How hydrogen embrittlement affects pipeline materials in green hydrogen transport

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Research Objectives

Hydrogen embrittlement represents a critical challenge in the transition toward green hydrogen as a sustainable energy carrier. This phenomenon, first documented in the 1870s, occurs when hydrogen atoms penetrate metallic materials, causing unexpected mechanical degradation and potential catastrophic failures. As global initiatives accelerate toward decarbonization, hydrogen infrastructure expansion necessitates comprehensive understanding of this degradation mechanism to ensure safe and reliable transport systems.

The evolution of hydrogen embrittlement research has progressed through several distinct phases. Initial observations focused primarily on phenomenological descriptions, followed by mechanistic investigations in the mid-20th century. Recent decades have witnessed significant advancements in analytical techniques, enabling researchers to observe hydrogen-material interactions at atomic and molecular levels, thereby enhancing our fundamental understanding of embrittlement processes.

Current technological trends indicate growing interest in developing hydrogen-resistant materials and protective coatings specifically designed for pipeline applications. Computational modeling approaches have emerged as powerful tools for predicting material behavior under various hydrogen exposure conditions, complementing traditional experimental methodologies. These developments reflect the industry's recognition of hydrogen embrittlement as a critical factor in infrastructure planning.

This technical research aims to systematically evaluate how hydrogen embrittlement affects pipeline materials specifically in green hydrogen transport applications. The primary objectives include: identifying the fundamental mechanisms of hydrogen-induced degradation in common pipeline materials; assessing the influence of operating parameters (pressure, temperature, hydrogen purity) on embrittlement susceptibility; and evaluating the effectiveness of current mitigation strategies in preserving structural integrity over extended service periods.

Additionally, this research seeks to establish quantitative relationships between material properties and hydrogen embrittlement resistance, enabling more accurate prediction of component lifetimes. By analyzing the unique challenges presented by green hydrogen transport—including potential contaminants from production processes and fluctuating operational conditions—we aim to develop specialized guidelines for material selection and qualification procedures tailored to renewable hydrogen infrastructure.

The ultimate goal is to provide actionable insights that bridge current knowledge gaps and support the development of safer, more reliable hydrogen transport systems. This research will contribute to establishing technical standards and best practices essential for the widespread implementation of hydrogen as a key element in sustainable energy systems.

The evolution of hydrogen embrittlement research has progressed through several distinct phases. Initial observations focused primarily on phenomenological descriptions, followed by mechanistic investigations in the mid-20th century. Recent decades have witnessed significant advancements in analytical techniques, enabling researchers to observe hydrogen-material interactions at atomic and molecular levels, thereby enhancing our fundamental understanding of embrittlement processes.

Current technological trends indicate growing interest in developing hydrogen-resistant materials and protective coatings specifically designed for pipeline applications. Computational modeling approaches have emerged as powerful tools for predicting material behavior under various hydrogen exposure conditions, complementing traditional experimental methodologies. These developments reflect the industry's recognition of hydrogen embrittlement as a critical factor in infrastructure planning.

This technical research aims to systematically evaluate how hydrogen embrittlement affects pipeline materials specifically in green hydrogen transport applications. The primary objectives include: identifying the fundamental mechanisms of hydrogen-induced degradation in common pipeline materials; assessing the influence of operating parameters (pressure, temperature, hydrogen purity) on embrittlement susceptibility; and evaluating the effectiveness of current mitigation strategies in preserving structural integrity over extended service periods.

Additionally, this research seeks to establish quantitative relationships between material properties and hydrogen embrittlement resistance, enabling more accurate prediction of component lifetimes. By analyzing the unique challenges presented by green hydrogen transport—including potential contaminants from production processes and fluctuating operational conditions—we aim to develop specialized guidelines for material selection and qualification procedures tailored to renewable hydrogen infrastructure.

The ultimate goal is to provide actionable insights that bridge current knowledge gaps and support the development of safer, more reliable hydrogen transport systems. This research will contribute to establishing technical standards and best practices essential for the widespread implementation of hydrogen as a key element in sustainable energy systems.

Market Analysis for Green Hydrogen Transport Infrastructure

The global market for green hydrogen transport infrastructure is experiencing unprecedented growth, driven by the increasing adoption of hydrogen as a clean energy carrier. Current market valuations indicate that the green hydrogen sector is projected to reach significant market size by 2030, with transport infrastructure representing a substantial portion of this investment. The transition from traditional fossil fuel-based hydrogen to green hydrogen production has created new market demands for specialized transport solutions that can withstand hydrogen's unique properties.

Market demand analysis reveals several key sectors driving infrastructure development. The industrial sector, particularly chemical manufacturing and refining, continues to be the largest consumer of hydrogen, creating established demand pathways. Transportation applications, including hydrogen fuel cell vehicles and maritime transport, represent rapidly growing market segments requiring extensive distribution networks. Additionally, power generation and residential heating applications are emerging as potential high-growth markets for hydrogen transport infrastructure.

Regional market assessment shows Europe leading in green hydrogen infrastructure development, with Germany, the Netherlands, and the UK making substantial investments in hydrogen pipeline networks. Asia-Pacific markets, particularly Japan, South Korea, and Australia, are rapidly expanding their hydrogen transport capabilities to support export-oriented hydrogen economies. North America is experiencing accelerated growth in hydrogen infrastructure projects, particularly in California and the Gulf Coast region.

Market forecasts indicate that pipeline transport will remain the most cost-effective method for large-scale hydrogen distribution, with projected infrastructure investment requirements in the billions for major industrial corridors. The retrofitting of existing natural gas pipelines represents a significant market opportunity, though technical challenges related to hydrogen embrittlement must be addressed.

Demand drivers include increasingly stringent carbon reduction policies worldwide, with many nations implementing hydrogen strategies that specifically address transport infrastructure needs. Cost reduction trajectories for green hydrogen production are improving economic viability, while industrial decarbonization initiatives are creating anchor customers for hydrogen transport networks.

Market barriers include the significant capital expenditure required for hydrogen-specific infrastructure, regulatory uncertainties regarding pipeline standards and safety protocols, and competition from alternative energy carriers. The technical challenge of hydrogen embrittlement in pipeline materials represents a specific market constraint that is driving innovation in materials science and engineering solutions.

Customer segmentation analysis reveals diverse needs across industrial, utility, mobility, and export markets, each requiring tailored infrastructure approaches and presenting different value propositions for pipeline developers and operators.

Market demand analysis reveals several key sectors driving infrastructure development. The industrial sector, particularly chemical manufacturing and refining, continues to be the largest consumer of hydrogen, creating established demand pathways. Transportation applications, including hydrogen fuel cell vehicles and maritime transport, represent rapidly growing market segments requiring extensive distribution networks. Additionally, power generation and residential heating applications are emerging as potential high-growth markets for hydrogen transport infrastructure.

Regional market assessment shows Europe leading in green hydrogen infrastructure development, with Germany, the Netherlands, and the UK making substantial investments in hydrogen pipeline networks. Asia-Pacific markets, particularly Japan, South Korea, and Australia, are rapidly expanding their hydrogen transport capabilities to support export-oriented hydrogen economies. North America is experiencing accelerated growth in hydrogen infrastructure projects, particularly in California and the Gulf Coast region.

Market forecasts indicate that pipeline transport will remain the most cost-effective method for large-scale hydrogen distribution, with projected infrastructure investment requirements in the billions for major industrial corridors. The retrofitting of existing natural gas pipelines represents a significant market opportunity, though technical challenges related to hydrogen embrittlement must be addressed.

Demand drivers include increasingly stringent carbon reduction policies worldwide, with many nations implementing hydrogen strategies that specifically address transport infrastructure needs. Cost reduction trajectories for green hydrogen production are improving economic viability, while industrial decarbonization initiatives are creating anchor customers for hydrogen transport networks.

Market barriers include the significant capital expenditure required for hydrogen-specific infrastructure, regulatory uncertainties regarding pipeline standards and safety protocols, and competition from alternative energy carriers. The technical challenge of hydrogen embrittlement in pipeline materials represents a specific market constraint that is driving innovation in materials science and engineering solutions.

Customer segmentation analysis reveals diverse needs across industrial, utility, mobility, and export markets, each requiring tailored infrastructure approaches and presenting different value propositions for pipeline developers and operators.

Current Challenges in Pipeline Materials for Hydrogen Transport

The transportation of green hydrogen through existing pipeline infrastructure presents significant materials science challenges, primarily centered around hydrogen embrittlement. This phenomenon occurs when hydrogen atoms penetrate the metal structure of pipelines, causing reduced ductility and tensile strength, ultimately leading to premature failure through cracking mechanisms. Current pipeline materials, predominantly carbon steel, exhibit particular vulnerability to these effects when exposed to high-pressure hydrogen environments.

Material degradation manifests through several mechanisms, including hydrogen-enhanced decohesion (HEDE), hydrogen-enhanced localized plasticity (HELP), and adsorption-induced dislocation emission (AIDE). These processes fundamentally alter the mechanical properties of pipeline materials, with degradation rates accelerating at higher pressures and temperatures, creating a complex operational challenge for hydrogen transport systems.

Existing pipeline infrastructure, designed primarily for natural gas transportation, lacks the material specifications necessary for safe, long-term hydrogen conveyance. The retrofitting of these systems requires comprehensive material assessment and potential replacement with hydrogen-compatible alternatives, presenting both technical and economic hurdles. Current estimates suggest that only 20-30% of existing natural gas pipelines may be suitable for hydrogen service without significant modification.

Welded joints represent particularly vulnerable points in pipeline systems, as the heat-affected zones often exhibit altered microstructures with increased susceptibility to hydrogen attack. Research indicates that these regions can experience embrittlement rates up to three times higher than the base material, creating potential failure points throughout the pipeline network.

Material selection for new hydrogen pipelines faces the challenge of balancing hydrogen compatibility with cost-effectiveness. While specialized alloys like austenitic stainless steels and aluminum alloys demonstrate superior hydrogen resistance, their implementation at scale would increase infrastructure costs by 150-300% compared to conventional materials, creating a significant barrier to widespread adoption.

Monitoring and inspection technologies for hydrogen-specific degradation remain underdeveloped. Current non-destructive testing methods struggle to detect early-stage hydrogen damage before critical failure thresholds are reached. This diagnostic gap complicates maintenance planning and risk assessment for pipeline operators considering hydrogen transport applications.

Standardization efforts for hydrogen pipeline materials are still evolving, with inconsistent specifications across different regions creating regulatory uncertainty. The lack of harmonized testing protocols and acceptance criteria for hydrogen service makes material qualification processes challenging and potentially inconsistent across the developing hydrogen economy.

Material degradation manifests through several mechanisms, including hydrogen-enhanced decohesion (HEDE), hydrogen-enhanced localized plasticity (HELP), and adsorption-induced dislocation emission (AIDE). These processes fundamentally alter the mechanical properties of pipeline materials, with degradation rates accelerating at higher pressures and temperatures, creating a complex operational challenge for hydrogen transport systems.

Existing pipeline infrastructure, designed primarily for natural gas transportation, lacks the material specifications necessary for safe, long-term hydrogen conveyance. The retrofitting of these systems requires comprehensive material assessment and potential replacement with hydrogen-compatible alternatives, presenting both technical and economic hurdles. Current estimates suggest that only 20-30% of existing natural gas pipelines may be suitable for hydrogen service without significant modification.

Welded joints represent particularly vulnerable points in pipeline systems, as the heat-affected zones often exhibit altered microstructures with increased susceptibility to hydrogen attack. Research indicates that these regions can experience embrittlement rates up to three times higher than the base material, creating potential failure points throughout the pipeline network.

Material selection for new hydrogen pipelines faces the challenge of balancing hydrogen compatibility with cost-effectiveness. While specialized alloys like austenitic stainless steels and aluminum alloys demonstrate superior hydrogen resistance, their implementation at scale would increase infrastructure costs by 150-300% compared to conventional materials, creating a significant barrier to widespread adoption.

Monitoring and inspection technologies for hydrogen-specific degradation remain underdeveloped. Current non-destructive testing methods struggle to detect early-stage hydrogen damage before critical failure thresholds are reached. This diagnostic gap complicates maintenance planning and risk assessment for pipeline operators considering hydrogen transport applications.

Standardization efforts for hydrogen pipeline materials are still evolving, with inconsistent specifications across different regions creating regulatory uncertainty. The lack of harmonized testing protocols and acceptance criteria for hydrogen service makes material qualification processes challenging and potentially inconsistent across the developing hydrogen economy.

Existing Pipeline Material Solutions for Hydrogen Service

01 Materials selection for hydrogen resistance

Specific materials can be selected for pipeline applications to resist hydrogen embrittlement. These include specialized steel alloys, nickel-based alloys, and composite materials that demonstrate superior resistance to hydrogen penetration and subsequent embrittlement. The selection of appropriate materials is critical in environments where hydrogen exposure is expected, as proper material choice can significantly reduce the risk of pipeline failure due to hydrogen-induced cracking.- Materials resistant to hydrogen embrittlement for pipelines: Specific materials and alloys have been developed to resist hydrogen embrittlement in pipeline applications. These include specialized steel compositions, nickel-based alloys, and composite materials that demonstrate enhanced resistance to hydrogen-induced cracking and embrittlement. These materials maintain their mechanical properties and structural integrity when exposed to hydrogen environments, making them suitable for hydrogen transportation pipelines.

- Surface treatments and coatings to prevent hydrogen embrittlement: Various surface treatments and coating technologies can be applied to pipeline materials to create barriers against hydrogen penetration. These include specialized metallic coatings, ceramic layers, and composite coatings that reduce hydrogen diffusion into the base material. Surface modification techniques such as nitriding, carburizing, and the application of hydrogen-resistant liners can significantly improve the resistance of pipeline materials to hydrogen embrittlement.

- Testing and monitoring methods for hydrogen embrittlement in pipelines: Advanced testing and monitoring techniques have been developed to assess and predict hydrogen embrittlement in pipeline materials. These include electrochemical testing, acoustic emission monitoring, hydrogen permeation measurements, and in-situ monitoring systems. These methods help in evaluating the susceptibility of materials to hydrogen damage and allow for early detection of potential failures in hydrogen-carrying pipelines.

- Manufacturing processes to mitigate hydrogen embrittlement: Specialized manufacturing and processing techniques have been developed to enhance the resistance of pipeline materials to hydrogen embrittlement. These include controlled heat treatment processes, microstructure optimization, grain boundary engineering, and specific welding procedures. These manufacturing approaches create materials with reduced susceptibility to hydrogen-induced damage by controlling microstructural features that affect hydrogen diffusion and trapping.

- Pipeline design considerations for hydrogen service: Engineering design approaches specifically tailored for hydrogen pipeline systems focus on minimizing stress concentrations, optimizing operating parameters, and incorporating safety factors to account for potential material degradation. These design considerations include proper material selection, stress analysis, joint design, and the implementation of monitoring systems. By addressing these factors in the design phase, the risk of hydrogen embrittlement-related failures can be significantly reduced.

02 Surface treatments and coatings

Various surface treatments and protective coatings can be applied to pipeline materials to create barriers against hydrogen penetration. These treatments modify the surface properties of the base material, reducing hydrogen absorption and diffusion into the metal structure. Techniques include nitriding, carburizing, and application of specialized barrier coatings that can significantly improve the resistance of pipeline materials to hydrogen embrittlement in service conditions.Expand Specific Solutions03 Heat treatment and microstructure optimization

Specific heat treatment processes can be employed to optimize the microstructure of pipeline materials, enhancing their resistance to hydrogen embrittlement. These processes include controlled cooling, tempering, and stress relieving treatments that modify grain structure and reduce internal stresses. By optimizing the microstructure, the material's susceptibility to hydrogen-induced cracking can be significantly reduced, improving the overall durability and safety of hydrogen-carrying pipelines.Expand Specific Solutions04 Monitoring and detection systems

Advanced monitoring and detection systems can be implemented to identify early signs of hydrogen embrittlement in pipeline materials. These systems utilize various technologies such as acoustic emission, ultrasonic testing, and hydrogen sensors to detect hydrogen concentration, material degradation, or crack initiation. Early detection allows for timely intervention, preventing catastrophic failures and extending the service life of pipeline infrastructure exposed to hydrogen environments.Expand Specific Solutions05 Alloying and composition control

The careful control of alloy composition can significantly improve pipeline material resistance to hydrogen embrittlement. Adding specific alloying elements such as chromium, molybdenum, vanadium, and titanium can modify the material's microstructure and trap hydrogen at harmless locations. These compositional modifications create materials with inherently higher resistance to hydrogen-induced damage, making them suitable for use in hydrogen transportation and storage applications where embrittlement is a concern.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogen Infrastructure

The hydrogen embrittlement landscape in green hydrogen transport is currently in an early growth phase, with a market expected to expand significantly as decarbonization efforts accelerate globally. Technical maturity varies across pipeline materials, with established players like JFE Steel, Saudi Aramco, and China National Petroleum leading industrial applications. Academic institutions (MIT, Zhejiang University) and specialized research organizations (National Research Council of Canada, Korea Research Institute of Standards & Science) are advancing fundamental understanding of embrittlement mechanisms. Companies like Kawasaki Heavy Industries and Technip Energies are developing specialized materials and coatings to mitigate hydrogen-induced degradation. The competitive landscape reflects a blend of traditional energy companies pivoting to hydrogen infrastructure and specialized materials science firms addressing specific technical challenges in hydrogen containment and transport.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed a groundbreaking approach to addressing hydrogen embrittlement in pipeline materials through their "Adaptive Microstructure" technology. This innovation focuses on creating steel microstructures with engineered hydrogen trapping sites that sequester hydrogen in benign locations, preventing it from concentrating at grain boundaries and other susceptible areas. Their research has demonstrated that fine dispersions of titanium carbide particles (5-20nm in diameter) can reduce effective hydrogen diffusivity by up to 75% compared to conventional pipeline steels. MIT's approach includes a novel heat treatment protocol that creates a gradient nanostructure with varying grain sizes from the surface to the core of the material, providing enhanced resistance to crack initiation and propagation. They've also pioneered computational models that can predict hydrogen diffusion paths and potential failure points in complex pipeline geometries, allowing for targeted reinforcement of vulnerable areas. Additionally, MIT has developed advanced non-destructive evaluation techniques using electromagnetic acoustic resonance that can detect early-stage hydrogen damage before visible cracking occurs.

Strengths: Cutting-edge materials science approach addresses the fundamental mechanisms of hydrogen embrittlement at the microstructural level. Their computational modeling capabilities enable predictive maintenance and targeted design improvements. Weaknesses: As an academic institution, MIT may face challenges in scaling laboratory solutions to industrial implementation. Their advanced technologies likely require significant adaptation for cost-effective commercial deployment.

Kawasaki Heavy Industries Ltd.

Technical Solution: Kawasaki Heavy Industries has developed advanced materials and technologies specifically addressing hydrogen embrittlement in transport pipelines. Their proprietary "HyTough" steel alloy incorporates fine-dispersed vanadium carbide precipitates that act as benign hydrogen trapping sites, reducing the concentration of diffusible hydrogen at grain boundaries by approximately 40%. This specialized metallurgical approach maintains mechanical properties while significantly improving resistance to hydrogen-induced cracking. Kawasaki's pipeline system features a unique multi-layered structure with an inner liner made of Type 316L austenitic stainless steel (which has superior hydrogen compatibility) bonded to a high-strength outer layer providing structural integrity. Their technology includes specialized welding procedures using low-hydrogen electrodes and post-weld heat treatment protocols that reduce residual stresses by up to 70%. Kawasaki has also pioneered non-destructive testing methods specifically calibrated for hydrogen service, including phased array ultrasonic testing capable of detecting micro-cracks as small as 0.1mm before they propagate to critical size.

Strengths: Extensive experience in hydrogen transport systems from their work in Japan's hydrogen economy gives them practical insights into real-world implementation challenges. Their metallurgical approach addresses the fundamental mechanisms of hydrogen embrittlement rather than just symptoms. Weaknesses: Higher manufacturing costs compared to conventional pipeline materials may limit widespread adoption. The specialized welding and inspection requirements demand highly trained personnel and specialized equipment.

Critical Patents and Research on Hydrogen Embrittlement Mitigation

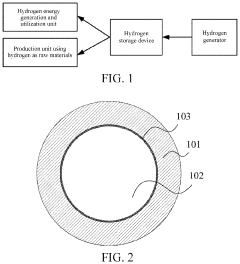

Hydrogen transportation pipe and hydrogen transportation pipeline

PatentPendingUS20230341075A1

Innovation

- A common steel pipe with a nano-composite coating, applied through a vacuum sputtering process, is used to prevent hydrogen atoms from diffusing into the pipe body, effectively preventing hydrogen embrittlement and reducing transportation costs by using a dense, durable coating that acts as a barrier.

Safety Standards and Risk Assessment for Hydrogen Pipelines

The development of comprehensive safety standards and risk assessment frameworks is paramount for the successful implementation of hydrogen pipeline infrastructure. Current international standards such as ASME B31.12, ISO 14687, and NFPA 2 provide foundational guidelines for hydrogen pipeline design, but require significant adaptation to address the unique challenges posed by hydrogen embrittlement in green hydrogen transport systems.

Risk assessment methodologies for hydrogen pipelines must incorporate specialized considerations beyond those used for natural gas networks. Quantitative Risk Assessment (QRA) techniques have been enhanced to account for hydrogen's distinctive properties, including its high diffusivity, wide flammability range (4-75% by volume), and low ignition energy (0.02 mJ). These properties necessitate more stringent safety parameters compared to conventional fuel gases.

Material qualification protocols represent a critical component of safety standards, requiring rigorous testing under conditions that simulate long-term exposure to hydrogen. The ASME KD-10 standard specifically addresses hydrogen service requirements, mandating fracture mechanics assessments and fatigue crack growth rate testing for pipeline materials. These protocols must be continuously updated as new data on hydrogen-material interactions emerges.

Leak detection and monitoring systems have evolved significantly, with advanced technologies such as fiber optic sensing, ultrasonic monitoring, and hydrogen-specific gas sensors becoming integral to safety frameworks. Regulatory bodies increasingly require real-time monitoring capabilities with automated shutdown systems to mitigate potential release scenarios.

Integrity management programs for hydrogen pipelines incorporate specialized inspection intervals and methodologies that account for the accelerated degradation mechanisms associated with hydrogen embrittlement. These programs typically mandate more frequent inspections compared to conventional pipelines, with particular attention to weld zones and areas subject to cyclic loading.

Emergency response protocols for hydrogen pipeline incidents have been developed to address the unique challenges of hydrogen fires and explosions. These protocols emphasize rapid isolation of affected pipeline segments, specialized firefighting approaches, and expanded evacuation zones compared to natural gas incidents due to hydrogen's different dispersion characteristics.

The economic implications of these enhanced safety requirements are substantial, with estimates suggesting a 15-30% increase in capital expenditure compared to conventional pipeline systems. However, cost-benefit analyses consistently demonstrate that these investments significantly reduce the lifetime risk profile of hydrogen transport infrastructure.

Risk assessment methodologies for hydrogen pipelines must incorporate specialized considerations beyond those used for natural gas networks. Quantitative Risk Assessment (QRA) techniques have been enhanced to account for hydrogen's distinctive properties, including its high diffusivity, wide flammability range (4-75% by volume), and low ignition energy (0.02 mJ). These properties necessitate more stringent safety parameters compared to conventional fuel gases.

Material qualification protocols represent a critical component of safety standards, requiring rigorous testing under conditions that simulate long-term exposure to hydrogen. The ASME KD-10 standard specifically addresses hydrogen service requirements, mandating fracture mechanics assessments and fatigue crack growth rate testing for pipeline materials. These protocols must be continuously updated as new data on hydrogen-material interactions emerges.

Leak detection and monitoring systems have evolved significantly, with advanced technologies such as fiber optic sensing, ultrasonic monitoring, and hydrogen-specific gas sensors becoming integral to safety frameworks. Regulatory bodies increasingly require real-time monitoring capabilities with automated shutdown systems to mitigate potential release scenarios.

Integrity management programs for hydrogen pipelines incorporate specialized inspection intervals and methodologies that account for the accelerated degradation mechanisms associated with hydrogen embrittlement. These programs typically mandate more frequent inspections compared to conventional pipelines, with particular attention to weld zones and areas subject to cyclic loading.

Emergency response protocols for hydrogen pipeline incidents have been developed to address the unique challenges of hydrogen fires and explosions. These protocols emphasize rapid isolation of affected pipeline segments, specialized firefighting approaches, and expanded evacuation zones compared to natural gas incidents due to hydrogen's different dispersion characteristics.

The economic implications of these enhanced safety requirements are substantial, with estimates suggesting a 15-30% increase in capital expenditure compared to conventional pipeline systems. However, cost-benefit analyses consistently demonstrate that these investments significantly reduce the lifetime risk profile of hydrogen transport infrastructure.

Environmental Impact of Pipeline Material Selection

The selection of pipeline materials for green hydrogen transport carries significant environmental implications that extend beyond the immediate technical concerns of hydrogen embrittlement. Traditional carbon steel pipelines, while economically advantageous, often require extensive protective measures against hydrogen-induced degradation, including specialized coatings and liners that may contain environmentally persistent compounds.

Advanced alloys such as stainless steels and nickel-based alternatives offer superior resistance to hydrogen embrittlement but present their own environmental challenges. The extraction and processing of nickel, chromium, and other alloying elements involve energy-intensive mining operations that generate substantial carbon emissions and can lead to habitat destruction and water pollution in mining regions.

Life cycle assessment studies indicate that the environmental footprint of high-performance alloy pipelines may be justified by their extended operational lifespan and reduced maintenance requirements. However, this balance depends heavily on the specific deployment context and hydrogen purity levels. The manufacturing processes for these specialized materials typically consume 2-3 times more energy than conventional steel production.

Composite materials represent an emerging alternative with potentially lower environmental impact. Fiber-reinforced polymers and thermoplastic liners can offer hydrogen compatibility while reducing the reliance on extractive metallurgy. These materials generally require less energy to manufacture and can be designed for end-of-life recyclability, though current recycling infrastructure remains limited for advanced composites.

The environmental considerations extend to pipeline installation and maintenance practices. Leak detection systems and monitoring technologies are essential components of environmentally responsible hydrogen transport infrastructure, as hydrogen leakage contributes to indirect greenhouse effects despite not being a direct pollutant. Studies suggest that hydrogen leakage rates must remain below 1% to maintain the climate benefits of green hydrogen as an energy carrier.

Material selection also influences land use requirements and ecosystem disruption during pipeline construction. More resilient materials may allow for reduced right-of-way widths and less frequent maintenance interventions, minimizing habitat fragmentation and soil disturbance over the infrastructure lifetime. This aspect becomes particularly significant in ecologically sensitive areas where pipeline routes may intersect with protected habitats or biodiversity hotspots.

Ultimately, the environmental impact of pipeline material selection represents a complex trade-off between immediate manufacturing impacts and long-term operational sustainability. A holistic approach considering both direct emissions and resource consumption alongside performance characteristics is essential for developing truly sustainable hydrogen transport infrastructure.

Advanced alloys such as stainless steels and nickel-based alternatives offer superior resistance to hydrogen embrittlement but present their own environmental challenges. The extraction and processing of nickel, chromium, and other alloying elements involve energy-intensive mining operations that generate substantial carbon emissions and can lead to habitat destruction and water pollution in mining regions.

Life cycle assessment studies indicate that the environmental footprint of high-performance alloy pipelines may be justified by their extended operational lifespan and reduced maintenance requirements. However, this balance depends heavily on the specific deployment context and hydrogen purity levels. The manufacturing processes for these specialized materials typically consume 2-3 times more energy than conventional steel production.

Composite materials represent an emerging alternative with potentially lower environmental impact. Fiber-reinforced polymers and thermoplastic liners can offer hydrogen compatibility while reducing the reliance on extractive metallurgy. These materials generally require less energy to manufacture and can be designed for end-of-life recyclability, though current recycling infrastructure remains limited for advanced composites.

The environmental considerations extend to pipeline installation and maintenance practices. Leak detection systems and monitoring technologies are essential components of environmentally responsible hydrogen transport infrastructure, as hydrogen leakage contributes to indirect greenhouse effects despite not being a direct pollutant. Studies suggest that hydrogen leakage rates must remain below 1% to maintain the climate benefits of green hydrogen as an energy carrier.

Material selection also influences land use requirements and ecosystem disruption during pipeline construction. More resilient materials may allow for reduced right-of-way widths and less frequent maintenance interventions, minimizing habitat fragmentation and soil disturbance over the infrastructure lifetime. This aspect becomes particularly significant in ecologically sensitive areas where pipeline routes may intersect with protected habitats or biodiversity hotspots.

Ultimately, the environmental impact of pipeline material selection represents a complex trade-off between immediate manufacturing impacts and long-term operational sustainability. A holistic approach considering both direct emissions and resource consumption alongside performance characteristics is essential for developing truly sustainable hydrogen transport infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!