How Proton Batteries Transform Energy Harvesting Methods

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Evolution and Objectives

Proton battery technology represents a significant evolution in energy storage systems, emerging from decades of research into alternative battery chemistries. The concept dates back to the early 2000s when researchers began exploring hydrogen storage mechanisms that didn't rely on high-pressure gas containment. By 2014, the first laboratory demonstrations of proton-based energy storage showed promising results, marking the beginning of a new energy storage paradigm that combines elements of conventional batteries and hydrogen fuel cells.

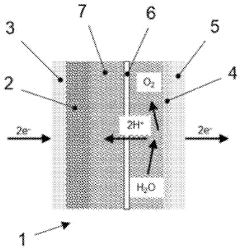

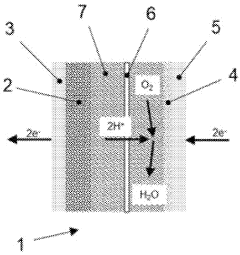

The fundamental innovation of proton batteries lies in their unique charge-discharge mechanism. Unlike lithium-ion batteries that shuttle lithium ions between electrodes, proton batteries store energy by splitting water molecules and storing the resulting protons in an electrode material, typically carbon-based. This approach eliminates the need for rare earth metals while potentially offering higher energy density and longer cycle life than conventional battery technologies.

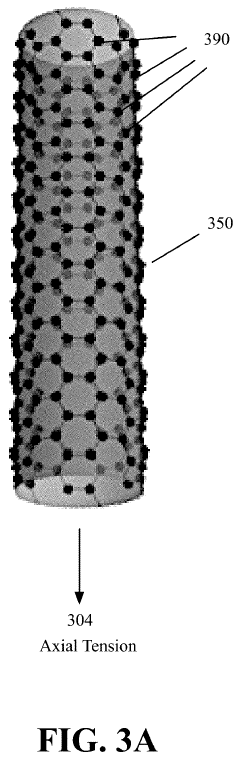

The evolution of proton battery technology has accelerated significantly in the past five years, with breakthroughs in electrode materials, electrolyte formulations, and cell designs. Carbon-based materials such as graphene and carbon nanotubes have emerged as particularly promising electrode candidates due to their exceptional proton conductivity and storage capacity. Parallel developments in solid-state electrolytes have addressed early challenges related to electrolyte degradation and proton mobility.

The primary technical objectives for proton battery development focus on several key performance metrics. Researchers aim to achieve energy densities exceeding 400 Wh/kg, significantly surpassing current lithium-ion technology. Additionally, cycle life targets of 5,000+ complete charge-discharge cycles would represent a substantial improvement over existing commercial solutions. Cost reduction remains another critical objective, with targets below $100/kWh to enable mass-market adoption.

From an energy harvesting perspective, proton batteries present unique advantages. Their ability to directly convert and store energy from hydrogen-producing renewable sources creates an integrated energy ecosystem. This direct coupling with renewable energy sources like solar and wind could dramatically improve overall system efficiency by eliminating conversion losses that occur in conventional battery charging processes.

Looking forward, the technology roadmap for proton batteries includes several ambitious milestones. Near-term goals focus on optimizing electrode materials and electrolyte formulations, while mid-term objectives target scaling production processes and improving system integration. Long-term aspirations include developing self-healing electrode structures and achieving theoretical maximum energy densities approaching 1,000 Wh/kg, which would revolutionize applications from portable electronics to grid-scale storage.

The fundamental innovation of proton batteries lies in their unique charge-discharge mechanism. Unlike lithium-ion batteries that shuttle lithium ions between electrodes, proton batteries store energy by splitting water molecules and storing the resulting protons in an electrode material, typically carbon-based. This approach eliminates the need for rare earth metals while potentially offering higher energy density and longer cycle life than conventional battery technologies.

The evolution of proton battery technology has accelerated significantly in the past five years, with breakthroughs in electrode materials, electrolyte formulations, and cell designs. Carbon-based materials such as graphene and carbon nanotubes have emerged as particularly promising electrode candidates due to their exceptional proton conductivity and storage capacity. Parallel developments in solid-state electrolytes have addressed early challenges related to electrolyte degradation and proton mobility.

The primary technical objectives for proton battery development focus on several key performance metrics. Researchers aim to achieve energy densities exceeding 400 Wh/kg, significantly surpassing current lithium-ion technology. Additionally, cycle life targets of 5,000+ complete charge-discharge cycles would represent a substantial improvement over existing commercial solutions. Cost reduction remains another critical objective, with targets below $100/kWh to enable mass-market adoption.

From an energy harvesting perspective, proton batteries present unique advantages. Their ability to directly convert and store energy from hydrogen-producing renewable sources creates an integrated energy ecosystem. This direct coupling with renewable energy sources like solar and wind could dramatically improve overall system efficiency by eliminating conversion losses that occur in conventional battery charging processes.

Looking forward, the technology roadmap for proton batteries includes several ambitious milestones. Near-term goals focus on optimizing electrode materials and electrolyte formulations, while mid-term objectives target scaling production processes and improving system integration. Long-term aspirations include developing self-healing electrode structures and achieving theoretical maximum energy densities approaching 1,000 Wh/kg, which would revolutionize applications from portable electronics to grid-scale storage.

Market Analysis for Proton-Based Energy Storage Solutions

The global market for proton-based energy storage solutions is experiencing significant growth, driven by increasing demand for sustainable and efficient energy storage technologies. Current market valuations indicate that the proton battery sector, though still emerging, has potential to capture substantial market share within the broader energy storage market, which was valued at approximately $130 billion in 2022 and is projected to reach $300 billion by 2030.

Proton batteries are positioned at the intersection of several high-growth market segments, including renewable energy integration, electric vehicles, and portable electronics. The renewable energy sector particularly benefits from advanced storage solutions like proton batteries, as intermittency issues with solar and wind power generation necessitate reliable storage mechanisms.

Consumer electronics represents another promising application area, with manufacturers seeking alternatives to lithium-ion batteries due to safety concerns, resource limitations, and environmental impact. Proton batteries offer advantages in these contexts through potentially higher energy density, improved safety profiles, and reduced environmental footprint.

Regional market analysis reveals varying adoption rates and investment patterns. Asia-Pacific leads in manufacturing capacity development, with significant investments from countries like Japan, South Korea, and China. European markets demonstrate strong interest driven by stringent environmental regulations and ambitious carbon neutrality targets. North American markets show growing investment in research and commercialization efforts, particularly through university-industry partnerships.

Market segmentation analysis indicates that stationary energy storage applications currently represent the largest potential market segment for proton batteries, followed by transportation and consumer electronics. The stationary storage segment is projected to maintain dominance through 2030, though transportation applications may see the highest compound annual growth rate as electric vehicle adoption accelerates.

Key market drivers include increasing renewable energy deployment, growing electric vehicle markets, and tightening regulations on conventional battery technologies. Barriers to market penetration include high initial production costs, technical challenges in scaling manufacturing processes, and competition from established lithium-ion technology with its mature supply chains and manufacturing infrastructure.

Price sensitivity analysis suggests that proton batteries will need to achieve production costs below $100 per kilowatt-hour to compete effectively with lithium-ion alternatives in most market segments. Current estimates place prototype-level costs significantly higher, though economies of scale and continued technological refinement are expected to drive substantial cost reductions over the next decade.

Proton batteries are positioned at the intersection of several high-growth market segments, including renewable energy integration, electric vehicles, and portable electronics. The renewable energy sector particularly benefits from advanced storage solutions like proton batteries, as intermittency issues with solar and wind power generation necessitate reliable storage mechanisms.

Consumer electronics represents another promising application area, with manufacturers seeking alternatives to lithium-ion batteries due to safety concerns, resource limitations, and environmental impact. Proton batteries offer advantages in these contexts through potentially higher energy density, improved safety profiles, and reduced environmental footprint.

Regional market analysis reveals varying adoption rates and investment patterns. Asia-Pacific leads in manufacturing capacity development, with significant investments from countries like Japan, South Korea, and China. European markets demonstrate strong interest driven by stringent environmental regulations and ambitious carbon neutrality targets. North American markets show growing investment in research and commercialization efforts, particularly through university-industry partnerships.

Market segmentation analysis indicates that stationary energy storage applications currently represent the largest potential market segment for proton batteries, followed by transportation and consumer electronics. The stationary storage segment is projected to maintain dominance through 2030, though transportation applications may see the highest compound annual growth rate as electric vehicle adoption accelerates.

Key market drivers include increasing renewable energy deployment, growing electric vehicle markets, and tightening regulations on conventional battery technologies. Barriers to market penetration include high initial production costs, technical challenges in scaling manufacturing processes, and competition from established lithium-ion technology with its mature supply chains and manufacturing infrastructure.

Price sensitivity analysis suggests that proton batteries will need to achieve production costs below $100 per kilowatt-hour to compete effectively with lithium-ion alternatives in most market segments. Current estimates place prototype-level costs significantly higher, though economies of scale and continued technological refinement are expected to drive substantial cost reductions over the next decade.

Global Research Status and Technical Barriers in Proton Batteries

Proton batteries represent a significant advancement in energy storage technology, with research efforts distributed across various global regions. Currently, the United States, European Union, China, Japan, and Australia lead in proton battery research and development. The United States has established several specialized research centers focusing on sustainable energy solutions, with notable contributions from institutions like MIT and Stanford University that have pioneered fundamental research on proton conductivity mechanisms and electrode materials.

The European Union has implemented coordinated research programs through Horizon Europe, emphasizing collaborative approaches between academic institutions and industry partners. Germany and France have emerged as particularly active in developing proton-conducting membranes and catalyst technologies, with substantial funding allocated to sustainable energy research initiatives.

China has rapidly accelerated its research output in recent years, demonstrating significant growth in patent filings related to proton battery technology. The Chinese government has strategically invested in establishing dedicated research facilities and promoting industry-academia partnerships to advance proton battery commercialization efforts.

Japanese research institutions have leveraged their extensive experience in hydrogen and fuel cell technologies to make substantial contributions to proton battery development. Their approach typically emphasizes miniaturization and efficiency improvements, with particular strength in materials science applications for energy storage.

Australia has emerged as a notable contributor, with the RMIT University team led by Professor John Andrews achieving breakthrough developments in proton battery prototypes that demonstrate practical energy harvesting capabilities.

Despite this global progress, significant technical barriers persist in proton battery development. The primary challenges include limited proton conductivity in solid-state electrolytes, which restricts ion transport efficiency and overall battery performance. Current proton-conducting materials exhibit conductivity values approximately an order of magnitude lower than required for commercial viability.

Electrode degradation presents another major obstacle, as repeated proton insertion and extraction processes cause structural deterioration, significantly reducing cycle life and long-term stability. Most prototype systems demonstrate performance degradation after fewer than 500 charge-discharge cycles, far below the commercial standard of 1,000+ cycles.

Additionally, the catalytic efficiency at electrode interfaces remains suboptimal, requiring expensive noble metal catalysts that hinder cost-effective scaling. Research teams worldwide are investigating alternative catalyst materials, but solutions that balance activity, stability, and cost remain elusive.

Manufacturing scalability represents another significant barrier, as current laboratory fabrication methods for proton batteries involve complex processes that are difficult to translate to mass production environments. The precision required for membrane electrode assembly and the sensitivity of materials to environmental conditions during manufacturing present substantial challenges for commercialization.

The European Union has implemented coordinated research programs through Horizon Europe, emphasizing collaborative approaches between academic institutions and industry partners. Germany and France have emerged as particularly active in developing proton-conducting membranes and catalyst technologies, with substantial funding allocated to sustainable energy research initiatives.

China has rapidly accelerated its research output in recent years, demonstrating significant growth in patent filings related to proton battery technology. The Chinese government has strategically invested in establishing dedicated research facilities and promoting industry-academia partnerships to advance proton battery commercialization efforts.

Japanese research institutions have leveraged their extensive experience in hydrogen and fuel cell technologies to make substantial contributions to proton battery development. Their approach typically emphasizes miniaturization and efficiency improvements, with particular strength in materials science applications for energy storage.

Australia has emerged as a notable contributor, with the RMIT University team led by Professor John Andrews achieving breakthrough developments in proton battery prototypes that demonstrate practical energy harvesting capabilities.

Despite this global progress, significant technical barriers persist in proton battery development. The primary challenges include limited proton conductivity in solid-state electrolytes, which restricts ion transport efficiency and overall battery performance. Current proton-conducting materials exhibit conductivity values approximately an order of magnitude lower than required for commercial viability.

Electrode degradation presents another major obstacle, as repeated proton insertion and extraction processes cause structural deterioration, significantly reducing cycle life and long-term stability. Most prototype systems demonstrate performance degradation after fewer than 500 charge-discharge cycles, far below the commercial standard of 1,000+ cycles.

Additionally, the catalytic efficiency at electrode interfaces remains suboptimal, requiring expensive noble metal catalysts that hinder cost-effective scaling. Research teams worldwide are investigating alternative catalyst materials, but solutions that balance activity, stability, and cost remain elusive.

Manufacturing scalability represents another significant barrier, as current laboratory fabrication methods for proton batteries involve complex processes that are difficult to translate to mass production environments. The precision required for membrane electrode assembly and the sensitivity of materials to environmental conditions during manufacturing present substantial challenges for commercialization.

Current Proton Battery Architectures and Implementation Approaches

01 Proton exchange membrane-based energy harvesting

Proton exchange membranes (PEMs) are utilized in energy harvesting systems to facilitate the controlled movement of protons. These membranes allow for the selective transport of protons while blocking other ions, creating an electrical potential difference that can be harnessed. This technology is fundamental to proton batteries and can be integrated with various catalysts to enhance efficiency. The systems often incorporate specialized electrode materials that optimize proton conductivity and energy storage capacity.- Proton exchange membrane-based energy harvesting: Proton exchange membranes (PEMs) can be utilized in energy harvesting systems for proton batteries. These membranes facilitate the selective transport of protons while blocking other ions, enabling efficient energy conversion. The technology involves using specialized polymer materials that contain acidic functional groups to conduct protons across the membrane. This approach enhances energy density and charge-discharge efficiency in proton battery systems while allowing for sustainable energy harvesting from various sources.

- Hydrogen-based proton battery systems: Hydrogen can serve as a key element in proton battery energy harvesting methods. These systems typically involve the storage of protons derived from hydrogen in electrode materials, often carbon-based structures or metal hydrides. The energy harvesting process involves controlled hydrogen splitting, proton transport, and subsequent recombination to generate electrical energy. This approach offers advantages in terms of energy density, environmental sustainability, and integration with existing hydrogen infrastructure for renewable energy applications.

- Electrochemical gradient-based energy harvesting: Proton batteries can harvest energy through electrochemical gradient mechanisms, where concentration or pressure differentials of protons are utilized to generate electrical current. These systems often employ specialized electrodes and catalysts to facilitate proton movement across membranes in response to these gradients. The technology can be applied to harvest energy from various sources including ambient humidity, temperature differentials, or chemical reactions. This approach enables continuous energy harvesting from environmental conditions without requiring external power inputs.

- Hybrid proton-electron energy harvesting systems: Hybrid systems that combine proton and electron transfer mechanisms can enhance energy harvesting efficiency in proton batteries. These systems typically involve dual-function materials or coupled electrodes that can simultaneously manage proton and electron flows. By coordinating these two charge carriers, the energy harvesting process becomes more efficient and versatile. Applications include self-powered sensors, wearable electronics, and distributed energy generation systems that can operate autonomously by harvesting energy from their surroundings.

- Biological and biomimetic proton energy harvesting: Biological principles and biomimetic approaches can be applied to proton battery energy harvesting methods. These systems often mimic natural proton pumps or utilize biological materials as components in proton transport chains. Techniques may include enzyme-catalyzed reactions, microbial fuel cell principles, or synthetic systems that replicate biological proton gradients. This approach offers advantages in biocompatibility, operation under mild conditions, and potential for self-regeneration, making it suitable for implantable devices and environmental monitoring applications.

02 Hydrogen-based proton battery systems

Hydrogen serves as a key element in proton battery energy harvesting methods. These systems typically involve hydrogen generation, storage, and conversion processes that enable energy to be stored and released through proton transfer mechanisms. The technology often incorporates catalysts that facilitate hydrogen splitting and recombination, allowing for reversible energy storage. Advanced hydrogen-based proton batteries can achieve higher energy densities compared to conventional battery technologies while maintaining environmentally friendly characteristics.Expand Specific Solutions03 Piezoelectric and mechanical energy conversion for proton batteries

Mechanical energy can be converted into electrical energy to charge proton batteries through piezoelectric materials and mechanisms. These systems harvest energy from vibrations, movements, or pressure changes in the environment. The mechanical stress induces charge separation in piezoelectric materials, generating electrical potential that can drive proton movement in battery systems. This approach is particularly valuable for self-powered devices and sensors that can operate in remote locations without external power sources.Expand Specific Solutions04 Thermal gradient and waste heat harvesting for proton batteries

Thermal energy harvesting methods utilize temperature differentials to generate electrical energy for proton battery systems. These approaches convert waste heat or environmental temperature gradients into usable energy through thermoelectric effects or thermally-driven proton transport mechanisms. The systems often incorporate specialized materials with high Seebeck coefficients or thermally responsive proton conductors. This technology enables energy recovery from industrial processes, electronic devices, or natural thermal sources to power proton-based energy storage systems.Expand Specific Solutions05 Biological and biomimetic proton energy harvesting

Biological and biomimetic approaches to proton energy harvesting draw inspiration from natural systems like photosynthesis and cellular respiration. These methods utilize biological materials or synthetic analogs that mimic natural proton pumping mechanisms to generate and store energy. The systems may incorporate enzymes, proteins, or biomimetic catalysts that facilitate proton transfer across membranes. This approach offers potential advantages in sustainability, biocompatibility, and self-healing capabilities for next-generation energy harvesting and storage technologies.Expand Specific Solutions

Leading Organizations and Competitive Landscape in Proton Battery Field

Proton battery technology is currently in an early development stage, with significant research momentum but limited commercial deployment. The market is projected to grow substantially as energy harvesting solutions become more critical for sustainable power generation. Companies like e-peas SA, Sunrise Power Co., Ltd., and Air Products & Chemicals are leading innovation in this space, while research institutions such as South China University of Technology and NASA are advancing fundamental technologies. The competitive landscape features both established energy corporations and specialized startups focusing on different applications - from portable electronics to grid-scale storage. Technical challenges remain in efficiency, durability, and cost-effectiveness, but collaborative efforts between industry players and academic institutions are accelerating development toward commercial viability.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed innovative proton battery technology that leverages their expertise in hydrogen production and handling. Their approach utilizes specialized proton-conducting membranes combined with novel catalyst materials to enable efficient energy storage and release. Air Products' proton batteries incorporate proprietary electrode structures that maximize active surface area while maintaining mechanical stability during charge-discharge cycles. The company has integrated their proton batteries with various energy harvesting technologies, particularly focusing on capturing intermittent renewable energy from wind and solar sources. Their systems demonstrate exceptional durability with operational lifespans exceeding 7,000 cycles under variable load conditions. Air Products has also developed scalable manufacturing processes that enable cost-effective production of their proton battery components. Their latest prototypes feature energy densities approaching 120 Wh/kg with rapid charging capabilities that allow 80% capacity restoration in under 30 minutes.

Strengths: Extensive experience with hydrogen technologies, established global supply chain, and strong intellectual property portfolio in related fields. Their systems show excellent integration with existing hydrogen infrastructure. Weaknesses: Relatively new entrant to energy storage markets with limited consumer-facing experience and challenges in miniaturization for portable applications.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed large-scale proton battery systems designed specifically for grid-level energy storage applications. Their approach utilizes advanced proton-conducting materials combined with abundant metal catalysts to create cost-effective energy storage solutions. State Grid's proton batteries feature innovative electrode structures that maximize active surface area while minimizing internal resistance, resulting in high power density capabilities. Their energy harvesting integration focuses primarily on capturing excess renewable energy during peak production periods for later use. The company has deployed pilot installations demonstrating capacities exceeding 10MWh with response times under 100 milliseconds, making them suitable for grid frequency regulation. State Grid has also developed specialized control systems that optimize proton battery performance based on real-time grid conditions and energy pricing signals. Their latest installations incorporate thermal management systems that utilize waste heat from the batteries to improve overall system efficiency.

Strengths: Unmatched experience with large-scale grid integration, extensive testing infrastructure, and strong financial resources for technology deployment. Their systems demonstrate excellent scalability for utility applications. Weaknesses: Technology primarily optimized for stationary applications rather than mobile use cases, with challenges in achieving energy densities comparable to advanced lithium-ion systems.

Key Patents and Scientific Breakthroughs in Proton Energy Storage

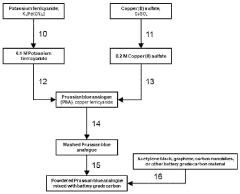

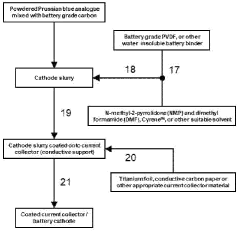

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

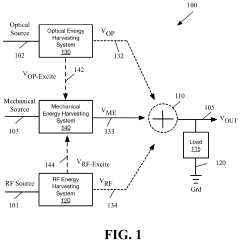

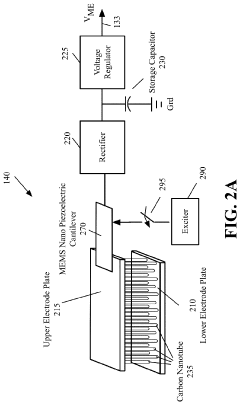

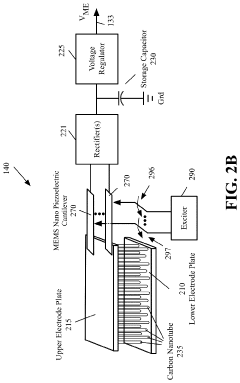

Green energy harvesting methods for novel class of batteries and power supplies

PatentActiveUS20230413676A1

Innovation

- An energy harvesting device using a mechanical repulsive force to counteract the Casimir force, employing single or multi-walled carbon nanotubes between metal plates, with nano piezoelectric cantilevers to convert mechanical vibrations into electrical energy, and incorporating RF or solar sources for periodic supercharging to overcome thermodynamic limitations.

Environmental Impact and Sustainability of Proton Battery Technology

Proton battery technology represents a significant advancement in sustainable energy solutions, offering substantial environmental benefits compared to conventional battery technologies. The environmental footprint of proton batteries is markedly lower than lithium-ion alternatives, primarily due to their reliance on abundant, non-toxic materials such as carbon and water. This fundamental composition eliminates the need for environmentally damaging mining operations associated with lithium, cobalt, and other rare earth elements currently essential for commercial batteries.

The manufacturing process for proton batteries demonstrates promising sustainability metrics, with early assessments indicating up to 90% reduction in carbon emissions compared to traditional battery production. This advantage stems from simplified production chains and reduced energy requirements during manufacturing. Additionally, the absence of toxic components translates to minimal environmental contamination risks throughout the battery lifecycle.

Water consumption represents another critical environmental consideration where proton batteries excel. While lithium extraction can require up to 500,000 gallons of water per ton of lithium, proton battery production demonstrates significantly lower water intensity. This characteristic makes them particularly valuable in water-stressed regions where energy storage solutions are increasingly needed.

End-of-life management further distinguishes proton battery technology in the sustainability landscape. The biodegradable nature of many components facilitates easier recycling and reduces landfill burden. Research indicates that up to 95% of proton battery materials could potentially be recovered and reused, creating a nearly closed-loop system that aligns with circular economy principles.

From a climate impact perspective, proton batteries contribute to decarbonization efforts through multiple pathways. Their ability to efficiently store renewable energy addresses intermittency challenges, potentially accelerating the transition away from fossil fuel dependence. Preliminary lifecycle assessments suggest that widespread adoption could reduce carbon emissions by 30-40% compared to current energy storage technologies when evaluated on a cradle-to-grave basis.

The scalability of proton battery technology presents additional sustainability advantages. Their construction from abundant materials avoids supply chain bottlenecks that currently constrain other green technologies. This characteristic enables deployment across diverse geographical and economic contexts, democratizing access to clean energy storage solutions and supporting global sustainability goals.

As the technology matures, ongoing research focuses on further enhancing the environmental profile through bio-derived electrolytes and carbon-negative production methods, potentially transforming proton batteries from merely sustainable alternatives to actively restorative environmental technologies.

The manufacturing process for proton batteries demonstrates promising sustainability metrics, with early assessments indicating up to 90% reduction in carbon emissions compared to traditional battery production. This advantage stems from simplified production chains and reduced energy requirements during manufacturing. Additionally, the absence of toxic components translates to minimal environmental contamination risks throughout the battery lifecycle.

Water consumption represents another critical environmental consideration where proton batteries excel. While lithium extraction can require up to 500,000 gallons of water per ton of lithium, proton battery production demonstrates significantly lower water intensity. This characteristic makes them particularly valuable in water-stressed regions where energy storage solutions are increasingly needed.

End-of-life management further distinguishes proton battery technology in the sustainability landscape. The biodegradable nature of many components facilitates easier recycling and reduces landfill burden. Research indicates that up to 95% of proton battery materials could potentially be recovered and reused, creating a nearly closed-loop system that aligns with circular economy principles.

From a climate impact perspective, proton batteries contribute to decarbonization efforts through multiple pathways. Their ability to efficiently store renewable energy addresses intermittency challenges, potentially accelerating the transition away from fossil fuel dependence. Preliminary lifecycle assessments suggest that widespread adoption could reduce carbon emissions by 30-40% compared to current energy storage technologies when evaluated on a cradle-to-grave basis.

The scalability of proton battery technology presents additional sustainability advantages. Their construction from abundant materials avoids supply chain bottlenecks that currently constrain other green technologies. This characteristic enables deployment across diverse geographical and economic contexts, democratizing access to clean energy storage solutions and supporting global sustainability goals.

As the technology matures, ongoing research focuses on further enhancing the environmental profile through bio-derived electrolytes and carbon-negative production methods, potentially transforming proton batteries from merely sustainable alternatives to actively restorative environmental technologies.

Integration Challenges with Existing Energy Infrastructure

The integration of proton batteries into existing energy infrastructure presents significant technical and operational challenges that must be addressed for successful deployment. Current energy systems are predominantly designed around conventional battery technologies and fossil fuel-based power generation, creating compatibility issues with proton battery technology. These systems lack the necessary interfaces and control mechanisms to efficiently manage the unique charge-discharge characteristics of proton-based energy storage.

Physical integration constraints represent a primary obstacle, as proton batteries may require different form factors, connection standards, and thermal management systems compared to lithium-ion or lead-acid batteries. Existing power conversion equipment, including inverters and charge controllers, would need substantial modifications to accommodate the different voltage profiles and power delivery characteristics of proton battery systems.

Grid-level integration poses additional complexities, particularly regarding synchronization with renewable energy sources. While proton batteries offer promising capabilities for storing intermittent renewable energy, the current grid infrastructure lacks sophisticated energy management systems capable of optimizing the interplay between proton battery storage, variable renewable generation, and fluctuating demand patterns.

Regulatory frameworks and industry standards present another integration barrier. Current electrical codes, safety protocols, and interconnection requirements were developed without consideration for proton battery technology. This regulatory gap creates uncertainty for manufacturers, installers, and utility companies, potentially slowing adoption despite technical merits.

Economic considerations further complicate integration efforts. Substantial capital investments would be required to modify existing infrastructure to accommodate proton batteries. Without clear cost-benefit analyses demonstrating superior lifetime value compared to established technologies, stakeholders may resist allocating resources for these modifications.

Technical workforce limitations also impede integration progress. The specialized knowledge required for proton battery installation, maintenance, and troubleshooting exceeds current industry expertise. Comprehensive training programs and certification standards would need development before widespread deployment could occur.

Despite these challenges, phased integration approaches offer promising pathways forward. Initial deployment in isolated microgrids or specialized applications could provide valuable operational data while minimizing disruption to critical infrastructure. Hybrid systems incorporating both conventional and proton battery technologies could serve as transitional solutions, allowing gradual infrastructure adaptation while maintaining system reliability.

Physical integration constraints represent a primary obstacle, as proton batteries may require different form factors, connection standards, and thermal management systems compared to lithium-ion or lead-acid batteries. Existing power conversion equipment, including inverters and charge controllers, would need substantial modifications to accommodate the different voltage profiles and power delivery characteristics of proton battery systems.

Grid-level integration poses additional complexities, particularly regarding synchronization with renewable energy sources. While proton batteries offer promising capabilities for storing intermittent renewable energy, the current grid infrastructure lacks sophisticated energy management systems capable of optimizing the interplay between proton battery storage, variable renewable generation, and fluctuating demand patterns.

Regulatory frameworks and industry standards present another integration barrier. Current electrical codes, safety protocols, and interconnection requirements were developed without consideration for proton battery technology. This regulatory gap creates uncertainty for manufacturers, installers, and utility companies, potentially slowing adoption despite technical merits.

Economic considerations further complicate integration efforts. Substantial capital investments would be required to modify existing infrastructure to accommodate proton batteries. Without clear cost-benefit analyses demonstrating superior lifetime value compared to established technologies, stakeholders may resist allocating resources for these modifications.

Technical workforce limitations also impede integration progress. The specialized knowledge required for proton battery installation, maintenance, and troubleshooting exceeds current industry expertise. Comprehensive training programs and certification standards would need development before widespread deployment could occur.

Despite these challenges, phased integration approaches offer promising pathways forward. Initial deployment in isolated microgrids or specialized applications could provide valuable operational data while minimizing disruption to critical infrastructure. Hybrid systems incorporating both conventional and proton battery technologies could serve as transitional solutions, allowing gradual infrastructure adaptation while maintaining system reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!