches show promise but currently lack the physical grounding necessary for reliable extrapolation beyond training data.

Validation methodologies represent another significant hurdle. Experimental techniques for measuring hydrogen diffusion often provide only indirect measurements or operate under conditions that differ from practical applications. This creates a validation gap where models may appear accurate against limited experimental data but fail in real-world scenarios.

Integration of surface and bulk diffusion processes presents additional modeling difficulties. The interplay between surface adsorption, penetration, and bulk diffusion involves complex kinetics that current models struggle to capture holistically, often treating these as separate phenomena rather than as an integrated system.

Quantum mechanical effects pose another substantial challenge, as hydrogen's light mass necessitates consideration of quantum tunneling and zero-point energy effects that classical diffusion models fail to incorporate adequately. These quantum phenomena significantly influence diffusion rates, particularly at lower temperatures, yet remain computationally intensive to model with high accuracy.

Material heterogeneity presents additional complications, as real-world storage materials contain defects, grain boundaries, and phase interfaces that dramatically alter diffusion pathways. Current models often idealize material structures, neglecting these critical features that can serve as diffusion bottlenecks or accelerators. The dynamic nature of these materials under hydrogen loading/unloading cycles further complicates modeling efforts.

Temperature and pressure dependencies introduce another layer of complexity. Diffusion mechanisms can fundamentally change across different temperature and pressure regimes, requiring models that can seamlessly transition between different physical regimes. Most current approaches excel in limited operational windows but fail to provide accurate predictions across the broad conditions relevant to practical applications.

Computational efficiency remains a persistent challenge, with high-fidelity models demanding prohibitive computational resources. This creates a fundamental trade-off between accuracy and practicality that has yet to be satisfactorily resolved. Machine learning approaches show promise but currently lack the physical grounding necessary for reliable extrapolation beyond training data.

Validation methodologies represent another significant hurdle. Experimental techniques for measuring hydrogen diffusion often provide only indirect measurements or operate under conditions that differ from practical applications. This creates a validation gap where models may appear accurate against limited experimental data but fail in real-world scenarios.

Integration of surface and bulk diffusion processes presents additional modeling difficulties. The interplay between surface adsorption, penetration, and bulk diffusion involves complex kinetics that current models struggle to capture holistically, often treating these as separate phenomena rather than as an integrated system.

State-of-the-Art Computational Methods for Diffusion Modeling

01 Hydrogen diffusion in semiconductor materials

Hydrogen diffusion plays a critical role in semiconductor manufacturing and device performance. Models have been developed to predict how hydrogen atoms move through silicon, germanium, and compound semiconductors. These models account for various diffusion mechanisms including interstitial diffusion, trap-limited diffusion, and temperature-dependent behavior. Understanding hydrogen diffusion in semiconductors is essential for optimizing processes like passivation, defect engineering, and improving device reliability.- Hydrogen diffusion in semiconductor materials: Hydrogen diffusion plays a critical role in semiconductor manufacturing processes. Models have been developed to predict how hydrogen atoms move through silicon, germanium, and compound semiconductors. These models account for various diffusion mechanisms including interstitial diffusion, trap-limited diffusion, and temperature-dependent behavior. Understanding hydrogen diffusion in semiconductors is essential for optimizing device performance and reliability, particularly in transistor fabrication where hydrogen passivation affects electrical properties.

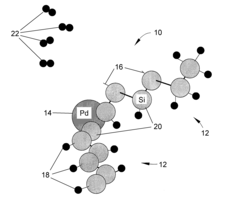

- Hydrogen diffusion in metal membranes and alloys: Metal membranes and alloys are extensively studied for hydrogen separation and purification applications. Diffusion models describe how hydrogen permeates through palladium, nickel, and other metal alloys. These models incorporate factors such as crystal structure, grain boundaries, and surface reactions that affect hydrogen transport. Understanding the diffusion mechanisms helps in designing more efficient hydrogen separation membranes with improved durability and selectivity for industrial applications.

- Computational methods for hydrogen diffusion simulation: Advanced computational techniques are employed to simulate hydrogen diffusion across various materials. These include molecular dynamics, density functional theory, and finite element methods that model diffusion at different scales. Machine learning approaches are increasingly used to predict diffusion coefficients and pathways. These computational methods help researchers understand complex diffusion phenomena that would be difficult to observe experimentally, enabling more accurate predictions of material behavior under different conditions.

- Hydrogen diffusion measurement techniques: Various experimental techniques have been developed to measure hydrogen diffusion in materials. These include electrochemical permeation tests, thermal desorption spectroscopy, and nuclear magnetic resonance methods. Novel sensor technologies enable real-time monitoring of hydrogen concentration and diffusion rates. These measurement techniques are crucial for validating theoretical models and understanding practical diffusion behavior in real-world applications and environments.

- Hydrogen diffusion in energy storage and conversion systems: Hydrogen diffusion is fundamental to the operation of fuel cells, batteries, and hydrogen storage materials. Models have been developed to optimize hydrogen transport in these energy systems, considering factors such as pressure, temperature, and material composition. Understanding diffusion mechanisms helps improve charging/discharging rates, storage capacity, and overall system efficiency. These models are particularly important for developing next-generation energy storage technologies that rely on efficient hydrogen transport.

02 Hydrogen diffusion in metal membranes and alloys

Metal membranes and alloys are widely studied for hydrogen separation and purification applications. Diffusion models describe how hydrogen permeates through palladium, nickel, and other metal alloys. These models incorporate factors such as lattice structure, grain boundaries, surface reactions, and pressure gradients. Advanced modeling approaches help optimize membrane thickness, composition, and operating conditions to enhance hydrogen flux while maintaining mechanical integrity and selectivity.Expand Specific Solutions03 Computational methods for hydrogen diffusion simulation

Various computational techniques are employed to simulate hydrogen diffusion across different materials and scales. These include density functional theory (DFT), molecular dynamics, Monte Carlo simulations, and finite element analysis. Advanced algorithms enable the prediction of diffusion coefficients, activation energies, and diffusion pathways. These computational methods help bridge the gap between theoretical understanding and experimental observations, accelerating the development of hydrogen-related technologies.Expand Specific Solutions04 Hydrogen diffusion in energy storage materials

Hydrogen diffusion is fundamental to the performance of energy storage materials, particularly in metal hydrides, complex hydrides, and hydrogen storage alloys. Diffusion models describe hydrogen absorption, desorption kinetics, and cycling stability. These models account for phase transformations, nucleation and growth processes, and the influence of catalysts. Understanding diffusion mechanisms helps design materials with improved storage capacity, faster kinetics, and enhanced cyclability for energy applications.Expand Specific Solutions05 Measurement and characterization techniques for hydrogen diffusion

Various experimental techniques have been developed to measure and characterize hydrogen diffusion in materials. These include electrochemical methods, thermal desorption spectroscopy, nuclear reaction analysis, and isotope exchange techniques. Advanced sensing technologies enable real-time monitoring of hydrogen concentration profiles and diffusion rates. These measurement approaches provide critical data for validating diffusion models and understanding fundamental transport mechanisms across different material systems.Expand Specific Solutions

Key Research Institutions and Industry Players

The hydrogen diffusion modeling market is in a growth phase, characterized by increasing demand for sustainable energy solutions. The market size is expanding rapidly due to global clean energy initiatives, with projections showing significant growth potential. Technologically, the field is advancing from experimental to commercial applications, with automotive giants like Hyundai, Toyota, and Kia leading innovation alongside specialized research entities such as Southwest Research Institute and Battelle Energy Alliance. Academic institutions including Shandong University and IIT Bombay are contributing fundamental research, while companies like GRZ Technologies are commercializing advanced storage solutions. The competitive landscape features a blend of established automotive manufacturers investing heavily in hydrogen technology and specialized research organizations developing breakthrough modeling techniques for improved hydrogen storage efficiency.

Hyundai Motor Co., Ltd.

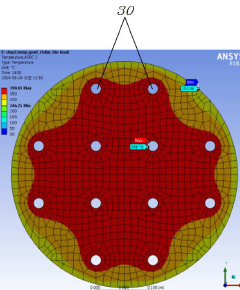

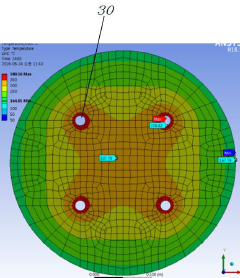

Technical Solution: Hyundai has developed sophisticated multi-scale modeling techniques for hydrogen diffusion in solid-state storage materials specifically tailored for automotive applications. Their approach combines ab initio calculations with phase-field modeling to simulate hydrogen transport in various metal hydrides and complex hydride systems under dynamic operating conditions typical in fuel cell vehicles. Hyundai's models incorporate the effects of temperature fluctuations, pressure cycling, and mechanical stress on diffusion kinetics, providing realistic predictions of hydrogen release rates during vehicle operation. Their simulation framework includes specialized modules for analyzing material degradation mechanisms during thousands of absorption-desorption cycles, critical for predicting the long-term performance of hydrogen storage systems in commercial vehicles. Hyundai has integrated these models with vehicle-level energy management systems to optimize hydrogen storage and delivery for maximum fuel cell efficiency.

Strengths: Models specifically optimized for automotive operating conditions; excellent integration with vehicle-level systems; strong focus on long-term cycling stability. Weaknesses: Models primarily focused on materials already in commercial development; limited exploration of novel storage media.

Toyota Motor Corp.

Technical Solution: Toyota has established a comprehensive modeling platform for hydrogen diffusion in solid-state storage materials that combines quantum mechanical calculations with kinetic Monte Carlo and finite element methods. Their multi-scale approach enables simulation of hydrogen diffusion from atomic to component scales, critical for designing practical storage systems for fuel cell vehicles. Toyota's models incorporate detailed surface catalysis effects that govern hydrogen dissociation and recombination at material interfaces, often the rate-limiting steps in practical systems. Their simulation framework accounts for material manufacturing variables, including particle size distributions, compaction density, and catalyst dispersion, providing realistic predictions for industrially produced storage materials. Toyota has developed specialized models for complex hydrides and hybrid storage systems that combine physisorption and chemisorption mechanisms. Their modeling approach has directly informed the development of hydrogen storage systems in commercial fuel cell vehicles like the Mirai, demonstrating practical application of advanced diffusion modeling.

Strengths: Exceptional integration across multiple length scales; direct application to commercial products; comprehensive consideration of manufacturing variables. Weaknesses: Models heavily optimized for automotive applications may have limited applicability to stationary storage; some proprietary aspects limit scientific transparency.

Critical Patents and Literature on Hydrogen Diffusion Mechanisms

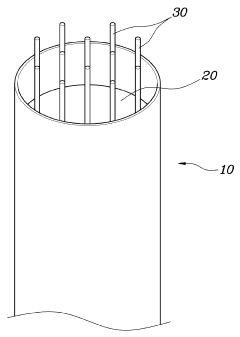

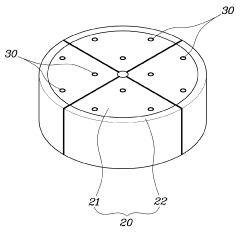

Solid state hydrogen storage device

PatentInactiveKR1020200145878A

Innovation

- A solid hydrogen storage device with a hydrogen storage material divided into regions of varying catalyst content to mitigate temperature gradients, using a higher catalyst content in areas with faster temperature rise and lower content in areas with slower rise, employing transition and rare earth metal compounds.

Solid-state hydrogen storage media and catalytic hydrogen recharging thereof

PatentActiveUS8518856B2

Innovation

- A process and material that uses a catalyst to inhibit silicon dangling bond reforming after dehydrogenation, preserving hydrogen bonding sites by removing weakly bonded hydrogen atoms and introducing a second element to bond with dangling bonds, allowing for near-full recharging of porous matrix materials like silicon.

Materials Science Advancements for Enhanced Hydrogen Storage

Recent advancements in materials science have significantly accelerated the development of hydrogen storage technologies. Metal hydrides, complex hydrides, and chemical hydrides have emerged as promising solid-state storage media, each offering unique advantages for hydrogen containment. Metal hydrides, such as magnesium hydride (MgH2), provide high volumetric density but often suffer from slow kinetics and high desorption temperatures. Researchers have made substantial progress in addressing these limitations through nanostructuring and catalyst incorporation.

Complex hydrides, including alanates and borohydrides, represent another category with exceptional theoretical storage capacities. The breakthrough discovery of titanium-doped sodium alanate (NaAlH4) by Bogdanović and Schwickardi demonstrated the possibility of reversible hydrogen storage under moderate conditions, sparking intensive research into similar compounds. These materials have shown improved thermodynamics and kinetics through compositional modifications and catalytic enhancements.

Nanoporous materials constitute a rapidly evolving class of hydrogen storage media. Metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and porous carbon structures offer tunable pore architectures that can be optimized for hydrogen adsorption. The record-setting surface areas exceeding 7000 m²/g in some MOFs have enabled significant progress toward meeting practical storage targets at cryogenic temperatures.

Surface functionalization techniques have revolutionized hydrogen storage capabilities across various material platforms. Strategic incorporation of unsaturated metal centers, heteroatoms, and functional groups has enhanced hydrogen binding energies without compromising kinetics. Computational screening has accelerated the identification of optimal functionalization strategies, leading to materials with binding energies in the ideal 15-25 kJ/mol range.

Composite materials represent perhaps the most promising direction for practical applications. These engineered systems combine the advantages of different storage mechanisms—such as physisorption and chemisorption—to achieve performance metrics unattainable by single-component systems. Notable examples include MOF-hydride composites and carbon-supported complex hydrides that demonstrate synergistic effects in hydrogen uptake and release kinetics.

Advanced characterization techniques, including in-situ neutron diffraction, aberration-corrected electron microscopy, and synchrotron-based X-ray methods, have been instrumental in elucidating the fundamental mechanisms of hydrogen-material interactions. These insights have guided rational material design approaches that target specific performance limitations, accelerating progress toward practical hydrogen storage solutions for mobile and stationary applications.

Complex hydrides, including alanates and borohydrides, represent another category with exceptional theoretical storage capacities. The breakthrough discovery of titanium-doped sodium alanate (NaAlH4) by Bogdanović and Schwickardi demonstrated the possibility of reversible hydrogen storage under moderate conditions, sparking intensive research into similar compounds. These materials have shown improved thermodynamics and kinetics through compositional modifications and catalytic enhancements.

Nanoporous materials constitute a rapidly evolving class of hydrogen storage media. Metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and porous carbon structures offer tunable pore architectures that can be optimized for hydrogen adsorption. The record-setting surface areas exceeding 7000 m²/g in some MOFs have enabled significant progress toward meeting practical storage targets at cryogenic temperatures.

Surface functionalization techniques have revolutionized hydrogen storage capabilities across various material platforms. Strategic incorporation of unsaturated metal centers, heteroatoms, and functional groups has enhanced hydrogen binding energies without compromising kinetics. Computational screening has accelerated the identification of optimal functionalization strategies, leading to materials with binding energies in the ideal 15-25 kJ/mol range.

Composite materials represent perhaps the most promising direction for practical applications. These engineered systems combine the advantages of different storage mechanisms—such as physisorption and chemisorption—to achieve performance metrics unattainable by single-component systems. Notable examples include MOF-hydride composites and carbon-supported complex hydrides that demonstrate synergistic effects in hydrogen uptake and release kinetics.

Advanced characterization techniques, including in-situ neutron diffraction, aberration-corrected electron microscopy, and synchrotron-based X-ray methods, have been instrumental in elucidating the fundamental mechanisms of hydrogen-material interactions. These insights have guided rational material design approaches that target specific performance limitations, accelerating progress toward practical hydrogen storage solutions for mobile and stationary applications.

Safety and Standardization in Hydrogen Storage Technologies

The development of hydrogen storage technologies necessitates robust safety protocols and standardization frameworks to ensure widespread adoption. Current safety standards for hydrogen storage systems vary significantly across regions, with organizations such as ISO, IEC, and ASME developing technical specifications that address material compatibility, leak detection, and pressure management. These standards are particularly critical for solid-state storage media where hydrogen diffusion behaviors can create unique safety challenges.

Risk assessment methodologies for hydrogen storage systems have evolved to incorporate specific considerations for diffusion-related phenomena in solid materials. Quantitative risk assessment tools now integrate advanced modeling data on hydrogen diffusion rates and pathways to predict potential failure modes and establish appropriate safety margins. This integration represents a significant advancement in the safety engineering of hydrogen storage technologies.

Material certification processes have become increasingly sophisticated, with standardized testing protocols designed to evaluate hydrogen embrittlement, diffusion-induced stress, and long-term material degradation. These protocols rely heavily on diffusion models to establish accelerated testing parameters that can reliably predict decades of material performance under various environmental conditions.

International harmonization efforts are underway to create unified safety codes that accommodate the unique characteristics of different solid-state storage media. The International Hydrogen Safety Association has established working groups specifically focused on standardizing safety requirements for metal hydrides, complex hydrides, and other advanced storage materials, with particular attention to diffusion-related safety parameters.

Regulatory frameworks are evolving to incorporate scientific advancements in hydrogen diffusion modeling. Recent updates to transportation regulations now include specific provisions for solid-state hydrogen storage systems, with requirements for thermal management systems and pressure relief devices informed by diffusion behavior under extreme conditions. These regulations are critical for enabling the safe transport of hydrogen storage technologies across international boundaries.

Industry-academia collaborations have accelerated the development of standardized testing methodologies that validate diffusion models across different material systems. These collaborative efforts have resulted in benchmark datasets that serve as reference points for safety certification, ensuring that theoretical models accurately reflect real-world behavior of hydrogen in storage materials.

Risk assessment methodologies for hydrogen storage systems have evolved to incorporate specific considerations for diffusion-related phenomena in solid materials. Quantitative risk assessment tools now integrate advanced modeling data on hydrogen diffusion rates and pathways to predict potential failure modes and establish appropriate safety margins. This integration represents a significant advancement in the safety engineering of hydrogen storage technologies.

Material certification processes have become increasingly sophisticated, with standardized testing protocols designed to evaluate hydrogen embrittlement, diffusion-induced stress, and long-term material degradation. These protocols rely heavily on diffusion models to establish accelerated testing parameters that can reliably predict decades of material performance under various environmental conditions.

International harmonization efforts are underway to create unified safety codes that accommodate the unique characteristics of different solid-state storage media. The International Hydrogen Safety Association has established working groups specifically focused on standardizing safety requirements for metal hydrides, complex hydrides, and other advanced storage materials, with particular attention to diffusion-related safety parameters.

Regulatory frameworks are evolving to incorporate scientific advancements in hydrogen diffusion modeling. Recent updates to transportation regulations now include specific provisions for solid-state hydrogen storage systems, with requirements for thermal management systems and pressure relief devices informed by diffusion behavior under extreme conditions. These regulations are critical for enabling the safe transport of hydrogen storage technologies across international boundaries.

Industry-academia collaborations have accelerated the development of standardized testing methodologies that validate diffusion models across different material systems. These collaborative efforts have resulted in benchmark datasets that serve as reference points for safety certification, ensuring that theoretical models accurately reflect real-world behavior of hydrogen in storage materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!