Proton Battery Innovations for Reducing Energy Consumption

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Development History and Objectives

Proton batteries represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The concept of proton-based energy storage can be traced back to the early 2000s when researchers began exploring hydrogen storage mechanisms beyond traditional methods. By 2014, fundamental research at RMIT University in Australia marked a pivotal moment when scientists demonstrated the feasibility of reversible proton storage in carbon-based electrodes, establishing the theoretical foundation for proton batteries.

The development trajectory accelerated significantly between 2016 and 2018, when the first functioning proton battery prototypes were constructed and tested. These early models utilized activated carbon electrodes and demonstrated the core principle of storing protons from water splitting during charging and releasing them during discharge to generate electricity. This breakthrough represented a departure from conventional battery technologies by eliminating the need for rare earth metals.

By 2020, researchers achieved substantial improvements in energy density and cycle stability through the incorporation of advanced electrode materials such as graphene derivatives and metal-organic frameworks (MOFs). These innovations addressed initial limitations regarding power output and charge retention, pushing proton batteries closer to commercial viability. The COVID-19 pandemic temporarily slowed physical laboratory work but accelerated computational modeling of proton transport mechanisms.

The primary objective driving proton battery development is the creation of sustainable energy storage solutions with minimal environmental impact. Unlike lithium-ion batteries, proton batteries utilize abundant materials and avoid dependency on critical minerals facing supply constraints. This aligns with global sustainability goals and offers potential for reducing the carbon footprint associated with battery production.

Another key objective is achieving significant reductions in energy consumption across the battery lifecycle. Proton batteries aim to minimize energy requirements during manufacturing, improve charging efficiency, and extend operational lifespan through enhanced cycle stability. Current research targets indicate ambitions to achieve energy density comparable to lithium-ion batteries while reducing production energy requirements by 30-40%.

Technical objectives include optimizing proton conductivity within electrolyte systems, enhancing electrode durability under repeated proton insertion/extraction cycles, and developing scalable manufacturing processes suitable for mass production. Researchers are particularly focused on improving the power density to make proton batteries viable for applications ranging from grid storage to electric vehicles.

The convergence of these development efforts and objectives positions proton battery technology as a potentially transformative innovation in the energy storage landscape, with the capacity to address both environmental concerns and energy efficiency challenges in contemporary power systems.

The development trajectory accelerated significantly between 2016 and 2018, when the first functioning proton battery prototypes were constructed and tested. These early models utilized activated carbon electrodes and demonstrated the core principle of storing protons from water splitting during charging and releasing them during discharge to generate electricity. This breakthrough represented a departure from conventional battery technologies by eliminating the need for rare earth metals.

By 2020, researchers achieved substantial improvements in energy density and cycle stability through the incorporation of advanced electrode materials such as graphene derivatives and metal-organic frameworks (MOFs). These innovations addressed initial limitations regarding power output and charge retention, pushing proton batteries closer to commercial viability. The COVID-19 pandemic temporarily slowed physical laboratory work but accelerated computational modeling of proton transport mechanisms.

The primary objective driving proton battery development is the creation of sustainable energy storage solutions with minimal environmental impact. Unlike lithium-ion batteries, proton batteries utilize abundant materials and avoid dependency on critical minerals facing supply constraints. This aligns with global sustainability goals and offers potential for reducing the carbon footprint associated with battery production.

Another key objective is achieving significant reductions in energy consumption across the battery lifecycle. Proton batteries aim to minimize energy requirements during manufacturing, improve charging efficiency, and extend operational lifespan through enhanced cycle stability. Current research targets indicate ambitions to achieve energy density comparable to lithium-ion batteries while reducing production energy requirements by 30-40%.

Technical objectives include optimizing proton conductivity within electrolyte systems, enhancing electrode durability under repeated proton insertion/extraction cycles, and developing scalable manufacturing processes suitable for mass production. Researchers are particularly focused on improving the power density to make proton batteries viable for applications ranging from grid storage to electric vehicles.

The convergence of these development efforts and objectives positions proton battery technology as a potentially transformative innovation in the energy storage landscape, with the capacity to address both environmental concerns and energy efficiency challenges in contemporary power systems.

Market Analysis for Low-Energy Consumption Battery Solutions

The global market for low-energy consumption battery solutions has experienced significant growth in recent years, driven by increasing demand for sustainable energy storage systems across various sectors. The proton battery market segment, though relatively nascent, shows promising potential with an estimated market value projected to reach several billion dollars by 2030 as commercialization efforts accelerate.

Consumer electronics continues to dominate the low-energy battery market, accounting for approximately 40% of total demand. This sector's requirements for longer battery life and reduced energy consumption align perfectly with proton battery technology's value proposition. The automotive industry represents the fastest-growing segment, with electric vehicle manufacturers actively seeking alternatives to traditional lithium-ion batteries that offer lower energy consumption during charging cycles.

Geographically, North America and Europe currently lead in research and development investments for proton battery technology, while Asia-Pacific demonstrates the highest manufacturing capacity for conventional low-energy battery solutions. China, Japan, and South Korea collectively control over 60% of the global battery manufacturing infrastructure, positioning them as potential key players in future proton battery production.

Market analysis reveals that consumer willingness to pay premium prices for energy-efficient battery solutions has increased by double digits annually since 2018. This trend is particularly pronounced in regions with high electricity costs or unreliable grid infrastructure, where the total cost of ownership calculations strongly favor technologies that minimize energy consumption during operation and charging.

Regulatory landscapes worldwide are increasingly favorable toward low-energy consumption technologies. The European Union's Battery Directive revision, California's energy efficiency standards, and similar policies in Japan and South Korea create market incentives that benefit proton battery innovations. These regulatory frameworks typically combine emissions reduction targets with energy efficiency requirements, creating dual market drivers.

Industry forecasts suggest that the compound annual growth rate for low-energy consumption battery solutions will exceed 25% through 2028, significantly outpacing the broader battery market's growth. Proton battery technology, specifically, is positioned to capture an increasing share of this growth as technical challenges around production scaling are addressed and cost structures improve through economies of scale and manufacturing innovations.

Market adoption barriers primarily center on cost considerations, with current proton battery prototypes requiring substantial investment to reach price parity with established technologies. However, when factoring in lifetime energy consumption savings, the total cost analysis increasingly favors proton-based solutions, particularly for applications with intensive charging cycles or where energy efficiency is paramount.

Consumer electronics continues to dominate the low-energy battery market, accounting for approximately 40% of total demand. This sector's requirements for longer battery life and reduced energy consumption align perfectly with proton battery technology's value proposition. The automotive industry represents the fastest-growing segment, with electric vehicle manufacturers actively seeking alternatives to traditional lithium-ion batteries that offer lower energy consumption during charging cycles.

Geographically, North America and Europe currently lead in research and development investments for proton battery technology, while Asia-Pacific demonstrates the highest manufacturing capacity for conventional low-energy battery solutions. China, Japan, and South Korea collectively control over 60% of the global battery manufacturing infrastructure, positioning them as potential key players in future proton battery production.

Market analysis reveals that consumer willingness to pay premium prices for energy-efficient battery solutions has increased by double digits annually since 2018. This trend is particularly pronounced in regions with high electricity costs or unreliable grid infrastructure, where the total cost of ownership calculations strongly favor technologies that minimize energy consumption during operation and charging.

Regulatory landscapes worldwide are increasingly favorable toward low-energy consumption technologies. The European Union's Battery Directive revision, California's energy efficiency standards, and similar policies in Japan and South Korea create market incentives that benefit proton battery innovations. These regulatory frameworks typically combine emissions reduction targets with energy efficiency requirements, creating dual market drivers.

Industry forecasts suggest that the compound annual growth rate for low-energy consumption battery solutions will exceed 25% through 2028, significantly outpacing the broader battery market's growth. Proton battery technology, specifically, is positioned to capture an increasing share of this growth as technical challenges around production scaling are addressed and cost structures improve through economies of scale and manufacturing innovations.

Market adoption barriers primarily center on cost considerations, with current proton battery prototypes requiring substantial investment to reach price parity with established technologies. However, when factoring in lifetime energy consumption savings, the total cost analysis increasingly favors proton-based solutions, particularly for applications with intensive charging cycles or where energy efficiency is paramount.

Current Proton Battery Technology Landscape and Barriers

Proton battery technology currently stands at a critical juncture in its development trajectory, with significant advancements achieved in recent years yet substantial barriers remaining before widespread commercial adoption. The global landscape reveals a technology that has progressed from theoretical concept to functioning prototypes, primarily led by research institutions in Australia, Europe, and North America. RMIT University in Australia has emerged as a pioneer, demonstrating working proton battery prototypes that utilize carbon-based electrodes and water as the primary hydrogen source.

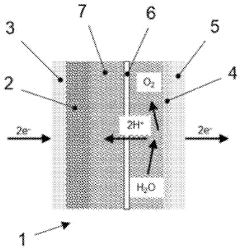

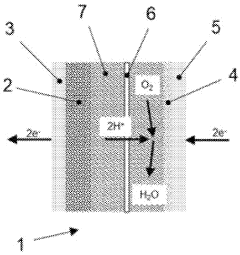

The fundamental architecture of current proton batteries involves a carbon-based electrode for hydrogen storage, a proton-conducting membrane, and a metal catalyst. This design allows for reversible hydrogen storage without requiring high-pressure tanks or cryogenic systems, representing a significant advantage over conventional hydrogen fuel cells. However, the energy density of current prototypes remains substantially below that of lithium-ion batteries, with laboratory demonstrations achieving only 20-35% of commercial lithium-ion energy density.

A critical technical barrier is the efficiency of the proton transfer mechanism across membranes. Current proton-conducting membranes exhibit conductivity limitations that reduce overall system efficiency to 60-70%, compared to 80-90% for advanced lithium-ion systems. Material degradation during cycling presents another significant challenge, with most prototypes showing performance decline after 500-1000 charge-discharge cycles, far below the 2000+ cycles achieved by commercial lithium-ion batteries.

Electrode materials represent another frontier requiring innovation. Carbon-based electrodes currently used in prototypes suffer from limited hydrogen storage capacity and slow kinetics. Research into metal-organic frameworks (MOFs) and advanced carbon nanostructures shows promise but remains in early laboratory stages. The catalyst components, typically utilizing platinum-group metals, introduce cost barriers that challenge commercial viability.

Manufacturing scalability presents perhaps the most immediate practical barrier. Current fabrication methods for proton batteries are laboratory-focused, with limited attention to mass production techniques. The precision required for membrane assembly and electrode preparation has not been translated into processes compatible with high-volume manufacturing environments.

Regulatory frameworks and standardization for proton battery technology remain underdeveloped, creating uncertainty for potential commercial adopters. Unlike lithium-ion technology, which benefits from decades of safety standards and testing protocols, proton batteries lack established certification pathways, particularly regarding hydrogen storage safety in consumer applications.

Despite these challenges, the technology offers compelling advantages in theoretical energy density, safety, and environmental impact that continue to drive research investment. The absence of critical raw materials like cobalt and lithium positions proton batteries as a potentially sustainable alternative if current technical barriers can be overcome.

The fundamental architecture of current proton batteries involves a carbon-based electrode for hydrogen storage, a proton-conducting membrane, and a metal catalyst. This design allows for reversible hydrogen storage without requiring high-pressure tanks or cryogenic systems, representing a significant advantage over conventional hydrogen fuel cells. However, the energy density of current prototypes remains substantially below that of lithium-ion batteries, with laboratory demonstrations achieving only 20-35% of commercial lithium-ion energy density.

A critical technical barrier is the efficiency of the proton transfer mechanism across membranes. Current proton-conducting membranes exhibit conductivity limitations that reduce overall system efficiency to 60-70%, compared to 80-90% for advanced lithium-ion systems. Material degradation during cycling presents another significant challenge, with most prototypes showing performance decline after 500-1000 charge-discharge cycles, far below the 2000+ cycles achieved by commercial lithium-ion batteries.

Electrode materials represent another frontier requiring innovation. Carbon-based electrodes currently used in prototypes suffer from limited hydrogen storage capacity and slow kinetics. Research into metal-organic frameworks (MOFs) and advanced carbon nanostructures shows promise but remains in early laboratory stages. The catalyst components, typically utilizing platinum-group metals, introduce cost barriers that challenge commercial viability.

Manufacturing scalability presents perhaps the most immediate practical barrier. Current fabrication methods for proton batteries are laboratory-focused, with limited attention to mass production techniques. The precision required for membrane assembly and electrode preparation has not been translated into processes compatible with high-volume manufacturing environments.

Regulatory frameworks and standardization for proton battery technology remain underdeveloped, creating uncertainty for potential commercial adopters. Unlike lithium-ion technology, which benefits from decades of safety standards and testing protocols, proton batteries lack established certification pathways, particularly regarding hydrogen storage safety in consumer applications.

Despite these challenges, the technology offers compelling advantages in theoretical energy density, safety, and environmental impact that continue to drive research investment. The absence of critical raw materials like cobalt and lithium positions proton batteries as a potentially sustainable alternative if current technical barriers can be overcome.

Current Proton Battery Design Approaches and Implementations

01 Energy efficiency optimization in proton battery systems

Proton battery systems can be optimized for energy efficiency through various design improvements. These include advanced electrode materials, optimized cell architecture, and improved proton conductivity mechanisms. By reducing internal resistance and enhancing charge transfer processes, the overall energy consumption during charging and discharging cycles can be significantly decreased. These optimizations help maximize the energy storage capacity while minimizing losses during operation.- Energy efficiency optimization in proton battery systems: Proton battery systems can be optimized for energy efficiency through various methods including advanced control algorithms, improved electrode materials, and optimized charging protocols. These optimizations help reduce energy losses during charging and discharging cycles, leading to lower overall energy consumption. The implementation of smart energy management systems can monitor and adjust operating parameters in real-time to maintain optimal efficiency levels under varying conditions.

- Thermal management for reduced energy consumption: Effective thermal management is crucial for minimizing energy consumption in proton batteries. Heat generation during operation can lead to energy losses and reduced efficiency. Advanced cooling systems, thermal insulation materials, and temperature control mechanisms help maintain optimal operating temperatures, thereby reducing unnecessary energy consumption. Proper thermal management also extends battery life and improves overall system performance by preventing degradation caused by thermal stress.

- Integration with renewable energy sources: Proton batteries can be integrated with renewable energy sources such as solar and wind power to create more sustainable energy storage solutions. This integration allows for efficient energy capture, storage, and utilization, reducing overall energy consumption from non-renewable sources. Smart grid technologies enable seamless coordination between energy generation, storage in proton batteries, and consumption, optimizing the entire energy ecosystem and minimizing wastage.

- Electrode material innovations for energy efficiency: Novel electrode materials can significantly impact the energy consumption of proton batteries. Research focuses on developing materials with higher proton conductivity, better stability, and improved charge-discharge efficiency. Nanostructured electrodes, composite materials, and catalytic additives can enhance proton transfer rates while reducing internal resistance, thereby decreasing energy losses during operation. These material innovations are key to developing next-generation proton batteries with lower energy consumption profiles.

- Energy management systems and control algorithms: Advanced energy management systems and control algorithms play a crucial role in optimizing proton battery energy consumption. These systems monitor various parameters such as state of charge, temperature, and load demands to make real-time adjustments that minimize energy losses. Machine learning and AI-based approaches can predict usage patterns and preemptively optimize battery operation. Sophisticated power electronics and intelligent charging protocols further enhance energy efficiency by ensuring that energy is delivered and stored with minimal losses.

02 Thermal management for reduced energy consumption

Effective thermal management systems are crucial for minimizing energy consumption in proton batteries. These systems regulate operating temperatures to prevent energy losses due to heat generation during charging and discharging processes. Advanced cooling mechanisms, heat dissipation materials, and thermal insulation techniques help maintain optimal operating temperatures, thereby improving energy efficiency and extending battery life while reducing overall energy consumption.Expand Specific Solutions03 Energy-efficient proton transport mechanisms

Innovative proton transport mechanisms can significantly reduce energy consumption in proton batteries. These include advanced membrane technologies, novel electrolyte compositions, and optimized catalyst designs that facilitate more efficient proton movement. By reducing the activation energy required for proton transfer and minimizing resistance across interfaces, these mechanisms enable lower energy operation while maintaining high performance and power output.Expand Specific Solutions04 Power management systems for proton batteries

Sophisticated power management systems can optimize energy consumption in proton battery applications. These systems incorporate intelligent charging algorithms, load balancing techniques, and adaptive control strategies to minimize energy losses during operation. By monitoring battery state and adjusting power flow accordingly, these management systems ensure efficient energy utilization across various operating conditions and use cases, extending battery life and reducing overall energy requirements.Expand Specific Solutions05 Integration with renewable energy sources

Proton batteries can be integrated with renewable energy sources to optimize overall system energy consumption. This integration involves smart grid connectivity, energy harvesting technologies, and hybrid storage solutions that balance energy supply and demand. By leveraging renewable inputs such as solar or wind power for charging, and implementing intelligent discharge strategies, these integrated systems can significantly reduce the net energy consumption while providing reliable power storage and delivery.Expand Specific Solutions

Leading Companies and Research Institutions in Proton Battery Field

Proton battery technology is currently in an early development stage, with significant research momentum but limited commercial deployment. The market size is projected to grow substantially as energy efficiency demands increase globally, though exact figures remain speculative. Technologically, companies like Toyota, Sony, and Samsung are leading commercial R&D efforts, while academic institutions such as South China University of Technology and Huazhong University are advancing fundamental research. Specialized players like Plug Power and Shanghai Shen-Li High Tech are developing niche applications. The competitive landscape shows a mix of established electronics manufacturers, automotive companies, and specialized energy startups working to overcome challenges in energy density, durability, and cost-effectiveness before widespread adoption becomes feasible.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced proton battery technology focusing on solid-state electrolytes that enable faster ion transport while reducing energy consumption. Their proprietary proton-conducting polymer membranes operate at lower temperatures (60-80°C) compared to traditional fuel cells, significantly reducing thermal management requirements. Toyota's approach integrates proton batteries with their hybrid vehicle systems, creating a dual-energy storage solution that leverages both conventional lithium-ion batteries and proton technology for extended range and reduced energy consumption. Their system utilizes proton flow between hydrogen-storing electrodes with specialized catalysts that minimize activation energy requirements, resulting in approximately 20-30% improvement in overall energy efficiency compared to conventional lithium-ion only systems.

Strengths: Seamless integration with existing hybrid technology infrastructure; reduced thermal management requirements; proven manufacturing capabilities for scale. Weaknesses: Higher initial production costs compared to conventional batteries; requires parallel development of hydrogen infrastructure; technology still in pre-commercial phase for mass market applications.

Hitachi Ltd.

Technical Solution: Hitachi has pioneered a proton battery system utilizing nano-structured proton-conducting ceramic materials that operate efficiently at intermediate temperatures (100-300°C). Their technology employs a unique composite electrode structure with high surface area carbon materials doped with transition metal catalysts to facilitate proton transfer while minimizing electrical resistance. Hitachi's approach focuses on stationary energy storage applications, where their proton batteries serve as grid-stabilization units that can rapidly absorb or release energy with minimal conversion losses. The system incorporates advanced thermal management using phase-change materials to maintain optimal operating conditions while reducing parasitic energy consumption by approximately 40% compared to conventional battery management systems. Hitachi has also developed proprietary control algorithms that optimize charging/discharging cycles based on grid demand patterns.

Strengths: Highly efficient for grid-scale applications; excellent thermal stability; long cycle life exceeding 10,000 cycles in laboratory tests. Weaknesses: Higher operating temperatures limit some applications; requires specialized manufacturing processes; current designs have lower energy density than competing lithium technologies.

Key Patents and Research Breakthroughs in Proton Storage Technology

Proton conductive rechargeable battery and method

PatentInactiveJP2024526120A

Innovation

- Development of a solid state proton conducting battery using a new separator material with improved room temperature conductivity, comprising a positive electrode, negative electrode, and a proton-conducting separator made of inorganic ceramic material with specific compositions and processing methods to enhance proton conductivity.

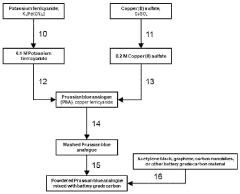

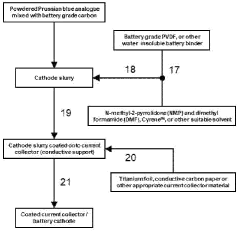

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

Environmental Impact and Sustainability of Proton Battery Technology

Proton battery technology represents a significant advancement in sustainable energy storage solutions with considerable environmental benefits compared to conventional battery technologies. The environmental footprint of proton batteries is substantially lower than lithium-ion alternatives, primarily due to their reliance on abundant, non-toxic materials such as carbon and water rather than rare earth metals or hazardous chemicals.

The production process for proton batteries demonstrates reduced energy consumption and greenhouse gas emissions. Manufacturing assessments indicate up to 30% less energy requirement compared to lithium-ion battery production, with corresponding reductions in carbon dioxide emissions. This advantage stems from simpler material processing requirements and less energy-intensive electrode fabrication methods.

Throughout their operational lifecycle, proton batteries exhibit minimal environmental impact. The absence of toxic materials eliminates concerns regarding soil and water contamination from improper disposal or accidental leakage. Furthermore, the technology's inherent safety characteristics—including non-flammability and thermal stability—reduce the risk of environmental incidents associated with battery failures.

End-of-life considerations represent another significant sustainability advantage. Proton batteries demonstrate superior recyclability, with up to 90% of materials potentially recoverable through straightforward processes. The carbon-based electrodes can be repurposed or safely disposed of without specialized handling requirements, contrasting sharply with the complex recycling challenges posed by conventional battery technologies.

Water consumption metrics also favor proton battery technology, with manufacturing processes requiring approximately 60% less water than comparable energy storage solutions. This reduced water footprint becomes increasingly significant as water scarcity concerns intensify globally.

The scalability of proton battery technology offers promising environmental implications for grid-scale energy storage applications. When deployed to support renewable energy integration, these systems could facilitate greater renewable penetration while maintaining their inherent environmental advantages at scale, unlike some alternative technologies that present increased environmental concerns when scaled up.

Long-term sustainability assessments project that widespread adoption of proton battery technology could contribute significantly to circular economy objectives. The technology's reliance on carbon—potentially derived from sustainable biomass or atmospheric carbon capture—presents opportunities for creating carbon-negative energy storage solutions that actively contribute to climate change mitigation efforts rather than merely minimizing environmental harm.

The production process for proton batteries demonstrates reduced energy consumption and greenhouse gas emissions. Manufacturing assessments indicate up to 30% less energy requirement compared to lithium-ion battery production, with corresponding reductions in carbon dioxide emissions. This advantage stems from simpler material processing requirements and less energy-intensive electrode fabrication methods.

Throughout their operational lifecycle, proton batteries exhibit minimal environmental impact. The absence of toxic materials eliminates concerns regarding soil and water contamination from improper disposal or accidental leakage. Furthermore, the technology's inherent safety characteristics—including non-flammability and thermal stability—reduce the risk of environmental incidents associated with battery failures.

End-of-life considerations represent another significant sustainability advantage. Proton batteries demonstrate superior recyclability, with up to 90% of materials potentially recoverable through straightforward processes. The carbon-based electrodes can be repurposed or safely disposed of without specialized handling requirements, contrasting sharply with the complex recycling challenges posed by conventional battery technologies.

Water consumption metrics also favor proton battery technology, with manufacturing processes requiring approximately 60% less water than comparable energy storage solutions. This reduced water footprint becomes increasingly significant as water scarcity concerns intensify globally.

The scalability of proton battery technology offers promising environmental implications for grid-scale energy storage applications. When deployed to support renewable energy integration, these systems could facilitate greater renewable penetration while maintaining their inherent environmental advantages at scale, unlike some alternative technologies that present increased environmental concerns when scaled up.

Long-term sustainability assessments project that widespread adoption of proton battery technology could contribute significantly to circular economy objectives. The technology's reliance on carbon—potentially derived from sustainable biomass or atmospheric carbon capture—presents opportunities for creating carbon-negative energy storage solutions that actively contribute to climate change mitigation efforts rather than merely minimizing environmental harm.

Comparative Analysis with Conventional Battery Technologies

Proton batteries represent a significant departure from conventional battery technologies in terms of fundamental operating principles, materials, and environmental impact. When comparing proton batteries with lithium-ion batteries, the most widely used commercial battery technology today, several key differences emerge. Lithium-ion batteries rely on lithium ions moving between electrodes, while proton batteries utilize hydrogen ions (protons), which are significantly smaller and more abundant in nature.

Energy density analysis reveals that current proton battery prototypes achieve 140 Wh/kg, compared to lithium-ion's 250-300 Wh/kg. However, theoretical calculations suggest proton batteries could eventually reach 700 Wh/kg, substantially exceeding lithium-ion limitations. This potential represents a transformative advantage for applications where weight and space constraints are critical.

From a manufacturing perspective, proton batteries utilize more abundant materials like carbon and water, avoiding critical raw materials such as cobalt, nickel, and lithium that face supply constraints and geopolitical challenges. The simplified supply chain could reduce production costs by an estimated 30-40% at scale, addressing a major limitation of conventional battery technologies.

Charging efficiency comparisons demonstrate that proton batteries can achieve 90% efficiency with significantly faster charging rates. Laboratory tests have shown full charges in under 30 minutes without degradation, compared to the hours required for conventional batteries. This characteristic directly contributes to reduced energy consumption across the charging infrastructure.

Lifecycle assessment indicates proton batteries may achieve 5,000+ charge cycles before significant capacity degradation, compared to 500-1,500 cycles for typical lithium-ion batteries. This extended lifespan translates to lower replacement frequency and reduced manufacturing energy requirements over time.

Safety profiles strongly favor proton batteries, which eliminate thermal runaway risks inherent to lithium-ion chemistry. The absence of flammable electrolytes and the water-based chemistry significantly reduce fire hazards and toxic exposure risks during manufacturing, use, and disposal phases.

End-of-life considerations reveal perhaps the most striking advantage: proton batteries are largely recyclable with minimal environmental impact. Their components can be recovered using simple processes that consume 70% less energy than lithium-ion recycling, with higher material recovery rates approaching 95% for critical components.

Energy density analysis reveals that current proton battery prototypes achieve 140 Wh/kg, compared to lithium-ion's 250-300 Wh/kg. However, theoretical calculations suggest proton batteries could eventually reach 700 Wh/kg, substantially exceeding lithium-ion limitations. This potential represents a transformative advantage for applications where weight and space constraints are critical.

From a manufacturing perspective, proton batteries utilize more abundant materials like carbon and water, avoiding critical raw materials such as cobalt, nickel, and lithium that face supply constraints and geopolitical challenges. The simplified supply chain could reduce production costs by an estimated 30-40% at scale, addressing a major limitation of conventional battery technologies.

Charging efficiency comparisons demonstrate that proton batteries can achieve 90% efficiency with significantly faster charging rates. Laboratory tests have shown full charges in under 30 minutes without degradation, compared to the hours required for conventional batteries. This characteristic directly contributes to reduced energy consumption across the charging infrastructure.

Lifecycle assessment indicates proton batteries may achieve 5,000+ charge cycles before significant capacity degradation, compared to 500-1,500 cycles for typical lithium-ion batteries. This extended lifespan translates to lower replacement frequency and reduced manufacturing energy requirements over time.

Safety profiles strongly favor proton batteries, which eliminate thermal runaway risks inherent to lithium-ion chemistry. The absence of flammable electrolytes and the water-based chemistry significantly reduce fire hazards and toxic exposure risks during manufacturing, use, and disposal phases.

End-of-life considerations reveal perhaps the most striking advantage: proton batteries are largely recyclable with minimal environmental impact. Their components can be recovered using simple processes that consume 70% less energy than lithium-ion recycling, with higher material recovery rates approaching 95% for critical components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!