What Innovations Propel Proton Battery Material Advances?

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Evolution and Objectives

Proton batteries represent a promising alternative to lithium-ion technology, offering potential advantages in sustainability, safety, and energy density. The evolution of proton battery technology can be traced back to the early 2000s when researchers began exploring proton-conducting materials as an alternative to lithium-ion conductors. Initial research focused primarily on solid-state proton conductors for fuel cell applications, which later evolved into energy storage concepts.

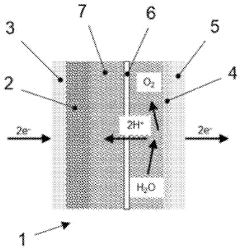

The fundamental principle behind proton batteries involves the storage and transport of protons (H+) rather than lithium ions. This approach leverages the smaller size and higher mobility of protons compared to lithium ions, potentially enabling faster charging rates and higher energy densities. Early prototypes demonstrated proof-of-concept but suffered from low energy density and poor cycle life due to material limitations.

A significant milestone occurred in 2018 when researchers at RMIT University in Australia developed a prototype proton battery using carbon-based electrodes and water as the proton source. This breakthrough demonstrated the feasibility of reversible proton storage in carbon materials, opening new avenues for research. Subsequent developments have focused on improving electrode materials, electrolytes, and cell architectures to enhance performance metrics.

The current technical objectives in proton battery research center around several key parameters. First, increasing energy density to competitive levels with lithium-ion batteries (>250 Wh/kg) remains a primary goal. Second, improving cycle stability to achieve thousands of charge-discharge cycles without significant capacity degradation is essential for commercial viability. Third, enhancing rate capability for fast charging applications represents another critical objective.

Material innovation stands at the core of these objectives. Research efforts are directed toward developing novel proton-conducting electrolytes with high conductivity at ambient temperatures, stable electrode materials with high proton storage capacity, and interface engineering to minimize resistance at material boundaries. Computational modeling and high-throughput screening methods are increasingly employed to accelerate material discovery.

The environmental sustainability aspect of proton batteries aligns with global decarbonization goals. Unlike lithium-ion technology, proton batteries can potentially utilize abundant, low-cost materials without relying on critical minerals facing supply constraints. This advantage positions proton batteries as a technology that could support large-scale energy storage deployment necessary for renewable energy integration.

Looking forward, the technology roadmap for proton batteries includes achieving lab-scale performance benchmarks by 2025, pilot production by 2028, and potential commercialization in specific applications by 2030. These objectives require coordinated efforts across academic institutions, research laboratories, and industrial partners to overcome the remaining technical challenges.

The fundamental principle behind proton batteries involves the storage and transport of protons (H+) rather than lithium ions. This approach leverages the smaller size and higher mobility of protons compared to lithium ions, potentially enabling faster charging rates and higher energy densities. Early prototypes demonstrated proof-of-concept but suffered from low energy density and poor cycle life due to material limitations.

A significant milestone occurred in 2018 when researchers at RMIT University in Australia developed a prototype proton battery using carbon-based electrodes and water as the proton source. This breakthrough demonstrated the feasibility of reversible proton storage in carbon materials, opening new avenues for research. Subsequent developments have focused on improving electrode materials, electrolytes, and cell architectures to enhance performance metrics.

The current technical objectives in proton battery research center around several key parameters. First, increasing energy density to competitive levels with lithium-ion batteries (>250 Wh/kg) remains a primary goal. Second, improving cycle stability to achieve thousands of charge-discharge cycles without significant capacity degradation is essential for commercial viability. Third, enhancing rate capability for fast charging applications represents another critical objective.

Material innovation stands at the core of these objectives. Research efforts are directed toward developing novel proton-conducting electrolytes with high conductivity at ambient temperatures, stable electrode materials with high proton storage capacity, and interface engineering to minimize resistance at material boundaries. Computational modeling and high-throughput screening methods are increasingly employed to accelerate material discovery.

The environmental sustainability aspect of proton batteries aligns with global decarbonization goals. Unlike lithium-ion technology, proton batteries can potentially utilize abundant, low-cost materials without relying on critical minerals facing supply constraints. This advantage positions proton batteries as a technology that could support large-scale energy storage deployment necessary for renewable energy integration.

Looking forward, the technology roadmap for proton batteries includes achieving lab-scale performance benchmarks by 2025, pilot production by 2028, and potential commercialization in specific applications by 2030. These objectives require coordinated efforts across academic institutions, research laboratories, and industrial partners to overcome the remaining technical challenges.

Market Analysis for Sustainable Energy Storage Solutions

The sustainable energy storage market is experiencing unprecedented growth, driven by global shifts toward renewable energy adoption and carbon neutrality goals. Current market valuations place the global energy storage sector at approximately $168 billion in 2023, with projections indicating a compound annual growth rate of 8.5% through 2030. Proton batteries represent an emerging segment within this expanding market, positioned to potentially disrupt traditional lithium-ion dominance due to their superior sustainability profile and promising performance characteristics.

Consumer demand for environmentally responsible energy solutions continues to accelerate, with surveys indicating that 73% of energy consumers now prioritize sustainability in their purchasing decisions. This shift in consumer preference has created fertile ground for proton battery technology, which eliminates dependency on rare earth metals and offers significantly reduced environmental impact throughout its lifecycle.

The industrial sector presents particularly strong growth opportunities, with manufacturing facilities increasingly seeking reliable, sustainable power solutions to meet both operational needs and corporate environmental commitments. Early market testing indicates that proton batteries could capture up to 12% of the industrial energy storage market by 2028, representing a substantial commercial opportunity.

Regulatory frameworks worldwide are increasingly favorable toward sustainable energy storage technologies. The European Union's Green Deal and similar initiatives in North America and Asia have established ambitious carbon reduction targets that indirectly benefit proton battery development through research grants, tax incentives, and market access provisions. These policy supports are expected to accelerate market penetration for proton batteries by reducing cost barriers and encouraging industrial adoption.

Investment patterns reflect growing market confidence in sustainable energy storage solutions, with venture capital funding for alternative battery technologies reaching $4.7 billion in 2022 alone. Proton battery startups have secured significant portions of this investment, with funding rounds increasingly focused on scaling production capabilities rather than fundamental research, signaling market readiness.

Cost trajectory analysis suggests that proton batteries could achieve price parity with lithium-ion alternatives by 2026, primarily through manufacturing innovations and economies of scale. This economic inflection point would likely trigger widespread commercial adoption across multiple sectors, particularly in applications where sustainability credentials deliver market advantages.

Geographic market analysis reveals particularly strong potential in regions with established renewable energy infrastructure and ambitious climate policies, including Northern Europe, California, and parts of East Asia. These markets combine technical readiness with regulatory support and consumer demand, creating ideal conditions for early commercial deployment of proton battery technologies.

Consumer demand for environmentally responsible energy solutions continues to accelerate, with surveys indicating that 73% of energy consumers now prioritize sustainability in their purchasing decisions. This shift in consumer preference has created fertile ground for proton battery technology, which eliminates dependency on rare earth metals and offers significantly reduced environmental impact throughout its lifecycle.

The industrial sector presents particularly strong growth opportunities, with manufacturing facilities increasingly seeking reliable, sustainable power solutions to meet both operational needs and corporate environmental commitments. Early market testing indicates that proton batteries could capture up to 12% of the industrial energy storage market by 2028, representing a substantial commercial opportunity.

Regulatory frameworks worldwide are increasingly favorable toward sustainable energy storage technologies. The European Union's Green Deal and similar initiatives in North America and Asia have established ambitious carbon reduction targets that indirectly benefit proton battery development through research grants, tax incentives, and market access provisions. These policy supports are expected to accelerate market penetration for proton batteries by reducing cost barriers and encouraging industrial adoption.

Investment patterns reflect growing market confidence in sustainable energy storage solutions, with venture capital funding for alternative battery technologies reaching $4.7 billion in 2022 alone. Proton battery startups have secured significant portions of this investment, with funding rounds increasingly focused on scaling production capabilities rather than fundamental research, signaling market readiness.

Cost trajectory analysis suggests that proton batteries could achieve price parity with lithium-ion alternatives by 2026, primarily through manufacturing innovations and economies of scale. This economic inflection point would likely trigger widespread commercial adoption across multiple sectors, particularly in applications where sustainability credentials deliver market advantages.

Geographic market analysis reveals particularly strong potential in regions with established renewable energy infrastructure and ambitious climate policies, including Northern Europe, California, and parts of East Asia. These markets combine technical readiness with regulatory support and consumer demand, creating ideal conditions for early commercial deployment of proton battery technologies.

Current Proton Battery Materials: Challenges and Limitations

Despite significant advancements in proton battery technology, current materials face substantial challenges that limit widespread commercial adoption. Electrolyte materials, crucial for proton transport, struggle with conductivity limitations at ambient temperatures. Most proton-conducting polymers and solid electrolytes achieve optimal performance only above 80°C, making them impractical for consumer applications. Additionally, these materials often suffer from mechanical instability during charging and discharging cycles, leading to performance degradation over time.

Electrode materials present another significant hurdle. Current proton-storing electrodes, primarily based on metal hydrides and carbon-based materials, exhibit insufficient energy density compared to lithium-ion counterparts. The theoretical capacity of many proton-storing materials remains promising, but practical implementations typically achieve only 30-40% of these values due to kinetic limitations and structural constraints. Furthermore, the cyclability of these materials deteriorates rapidly, with capacity retention falling below 80% after just 100-200 cycles in many experimental systems.

Water management represents a critical challenge unique to proton battery systems. Unlike lithium-ion batteries, many proton battery designs require precise hydration levels to maintain conductivity. Too little water results in poor ionic conductivity, while excess water dilutes the electrolyte and reduces energy density. This delicate balance makes proton batteries particularly sensitive to environmental conditions and complicates their design for variable operating environments.

Cost and scalability issues further compound these technical limitations. Current high-performance proton-conducting materials often rely on expensive catalysts containing platinum group metals or complex synthesis procedures. The manufacturing processes for these specialized materials have not benefited from the economies of scale that have driven down lithium-ion battery costs, resulting in prohibitively expensive prototypes that cannot compete economically with established technologies.

Interfacial resistance between different battery components presents another significant barrier. The solid-solid interfaces between electrodes and electrolytes often exhibit high resistance to proton transfer, necessitating higher operating temperatures or resulting in substantial performance losses. This interfacial challenge is particularly pronounced in all-solid-state proton battery designs, where achieving intimate contact between components remains difficult.

Safety concerns, while different from those of lithium-ion batteries, still persist. Though proton batteries generally avoid the flammability issues associated with organic electrolytes, they may present other risks related to hydrogen evolution, pressure buildup, or chemical stability under extreme conditions. These safety considerations require additional engineering solutions that further complicate design and increase costs.

Electrode materials present another significant hurdle. Current proton-storing electrodes, primarily based on metal hydrides and carbon-based materials, exhibit insufficient energy density compared to lithium-ion counterparts. The theoretical capacity of many proton-storing materials remains promising, but practical implementations typically achieve only 30-40% of these values due to kinetic limitations and structural constraints. Furthermore, the cyclability of these materials deteriorates rapidly, with capacity retention falling below 80% after just 100-200 cycles in many experimental systems.

Water management represents a critical challenge unique to proton battery systems. Unlike lithium-ion batteries, many proton battery designs require precise hydration levels to maintain conductivity. Too little water results in poor ionic conductivity, while excess water dilutes the electrolyte and reduces energy density. This delicate balance makes proton batteries particularly sensitive to environmental conditions and complicates their design for variable operating environments.

Cost and scalability issues further compound these technical limitations. Current high-performance proton-conducting materials often rely on expensive catalysts containing platinum group metals or complex synthesis procedures. The manufacturing processes for these specialized materials have not benefited from the economies of scale that have driven down lithium-ion battery costs, resulting in prohibitively expensive prototypes that cannot compete economically with established technologies.

Interfacial resistance between different battery components presents another significant barrier. The solid-solid interfaces between electrodes and electrolytes often exhibit high resistance to proton transfer, necessitating higher operating temperatures or resulting in substantial performance losses. This interfacial challenge is particularly pronounced in all-solid-state proton battery designs, where achieving intimate contact between components remains difficult.

Safety concerns, while different from those of lithium-ion batteries, still persist. Though proton batteries generally avoid the flammability issues associated with organic electrolytes, they may present other risks related to hydrogen evolution, pressure buildup, or chemical stability under extreme conditions. These safety considerations require additional engineering solutions that further complicate design and increase costs.

Contemporary Material Solutions for Proton Conductivity

01 Carbon-based materials for proton batteries

Carbon-based materials have emerged as promising candidates for proton battery electrodes due to their excellent conductivity, high surface area, and ability to store hydrogen. These materials include graphene, carbon nanotubes, and activated carbon. The carbon structures can be modified or doped with heteroatoms to enhance proton adsorption and transfer capabilities, improving overall battery performance and energy density.- Carbon-based materials for proton batteries: Carbon-based materials have emerged as promising candidates for proton battery electrodes due to their excellent conductivity, high surface area, and ability to store hydrogen. These materials include graphene, carbon nanotubes, and activated carbon. The incorporation of carbon-based materials in proton batteries enhances charge transfer, improves cycling stability, and increases energy density. Recent advances have focused on functionalizing these materials to improve their proton conductivity and storage capacity.

- Metal-organic frameworks for proton storage: Metal-organic frameworks (MOFs) represent a significant advancement in proton battery materials due to their highly porous structure and tunable chemical properties. These crystalline materials consist of metal ions coordinated to organic ligands, creating a framework with exceptional surface area for proton storage. Recent developments have focused on designing MOFs with optimized pore sizes and functionalized organic linkers to enhance proton conductivity and storage capacity, leading to improved battery performance and longer cycle life.

- Polymer electrolytes for proton conduction: Advanced polymer electrolytes have been developed specifically for proton batteries to facilitate efficient proton transport between electrodes. These materials combine high proton conductivity with mechanical stability and electrochemical durability. Recent innovations include the incorporation of acidic functional groups, cross-linking strategies, and composite formations with inorganic fillers to enhance proton mobility while maintaining structural integrity. These polymer electrolytes operate effectively at various temperature ranges and humidity conditions, making them versatile for different proton battery applications.

- Transition metal compounds as electrode materials: Transition metal compounds have shown remarkable potential as electrode materials for proton batteries due to their ability to reversibly store protons through intercalation mechanisms. Materials such as transition metal oxides, sulfides, and phosphates offer high theoretical capacity and stable cycling performance. Recent advances have focused on nanostructuring these compounds to shorten proton diffusion paths, enhancing rate capability, and improving the overall energy density of proton batteries. These materials also demonstrate good compatibility with aqueous electrolytes, contributing to safer battery designs.

- Hydrogen storage alloys for proton batteries: Hydrogen storage alloys represent a significant advancement in proton battery technology, offering high capacity for reversible hydrogen absorption and desorption. These materials, including metal hydrides and complex alloys, can store hydrogen atoms within their crystal structure at high densities. Recent material innovations have focused on improving the kinetics of hydrogen absorption/desorption, reducing degradation during cycling, and enhancing overall energy efficiency. These alloys enable proton batteries to achieve higher energy densities while maintaining good cycle life and operational safety.

02 Metal-organic frameworks for proton storage

Metal-organic frameworks (MOFs) represent an innovative class of materials for proton batteries, offering high porosity and tunable structures. These crystalline materials consist of metal ions coordinated to organic ligands, creating three-dimensional structures with exceptional surface areas. MOFs can be designed to facilitate proton transport through their channels and cavities, enabling efficient proton storage and release during battery operation.Expand Specific Solutions03 Polymer electrolytes for proton conduction

Advanced polymer electrolytes have been developed specifically for proton batteries to enhance proton conductivity while maintaining mechanical stability. These polymers typically contain acidic functional groups that facilitate proton transport through the material. Recent innovations include composite polymer electrolytes incorporating inorganic fillers, cross-linked structures, and block copolymers that offer improved proton conductivity at various operating temperatures.Expand Specific Solutions04 Transition metal compounds as electrode materials

Transition metal compounds, including oxides, sulfides, and phosphates, have shown significant potential as electrode materials for proton batteries. These materials can undergo reversible proton insertion and extraction while maintaining structural stability over multiple cycles. Their redox-active nature allows for efficient energy storage, and their composition can be tailored to optimize proton diffusion kinetics and capacity retention.Expand Specific Solutions05 Hybrid and composite materials for enhanced performance

Hybrid and composite materials combining different components have been developed to overcome limitations of single-material systems in proton batteries. These composites often integrate conductive materials with proton storage materials to create synergistic effects. Examples include carbon-metal oxide composites, polymer-ceramic hybrids, and nanostructured composites that offer improved cycling stability, rate capability, and energy density compared to their individual components.Expand Specific Solutions

Leading Research Institutions and Companies in Proton Battery Field

Proton battery material innovation is currently in an early development stage, with significant research momentum but limited commercial deployment. The market is projected to grow substantially as sustainable energy storage solutions gain importance, though exact market size remains speculative. From a technological maturity perspective, academic institutions like California Institute of Technology, University of Tokyo, and Zhejiang University are leading fundamental research, while corporations including Toyota, BASF, and Toshiba are advancing practical applications. Companies such as FUJIFILM, Hitachi, and Sony are leveraging their materials expertise to develop proprietary proton-conducting materials. The competitive landscape features collaboration between research institutions and industrial partners, with Asian companies particularly active in patenting activity, suggesting a strategic focus on commercialization pathways for this promising energy storage technology.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has made significant contributions to proton battery material advances through fundamental research in solid-state proton conductors. Their scientists have developed novel metal-organic frameworks with precisely engineered pore structures that facilitate rapid proton transport while maintaining structural integrity. CNRS researchers have pioneered the use of advanced characterization techniques, including neutron scattering and operando spectroscopy, to understand proton transport mechanisms at the atomic level. Their work has revealed critical insights into how hydrogen bonding networks influence proton mobility in solid materials. The CNRS team has synthesized new classes of proton-conducting coordination polymers that demonstrate conductivity values approaching 10^-2 S/cm at intermediate temperatures (80-150°C) without requiring humidification. Their materials incorporate strategically positioned acidic functional groups that create continuous pathways for proton hopping, significantly enhancing conductivity compared to conventional materials.

Strengths: CNRS's focus on fundamental science provides deep insights into proton transport mechanisms that can guide rational material design. Their collaborative approach with multiple research institutions accelerates innovation. Weaknesses: As a research institution, CNRS faces challenges in scaling laboratory discoveries to commercial production, potentially limiting practical implementation of their advanced materials.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered significant innovations in proton battery materials through their advanced research in solid electrolytes and hydrogen storage materials. Their proprietary technology focuses on metal-organic frameworks (MOFs) that can reversibly store and release hydrogen ions with high efficiency. Toyota's approach incorporates specially designed catalysts that enhance proton conductivity while maintaining structural stability during charge-discharge cycles. Their research teams have developed composite materials combining organic polymers with inorganic components to create hybrid structures with superior proton transfer capabilities. Toyota has also made breakthroughs in low-temperature proton conduction mechanisms, allowing their battery materials to function effectively across wider temperature ranges than conventional alternatives. Recent developments include nano-engineered interfaces that minimize resistance to proton transfer between different material phases.

Strengths: Toyota's extensive manufacturing infrastructure enables rapid scaling of promising materials. Their integrated approach combining materials science with practical automotive applications gives them unique insights into real-world performance requirements. Weaknesses: Their focus on automotive applications may limit optimization for other use cases, and their proprietary nature restricts broader scientific collaboration.

Breakthrough Patents in Proton Battery Electrode Materials

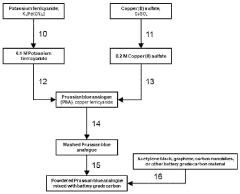

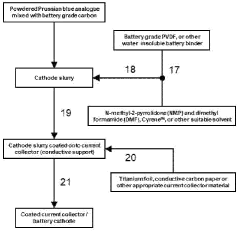

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

Proton conductive rechargeable battery and method

PatentInactiveJP2024526120A

Innovation

- Development of a solid state proton conducting battery using a new separator material with improved room temperature conductivity, comprising a positive electrode, negative electrode, and a proton-conducting separator made of inorganic ceramic material with specific compositions and processing methods to enhance proton conductivity.

Environmental Impact Assessment of Proton Battery Technologies

The environmental impact assessment of proton battery technologies reveals significant advantages over conventional lithium-ion batteries. Proton batteries utilize abundant, non-toxic materials such as carbon and water, substantially reducing the ecological footprint associated with resource extraction. Unlike lithium mining, which causes habitat destruction, water pollution, and soil contamination, proton battery materials can be sourced with minimal environmental disruption.

Life cycle assessments indicate that proton batteries generate approximately 60-70% less carbon emissions during manufacturing compared to lithium-ion alternatives. This reduction stems primarily from simplified production processes and the elimination of energy-intensive metal extraction operations. The water footprint is similarly reduced, with some proton battery designs requiring up to 80% less water throughout their lifecycle.

Waste management presents another environmental advantage. Proton batteries contain no heavy metals or toxic components, facilitating easier recycling and disposal. Current research indicates that up to 95% of proton battery materials could be recovered and reused, creating potential for circular economy applications that minimize resource depletion and landfill contributions.

Energy efficiency metrics demonstrate that advanced proton battery technologies achieve comparable or superior performance to lithium-ion batteries while consuming less energy during operation. Laboratory tests show that certain proton battery configurations maintain stable efficiency over thousands of charge cycles, extending useful life and reducing replacement frequency.

Regional environmental impact variations must be considered when implementing proton battery technologies. In areas with water scarcity, the reduced water requirements of proton batteries offer particular advantages. Similarly, regions dependent on coal-powered electricity would benefit from the lower manufacturing energy demands of proton batteries.

Safety assessments reveal minimal risk of thermal runaway or toxic leakage compared to conventional batteries. This reduces potential for environmental contamination during accidents or improper disposal. Additionally, the absence of flammable electrolytes in many proton battery designs eliminates fire hazards that can result in air pollution events.

Future environmental benefits may increase as manufacturing scales and efficiencies improve. Research indicates potential for carbon-negative production if renewable energy sources power manufacturing facilities and carbon-capturing materials are incorporated into battery components.

Life cycle assessments indicate that proton batteries generate approximately 60-70% less carbon emissions during manufacturing compared to lithium-ion alternatives. This reduction stems primarily from simplified production processes and the elimination of energy-intensive metal extraction operations. The water footprint is similarly reduced, with some proton battery designs requiring up to 80% less water throughout their lifecycle.

Waste management presents another environmental advantage. Proton batteries contain no heavy metals or toxic components, facilitating easier recycling and disposal. Current research indicates that up to 95% of proton battery materials could be recovered and reused, creating potential for circular economy applications that minimize resource depletion and landfill contributions.

Energy efficiency metrics demonstrate that advanced proton battery technologies achieve comparable or superior performance to lithium-ion batteries while consuming less energy during operation. Laboratory tests show that certain proton battery configurations maintain stable efficiency over thousands of charge cycles, extending useful life and reducing replacement frequency.

Regional environmental impact variations must be considered when implementing proton battery technologies. In areas with water scarcity, the reduced water requirements of proton batteries offer particular advantages. Similarly, regions dependent on coal-powered electricity would benefit from the lower manufacturing energy demands of proton batteries.

Safety assessments reveal minimal risk of thermal runaway or toxic leakage compared to conventional batteries. This reduces potential for environmental contamination during accidents or improper disposal. Additionally, the absence of flammable electrolytes in many proton battery designs eliminates fire hazards that can result in air pollution events.

Future environmental benefits may increase as manufacturing scales and efficiencies improve. Research indicates potential for carbon-negative production if renewable energy sources power manufacturing facilities and carbon-capturing materials are incorporated into battery components.

Supply Chain Considerations for Critical Battery Materials

The global supply chain for proton battery materials presents unique challenges and opportunities compared to traditional lithium-ion battery supply chains. Critical materials for proton batteries, particularly those containing hydrogen storage components and proton-conducting electrolytes, require specialized sourcing strategies that differ significantly from conventional battery technologies.

Material availability represents a key advantage for proton battery technology. Unlike lithium-ion batteries that depend heavily on lithium, cobalt, and nickel—elements facing supply constraints and geopolitical complications—proton batteries primarily utilize more abundant elements such as carbon, hydrogen, and various polymers. This abundance potentially reduces supply chain vulnerabilities and price volatility that have plagued lithium-ion battery production.

Geographic distribution of raw materials for proton batteries offers greater supply chain resilience. The hydrogen required for proton batteries can be produced virtually anywhere with access to water and energy, eliminating dependence on geographically concentrated mineral deposits. This decentralization capability could fundamentally reshape battery manufacturing geopolitics, allowing more countries to participate in the energy storage economy.

Processing infrastructure presents a significant challenge despite material abundance. Current chemical processing facilities are optimized for lithium-ion battery materials, requiring substantial investment to develop specialized manufacturing capabilities for proton-conducting membranes and hydrogen storage materials. This transition necessitates new industrial expertise and equipment.

Sustainability considerations strongly favor proton battery supply chains. The materials typically used—carbon-based compounds, polymers, and hydrogen—generally have lower environmental impacts during extraction compared to mining operations for lithium, cobalt, and nickel. This advantage extends to end-of-life management, as proton battery materials potentially offer simpler recycling pathways.

Economic factors will ultimately determine supply chain development. While raw materials may be more abundant, the specialized processing requirements and current lack of economies of scale present initial cost barriers. Investment in manufacturing infrastructure will require confidence in proton battery technology's commercial viability and performance advantages over established alternatives.

Regulatory frameworks will need adaptation to accommodate this emerging technology. Current battery material regulations focus heavily on lithium-ion chemistry hazards, whereas proton battery materials present different safety considerations, particularly around hydrogen storage and handling. Developing appropriate standards will be essential for supply chain development and market acceptance.

Material availability represents a key advantage for proton battery technology. Unlike lithium-ion batteries that depend heavily on lithium, cobalt, and nickel—elements facing supply constraints and geopolitical complications—proton batteries primarily utilize more abundant elements such as carbon, hydrogen, and various polymers. This abundance potentially reduces supply chain vulnerabilities and price volatility that have plagued lithium-ion battery production.

Geographic distribution of raw materials for proton batteries offers greater supply chain resilience. The hydrogen required for proton batteries can be produced virtually anywhere with access to water and energy, eliminating dependence on geographically concentrated mineral deposits. This decentralization capability could fundamentally reshape battery manufacturing geopolitics, allowing more countries to participate in the energy storage economy.

Processing infrastructure presents a significant challenge despite material abundance. Current chemical processing facilities are optimized for lithium-ion battery materials, requiring substantial investment to develop specialized manufacturing capabilities for proton-conducting membranes and hydrogen storage materials. This transition necessitates new industrial expertise and equipment.

Sustainability considerations strongly favor proton battery supply chains. The materials typically used—carbon-based compounds, polymers, and hydrogen—generally have lower environmental impacts during extraction compared to mining operations for lithium, cobalt, and nickel. This advantage extends to end-of-life management, as proton battery materials potentially offer simpler recycling pathways.

Economic factors will ultimately determine supply chain development. While raw materials may be more abundant, the specialized processing requirements and current lack of economies of scale present initial cost barriers. Investment in manufacturing infrastructure will require confidence in proton battery technology's commercial viability and performance advantages over established alternatives.

Regulatory frameworks will need adaptation to accommodate this emerging technology. Current battery material regulations focus heavily on lithium-ion chemistry hazards, whereas proton battery materials present different safety considerations, particularly around hydrogen storage and handling. Developing appropriate standards will be essential for supply chain development and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!