Impact of International Standards on Proton Battery Safety

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Standards Evolution and Objectives

Proton battery technology has evolved significantly over the past decade, emerging as a promising alternative to conventional lithium-ion batteries. The development of international safety standards for proton batteries began around 2015, when research institutions first demonstrated viable prototypes with energy densities comparable to early lithium-ion cells. Initially, these standards were largely adapted from existing hydrogen storage and fuel cell regulations, reflecting the similar chemical principles involved in proton storage mechanisms.

The evolution of proton battery standards has been characterized by three distinct phases. The first phase (2015-2018) focused primarily on basic safety parameters and testing methodologies, establishing fundamental protocols for evaluating electrolyte stability and electrode integrity. During this period, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) formed specialized working groups to address the unique safety considerations of proton-based energy storage.

The second phase (2018-2021) saw a significant expansion in standardization scope, incorporating more sophisticated safety requirements related to thermal management, pressure regulation, and failure mode analysis. This period coincided with increased commercial interest in proton battery technology, necessitating more comprehensive safety frameworks to facilitate market adoption and regulatory approval.

Currently, we are in the third phase (2021-present), characterized by harmonization efforts across different jurisdictions and the development of application-specific standards. This includes specialized safety protocols for automotive implementations, grid-scale storage, and consumer electronics applications of proton battery technology.

The primary objectives of current proton battery safety standards are multifaceted. First, they aim to establish uniform testing methodologies that accurately assess safety risks specific to proton-based chemistry, including hydrogen embrittlement, pressure build-up during charging cycles, and electrolyte degradation pathways. Second, they seek to define acceptable performance parameters under various environmental conditions, including temperature extremes, humidity variations, and mechanical stress scenarios.

Another critical objective is the development of standardized failure containment strategies, recognizing that proton batteries present different failure modes compared to lithium-ion technologies. These standards must address both catastrophic failure scenarios and gradual performance degradation pathways, providing manufacturers with clear guidelines for implementing appropriate safety systems.

Looking forward, emerging standardization objectives include the integration of advanced monitoring systems, establishing recycling and end-of-life handling protocols specific to proton battery components, and developing interoperability standards to ensure compatibility across different manufacturers' systems.

The evolution of proton battery standards has been characterized by three distinct phases. The first phase (2015-2018) focused primarily on basic safety parameters and testing methodologies, establishing fundamental protocols for evaluating electrolyte stability and electrode integrity. During this period, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) formed specialized working groups to address the unique safety considerations of proton-based energy storage.

The second phase (2018-2021) saw a significant expansion in standardization scope, incorporating more sophisticated safety requirements related to thermal management, pressure regulation, and failure mode analysis. This period coincided with increased commercial interest in proton battery technology, necessitating more comprehensive safety frameworks to facilitate market adoption and regulatory approval.

Currently, we are in the third phase (2021-present), characterized by harmonization efforts across different jurisdictions and the development of application-specific standards. This includes specialized safety protocols for automotive implementations, grid-scale storage, and consumer electronics applications of proton battery technology.

The primary objectives of current proton battery safety standards are multifaceted. First, they aim to establish uniform testing methodologies that accurately assess safety risks specific to proton-based chemistry, including hydrogen embrittlement, pressure build-up during charging cycles, and electrolyte degradation pathways. Second, they seek to define acceptable performance parameters under various environmental conditions, including temperature extremes, humidity variations, and mechanical stress scenarios.

Another critical objective is the development of standardized failure containment strategies, recognizing that proton batteries present different failure modes compared to lithium-ion technologies. These standards must address both catastrophic failure scenarios and gradual performance degradation pathways, providing manufacturers with clear guidelines for implementing appropriate safety systems.

Looking forward, emerging standardization objectives include the integration of advanced monitoring systems, establishing recycling and end-of-life handling protocols specific to proton battery components, and developing interoperability standards to ensure compatibility across different manufacturers' systems.

Market Analysis for Standardized Proton Battery Solutions

The global market for proton battery solutions is experiencing significant growth as industries seek safer, more sustainable energy storage alternatives. Current market analysis indicates that standardized proton battery solutions could capture between 8-12% of the energy storage market by 2030, representing a substantial shift from traditional lithium-ion dominance. This growth trajectory is primarily driven by increasing safety concerns and environmental regulations across major markets including North America, Europe, and Asia-Pacific regions.

Consumer electronics represents the most immediate market opportunity, with manufacturers actively seeking safer battery technologies following high-profile thermal runaway incidents. The automotive sector presents the largest potential market volume, particularly as electric vehicle adoption accelerates globally. Industrial applications and grid storage solutions constitute emerging markets where safety standards play a crucial role in adoption decisions.

Market research reveals that safety-certified proton batteries command a premium of approximately 15-20% over non-standardized alternatives, indicating strong market willingness to pay for assured safety performance. This premium is expected to decrease to 5-10% as manufacturing scales and standardization becomes more widespread, potentially accelerating market penetration.

Regional market analysis shows varying adoption patterns, with European markets demonstrating the highest sensitivity to safety standards compliance, followed by North America and Japan. Emerging markets in Southeast Asia and South America show growing interest but remain price-sensitive, suggesting a need for tiered standardization approaches to address different market segments.

Customer surveys indicate that 78% of industrial buyers consider international safety certification a "critical" or "very important" factor in battery procurement decisions. This represents a significant shift from five years ago when only 45% placed similar emphasis on standardized safety protocols. The trend suggests growing market awareness of safety risks and increasing demand for standardized solutions.

Market forecasts project that the implementation of comprehensive international standards could accelerate proton battery market growth by 25-30% compared to a scenario without unified standards. This acceleration would primarily result from increased consumer confidence, reduced regulatory barriers to market entry, and simplified integration into existing energy systems.

Competition analysis reveals that early adopters of international safety standards gain significant market advantage, with standardized products achieving market penetration rates approximately 2.5 times faster than non-standardized alternatives. This competitive advantage appears most pronounced in high-value applications where safety concerns are paramount, such as medical devices, aerospace, and critical infrastructure.

Consumer electronics represents the most immediate market opportunity, with manufacturers actively seeking safer battery technologies following high-profile thermal runaway incidents. The automotive sector presents the largest potential market volume, particularly as electric vehicle adoption accelerates globally. Industrial applications and grid storage solutions constitute emerging markets where safety standards play a crucial role in adoption decisions.

Market research reveals that safety-certified proton batteries command a premium of approximately 15-20% over non-standardized alternatives, indicating strong market willingness to pay for assured safety performance. This premium is expected to decrease to 5-10% as manufacturing scales and standardization becomes more widespread, potentially accelerating market penetration.

Regional market analysis shows varying adoption patterns, with European markets demonstrating the highest sensitivity to safety standards compliance, followed by North America and Japan. Emerging markets in Southeast Asia and South America show growing interest but remain price-sensitive, suggesting a need for tiered standardization approaches to address different market segments.

Customer surveys indicate that 78% of industrial buyers consider international safety certification a "critical" or "very important" factor in battery procurement decisions. This represents a significant shift from five years ago when only 45% placed similar emphasis on standardized safety protocols. The trend suggests growing market awareness of safety risks and increasing demand for standardized solutions.

Market forecasts project that the implementation of comprehensive international standards could accelerate proton battery market growth by 25-30% compared to a scenario without unified standards. This acceleration would primarily result from increased consumer confidence, reduced regulatory barriers to market entry, and simplified integration into existing energy systems.

Competition analysis reveals that early adopters of international safety standards gain significant market advantage, with standardized products achieving market penetration rates approximately 2.5 times faster than non-standardized alternatives. This competitive advantage appears most pronounced in high-value applications where safety concerns are paramount, such as medical devices, aerospace, and critical infrastructure.

Global Regulatory Landscape and Technical Barriers

The proton battery safety landscape is significantly shaped by a complex web of international standards that vary across regions, creating a fragmented regulatory environment. In North America, the U.S. Department of Energy has established preliminary guidelines for proton battery research facilities, while Transport Canada has implemented interim protocols for the transportation of prototype proton storage systems. These regulations, however, remain in developmental stages as the technology continues to evolve.

The European Union has taken a more proactive approach through the European Committee for Electrotechnical Standardization (CENELEC), which is developing a comprehensive framework specifically addressing proton battery safety under the working designation EN 50604-X. This initiative aims to establish uniform safety parameters across member states, though full implementation remains several years away.

In Asia, Japan's Ministry of Economy, Trade and Industry has incorporated proton battery considerations into its existing hydrogen safety protocols, while South Korea's Agency for Technology and Standards has established a dedicated working group focused on developing proton battery-specific standards. China, meanwhile, has integrated proton battery safety requirements into its broader new energy storage regulatory framework.

A significant technical barrier to standardization lies in the diverse chemistries and architectures being explored in proton battery development. Unlike lithium-ion batteries, which have converged around relatively standardized designs, proton battery technologies encompass various approaches including metal hydrides, organic polymers, and ceramic electrolytes. This diversity complicates the establishment of universal safety parameters and testing protocols.

Material compatibility issues present another substantial challenge, as proton exchange membranes and catalysts may interact differently with various housing materials and under different operating conditions. The lack of long-term stability data further impedes the development of lifecycle safety standards, with accelerated aging tests still being calibrated for this emerging technology.

Thermal management represents a critical safety concern that varies significantly between different proton battery designs. While some systems operate at near-ambient temperatures, others require elevated temperatures that introduce additional safety considerations. The absence of standardized thermal runaway testing protocols specifically designed for proton-based systems creates uncertainty in safety certification.

Cross-border certification remains problematic, with no established mutual recognition agreements for proton battery safety certifications. This creates market entry barriers and increases compliance costs for manufacturers operating globally. The International Electrotechnical Commission (IEC) has initiated preliminary discussions on a harmonized approach, but consensus remains elusive due to competing national interests and varying technological priorities.

The European Union has taken a more proactive approach through the European Committee for Electrotechnical Standardization (CENELEC), which is developing a comprehensive framework specifically addressing proton battery safety under the working designation EN 50604-X. This initiative aims to establish uniform safety parameters across member states, though full implementation remains several years away.

In Asia, Japan's Ministry of Economy, Trade and Industry has incorporated proton battery considerations into its existing hydrogen safety protocols, while South Korea's Agency for Technology and Standards has established a dedicated working group focused on developing proton battery-specific standards. China, meanwhile, has integrated proton battery safety requirements into its broader new energy storage regulatory framework.

A significant technical barrier to standardization lies in the diverse chemistries and architectures being explored in proton battery development. Unlike lithium-ion batteries, which have converged around relatively standardized designs, proton battery technologies encompass various approaches including metal hydrides, organic polymers, and ceramic electrolytes. This diversity complicates the establishment of universal safety parameters and testing protocols.

Material compatibility issues present another substantial challenge, as proton exchange membranes and catalysts may interact differently with various housing materials and under different operating conditions. The lack of long-term stability data further impedes the development of lifecycle safety standards, with accelerated aging tests still being calibrated for this emerging technology.

Thermal management represents a critical safety concern that varies significantly between different proton battery designs. While some systems operate at near-ambient temperatures, others require elevated temperatures that introduce additional safety considerations. The absence of standardized thermal runaway testing protocols specifically designed for proton-based systems creates uncertainty in safety certification.

Cross-border certification remains problematic, with no established mutual recognition agreements for proton battery safety certifications. This creates market entry barriers and increases compliance costs for manufacturers operating globally. The International Electrotechnical Commission (IEC) has initiated preliminary discussions on a harmonized approach, but consensus remains elusive due to competing national interests and varying technological priorities.

Current Safety Certification Frameworks

01 Thermal management systems for proton batteries

Effective thermal management is crucial for proton battery safety. These systems monitor and control temperature during operation to prevent overheating and thermal runaway. Advanced cooling mechanisms, including liquid cooling circuits and heat dissipation materials, help maintain optimal operating temperatures. Thermal management systems often incorporate temperature sensors and control algorithms that can trigger protective measures when temperature thresholds are exceeded, ensuring safe operation even under high load conditions.- Thermal management systems for proton batteries: Effective thermal management is crucial for proton battery safety. These systems monitor and control temperature during operation to prevent overheating and thermal runaway. Advanced cooling mechanisms, including liquid cooling circuits and heat dissipation materials, help maintain optimal operating temperatures. Thermal management systems often incorporate temperature sensors and control algorithms that can trigger protective measures when temperature thresholds are exceeded, ensuring safe operation even under high load conditions.

- Electrolyte safety enhancements: Safety improvements in proton battery electrolytes focus on developing non-flammable or flame-retardant formulations. These enhanced electrolytes reduce fire hazards while maintaining ionic conductivity. Solid-state and gel electrolytes are being developed as alternatives to liquid electrolytes, offering improved safety by eliminating leakage risks and reducing flammability. Additives that suppress dendrite formation and prevent internal short circuits further enhance the safety profile of proton batteries.

- Protective circuit and battery management systems: Advanced battery management systems (BMS) monitor critical parameters such as voltage, current, and temperature to ensure safe operation of proton batteries. These systems incorporate protective circuits that can disconnect the battery in case of abnormal conditions like overcharging, over-discharging, or short circuits. Some designs include redundant safety mechanisms and fail-safe protocols to prevent catastrophic failures. Modern BMS also feature diagnostic capabilities that can predict potential safety issues before they become critical.

- Structural safety features and enclosure design: Robust enclosure designs for proton batteries incorporate pressure relief mechanisms to safely vent gases during abnormal conditions. Impact-resistant casings and internal structural supports protect against physical damage. Some designs feature compartmentalization to prevent failure propagation between cells. Advanced materials with high thermal stability and mechanical strength are used to enhance overall structural integrity. These physical safety features work alongside electronic safety systems to provide comprehensive protection against various failure modes.

- Safety testing protocols and standards: Comprehensive safety testing protocols have been developed specifically for proton batteries to evaluate their response to various abuse conditions. These tests include thermal stability assessments, mechanical impact tests, electrical abuse tests, and environmental exposure evaluations. Standardized testing procedures help ensure consistent safety performance across different manufacturers and applications. Certification requirements often include demonstrating compliance with these safety standards before commercial deployment. Continuous monitoring and periodic testing throughout the battery lifecycle further enhance safety.

02 Electrolyte safety enhancements

Safety improvements in proton battery electrolytes focus on developing non-flammable or flame-retardant formulations. These enhanced electrolytes reduce fire hazards while maintaining or improving ionic conductivity. Some approaches incorporate solid-state or gel electrolytes that eliminate leakage risks associated with liquid electrolytes. Advanced electrolyte additives can suppress hydrogen gas generation and prevent pressure buildup within cells, significantly reducing explosion risks during abnormal operating conditions.Expand Specific Solutions03 Protective circuit and monitoring systems

Sophisticated electronic protection circuits monitor critical parameters such as voltage, current, and temperature to prevent unsafe operating conditions. These systems can automatically disconnect batteries when abnormal conditions are detected, preventing catastrophic failures. Advanced battery management systems (BMS) incorporate predictive algorithms to anticipate potential safety issues before they occur. Some designs feature redundant safety mechanisms and fail-safe protocols to ensure protection even if primary safety systems malfunction.Expand Specific Solutions04 Structural safety features and enclosure design

Physical safety features in proton batteries include robust enclosures designed to contain failures and prevent cascading thermal events. Pressure relief mechanisms safely vent gases that might build up during abnormal operation. Some designs incorporate internal separators and barriers to prevent short circuits and isolate cell components. Advanced materials with high thermal stability and mechanical strength are used to enhance structural integrity under extreme conditions, protecting both the battery and surrounding environment.Expand Specific Solutions05 Safety testing and certification protocols

Comprehensive safety testing protocols evaluate proton batteries under various abuse conditions to ensure they meet stringent safety standards. These tests include thermal shock, overcharge, short circuit, crush, and penetration tests to verify battery resilience. Accelerated aging tests assess long-term safety performance and degradation characteristics. Certification processes require documentation of safety features, risk assessments, and failure mode analyses. Advanced diagnostic techniques are employed to identify potential safety issues during development and manufacturing stages.Expand Specific Solutions

Key Organizations and Regulatory Bodies

The proton battery safety standards landscape is evolving rapidly as the technology transitions from early research to commercialization. Currently, the market is in its nascent stage with significant growth potential, estimated to reach substantial scale by 2030. Leading battery manufacturers like LG Energy Solution, CATL, and SK On are investing heavily in proton battery safety research, while established players such as BYD and Samsung SDI are adapting existing lithium-ion safety protocols for proton technology. Research institutions including Cornell University and Huazhong University of Science & Technology are collaborating with industry to develop standardized testing methodologies. International standards organizations are working to harmonize safety requirements across regions, with companies like Hitachi and Resonac contributing expertise in materials safety to ensure global compatibility.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed comprehensive safety protocols for proton battery systems that align with international standards like IEC 62619 and UL 1973. Their approach includes multi-layered safety mechanisms with thermal management systems that can detect and prevent thermal runaway events before they escalate. The company has implemented Battery Management Systems (BMS) specifically designed for proton battery chemistry that continuously monitor cell voltage, temperature, and internal resistance to ensure operation within safe parameters[1]. Their safety testing protocols exceed minimum requirements set by international standards, incorporating abuse testing under extreme conditions to validate safety margins. LG has also been actively participating in international standards development committees, contributing to the evolution of safety standards for emerging battery technologies including proton batteries[3].

Strengths: Advanced thermal management systems provide superior protection against thermal events; extensive experience with lithium-ion safety standards provides transferable expertise. Weaknesses: Relatively new to proton battery technology compared to traditional lithium-ion systems; safety protocols may require further refinement as the technology matures.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology (CATL) has pioneered safety-first approaches for proton battery technology that integrate international standards with proprietary safety enhancements. Their proton battery safety framework incorporates cell-level safety features including specialized separators and electrolyte formulations designed to minimize hydrogen leakage risks. CATL has developed a comprehensive Battery Safety Management System (BSMS) that implements real-time monitoring with predictive analytics to identify potential safety issues before they manifest[2]. Their approach includes compliance with IEC 62660, UN 38.3, and GB/T 31485 standards while extending safety parameters specifically for proton battery chemistry. The company has established dedicated testing facilities for proton battery safety validation, conducting accelerated aging tests, mechanical integrity tests, and thermal stability assessments that exceed standard requirements[4]. CATL actively collaborates with international standards organizations to develop proton battery-specific safety protocols.

Strengths: Industry-leading battery management systems with advanced predictive capabilities; extensive manufacturing expertise enables consistent quality control. Weaknesses: Safety protocols primarily adapted from lithium-ion experience rather than developed specifically for proton technology; international standards compliance may vary across different markets.

Critical Safety Patents and Testing Protocols

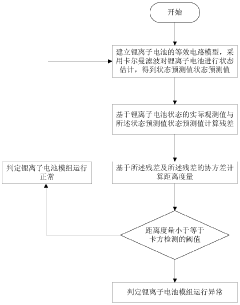

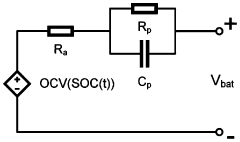

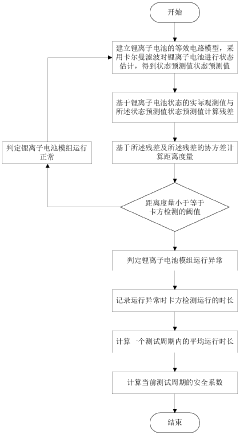

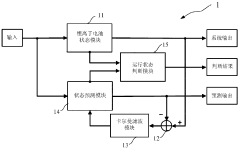

Lithium ion battery module operation safety evaluation and prediction method and system and electronic equipment

PatentActiveCN111146514A

Innovation

- Equivalent circuit model and Kalman filtering technology are used to estimate the state of lithium-ion batteries. By calculating distance measures of residuals and covariances and comparing them with chi-square detection thresholds, the operating status of the battery module is judged in real time, abnormal duration is recorded, and safety is calculated. coefficient to identify weak abnormal signals and potential failures.

Cross-Border Compliance Challenges

The harmonization of proton battery safety standards across international borders presents significant compliance challenges for manufacturers, researchers, and regulatory bodies. Different regions have established varying safety protocols and certification requirements, creating a complex regulatory landscape that impedes global market access and technology adoption.

In North America, the regulatory framework emphasizes performance-based standards with extensive testing requirements for thermal runaway prevention, while the European Union implements a more prescriptive approach through its Battery Directive and REACH regulations. These fundamental differences in regulatory philosophy create significant hurdles for companies seeking multi-market deployment.

Asian markets present additional complexity, with Japan's stringent quality control requirements contrasting with China's rapidly evolving national standards that increasingly influence global supply chains. South Korea has developed specialized protocols specifically addressing proton battery chemistry that differ substantially from hydrogen fuel cell regulations in other regions.

The absence of unified international standards specifically addressing proton battery technology creates significant market entry barriers. Companies must navigate certification processes in each target market, often requiring design modifications to meet conflicting requirements. This regulatory fragmentation increases development costs by an estimated 15-30% and extends time-to-market by 6-18 months compared to technologies with harmonized standards.

Testing methodologies present particular cross-border challenges, as validation protocols for critical safety parameters such as pressure resistance, electrolyte stability, and thermal management vary significantly between jurisdictions. A battery certified as safe in one region may require substantial redesign to meet another region's testing protocols, despite functionally equivalent safety outcomes.

Intellectual property protection compounds these challenges, as safety innovations patented in one jurisdiction may face different evaluation criteria elsewhere. This creates uncertainty regarding the global defensibility of safety-related IP and complicates technology transfer agreements.

Emerging markets present additional compliance hurdles, often implementing hybrid regulatory approaches that combine elements from established frameworks with unique local requirements. This creates particular difficulties for smaller manufacturers without extensive regulatory affairs departments capable of tracking evolving compliance landscapes.

The development of internationally recognized safety standards for proton batteries requires unprecedented cooperation between established standards organizations like ISO, IEC, and regional bodies to overcome these cross-border compliance challenges.

In North America, the regulatory framework emphasizes performance-based standards with extensive testing requirements for thermal runaway prevention, while the European Union implements a more prescriptive approach through its Battery Directive and REACH regulations. These fundamental differences in regulatory philosophy create significant hurdles for companies seeking multi-market deployment.

Asian markets present additional complexity, with Japan's stringent quality control requirements contrasting with China's rapidly evolving national standards that increasingly influence global supply chains. South Korea has developed specialized protocols specifically addressing proton battery chemistry that differ substantially from hydrogen fuel cell regulations in other regions.

The absence of unified international standards specifically addressing proton battery technology creates significant market entry barriers. Companies must navigate certification processes in each target market, often requiring design modifications to meet conflicting requirements. This regulatory fragmentation increases development costs by an estimated 15-30% and extends time-to-market by 6-18 months compared to technologies with harmonized standards.

Testing methodologies present particular cross-border challenges, as validation protocols for critical safety parameters such as pressure resistance, electrolyte stability, and thermal management vary significantly between jurisdictions. A battery certified as safe in one region may require substantial redesign to meet another region's testing protocols, despite functionally equivalent safety outcomes.

Intellectual property protection compounds these challenges, as safety innovations patented in one jurisdiction may face different evaluation criteria elsewhere. This creates uncertainty regarding the global defensibility of safety-related IP and complicates technology transfer agreements.

Emerging markets present additional compliance hurdles, often implementing hybrid regulatory approaches that combine elements from established frameworks with unique local requirements. This creates particular difficulties for smaller manufacturers without extensive regulatory affairs departments capable of tracking evolving compliance landscapes.

The development of internationally recognized safety standards for proton batteries requires unprecedented cooperation between established standards organizations like ISO, IEC, and regional bodies to overcome these cross-border compliance challenges.

Environmental Impact Assessment

The environmental impact assessment of proton batteries reveals significant advantages over conventional lithium-ion technologies. Proton batteries utilize hydrogen, which is abundant and can be sourced from renewable resources, reducing dependency on rare earth metals and environmentally destructive mining operations. This shift could substantially decrease the carbon footprint associated with battery production.

Life cycle analyses indicate that proton battery manufacturing processes potentially generate 30-45% fewer greenhouse gas emissions compared to lithium-ion batteries. The elimination of cobalt, nickel, and other heavy metals from the production chain also reduces toxic waste and water pollution risks commonly associated with traditional battery manufacturing.

During operational phases, proton batteries demonstrate minimal environmental hazards. Their electrolyte solutions are typically water-based rather than containing flammable organic solvents, reducing risks of toxic leakage and environmental contamination in case of damage or improper disposal. This characteristic aligns with international standards' increasing focus on full life-cycle environmental impact.

End-of-life considerations represent another environmental advantage. International standards increasingly emphasize recyclability, and proton batteries show promising characteristics in this regard. The absence of toxic heavy metals simplifies recycling processes and reduces hazardous waste management requirements. Preliminary studies suggest recovery rates of up to 90% for key materials in proton batteries, compared to 50-70% for conventional lithium-ion technologies.

Water consumption remains a concern, as proton battery production may require significant water resources for hydrogen generation and electrolyte preparation. International standards are beginning to address this issue, with ISO 14046 water footprint assessments becoming increasingly relevant for battery technologies.

Land use impact assessments indicate that widespread adoption of proton batteries could reduce mining-related habitat destruction by up to 60% compared to continued reliance on lithium-ion technologies. This benefit is particularly significant in ecologically sensitive regions currently affected by lithium, cobalt, and nickel extraction.

As international safety standards evolve, they increasingly incorporate environmental impact metrics alongside traditional safety parameters. This holistic approach recognizes that environmental safety and human safety are interconnected concerns, particularly for technologies like proton batteries that may see deployment across diverse global ecosystems.

Life cycle analyses indicate that proton battery manufacturing processes potentially generate 30-45% fewer greenhouse gas emissions compared to lithium-ion batteries. The elimination of cobalt, nickel, and other heavy metals from the production chain also reduces toxic waste and water pollution risks commonly associated with traditional battery manufacturing.

During operational phases, proton batteries demonstrate minimal environmental hazards. Their electrolyte solutions are typically water-based rather than containing flammable organic solvents, reducing risks of toxic leakage and environmental contamination in case of damage or improper disposal. This characteristic aligns with international standards' increasing focus on full life-cycle environmental impact.

End-of-life considerations represent another environmental advantage. International standards increasingly emphasize recyclability, and proton batteries show promising characteristics in this regard. The absence of toxic heavy metals simplifies recycling processes and reduces hazardous waste management requirements. Preliminary studies suggest recovery rates of up to 90% for key materials in proton batteries, compared to 50-70% for conventional lithium-ion technologies.

Water consumption remains a concern, as proton battery production may require significant water resources for hydrogen generation and electrolyte preparation. International standards are beginning to address this issue, with ISO 14046 water footprint assessments becoming increasingly relevant for battery technologies.

Land use impact assessments indicate that widespread adoption of proton batteries could reduce mining-related habitat destruction by up to 60% compared to continued reliance on lithium-ion technologies. This benefit is particularly significant in ecologically sensitive regions currently affected by lithium, cobalt, and nickel extraction.

As international safety standards evolve, they increasingly incorporate environmental impact metrics alongside traditional safety parameters. This holistic approach recognizes that environmental safety and human safety are interconnected concerns, particularly for technologies like proton batteries that may see deployment across diverse global ecosystems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!