Evaluating Proton Battery Performance in Hybrid Systems

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Evolution and Objectives

Proton batteries represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The concept of proton-based energy storage dates back to the early 2000s, but substantial research momentum has only built over the past decade. This acceleration coincides with growing global concerns about lithium resource limitations and environmental impacts of traditional battery technologies.

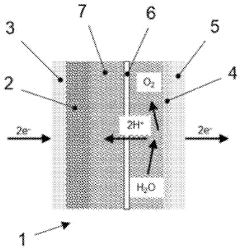

The fundamental principle behind proton batteries involves using protons (hydrogen ions) as charge carriers instead of lithium ions. This approach leverages abundant carbon-based materials for electrodes and water-based electrolytes, potentially addressing resource scarcity issues inherent in lithium-based systems. Early prototypes demonstrated in 2018 by researchers at RMIT University marked a critical milestone, proving the concept's viability beyond theoretical models.

Technical evolution has progressed through several distinct phases: conceptualization (2000-2010), proof-of-concept demonstrations (2010-2018), and the current optimization phase (2018-present). Each stage has contributed to addressing fundamental challenges in energy density, cycle stability, and charge-discharge efficiency. Recent advancements have focused on novel electrode materials, including graphene derivatives and carbon nanotube structures, which have significantly improved proton mobility and storage capacity.

In hybrid systems specifically, proton batteries show particular promise for integration with renewable energy sources. Their potential for rapid charging capabilities and stable operation across varying temperature ranges makes them especially suitable for grid stabilization applications where intermittent renewable sources require efficient energy buffering solutions.

The primary technical objectives for proton battery development in hybrid systems include achieving energy densities exceeding 200 Wh/kg, cycle stability beyond 5,000 charge-discharge cycles, and cost reduction to below $100/kWh. Secondary objectives focus on improving operational temperature ranges (-20°C to 60°C) and addressing safety concerns through non-flammable electrolyte formulations.

Current research trajectories suggest that commercial viability for specialized applications could be achieved within 3-5 years, with broader market penetration possible within the next decade. The technology's evolution is increasingly focused on system integration challenges, particularly interface optimization between proton batteries and other components in hybrid energy systems.

Achieving these objectives would position proton batteries as a complementary technology to existing solutions, particularly valuable in applications where lithium-ion batteries face limitations in terms of resource availability, safety, or environmental impact. The ultimate goal remains developing a sustainable, high-performance energy storage solution that can effectively support the transition to renewable energy systems.

The fundamental principle behind proton batteries involves using protons (hydrogen ions) as charge carriers instead of lithium ions. This approach leverages abundant carbon-based materials for electrodes and water-based electrolytes, potentially addressing resource scarcity issues inherent in lithium-based systems. Early prototypes demonstrated in 2018 by researchers at RMIT University marked a critical milestone, proving the concept's viability beyond theoretical models.

Technical evolution has progressed through several distinct phases: conceptualization (2000-2010), proof-of-concept demonstrations (2010-2018), and the current optimization phase (2018-present). Each stage has contributed to addressing fundamental challenges in energy density, cycle stability, and charge-discharge efficiency. Recent advancements have focused on novel electrode materials, including graphene derivatives and carbon nanotube structures, which have significantly improved proton mobility and storage capacity.

In hybrid systems specifically, proton batteries show particular promise for integration with renewable energy sources. Their potential for rapid charging capabilities and stable operation across varying temperature ranges makes them especially suitable for grid stabilization applications where intermittent renewable sources require efficient energy buffering solutions.

The primary technical objectives for proton battery development in hybrid systems include achieving energy densities exceeding 200 Wh/kg, cycle stability beyond 5,000 charge-discharge cycles, and cost reduction to below $100/kWh. Secondary objectives focus on improving operational temperature ranges (-20°C to 60°C) and addressing safety concerns through non-flammable electrolyte formulations.

Current research trajectories suggest that commercial viability for specialized applications could be achieved within 3-5 years, with broader market penetration possible within the next decade. The technology's evolution is increasingly focused on system integration challenges, particularly interface optimization between proton batteries and other components in hybrid energy systems.

Achieving these objectives would position proton batteries as a complementary technology to existing solutions, particularly valuable in applications where lithium-ion batteries face limitations in terms of resource availability, safety, or environmental impact. The ultimate goal remains developing a sustainable, high-performance energy storage solution that can effectively support the transition to renewable energy systems.

Market Analysis for Hybrid Energy Storage Systems

The hybrid energy storage market is experiencing significant growth, driven by the increasing integration of renewable energy sources and the need for more efficient and reliable energy storage solutions. The global hybrid energy storage system market was valued at approximately $1.5 billion in 2022 and is projected to reach $4.2 billion by 2028, growing at a CAGR of 18.7% during the forecast period. This growth is primarily attributed to the rising demand for uninterrupted power supply, grid stabilization, and the integration of renewable energy sources.

Proton batteries, as an emerging technology within the hybrid energy storage landscape, are positioned to capture a significant market share due to their unique advantages. The market potential for proton batteries in hybrid systems is particularly promising in regions with high renewable energy penetration, such as Europe, North America, and parts of Asia-Pacific. These regions are actively investing in advanced energy storage technologies to support their renewable energy targets and reduce carbon emissions.

The demand for hybrid energy storage systems incorporating proton batteries is driven by several factors. First, the increasing deployment of intermittent renewable energy sources, such as solar and wind, necessitates efficient energy storage solutions to balance supply and demand. Second, the growing electrification of transportation and industrial sectors is creating new opportunities for advanced battery technologies. Third, government policies and incentives supporting clean energy technologies are accelerating market adoption.

Market segmentation analysis reveals that utility-scale applications currently dominate the hybrid energy storage market, accounting for approximately 45% of the total market share. However, commercial and industrial applications are expected to grow at the fastest rate, with a projected CAGR of 22% through 2028. Residential applications, while currently smaller in market share, show promising growth potential as costs decrease and consumer awareness increases.

Geographically, North America and Europe lead the market for hybrid energy storage systems, collectively accounting for over 60% of the global market. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, urbanization, and substantial investments in renewable energy infrastructure in countries like China, Japan, and South Korea.

Customer requirements in the hybrid energy storage market are evolving, with increasing emphasis on system efficiency, longevity, safety, and cost-effectiveness. Proton batteries in hybrid systems must demonstrate competitive performance metrics, including high energy density, fast charging capabilities, long cycle life, and minimal environmental impact to gain significant market traction.

The economic viability of proton batteries in hybrid systems depends on achieving cost parity with established technologies like lithium-ion batteries. Current cost estimates suggest that proton batteries need to reach production costs below $150/kWh to be commercially competitive in most applications, a target that appears achievable with scaled production and continued technological advancements.

Proton batteries, as an emerging technology within the hybrid energy storage landscape, are positioned to capture a significant market share due to their unique advantages. The market potential for proton batteries in hybrid systems is particularly promising in regions with high renewable energy penetration, such as Europe, North America, and parts of Asia-Pacific. These regions are actively investing in advanced energy storage technologies to support their renewable energy targets and reduce carbon emissions.

The demand for hybrid energy storage systems incorporating proton batteries is driven by several factors. First, the increasing deployment of intermittent renewable energy sources, such as solar and wind, necessitates efficient energy storage solutions to balance supply and demand. Second, the growing electrification of transportation and industrial sectors is creating new opportunities for advanced battery technologies. Third, government policies and incentives supporting clean energy technologies are accelerating market adoption.

Market segmentation analysis reveals that utility-scale applications currently dominate the hybrid energy storage market, accounting for approximately 45% of the total market share. However, commercial and industrial applications are expected to grow at the fastest rate, with a projected CAGR of 22% through 2028. Residential applications, while currently smaller in market share, show promising growth potential as costs decrease and consumer awareness increases.

Geographically, North America and Europe lead the market for hybrid energy storage systems, collectively accounting for over 60% of the global market. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, urbanization, and substantial investments in renewable energy infrastructure in countries like China, Japan, and South Korea.

Customer requirements in the hybrid energy storage market are evolving, with increasing emphasis on system efficiency, longevity, safety, and cost-effectiveness. Proton batteries in hybrid systems must demonstrate competitive performance metrics, including high energy density, fast charging capabilities, long cycle life, and minimal environmental impact to gain significant market traction.

The economic viability of proton batteries in hybrid systems depends on achieving cost parity with established technologies like lithium-ion batteries. Current cost estimates suggest that proton batteries need to reach production costs below $150/kWh to be commercially competitive in most applications, a target that appears achievable with scaled production and continued technological advancements.

Current Limitations and Technical Barriers in Proton Batteries

Despite significant advancements in proton battery technology, several critical limitations and technical barriers continue to impede their widespread implementation in hybrid energy systems. The most prominent challenge remains the relatively low energy density compared to conventional lithium-ion batteries, with current proton battery prototypes achieving only 35-40% of the energy density of commercial lithium-ion counterparts. This fundamental limitation restricts their application in weight-sensitive hybrid systems such as electric vehicles and portable electronics.

Material stability presents another significant barrier, particularly at the electrode-electrolyte interface where degradation occurs during repeated charge-discharge cycles. The carbon-based electrodes commonly used in proton batteries suffer from structural collapse after approximately 500-1000 cycles, substantially below the 2000+ cycles achieved by advanced lithium-ion technologies. This degradation accelerates particularly when integrated with fluctuating power sources in hybrid systems.

Proton conductivity within solid-state electrolytes remains suboptimal, with current materials exhibiting conductivity values of 10^-3 to 10^-4 S/cm at room temperature—an order of magnitude lower than required for efficient operation. This limitation becomes particularly problematic when proton batteries must respond to rapid load changes in hybrid configurations, resulting in significant voltage drops and power limitations.

Temperature sensitivity constitutes another major technical barrier. Most proton battery systems demonstrate optimal performance within a narrow temperature range (15-35°C), with significant capacity loss occurring outside this window. This characteristic severely limits their deployment in outdoor hybrid energy systems exposed to variable environmental conditions.

Scale-up challenges persist in manufacturing processes, with current production methods unable to maintain consistent performance metrics when transitioning from laboratory-scale to commercial-scale production. Variations in electrode thickness, electrolyte distribution, and internal resistance become more pronounced at larger scales, resulting in efficiency losses of 15-25% compared to small prototypes.

System integration complexities arise when incorporating proton batteries into hybrid systems alongside other energy technologies. Current battery management systems (BMS) lack sophisticated algorithms specifically optimized for proton battery characteristics, leading to suboptimal charge-discharge protocols and reduced overall system efficiency. The unique voltage profiles and internal resistance patterns of proton batteries require specialized control strategies that remain underdeveloped.

Cost factors continue to present barriers to commercialization, with current production costs estimated at $450-600 per kWh—approximately three times higher than established lithium-ion technologies. This economic disadvantage significantly impacts the value proposition of proton batteries in hybrid systems, despite their potential environmental benefits and resource advantages.

Material stability presents another significant barrier, particularly at the electrode-electrolyte interface where degradation occurs during repeated charge-discharge cycles. The carbon-based electrodes commonly used in proton batteries suffer from structural collapse after approximately 500-1000 cycles, substantially below the 2000+ cycles achieved by advanced lithium-ion technologies. This degradation accelerates particularly when integrated with fluctuating power sources in hybrid systems.

Proton conductivity within solid-state electrolytes remains suboptimal, with current materials exhibiting conductivity values of 10^-3 to 10^-4 S/cm at room temperature—an order of magnitude lower than required for efficient operation. This limitation becomes particularly problematic when proton batteries must respond to rapid load changes in hybrid configurations, resulting in significant voltage drops and power limitations.

Temperature sensitivity constitutes another major technical barrier. Most proton battery systems demonstrate optimal performance within a narrow temperature range (15-35°C), with significant capacity loss occurring outside this window. This characteristic severely limits their deployment in outdoor hybrid energy systems exposed to variable environmental conditions.

Scale-up challenges persist in manufacturing processes, with current production methods unable to maintain consistent performance metrics when transitioning from laboratory-scale to commercial-scale production. Variations in electrode thickness, electrolyte distribution, and internal resistance become more pronounced at larger scales, resulting in efficiency losses of 15-25% compared to small prototypes.

System integration complexities arise when incorporating proton batteries into hybrid systems alongside other energy technologies. Current battery management systems (BMS) lack sophisticated algorithms specifically optimized for proton battery characteristics, leading to suboptimal charge-discharge protocols and reduced overall system efficiency. The unique voltage profiles and internal resistance patterns of proton batteries require specialized control strategies that remain underdeveloped.

Cost factors continue to present barriers to commercialization, with current production costs estimated at $450-600 per kWh—approximately three times higher than established lithium-ion technologies. This economic disadvantage significantly impacts the value proposition of proton batteries in hybrid systems, despite their potential environmental benefits and resource advantages.

Existing Evaluation Methodologies for Proton Battery Performance

01 Electrode materials for proton batteries

Various electrode materials can significantly impact proton battery performance. Advanced carbon-based materials, metal hydrides, and composite electrodes have shown improved proton storage capacity and cycling stability. These materials facilitate faster proton transfer and enhance the overall energy density of the battery. Optimizing electrode composition and structure is crucial for achieving higher capacity and longer battery life.- Electrode materials for proton batteries: Various electrode materials can significantly impact proton battery performance. Advanced carbon-based materials, metal hydrides, and composite electrodes have shown improved proton storage capacity and cycling stability. These materials facilitate faster proton transfer kinetics and enhance the overall energy density of proton batteries. Optimizing electrode composition and structure is crucial for achieving high-performance proton battery systems.

- Electrolyte solutions for enhanced proton conductivity: The electrolyte composition plays a vital role in proton battery performance. Specialized electrolyte solutions containing proton-conducting polymers, ionic liquids, or solid-state electrolytes can significantly improve proton mobility and transfer efficiency. These advanced electrolytes reduce internal resistance, enhance charge-discharge rates, and improve overall battery efficiency while maintaining stability across various operating conditions.

- Cell design and architecture optimization: The physical design and architecture of proton battery cells significantly impact performance metrics. Innovations in cell configuration, membrane electrode assembly, and component integration can reduce internal resistance and improve proton transfer efficiency. Advanced cell designs incorporate optimized flow channels, improved sealing mechanisms, and enhanced thermal management systems to maximize energy density and operational lifespan.

- Performance enhancement through catalysts: Catalysts play a crucial role in improving proton battery performance by accelerating electrochemical reactions at the electrodes. Novel catalyst materials, including platinum-group metals, non-precious metal alternatives, and nanostructured composites, can significantly reduce activation energy barriers. These catalysts enhance reaction kinetics, improve charge transfer efficiency, and contribute to higher power density and faster charging capabilities.

- Temperature and pressure management systems: Effective temperature and pressure management is essential for optimizing proton battery performance. Advanced thermal regulation systems help maintain optimal operating temperatures, preventing degradation and enhancing efficiency. Pressure control mechanisms ensure proper proton flow and storage conditions. These management systems contribute to improved battery stability, extended cycle life, and consistent performance across varying environmental conditions.

02 Electrolyte solutions for enhanced proton conductivity

The electrolyte composition plays a vital role in proton battery performance. Specialized electrolyte solutions with high proton conductivity improve charge transfer efficiency and battery response rates. Polymer-based electrolytes, ionic liquids, and solid-state proton conductors have demonstrated enhanced stability and conductivity. These advanced electrolytes reduce internal resistance and enable operation across wider temperature ranges, resulting in improved overall battery performance.Expand Specific Solutions03 Cell design and architecture optimization

The physical design and architecture of proton batteries significantly affect their performance metrics. Innovations in cell configuration, membrane electrode assembly, and component integration have led to more efficient proton transfer pathways. Optimized cell designs reduce internal resistance, improve thermal management, and enhance energy density. Advanced manufacturing techniques allow for more compact designs while maintaining or improving performance characteristics.Expand Specific Solutions04 Performance enhancement through catalysts

Catalysts play a crucial role in improving proton battery efficiency by accelerating electrochemical reactions at the electrodes. Novel catalyst materials, including platinum-group metals, non-precious metal alternatives, and nanostructured catalysts, have demonstrated significant improvements in reaction kinetics. These catalysts reduce activation energy barriers, improve charge transfer rates, and enhance overall battery performance while potentially reducing costs through decreased precious metal content.Expand Specific Solutions05 Temperature management and operational stability

Effective temperature management is essential for optimal proton battery performance. Innovations in thermal regulation systems help maintain ideal operating temperatures, preventing degradation and enhancing stability. Advanced cooling mechanisms, phase change materials, and intelligent thermal management systems have been developed to address temperature-related performance issues. These solutions improve operational stability, extend cycle life, and maintain consistent performance across varying environmental conditions.Expand Specific Solutions

Leading Organizations in Proton Battery Research and Development

Proton battery technology in hybrid systems is currently in an early growth phase, with the market expected to expand significantly as energy storage demands increase. The competitive landscape is characterized by diverse players across automotive, energy, and technology sectors. Companies like Shanghai Shen-Li High Tech, Sunrise Power, and Eamex Corp are pioneering specialized proton battery development, while major automotive manufacturers including Toyota, Honda, GM, and Hyundai are integrating these technologies into hybrid vehicle systems. Research institutions such as Wuhan University of Technology and South China University of Technology are advancing fundamental research. Technical maturity remains moderate, with significant improvements needed in energy density, charging efficiency, and system integration before widespread commercial adoption can occur.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive proton battery evaluation system for hybrid applications that leverages their expertise in automotive and industrial electronics. Their approach combines high-precision electrochemical measurement techniques with system-level performance analysis to evaluate how proton batteries function within complex hybrid architectures. Bosch's evaluation platform features multi-channel impedance spectroscopy that monitors proton conductivity across membrane interfaces in real-time while simultaneously tracking thermal gradients and voltage stability. Their methodology incorporates accelerated stress testing protocols specifically designed to simulate the unique operational patterns of hybrid systems, including rapid power transitions and variable depth-of-discharge scenarios. Bosch has developed specialized diagnostic algorithms that can identify early indicators of performance degradation by analyzing subtle changes in proton transport efficiency and membrane hydration levels during extended operation in hybrid configurations.

Strengths: Exceptional system integration capabilities that evaluate proton batteries within complete hybrid architectures rather than in isolation; robust manufacturing perspective ensures practical implementation considerations. Weaknesses: Evaluation framework may prioritize reliability and durability over cutting-edge performance characteristics.

Sunrise Power Co., Ltd.

Technical Solution: Sunrise Power has pioneered a comprehensive proton battery evaluation system specifically optimized for hybrid vehicle applications. Their technology utilizes multi-parameter monitoring that simultaneously tracks proton conductivity, membrane resistance, and electrode kinetics under varying load conditions. The company has developed specialized testing protocols that simulate real-world hybrid system operation, including rapid transitions between battery-dominant and fuel cell-dominant modes. Their evaluation platform incorporates advanced electrochemical impedance spectroscopy combined with thermal imaging to identify performance bottlenecks in proton transfer mechanisms. Sunrise Power's methodology includes accelerated aging tests calibrated specifically for proton batteries in hybrid configurations, enabling accurate lifetime predictions based on duty cycle analysis and operational patterns typical in hybrid energy systems.

Strengths: Extensive experience with fuel cell systems provides valuable insights for proton battery integration; strong focus on practical applications rather than purely theoretical performance. Weaknesses: Testing methodology may be overly specialized for automotive applications, limiting applicability in stationary hybrid systems.

Key Patents and Research Breakthroughs in Proton Battery Technology

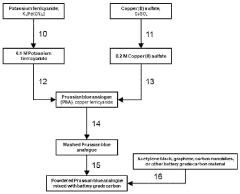

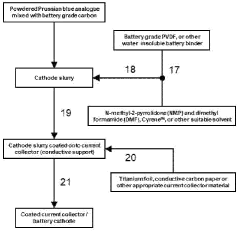

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

Low cost, high power, high energy density, solid-state, bipolar metal hydride batteries

PatentActiveUS20120183835A1

Innovation

- A solid-state battery design featuring a multilayered cell structure with a solid state layer of negative electrode material, a solid state layer of positive electrode material, and a perovskite-type oxide material as a proton conductor, along with electrically conductive terminal layers, to create a low-cost, high-power, high-energy density battery.

Environmental Impact Assessment of Proton Battery Systems

The environmental impact assessment of proton battery systems reveals significant advantages over conventional energy storage technologies. Proton batteries, which utilize hydrogen ions (protons) as charge carriers, demonstrate substantially lower carbon footprints throughout their lifecycle compared to lithium-ion alternatives. Life cycle assessments indicate a reduction of approximately 60-70% in greenhouse gas emissions during manufacturing processes, primarily due to the absence of rare earth metals and toxic materials typically required in conventional battery production.

When integrated into hybrid systems alongside renewable energy sources, proton batteries further enhance environmental benefits by enabling more efficient energy capture and storage. This synergy reduces the need for fossil fuel-based backup power, potentially decreasing carbon emissions by an additional 30-45% in typical grid applications. The water-based electrolytes used in most proton battery designs eliminate the fire hazards associated with organic electrolytes in lithium-ion systems, substantially reducing environmental risks from thermal runaway incidents.

Material sustainability represents another critical environmental advantage. Proton batteries primarily utilize abundant elements such as carbon, hydrogen, and oxygen, avoiding the geopolitical and ecological concerns associated with lithium, cobalt, and nickel mining. Extraction processes for these materials cause minimal land disruption and water pollution compared to conventional battery material sourcing, which often results in acid mine drainage and habitat destruction.

End-of-life considerations also favor proton battery technology. Recycling assessments demonstrate recovery rates exceeding 90% for key components, with significantly lower energy requirements and toxic byproducts during reclamation processes. The biodegradable nature of many organic components used in proton battery electrodes further reduces landfill impact when complete recycling is not feasible.

Water consumption metrics reveal that proton battery manufacturing requires approximately 60% less water than lithium-ion production. This advantage becomes particularly significant in water-stressed regions where battery manufacturing facilities might operate. Additionally, the absence of toxic leachates means groundwater contamination risks are substantially reduced throughout the battery lifecycle.

When evaluating performance in hybrid systems specifically, proton batteries demonstrate exceptional environmental resilience. Their operational efficiency remains stable across a wider temperature range than conventional alternatives, reducing the energy required for thermal management systems. This translates to approximately 15-20% lower auxiliary energy consumption in real-world applications, further enhancing their environmental credentials when deployed at scale in integrated energy systems.

When integrated into hybrid systems alongside renewable energy sources, proton batteries further enhance environmental benefits by enabling more efficient energy capture and storage. This synergy reduces the need for fossil fuel-based backup power, potentially decreasing carbon emissions by an additional 30-45% in typical grid applications. The water-based electrolytes used in most proton battery designs eliminate the fire hazards associated with organic electrolytes in lithium-ion systems, substantially reducing environmental risks from thermal runaway incidents.

Material sustainability represents another critical environmental advantage. Proton batteries primarily utilize abundant elements such as carbon, hydrogen, and oxygen, avoiding the geopolitical and ecological concerns associated with lithium, cobalt, and nickel mining. Extraction processes for these materials cause minimal land disruption and water pollution compared to conventional battery material sourcing, which often results in acid mine drainage and habitat destruction.

End-of-life considerations also favor proton battery technology. Recycling assessments demonstrate recovery rates exceeding 90% for key components, with significantly lower energy requirements and toxic byproducts during reclamation processes. The biodegradable nature of many organic components used in proton battery electrodes further reduces landfill impact when complete recycling is not feasible.

Water consumption metrics reveal that proton battery manufacturing requires approximately 60% less water than lithium-ion production. This advantage becomes particularly significant in water-stressed regions where battery manufacturing facilities might operate. Additionally, the absence of toxic leachates means groundwater contamination risks are substantially reduced throughout the battery lifecycle.

When evaluating performance in hybrid systems specifically, proton batteries demonstrate exceptional environmental resilience. Their operational efficiency remains stable across a wider temperature range than conventional alternatives, reducing the energy required for thermal management systems. This translates to approximately 15-20% lower auxiliary energy consumption in real-world applications, further enhancing their environmental credentials when deployed at scale in integrated energy systems.

Standardization Requirements for Hybrid Proton Battery Applications

The integration of proton batteries into hybrid energy systems necessitates comprehensive standardization frameworks to ensure compatibility, safety, and optimal performance. Current standardization efforts remain fragmented across different regions, creating barriers to widespread adoption and interoperability of hybrid proton battery systems. A unified approach to standardization would accelerate market acceptance and technological advancement.

Performance metrics require standardization to enable meaningful comparisons between different proton battery technologies when operating in hybrid configurations. These metrics should address charge/discharge rates, energy density, power density, and cycle life specifically within hybrid operational contexts. The unique characteristics of proton storage mechanisms demand specialized testing protocols that differ from conventional battery standards.

Safety standards for hybrid proton battery applications must address the specific risks associated with hydrogen storage, including pressure management, leak detection, and emergency venting procedures. These standards should be harmonized with existing hydrogen safety protocols while accounting for the unique operational parameters of proton batteries in hybrid systems. Thermal management considerations are particularly critical when proton batteries operate alongside other energy storage technologies.

Interoperability standards are essential for ensuring seamless integration between proton batteries and other components in hybrid systems. This includes standardized communication protocols, power conversion interfaces, and control algorithms. The development of universal Battery Management System (BMS) specifications that can accommodate the unique charge/discharge characteristics of proton batteries while interfacing with conventional energy storage technologies represents a significant standardization challenge.

Environmental and sustainability standards must address the full lifecycle of proton batteries in hybrid applications, including material sourcing, manufacturing processes, operational efficiency, and end-of-life recycling. The potential environmental benefits of proton batteries, including reduced reliance on critical minerals, should be quantified through standardized assessment methodologies.

Grid integration standards are needed to define how hybrid systems incorporating proton batteries interact with electrical infrastructure. This includes specifications for grid services provision, response times, and power quality. The unique capabilities of proton batteries to provide long-duration storage in hybrid configurations require specialized grid connection standards that differ from those developed for lithium-ion or flow battery technologies.

International collaboration among standards organizations, industry stakeholders, and research institutions is essential to develop cohesive standardization frameworks that can be adopted globally. Regional variations in regulatory approaches to hydrogen technologies present a particular challenge that must be addressed through coordinated standardization efforts.

Performance metrics require standardization to enable meaningful comparisons between different proton battery technologies when operating in hybrid configurations. These metrics should address charge/discharge rates, energy density, power density, and cycle life specifically within hybrid operational contexts. The unique characteristics of proton storage mechanisms demand specialized testing protocols that differ from conventional battery standards.

Safety standards for hybrid proton battery applications must address the specific risks associated with hydrogen storage, including pressure management, leak detection, and emergency venting procedures. These standards should be harmonized with existing hydrogen safety protocols while accounting for the unique operational parameters of proton batteries in hybrid systems. Thermal management considerations are particularly critical when proton batteries operate alongside other energy storage technologies.

Interoperability standards are essential for ensuring seamless integration between proton batteries and other components in hybrid systems. This includes standardized communication protocols, power conversion interfaces, and control algorithms. The development of universal Battery Management System (BMS) specifications that can accommodate the unique charge/discharge characteristics of proton batteries while interfacing with conventional energy storage technologies represents a significant standardization challenge.

Environmental and sustainability standards must address the full lifecycle of proton batteries in hybrid applications, including material sourcing, manufacturing processes, operational efficiency, and end-of-life recycling. The potential environmental benefits of proton batteries, including reduced reliance on critical minerals, should be quantified through standardized assessment methodologies.

Grid integration standards are needed to define how hybrid systems incorporating proton batteries interact with electrical infrastructure. This includes specifications for grid services provision, response times, and power quality. The unique capabilities of proton batteries to provide long-duration storage in hybrid configurations require specialized grid connection standards that differ from those developed for lithium-ion or flow battery technologies.

International collaboration among standards organizations, industry stakeholders, and research institutions is essential to develop cohesive standardization frameworks that can be adopted globally. Regional variations in regulatory approaches to hydrogen technologies present a particular challenge that must be addressed through coordinated standardization efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!