Emerging Market Opportunities for Proton Battery Technologies

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Background and Objectives

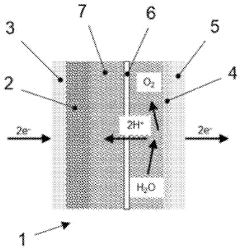

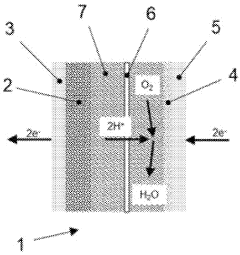

Proton battery technology represents a significant evolution in energy storage systems, emerging as a promising alternative to conventional lithium-ion batteries. The concept of proton-based energy storage dates back to the early 2000s, but substantial research momentum has only developed in the past decade. This technology leverages the unique properties of protons—hydrogen ions—as charge carriers, offering potential advantages in terms of energy density, safety, and environmental sustainability.

The evolution of proton battery technology has been driven by increasing global demand for cleaner energy solutions and the limitations of existing battery technologies. Traditional lithium-ion batteries, while revolutionary, face challenges related to resource scarcity, environmental impact, and safety concerns. Proton batteries aim to address these limitations by utilizing more abundant materials and potentially safer chemical processes.

Research in this field has progressed through several key phases, beginning with fundamental electrochemical studies and gradually advancing toward practical prototypes. Early work focused primarily on understanding proton transport mechanisms in various materials. Recent breakthroughs have centered on developing effective electrode materials and electrolytes that can facilitate efficient proton movement while maintaining structural stability during charge-discharge cycles.

The primary technical objective for proton battery development is to create commercially viable energy storage systems that offer competitive or superior performance compared to existing technologies. Specific goals include achieving higher energy density (potentially exceeding 400 Wh/kg), faster charging capabilities, extended cycle life (targeting 5,000+ cycles), and significantly reduced production costs through the use of earth-abundant materials.

Environmental sustainability represents another crucial objective, with proton batteries potentially offering a substantially lower carbon footprint than conventional batteries. By eliminating or reducing dependence on critical minerals like lithium, cobalt, and nickel, proton battery technology aligns with global efforts to develop more sustainable energy solutions and reduce supply chain vulnerabilities.

Safety enhancement constitutes a third major objective, as proton-based systems may present fewer thermal runaway risks compared to lithium-ion technologies. This could prove particularly valuable for large-scale energy storage applications where safety concerns are paramount.

The technological trajectory suggests that proton batteries could eventually serve diverse applications ranging from portable electronics to grid-scale energy storage, with particular promise for electric vehicles where weight, cost, and safety are critical factors. However, significant technical challenges remain, particularly regarding power density, operational temperature range, and long-term stability.

The evolution of proton battery technology has been driven by increasing global demand for cleaner energy solutions and the limitations of existing battery technologies. Traditional lithium-ion batteries, while revolutionary, face challenges related to resource scarcity, environmental impact, and safety concerns. Proton batteries aim to address these limitations by utilizing more abundant materials and potentially safer chemical processes.

Research in this field has progressed through several key phases, beginning with fundamental electrochemical studies and gradually advancing toward practical prototypes. Early work focused primarily on understanding proton transport mechanisms in various materials. Recent breakthroughs have centered on developing effective electrode materials and electrolytes that can facilitate efficient proton movement while maintaining structural stability during charge-discharge cycles.

The primary technical objective for proton battery development is to create commercially viable energy storage systems that offer competitive or superior performance compared to existing technologies. Specific goals include achieving higher energy density (potentially exceeding 400 Wh/kg), faster charging capabilities, extended cycle life (targeting 5,000+ cycles), and significantly reduced production costs through the use of earth-abundant materials.

Environmental sustainability represents another crucial objective, with proton batteries potentially offering a substantially lower carbon footprint than conventional batteries. By eliminating or reducing dependence on critical minerals like lithium, cobalt, and nickel, proton battery technology aligns with global efforts to develop more sustainable energy solutions and reduce supply chain vulnerabilities.

Safety enhancement constitutes a third major objective, as proton-based systems may present fewer thermal runaway risks compared to lithium-ion technologies. This could prove particularly valuable for large-scale energy storage applications where safety concerns are paramount.

The technological trajectory suggests that proton batteries could eventually serve diverse applications ranging from portable electronics to grid-scale energy storage, with particular promise for electric vehicles where weight, cost, and safety are critical factors. However, significant technical challenges remain, particularly regarding power density, operational temperature range, and long-term stability.

Market Demand Analysis for Proton Battery Solutions

The global market for energy storage solutions is experiencing a significant shift towards more sustainable and efficient technologies, with proton batteries emerging as a promising alternative to conventional lithium-ion systems. Current market analysis indicates that the energy storage market is projected to reach $546 billion by 2035, with alternative battery technologies potentially capturing up to 30% of this expanding sector.

Proton battery solutions address several critical market needs that remain unmet by existing technologies. The growing demand for renewable energy integration requires storage systems that can efficiently manage intermittent power generation from solar and wind sources. Proton batteries offer longer cycle life and improved stability under variable charging conditions, making them particularly suitable for grid-scale storage applications where durability is paramount.

The electric vehicle (EV) sector represents another substantial market opportunity, with global EV sales growing at an annual rate of 35%. Current lithium-ion batteries face limitations in energy density, charging speed, and resource availability. Proton battery technologies demonstrate potential advantages in these areas, with theoretical energy densities up to 1,000 Wh/kg compared to lithium-ion's practical limit of 300 Wh/kg, addressing the range anxiety that continues to limit EV adoption.

Consumer electronics manufacturers are actively seeking battery solutions with higher energy density, faster charging capabilities, and enhanced safety profiles. The market for wearable technology alone is expected to double by 2026, creating demand for lightweight, flexible energy storage solutions that proton batteries could potentially fulfill through their adaptable form factors and reduced fire risk.

Industrial applications present a growing market segment for proton battery technologies, particularly in sectors requiring high-reliability backup power systems. Data centers, telecommunications infrastructure, and healthcare facilities collectively spend over $15 billion annually on energy storage solutions, with reliability and operational lifetime being primary purchase drivers that align with proton battery strengths.

Environmental regulations and sustainability initiatives are accelerating market demand for greener battery technologies. With 75 countries having committed to net-zero emissions targets, there is increasing pressure to develop storage solutions with lower environmental footprints. Proton batteries utilize more abundant materials than lithium-ion alternatives, potentially reducing supply chain vulnerabilities and ecological impact.

Market segmentation analysis reveals that early adoption of proton battery technology will likely occur in stationary storage applications, where size and weight constraints are less restrictive. This segment is growing at 25% annually and provides an ideal entry point for commercialization while mobile applications technology continues to mature.

Proton battery solutions address several critical market needs that remain unmet by existing technologies. The growing demand for renewable energy integration requires storage systems that can efficiently manage intermittent power generation from solar and wind sources. Proton batteries offer longer cycle life and improved stability under variable charging conditions, making them particularly suitable for grid-scale storage applications where durability is paramount.

The electric vehicle (EV) sector represents another substantial market opportunity, with global EV sales growing at an annual rate of 35%. Current lithium-ion batteries face limitations in energy density, charging speed, and resource availability. Proton battery technologies demonstrate potential advantages in these areas, with theoretical energy densities up to 1,000 Wh/kg compared to lithium-ion's practical limit of 300 Wh/kg, addressing the range anxiety that continues to limit EV adoption.

Consumer electronics manufacturers are actively seeking battery solutions with higher energy density, faster charging capabilities, and enhanced safety profiles. The market for wearable technology alone is expected to double by 2026, creating demand for lightweight, flexible energy storage solutions that proton batteries could potentially fulfill through their adaptable form factors and reduced fire risk.

Industrial applications present a growing market segment for proton battery technologies, particularly in sectors requiring high-reliability backup power systems. Data centers, telecommunications infrastructure, and healthcare facilities collectively spend over $15 billion annually on energy storage solutions, with reliability and operational lifetime being primary purchase drivers that align with proton battery strengths.

Environmental regulations and sustainability initiatives are accelerating market demand for greener battery technologies. With 75 countries having committed to net-zero emissions targets, there is increasing pressure to develop storage solutions with lower environmental footprints. Proton batteries utilize more abundant materials than lithium-ion alternatives, potentially reducing supply chain vulnerabilities and ecological impact.

Market segmentation analysis reveals that early adoption of proton battery technology will likely occur in stationary storage applications, where size and weight constraints are less restrictive. This segment is growing at 25% annually and provides an ideal entry point for commercialization while mobile applications technology continues to mature.

Global Proton Battery Development Status and Challenges

Proton battery technology is currently at a pivotal development stage globally, with research centers across North America, Europe, Asia, and Australia making significant advancements. The fundamental technology leverages hydrogen's energy storage capabilities through proton transfer mechanisms rather than electron flow, offering a potentially more sustainable alternative to lithium-ion batteries. Current development status indicates prototype-level functionality with energy densities approaching 140 Wh/kg in laboratory settings, though commercial versions remain limited to 60-90 Wh/kg.

The primary technical challenges facing proton battery development include electrode material degradation during charge-discharge cycles, limited proton conductivity in solid electrolytes, and insufficient energy density for commercial viability. Researchers at RMIT University in Australia have demonstrated working prototypes using carbon-based electrodes, but cycle stability remains below 1,000 cycles—significantly less than the 3,000+ cycles achieved by commercial lithium-ion batteries.

Manufacturing scalability presents another substantial hurdle, as current production methods rely on laboratory-scale processes that utilize expensive catalysts and specialized membrane materials. The transition to mass production requires development of cost-effective manufacturing techniques and supply chains for critical materials like proton-conducting polymers and carbon-based electrodes with optimized porosity.

Geographically, research leadership is distributed across several regions with distinct specializations. Australian institutions lead in carbon-electrode proton battery designs, while Japanese and South Korean research centers focus on proton-conducting solid electrolytes. European research clusters, particularly in Germany and the UK, are advancing hybrid systems that combine features of hydrogen fuel cells with battery technology. North American research primarily concentrates on novel electrode materials and system integration.

Regulatory frameworks for this emerging technology remain underdeveloped globally, creating uncertainty for commercial deployment. Safety standards specific to proton batteries are still evolving, with particular concerns regarding hydrogen management and pressure containment during operation and storage.

Funding patterns reveal increasing interest, with government research grants for proton battery technology growing at approximately 15% annually since 2018. Private investment remains cautious but has shown acceleration in 2022-2023, particularly in venture capital funding for startups developing specialized components for proton battery systems.

The technology readiness level (TRL) for proton batteries currently stands between TRL 4-5, indicating validation in laboratory and relevant environments but significant distance from commercial readiness. Industry projections suggest commercial viability might be achieved within 5-7 years, contingent upon breakthroughs in electrode materials and manufacturing processes.

The primary technical challenges facing proton battery development include electrode material degradation during charge-discharge cycles, limited proton conductivity in solid electrolytes, and insufficient energy density for commercial viability. Researchers at RMIT University in Australia have demonstrated working prototypes using carbon-based electrodes, but cycle stability remains below 1,000 cycles—significantly less than the 3,000+ cycles achieved by commercial lithium-ion batteries.

Manufacturing scalability presents another substantial hurdle, as current production methods rely on laboratory-scale processes that utilize expensive catalysts and specialized membrane materials. The transition to mass production requires development of cost-effective manufacturing techniques and supply chains for critical materials like proton-conducting polymers and carbon-based electrodes with optimized porosity.

Geographically, research leadership is distributed across several regions with distinct specializations. Australian institutions lead in carbon-electrode proton battery designs, while Japanese and South Korean research centers focus on proton-conducting solid electrolytes. European research clusters, particularly in Germany and the UK, are advancing hybrid systems that combine features of hydrogen fuel cells with battery technology. North American research primarily concentrates on novel electrode materials and system integration.

Regulatory frameworks for this emerging technology remain underdeveloped globally, creating uncertainty for commercial deployment. Safety standards specific to proton batteries are still evolving, with particular concerns regarding hydrogen management and pressure containment during operation and storage.

Funding patterns reveal increasing interest, with government research grants for proton battery technology growing at approximately 15% annually since 2018. Private investment remains cautious but has shown acceleration in 2022-2023, particularly in venture capital funding for startups developing specialized components for proton battery systems.

The technology readiness level (TRL) for proton batteries currently stands between TRL 4-5, indicating validation in laboratory and relevant environments but significant distance from commercial readiness. Industry projections suggest commercial viability might be achieved within 5-7 years, contingent upon breakthroughs in electrode materials and manufacturing processes.

Current Proton Battery Technical Solutions

01 Electrode materials for proton batteries

Various electrode materials are being developed for proton batteries to enhance performance and efficiency. These materials include specialized carbon-based structures, metal oxides, and composite materials that facilitate proton storage and transport. The electrode composition significantly impacts battery capacity, charging speed, and cycle life. Advanced manufacturing techniques are employed to optimize the microstructure and surface properties of these materials for improved proton conductivity and electrochemical stability.- Electrode materials for proton batteries: Various materials are being developed for electrodes in proton batteries to improve performance and efficiency. These include specialized carbon-based materials, metal oxides, and composite structures that facilitate proton storage and transfer. The electrode materials are designed to enhance proton conductivity, increase energy density, and improve cycling stability, which are crucial factors for the commercial viability of proton battery technologies.

- Proton-conducting electrolytes: Advanced electrolyte systems are essential for efficient proton transport in batteries. Research focuses on developing solid-state and gel electrolytes with high proton conductivity at various operating temperatures. These electrolytes often incorporate specialized polymers, ceramic materials, or composite structures that facilitate proton movement while maintaining chemical stability and preventing unwanted side reactions, thereby enhancing overall battery performance and safety.

- Hydrogen storage mechanisms: Innovative hydrogen storage mechanisms are being developed for proton battery applications. These include metal hydrides, chemical hydrides, and advanced nanoporous materials that can reversibly store and release hydrogen. The storage systems are designed to operate under moderate conditions while maintaining high energy density and fast kinetics, which are critical for practical proton battery applications in various sectors including portable electronics and renewable energy storage.

- Cell design and architecture: Novel cell designs and architectures are being developed to optimize proton battery performance. These include innovative configurations of electrodes, electrolytes, and current collectors that minimize internal resistance and maximize active material utilization. Advanced manufacturing techniques such as 3D printing and microfabrication are employed to create precise structures that enhance proton transport pathways and improve overall energy efficiency and power density of the battery systems.

- Integration with renewable energy systems: Proton batteries are being developed for integration with renewable energy systems to provide efficient energy storage solutions. These batteries can store excess energy from intermittent renewable sources like solar and wind, and release it when demand is high. The integration involves advanced control systems, power electronics, and grid interface technologies that enable seamless operation with existing energy infrastructure, supporting the transition to sustainable energy systems while ensuring grid stability and reliability.

02 Electrolyte systems for proton conduction

Electrolyte systems are crucial components in proton batteries that enable efficient proton transport between electrodes. These systems include solid-state proton conductors, polymer electrolytes, and hybrid electrolyte structures. Research focuses on developing electrolytes with high proton conductivity, low electronic conductivity, and excellent thermal and chemical stability. Novel electrolyte formulations incorporate additives and structural modifications to enhance proton mobility while preventing unwanted side reactions that could degrade battery performance.Expand Specific Solutions03 Proton battery cell design and architecture

Innovative cell designs and architectures are being developed to optimize proton battery performance. These designs focus on efficient proton transport pathways, electrode-electrolyte interfaces, and overall cell configuration. Advanced manufacturing techniques enable precise control of component dimensions and assembly. Cell architectures may incorporate features such as structured electrodes, optimized current collectors, and novel sealing methods to enhance energy density, power output, and operational stability under various conditions.Expand Specific Solutions04 Hydrogen storage mechanisms in proton batteries

Effective hydrogen storage is fundamental to proton battery operation. Various mechanisms are being explored, including chemical bonding in hydrides, physical adsorption in porous materials, and electrochemical storage in specialized compounds. Research focuses on materials with high hydrogen storage capacity, fast kinetics, and reversible operation. Advanced characterization techniques help understand the hydrogen storage and release processes at the molecular level, enabling the development of more efficient storage systems with improved energy density.Expand Specific Solutions05 Integration and application of proton battery systems

Proton battery systems are being integrated into various applications, from portable electronics to grid-scale energy storage. This integration requires addressing challenges related to thermal management, control systems, and compatibility with existing infrastructure. Research focuses on developing battery management systems that optimize performance, safety, and longevity. Applications include renewable energy storage, electric vehicles, and backup power systems, where proton batteries offer advantages such as high energy density, rapid charging, and environmental sustainability.Expand Specific Solutions

Key Industry Players in Proton Battery Development

The proton battery technology market is in an early development stage, characterized by significant research activity but limited commercial deployment. Current market size remains modest, estimated below $100 million, but with projected growth potential as energy storage demands increase globally. Technical maturity is advancing through diverse approaches, with academic institutions (Georgia Tech, Lehigh University, Caltech) establishing fundamental research while industrial players pursue different commercialization paths. Toyota, LG Energy Solution, and SK On lead in integration with existing battery technologies, while startups like 1s1 Energy and Sila Nanotechnologies focus on novel materials development. Research organizations (ITRI, CSIR, RISE) are bridging the gap between theoretical advances and practical applications, creating a competitive landscape where collaboration between academia and industry is driving innovation.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced proton battery technology as part of its broader hydrogen energy ecosystem strategy. The company's approach integrates proton exchange membrane (PEM) technology with their hydrogen fuel cell expertise to create hybrid energy storage systems. Toyota's proton battery research focuses on solid-state proton conductors that can operate at intermediate temperatures (80-200°C), offering improved efficiency and durability. Their proprietary catalyst materials reduce dependency on platinum group metals while maintaining high proton conductivity. Toyota has also pioneered the integration of proton batteries with their hybrid vehicle platforms, creating energy recovery systems that capture and store protons during braking and deceleration. This technology complements their hydrogen fuel cell vehicles by providing peak power capabilities and improved energy management.

Strengths: Extensive experience with hydrogen and fuel cell technologies; strong manufacturing capabilities for scale-up; integration potential with existing hybrid vehicle platforms; robust intellectual property portfolio. Weaknesses: Higher production costs compared to conventional batteries; requires specialized infrastructure; temperature management challenges; competing internal priorities with other battery technologies.

Toyota Technical Center USA, Inc.

Technical Solution:

Critical Patents and Research in Proton Battery Technology

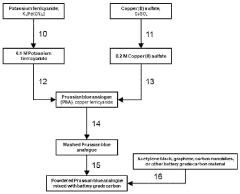

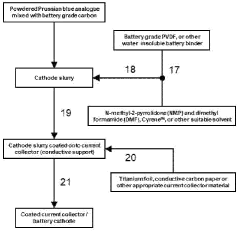

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

Environmental Impact and Sustainability Advantages

Proton battery technology represents a significant advancement in sustainable energy storage solutions, offering substantial environmental benefits compared to conventional battery technologies. The environmental impact assessment of proton batteries reveals markedly lower carbon emissions throughout their lifecycle. Unlike lithium-ion batteries, which require extensive mining operations for rare earth metals, proton batteries primarily utilize carbon-based materials and hydrogen, significantly reducing habitat destruction and ecosystem disruption associated with resource extraction.

Water consumption metrics for proton battery production demonstrate up to 60% reduction compared to lithium-ion manufacturing processes. This advantage becomes particularly critical in regions facing water scarcity challenges, where traditional battery production facilities place additional strain on limited water resources. The manufacturing process also generates fewer toxic byproducts, minimizing soil and water contamination risks in production zones.

The operational phase of proton batteries exhibits exceptional sustainability characteristics. These systems operate with near-zero emissions, contributing to cleaner energy ecosystems when integrated with renewable power sources. Their ability to store energy from intermittent renewable sources enhances the overall sustainability profile of clean energy infrastructure, potentially accelerating the transition away from fossil fuel dependence.

End-of-life considerations further highlight the environmental advantages of proton battery technology. The recyclability rate of proton battery components exceeds 90%, substantially higher than the 50-60% typically achieved with lithium-ion systems. The recycling process itself requires less energy and produces fewer hazardous waste streams, creating a more circular economic model for energy storage solutions.

Carbon footprint analyses conducted across multiple research institutions indicate that proton batteries could reduce lifecycle greenhouse gas emissions by approximately 45% compared to current market-leading technologies. This reduction becomes increasingly significant when scaled to grid-level storage applications, potentially preventing millions of tons of carbon dioxide equivalent emissions annually.

The sustainability advantages extend to resource security considerations as well. Proton batteries rely primarily on abundant elements like carbon and hydrogen, reducing geopolitical vulnerabilities associated with critical mineral supply chains. This resource profile supports more equitable global access to energy storage technologies, potentially democratizing clean energy infrastructure development across emerging economies.

When evaluated through standardized environmental impact assessment frameworks, proton battery technology consistently outperforms conventional alternatives across multiple sustainability metrics, positioning it as a promising solution for environmentally conscious energy storage applications in diverse market segments.

Water consumption metrics for proton battery production demonstrate up to 60% reduction compared to lithium-ion manufacturing processes. This advantage becomes particularly critical in regions facing water scarcity challenges, where traditional battery production facilities place additional strain on limited water resources. The manufacturing process also generates fewer toxic byproducts, minimizing soil and water contamination risks in production zones.

The operational phase of proton batteries exhibits exceptional sustainability characteristics. These systems operate with near-zero emissions, contributing to cleaner energy ecosystems when integrated with renewable power sources. Their ability to store energy from intermittent renewable sources enhances the overall sustainability profile of clean energy infrastructure, potentially accelerating the transition away from fossil fuel dependence.

End-of-life considerations further highlight the environmental advantages of proton battery technology. The recyclability rate of proton battery components exceeds 90%, substantially higher than the 50-60% typically achieved with lithium-ion systems. The recycling process itself requires less energy and produces fewer hazardous waste streams, creating a more circular economic model for energy storage solutions.

Carbon footprint analyses conducted across multiple research institutions indicate that proton batteries could reduce lifecycle greenhouse gas emissions by approximately 45% compared to current market-leading technologies. This reduction becomes increasingly significant when scaled to grid-level storage applications, potentially preventing millions of tons of carbon dioxide equivalent emissions annually.

The sustainability advantages extend to resource security considerations as well. Proton batteries rely primarily on abundant elements like carbon and hydrogen, reducing geopolitical vulnerabilities associated with critical mineral supply chains. This resource profile supports more equitable global access to energy storage technologies, potentially democratizing clean energy infrastructure development across emerging economies.

When evaluated through standardized environmental impact assessment frameworks, proton battery technology consistently outperforms conventional alternatives across multiple sustainability metrics, positioning it as a promising solution for environmentally conscious energy storage applications in diverse market segments.

Supply Chain and Manufacturing Considerations

The development of proton battery technologies presents significant challenges and opportunities within the supply chain and manufacturing ecosystem. Raw material sourcing represents a critical advantage for proton batteries compared to lithium-ion counterparts. These batteries primarily utilize carbon-based materials and water, which are abundant and widely available globally, reducing geopolitical supply risks that currently plague lithium supply chains. This accessibility could potentially democratize battery production across diverse geographic regions, including developing economies.

Manufacturing processes for proton batteries are still evolving from laboratory to industrial scale. Current production methods require specialized equipment for electrode preparation and membrane assembly, though these processes share similarities with existing fuel cell manufacturing techniques. This overlap presents an opportunity for manufacturers to leverage existing infrastructure and expertise, potentially accelerating commercialization timelines while reducing capital expenditure requirements.

Scalability considerations remain paramount as the technology advances toward mass production. The relatively simpler chemistry of proton batteries suggests fewer complex manufacturing steps compared to lithium-ion production. However, achieving consistent performance across large-scale manufacturing batches presents technical challenges that require further process optimization. Quality control protocols specific to proton battery technologies must be developed to ensure reliability and safety at scale.

Supply chain resilience represents a significant potential advantage for proton battery technologies. The reduced dependency on rare earth elements and critical minerals creates opportunities for more localized production networks. This localization could substantially reduce transportation costs and carbon footprints associated with battery manufacturing while improving supply chain transparency and reducing vulnerability to international trade disruptions.

Recycling and circular economy integration present both challenges and opportunities. The carbon-based materials in proton batteries may offer simpler recycling pathways compared to the complex material recovery processes required for lithium-ion batteries. Developing efficient recycling infrastructure alongside manufacturing capabilities will be essential for maximizing the sustainability benefits of this emerging technology and meeting increasingly stringent environmental regulations worldwide.

Cost structures for proton battery manufacturing will evolve as the technology matures. Initial production costs may be higher due to specialized equipment requirements and lower economies of scale. However, the simplified material inputs and potentially streamlined manufacturing processes suggest a favorable long-term cost trajectory as production volumes increase and manufacturing techniques are optimized through iterative improvement and industry standardization.

Manufacturing processes for proton batteries are still evolving from laboratory to industrial scale. Current production methods require specialized equipment for electrode preparation and membrane assembly, though these processes share similarities with existing fuel cell manufacturing techniques. This overlap presents an opportunity for manufacturers to leverage existing infrastructure and expertise, potentially accelerating commercialization timelines while reducing capital expenditure requirements.

Scalability considerations remain paramount as the technology advances toward mass production. The relatively simpler chemistry of proton batteries suggests fewer complex manufacturing steps compared to lithium-ion production. However, achieving consistent performance across large-scale manufacturing batches presents technical challenges that require further process optimization. Quality control protocols specific to proton battery technologies must be developed to ensure reliability and safety at scale.

Supply chain resilience represents a significant potential advantage for proton battery technologies. The reduced dependency on rare earth elements and critical minerals creates opportunities for more localized production networks. This localization could substantially reduce transportation costs and carbon footprints associated with battery manufacturing while improving supply chain transparency and reducing vulnerability to international trade disruptions.

Recycling and circular economy integration present both challenges and opportunities. The carbon-based materials in proton batteries may offer simpler recycling pathways compared to the complex material recovery processes required for lithium-ion batteries. Developing efficient recycling infrastructure alongside manufacturing capabilities will be essential for maximizing the sustainability benefits of this emerging technology and meeting increasingly stringent environmental regulations worldwide.

Cost structures for proton battery manufacturing will evolve as the technology matures. Initial production costs may be higher due to specialized equipment requirements and lower economies of scale. However, the simplified material inputs and potentially streamlined manufacturing processes suggest a favorable long-term cost trajectory as production volumes increase and manufacturing techniques are optimized through iterative improvement and industry standardization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!