Innovations in electrolysis stack cooling and heat management

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolysis Cooling Technology Background and Objectives

Electrolysis technology has evolved significantly since its inception in the early 19th century when William Nicholson and Anthony Carlisle first demonstrated water electrolysis. The fundamental process involves passing an electric current through water to split it into hydrogen and oxygen gases. Over the past two centuries, this technology has progressed from laboratory demonstrations to industrial-scale applications, with recent advancements focusing on improving efficiency, durability, and cost-effectiveness.

The thermal management of electrolysis systems represents one of the most critical challenges in modern hydrogen production. During electrolysis, approximately 20-30% of the input energy converts to heat rather than contributing to the desired electrochemical reaction. This heat generation increases with higher current densities, creating a significant thermal management challenge that directly impacts system efficiency, component longevity, and safety parameters.

Historical approaches to cooling electrolysis stacks have evolved from simple passive cooling methods to sophisticated integrated thermal management systems. Early systems relied primarily on natural convection and basic water circulation, while contemporary designs incorporate advanced heat exchangers, specialized coolants, and intelligent thermal control algorithms. This evolution reflects the increasing power densities and efficiency requirements of modern electrolyzers.

The global push toward hydrogen as a clean energy carrier has accelerated research in electrolysis cooling technologies. With projections indicating that hydrogen could meet up to 24% of global energy demand by 2050, the need for efficient, scalable electrolysis systems has never been more urgent. This has catalyzed innovations in cooling technologies that can handle the thermal loads of megawatt-scale electrolysis plants while maintaining optimal operating temperatures.

The primary objectives of current research in electrolysis stack cooling include: reducing parasitic energy consumption of cooling systems; enabling higher current density operation without thermal degradation; recovering and utilizing waste heat for system efficiency improvements; developing cooling solutions compatible with intermittent renewable energy inputs; and creating standardized thermal management approaches that can scale from kilowatt to gigawatt installations.

Temperature uniformity across electrolysis stacks presents another significant challenge, as temperature gradients can lead to uneven current distribution, localized degradation, and reduced overall efficiency. Advanced cooling technologies aim to maintain temperature variations below 5°C across large-scale stacks, requiring sophisticated flow distribution and control systems.

As electrolysis technology continues to mature, cooling system innovations are increasingly focused on integration with broader energy systems, allowing for heat recovery and utilization in district heating, industrial processes, or power generation through organic Rankine cycles. This systemic approach to thermal management represents the frontier of electrolysis technology development.

The thermal management of electrolysis systems represents one of the most critical challenges in modern hydrogen production. During electrolysis, approximately 20-30% of the input energy converts to heat rather than contributing to the desired electrochemical reaction. This heat generation increases with higher current densities, creating a significant thermal management challenge that directly impacts system efficiency, component longevity, and safety parameters.

Historical approaches to cooling electrolysis stacks have evolved from simple passive cooling methods to sophisticated integrated thermal management systems. Early systems relied primarily on natural convection and basic water circulation, while contemporary designs incorporate advanced heat exchangers, specialized coolants, and intelligent thermal control algorithms. This evolution reflects the increasing power densities and efficiency requirements of modern electrolyzers.

The global push toward hydrogen as a clean energy carrier has accelerated research in electrolysis cooling technologies. With projections indicating that hydrogen could meet up to 24% of global energy demand by 2050, the need for efficient, scalable electrolysis systems has never been more urgent. This has catalyzed innovations in cooling technologies that can handle the thermal loads of megawatt-scale electrolysis plants while maintaining optimal operating temperatures.

The primary objectives of current research in electrolysis stack cooling include: reducing parasitic energy consumption of cooling systems; enabling higher current density operation without thermal degradation; recovering and utilizing waste heat for system efficiency improvements; developing cooling solutions compatible with intermittent renewable energy inputs; and creating standardized thermal management approaches that can scale from kilowatt to gigawatt installations.

Temperature uniformity across electrolysis stacks presents another significant challenge, as temperature gradients can lead to uneven current distribution, localized degradation, and reduced overall efficiency. Advanced cooling technologies aim to maintain temperature variations below 5°C across large-scale stacks, requiring sophisticated flow distribution and control systems.

As electrolysis technology continues to mature, cooling system innovations are increasingly focused on integration with broader energy systems, allowing for heat recovery and utilization in district heating, industrial processes, or power generation through organic Rankine cycles. This systemic approach to thermal management represents the frontier of electrolysis technology development.

Market Demand Analysis for Advanced Heat Management Solutions

The global market for advanced heat management solutions in electrolysis systems is experiencing significant growth, driven primarily by the expanding hydrogen economy. As countries worldwide commit to decarbonization targets, the demand for green hydrogen production has surged, with the global electrolyzer market projected to reach $8.7 billion by 2028, growing at a CAGR of 24.6% from 2023.

Heat management represents a critical challenge in this expanding market. Approximately 30% of energy input in electrolysis processes is converted to waste heat, creating substantial demand for innovative cooling solutions that can improve overall system efficiency. Industrial surveys indicate that operators are willing to invest 15-20% premium on electrolyzer systems that offer superior thermal management capabilities, as these directly translate to operational cost savings.

The renewable energy sector's intermittent nature has further intensified market demand for heat management solutions. With electrolyzers increasingly paired with variable renewable energy sources, systems must handle fluctuating thermal loads efficiently. This has created a specialized market segment for dynamic cooling systems that can adapt to changing operational conditions, estimated to grow at 32% annually through 2030.

Regional analysis reveals differentiated market needs. European markets prioritize integrated heat recovery systems that can capture and repurpose waste heat for district heating or industrial processes, with potential energy savings of 20-25%. In contrast, Asia-Pacific markets, particularly China and India, focus on cost-effective cooling solutions that minimize water consumption, reflecting regional water scarcity concerns.

The industrial sector represents the largest end-user segment, accounting for 63% of market demand. Chemical processing, refining, and ammonia production industries seek heat management solutions that can be retrofitted to existing infrastructure while providing precise temperature control within ±1°C to ensure optimal electrolysis performance and catalyst longevity.

Emerging applications in transportation and portable power are creating new market opportunities. The maritime sector is exploring megawatt-scale electrolyzers with advanced cooling systems for onboard hydrogen production, while remote and off-grid applications demand compact, low-maintenance cooling solutions that can operate in harsh environments.

Market research indicates that customers increasingly value integrated solutions that combine cooling with heat recovery functionality. Systems that can maintain optimal operating temperatures while capturing waste heat for secondary applications command premium pricing, with payback periods typically under three years making them attractive investments despite higher initial capital costs.

Heat management represents a critical challenge in this expanding market. Approximately 30% of energy input in electrolysis processes is converted to waste heat, creating substantial demand for innovative cooling solutions that can improve overall system efficiency. Industrial surveys indicate that operators are willing to invest 15-20% premium on electrolyzer systems that offer superior thermal management capabilities, as these directly translate to operational cost savings.

The renewable energy sector's intermittent nature has further intensified market demand for heat management solutions. With electrolyzers increasingly paired with variable renewable energy sources, systems must handle fluctuating thermal loads efficiently. This has created a specialized market segment for dynamic cooling systems that can adapt to changing operational conditions, estimated to grow at 32% annually through 2030.

Regional analysis reveals differentiated market needs. European markets prioritize integrated heat recovery systems that can capture and repurpose waste heat for district heating or industrial processes, with potential energy savings of 20-25%. In contrast, Asia-Pacific markets, particularly China and India, focus on cost-effective cooling solutions that minimize water consumption, reflecting regional water scarcity concerns.

The industrial sector represents the largest end-user segment, accounting for 63% of market demand. Chemical processing, refining, and ammonia production industries seek heat management solutions that can be retrofitted to existing infrastructure while providing precise temperature control within ±1°C to ensure optimal electrolysis performance and catalyst longevity.

Emerging applications in transportation and portable power are creating new market opportunities. The maritime sector is exploring megawatt-scale electrolyzers with advanced cooling systems for onboard hydrogen production, while remote and off-grid applications demand compact, low-maintenance cooling solutions that can operate in harsh environments.

Market research indicates that customers increasingly value integrated solutions that combine cooling with heat recovery functionality. Systems that can maintain optimal operating temperatures while capturing waste heat for secondary applications command premium pricing, with payback periods typically under three years making them attractive investments despite higher initial capital costs.

Current Challenges in Electrolysis Stack Thermal Management

Electrolysis stack thermal management presents significant challenges that impede the efficiency and durability of hydrogen production systems. The exothermic nature of the electrolysis reaction generates substantial heat during operation, with approximately 30-40% of input energy converted to heat rather than hydrogen production. This heat accumulation can lead to temperature gradients across the stack, causing thermal stress, material degradation, and reduced system lifespan.

Current cooling systems predominantly rely on water circulation methods that often prove inadequate for high-power density operations. These conventional approaches struggle to maintain uniform temperature distribution across large-scale stacks, resulting in localized hotspots that accelerate component degradation. The challenge is particularly acute in PEM (Proton Exchange Membrane) electrolyzers where temperature sensitivity is critical for membrane performance and longevity.

Material limitations further complicate thermal management efforts. Many components in electrolysis stacks have different thermal expansion coefficients, creating mechanical stress during temperature fluctuations. Additionally, cooling system materials must withstand both high temperatures and potentially corrosive environments while maintaining electrical isolation where necessary.

Energy efficiency remains a paramount concern in current systems. Parasitic power consumption by cooling pumps and auxiliary equipment can significantly reduce the overall system efficiency. Most existing cooling solutions fail to effectively capture and repurpose waste heat, representing a substantial loss of potential energy that could otherwise be integrated into broader energy systems.

Scale-up challenges persist as laboratory-proven cooling technologies often encounter unforeseen complications when implemented in industrial-scale electrolyzers. The increased stack size creates more complex flow dynamics and heat distribution patterns that are difficult to model and control effectively.

Control system integration presents another significant hurdle. Many current thermal management systems lack sophisticated real-time monitoring and adaptive control capabilities necessary to respond to varying operational conditions. This limitation restricts operational flexibility and prevents optimal performance across different power loads and ambient conditions.

Cost considerations further constrain innovation, as advanced cooling technologies must balance performance improvements against economic viability. Expensive materials and complex manufacturing processes for specialized cooling components can significantly impact the overall system cost, limiting commercial adoption despite technical advantages.

These multifaceted challenges necessitate innovative approaches to thermal management that can simultaneously address temperature uniformity, energy efficiency, durability, and cost-effectiveness while enabling the scale-up required for industrial hydrogen production.

Current cooling systems predominantly rely on water circulation methods that often prove inadequate for high-power density operations. These conventional approaches struggle to maintain uniform temperature distribution across large-scale stacks, resulting in localized hotspots that accelerate component degradation. The challenge is particularly acute in PEM (Proton Exchange Membrane) electrolyzers where temperature sensitivity is critical for membrane performance and longevity.

Material limitations further complicate thermal management efforts. Many components in electrolysis stacks have different thermal expansion coefficients, creating mechanical stress during temperature fluctuations. Additionally, cooling system materials must withstand both high temperatures and potentially corrosive environments while maintaining electrical isolation where necessary.

Energy efficiency remains a paramount concern in current systems. Parasitic power consumption by cooling pumps and auxiliary equipment can significantly reduce the overall system efficiency. Most existing cooling solutions fail to effectively capture and repurpose waste heat, representing a substantial loss of potential energy that could otherwise be integrated into broader energy systems.

Scale-up challenges persist as laboratory-proven cooling technologies often encounter unforeseen complications when implemented in industrial-scale electrolyzers. The increased stack size creates more complex flow dynamics and heat distribution patterns that are difficult to model and control effectively.

Control system integration presents another significant hurdle. Many current thermal management systems lack sophisticated real-time monitoring and adaptive control capabilities necessary to respond to varying operational conditions. This limitation restricts operational flexibility and prevents optimal performance across different power loads and ambient conditions.

Cost considerations further constrain innovation, as advanced cooling technologies must balance performance improvements against economic viability. Expensive materials and complex manufacturing processes for specialized cooling components can significantly impact the overall system cost, limiting commercial adoption despite technical advantages.

These multifaceted challenges necessitate innovative approaches to thermal management that can simultaneously address temperature uniformity, energy efficiency, durability, and cost-effectiveness while enabling the scale-up required for industrial hydrogen production.

Current Heat Management Solutions for Electrolysis Stacks

01 Liquid cooling systems for electrolysis stacks

Liquid cooling systems are employed to manage heat in electrolysis stacks by circulating coolant through channels or plates integrated within the stack. These systems efficiently remove excess heat generated during the electrolysis process, maintaining optimal operating temperatures and preventing thermal damage to components. The coolant absorbs heat from the stack and transfers it to external heat exchangers, allowing for precise temperature control and improved overall system efficiency.- Liquid cooling systems for electrolysis stacks: Liquid cooling systems are employed to manage heat in electrolysis stacks by circulating coolant through channels or plates integrated within the stack. These systems efficiently remove excess heat generated during the electrolysis process, maintaining optimal operating temperatures and preventing thermal damage to components. The coolant absorbs heat from the stack and transfers it to external heat exchangers, allowing for precise temperature control and improved system efficiency.

- Heat recovery and utilization from electrolysis stacks: Heat recovery systems capture and repurpose thermal energy generated during electrolysis operations. These systems integrate heat exchangers to transfer waste heat from the electrolysis stack to other processes or applications, such as space heating, water heating, or preheating reactants. By utilizing waste heat that would otherwise be dissipated, these systems improve overall energy efficiency and reduce operational costs while maintaining optimal stack temperatures.

- Air cooling and ventilation techniques: Air cooling systems use forced or natural convection to remove heat from electrolysis stacks. These systems incorporate fans, blowers, or strategic ventilation designs to direct airflow across heat-generating components. Air cooling offers advantages including simplicity, lower maintenance requirements, and elimination of potential coolant leakage issues. Some designs feature finned heat sinks or extended surfaces to enhance heat transfer to the surrounding air, effectively managing stack temperatures in less demanding applications.

- Integrated thermal management with phase change materials: Advanced thermal management systems incorporate phase change materials (PCMs) to absorb and release heat during electrolysis operations. These materials change state at specific temperatures, absorbing excess heat during peak operation and releasing it when temperatures drop, creating a passive temperature regulation mechanism. This approach helps maintain consistent operating temperatures, reduces thermal cycling stress, and can provide thermal buffering during transient operations, enhancing overall system reliability and efficiency.

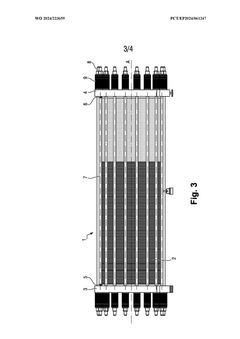

- Stack design optimization for thermal management: Innovative stack designs incorporate features specifically engineered to enhance thermal management. These include optimized flow field patterns, strategic placement of cooling channels, thermally conductive materials, and specialized geometries that promote uniform heat distribution. Some designs feature modular approaches that allow for more effective cooling of individual cells or sections. By addressing thermal management at the design stage, these approaches minimize hotspots, reduce thermal gradients, and improve overall system durability and performance.

02 Heat recovery and utilization systems

Heat recovery systems capture and repurpose thermal energy generated during electrolysis operations. These systems integrate heat exchangers to transfer waste heat from the electrolysis stack to other processes or applications, such as space heating, water heating, or preheating reactants. By utilizing waste heat that would otherwise be dissipated, these systems improve overall energy efficiency, reduce operating costs, and minimize environmental impact while maintaining optimal operating temperatures for the electrolysis process.Expand Specific Solutions03 Air cooling and ventilation techniques

Air cooling systems utilize forced or natural convection to remove heat from electrolysis stacks. These systems incorporate fans, blowers, or strategic ventilation channels to direct airflow across heat-generating components. Some designs feature heat sinks or extended surfaces to enhance heat transfer to the surrounding air. Air cooling solutions offer advantages including simplicity, lower maintenance requirements, and elimination of potential coolant leakage issues, though they may provide less precise temperature control compared to liquid cooling systems.Expand Specific Solutions04 Integrated thermal management control systems

Integrated control systems monitor and regulate temperature across electrolysis stacks using sensors, controllers, and automated response mechanisms. These systems continuously track thermal conditions and adjust cooling parameters accordingly, maintaining optimal operating temperatures throughout the stack. Advanced implementations incorporate predictive algorithms to anticipate thermal changes based on operating conditions, enabling proactive temperature management. By providing precise thermal control, these systems enhance efficiency, extend component lifespan, and improve overall system reliability.Expand Specific Solutions05 Phase change materials and passive cooling solutions

Passive cooling solutions utilize phase change materials (PCMs) and other thermal management techniques that require minimal or no external energy input. PCMs absorb excess heat during operation by changing from solid to liquid state, then release this heat during idle periods when they resolidify. These materials help stabilize temperature fluctuations and provide thermal buffering. Other passive approaches include strategic material selection, component arrangement, and natural convection pathways designed to dissipate heat efficiently without active cooling systems.Expand Specific Solutions

Leading Companies in Electrolysis Thermal Management

The electrolysis stack cooling and heat management innovation landscape is currently in a growth phase, with the market expected to reach significant expansion as hydrogen production scales globally. The technology maturity varies across different approaches, with established industrial players like Air Liquide, Siemens Energy, and Toshiba leading conventional solutions. Emerging specialists such as Nel Hydrogen, H2B2, and DynElectro are advancing novel thermal management technologies that improve efficiency and durability. Research institutions including Tsinghua University, Xi'an Jiaotong University, and CEA are contributing fundamental breakthroughs, while automotive companies like Honda, Boeing, and FAW are driving integration innovations for mobile applications. The competitive landscape reflects a blend of established industrial expertise and specialized hydrogen technology startups addressing efficiency and scale challenges.

Air Liquide SA

Technical Solution: Air Liquide has developed comprehensive thermal management solutions for their electrolysis systems, focusing on both active and passive cooling technologies. Their approach includes advanced bipolar plate designs with integrated cooling channels that provide direct cooling to the electrochemical reaction sites. Air Liquide's systems utilize specialized coolants with optimized thermal properties to enhance heat transfer efficiency while maintaining electrical isolation. The company has implemented a cascaded cooling architecture that enables waste heat recovery at different temperature levels, maximizing overall system efficiency. Their latest innovations include dynamic cooling control systems that adapt to varying load conditions, maintaining optimal operating temperatures during both steady-state and transient operations. Air Liquide has also developed specialized heat exchangers with enhanced surface geometries that improve heat transfer coefficients while minimizing pressure drops in the cooling circuits. Their thermal management systems incorporate advanced sensors and control algorithms that continuously optimize cooling parameters based on multiple operating variables.

Strengths: Highly efficient heat recovery systems that can be integrated with other industrial processes; proven reliability in large-scale industrial applications; sophisticated control systems for precise temperature management. Weaknesses: Complex system architecture requires specialized maintenance; higher capital costs compared to simpler cooling solutions; integration complexity with existing infrastructure.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has pioneered innovative cooling solutions for their Silyzer electrolysis systems, focusing on optimizing thermal management for large-scale industrial applications. Their approach integrates cooling systems directly into the stack design with specialized flow field plates that incorporate cooling channels. This design enables precise temperature control across the entire active area while minimizing temperature gradients. Siemens has developed a multi-stage cooling architecture that separates low and high-temperature cooling circuits to maximize heat recovery potential. Their systems utilize advanced materials with high thermal conductivity to enhance heat transfer from reaction sites to cooling media. The company's latest innovations include predictive thermal management systems that use real-time data analytics to anticipate thermal loads and adjust cooling parameters proactively. Siemens has also implemented modular cooling designs that allow for scalable heat management solutions across different system sizes, maintaining optimal efficiency regardless of production capacity.

Strengths: Highly efficient heat recovery systems that integrate with industrial processes; sophisticated control algorithms for precise temperature management; proven reliability in industrial-scale implementations. Weaknesses: Higher initial capital investment; complex integration requirements with existing plant infrastructure; specialized maintenance expertise required.

Key Innovations in Electrolysis Cooling Technologies

Cooling system for an electrolysis device for producing hydrogen

PatentWO2025091059A1

Innovation

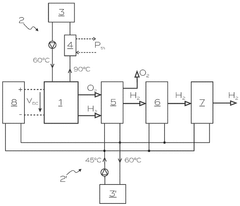

- A cooling system with two separate coolant circuits is designed, where one circuit operates at a higher temperature to efficiently cool the electrolysis stack, and a second circuit at a lower temperature cools the investment components, optimizing cooling capacity and reducing overall effort.

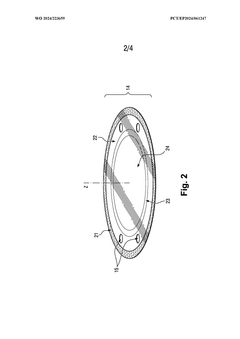

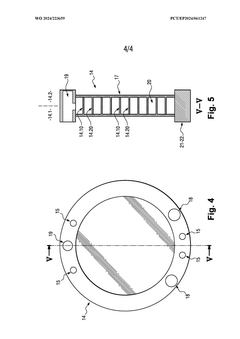

Bipolar plate, electrolytic cell and electrolyzer stack with integrated cooling circuit

PatentWO2024223659A1

Innovation

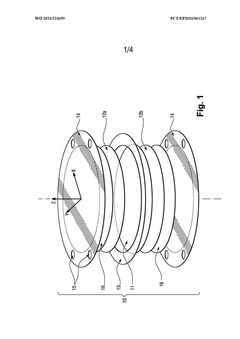

- The introduction of bipolar plates with separate conduits for electrolyte supply, electrolysis product evacuation, and a built-in cooling fluid circuit, allowing for independent management and enhancing heat transfer efficiency using a heat transfer liquid with higher specific heat capacity than traditional electrolytes.

Energy Efficiency Implications of Advanced Cooling Systems

Advanced cooling systems in electrolysis stacks represent a critical frontier in improving the overall energy efficiency of hydrogen production processes. The thermal management innovations directly impact the electrical-to-hydrogen conversion efficiency, which traditionally ranges from 60-80% depending on the electrolysis technology employed. By implementing sophisticated cooling solutions, efficiency improvements of 3-7% have been documented in recent industrial applications.

The energy implications of these cooling advancements manifest in multiple dimensions. Primarily, optimized thermal management reduces parasitic energy losses that occur when electrolysis cells operate outside their ideal temperature windows. For PEM electrolyzers, maintaining precise temperatures between 50-80°C has shown to minimize activation energy requirements and improve reaction kinetics, resulting in lower overall energy consumption per unit of hydrogen produced.

Heat recovery systems integrated with advanced cooling architectures create significant energy cascades. Waste heat captured from electrolysis stacks can be repurposed for multiple applications, including preheating feed water, space heating in production facilities, or integration with district heating networks. This thermal energy recovery can improve the system-level efficiency by 10-15% when properly implemented, transforming what was previously considered waste into a valuable energy resource.

The relationship between cooling system design and electrical input requirements demonstrates clear correlations. Studies indicate that for every 1°C deviation from optimal operating temperature, efficiency penalties of 0.2-0.5% may occur. Advanced cooling systems that maintain temperature uniformity across the entire stack prevent these efficiency losses and reduce the electrical demand fluctuations that challenge grid integration.

Material performance and longevity also factor into the energy efficiency equation. Electrolysis components subjected to proper thermal management exhibit significantly extended operational lifespans, reducing the embodied energy costs associated with premature component replacement. Data from field deployments suggests that membrane degradation rates can be reduced by 30-40% when temperature excursions are effectively controlled.

From a system integration perspective, the dynamic response capabilities enabled by advanced cooling systems allow electrolyzers to better participate in grid balancing services. This operational flexibility creates additional value streams while supporting renewable energy integration, effectively improving the net energy efficiency of the entire power-to-hydrogen pathway by enabling operation during periods of renewable energy abundance.

The energy implications of these cooling advancements manifest in multiple dimensions. Primarily, optimized thermal management reduces parasitic energy losses that occur when electrolysis cells operate outside their ideal temperature windows. For PEM electrolyzers, maintaining precise temperatures between 50-80°C has shown to minimize activation energy requirements and improve reaction kinetics, resulting in lower overall energy consumption per unit of hydrogen produced.

Heat recovery systems integrated with advanced cooling architectures create significant energy cascades. Waste heat captured from electrolysis stacks can be repurposed for multiple applications, including preheating feed water, space heating in production facilities, or integration with district heating networks. This thermal energy recovery can improve the system-level efficiency by 10-15% when properly implemented, transforming what was previously considered waste into a valuable energy resource.

The relationship between cooling system design and electrical input requirements demonstrates clear correlations. Studies indicate that for every 1°C deviation from optimal operating temperature, efficiency penalties of 0.2-0.5% may occur. Advanced cooling systems that maintain temperature uniformity across the entire stack prevent these efficiency losses and reduce the electrical demand fluctuations that challenge grid integration.

Material performance and longevity also factor into the energy efficiency equation. Electrolysis components subjected to proper thermal management exhibit significantly extended operational lifespans, reducing the embodied energy costs associated with premature component replacement. Data from field deployments suggests that membrane degradation rates can be reduced by 30-40% when temperature excursions are effectively controlled.

From a system integration perspective, the dynamic response capabilities enabled by advanced cooling systems allow electrolyzers to better participate in grid balancing services. This operational flexibility creates additional value streams while supporting renewable energy integration, effectively improving the net energy efficiency of the entire power-to-hydrogen pathway by enabling operation during periods of renewable energy abundance.

Environmental Impact of Cooling Technology Innovations

The evolution of cooling technologies in electrolysis systems has significant environmental implications that extend beyond operational efficiency. Traditional cooling methods often rely on water-intensive processes, contributing to water scarcity issues in regions where this resource is already limited. Recent innovations in electrolysis stack cooling have demonstrated potential to reduce water consumption by up to 40% through closed-loop systems and advanced heat exchangers, representing a substantial environmental benefit.

Energy consumption associated with cooling systems constitutes approximately 15-20% of the total energy requirements in electrolysis operations. Innovations such as passive cooling designs and thermally integrated systems have shown promising results in reducing this energy footprint. Studies indicate that next-generation cooling technologies can decrease cooling-related energy consumption by 25-30%, directly translating to reduced carbon emissions when the electricity source is non-renewable.

Material sustainability represents another critical environmental dimension. Conventional cooling systems often utilize refrigerants with high global warming potential (GWP). New cooling technologies are increasingly adopting natural refrigerants or completely refrigerant-free approaches, eliminating potential emissions from leakage. Additionally, advanced heat management systems are being designed with recyclable materials and longer operational lifespans, reducing waste generation and resource depletion.

Waste heat recovery innovations present perhaps the most significant environmental opportunity. Modern electrolysis cooling systems are increasingly designed to capture and repurpose thermal energy that would otherwise be dissipated. This recovered heat can be integrated into district heating networks, used for preheating processes, or converted to other forms of useful energy. Field implementations have demonstrated that up to 60% of waste heat can be effectively recovered, substantially improving the overall energy efficiency of hydrogen production facilities.

The environmental benefits extend to land and space utilization as well. Compact cooling technologies reduce the physical footprint of electrolysis installations, minimizing habitat disruption and allowing for more flexible siting options, including integration with existing industrial facilities. This spatial efficiency becomes particularly important as hydrogen production scales up to meet growing demand.

Lifecycle assessment studies comparing conventional and innovative cooling technologies reveal that advanced systems can reduce the environmental impact across multiple categories, including carbon footprint, water usage, and ecotoxicity. However, these benefits must be balanced against potential new environmental challenges, such as the use of specialized materials that may have complex supply chains or end-of-life management requirements.

Energy consumption associated with cooling systems constitutes approximately 15-20% of the total energy requirements in electrolysis operations. Innovations such as passive cooling designs and thermally integrated systems have shown promising results in reducing this energy footprint. Studies indicate that next-generation cooling technologies can decrease cooling-related energy consumption by 25-30%, directly translating to reduced carbon emissions when the electricity source is non-renewable.

Material sustainability represents another critical environmental dimension. Conventional cooling systems often utilize refrigerants with high global warming potential (GWP). New cooling technologies are increasingly adopting natural refrigerants or completely refrigerant-free approaches, eliminating potential emissions from leakage. Additionally, advanced heat management systems are being designed with recyclable materials and longer operational lifespans, reducing waste generation and resource depletion.

Waste heat recovery innovations present perhaps the most significant environmental opportunity. Modern electrolysis cooling systems are increasingly designed to capture and repurpose thermal energy that would otherwise be dissipated. This recovered heat can be integrated into district heating networks, used for preheating processes, or converted to other forms of useful energy. Field implementations have demonstrated that up to 60% of waste heat can be effectively recovered, substantially improving the overall energy efficiency of hydrogen production facilities.

The environmental benefits extend to land and space utilization as well. Compact cooling technologies reduce the physical footprint of electrolysis installations, minimizing habitat disruption and allowing for more flexible siting options, including integration with existing industrial facilities. This spatial efficiency becomes particularly important as hydrogen production scales up to meet growing demand.

Lifecycle assessment studies comparing conventional and innovative cooling technologies reveal that advanced systems can reduce the environmental impact across multiple categories, including carbon footprint, water usage, and ecotoxicity. However, these benefits must be balanced against potential new environmental challenges, such as the use of specialized materials that may have complex supply chains or end-of-life management requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!