Exploring Proton Battery Thermal Conductivity Variations

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Thermal Conductivity Background and Objectives

Proton batteries represent a significant advancement in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development of proton batteries can be traced back to early research in the 1990s, but substantial progress has been made in the past decade with breakthroughs in proton-conducting materials and electrode designs. This technology leverages the unique properties of protons as charge carriers, offering potential advantages in energy density, safety, and environmental sustainability.

The thermal conductivity characteristics of proton batteries have become a critical focus area as researchers seek to optimize performance and safety. Historical data indicates that thermal management challenges have been a persistent obstacle in battery technology evolution, with thermal runaway incidents highlighting the importance of understanding heat transfer mechanisms within energy storage systems. The thermal conductivity variations in proton batteries specifically present both challenges and opportunities that warrant comprehensive investigation.

Current technological trends point toward increasing energy densities and faster charging capabilities in battery systems, which inevitably generate more heat during operation. This evolution necessitates a deeper understanding of thermal conductivity behavior across different operational conditions, materials, and structural configurations in proton battery systems. The scientific community has recently shifted focus toward nanoscale thermal transport phenomena that significantly impact overall battery performance.

The primary technical objectives of this research include: quantifying the thermal conductivity variations across different proton battery materials and interfaces; identifying the fundamental mechanisms governing these variations; developing predictive models for thermal behavior under various operational conditions; and establishing design guidelines for optimized thermal management systems specific to proton battery technology.

Additionally, this investigation aims to explore the correlation between proton mobility and thermal transport properties, as preliminary research suggests a complex relationship that could be leveraged for enhanced battery performance. Understanding these relationships could potentially lead to breakthrough designs that simultaneously optimize both ionic conductivity and thermal management.

The long-term technological goal is to develop proton battery systems with precisely engineered thermal conductivity profiles that maintain optimal operating temperatures across diverse usage scenarios, from consumer electronics to grid-scale energy storage. This would enable significant improvements in battery lifespan, charging speeds, and safety profiles compared to current technologies.

This research aligns with broader industry trends toward sustainable energy solutions and addresses the growing demand for safer, more efficient energy storage technologies in applications ranging from electric vehicles to renewable energy integration systems.

The thermal conductivity characteristics of proton batteries have become a critical focus area as researchers seek to optimize performance and safety. Historical data indicates that thermal management challenges have been a persistent obstacle in battery technology evolution, with thermal runaway incidents highlighting the importance of understanding heat transfer mechanisms within energy storage systems. The thermal conductivity variations in proton batteries specifically present both challenges and opportunities that warrant comprehensive investigation.

Current technological trends point toward increasing energy densities and faster charging capabilities in battery systems, which inevitably generate more heat during operation. This evolution necessitates a deeper understanding of thermal conductivity behavior across different operational conditions, materials, and structural configurations in proton battery systems. The scientific community has recently shifted focus toward nanoscale thermal transport phenomena that significantly impact overall battery performance.

The primary technical objectives of this research include: quantifying the thermal conductivity variations across different proton battery materials and interfaces; identifying the fundamental mechanisms governing these variations; developing predictive models for thermal behavior under various operational conditions; and establishing design guidelines for optimized thermal management systems specific to proton battery technology.

Additionally, this investigation aims to explore the correlation between proton mobility and thermal transport properties, as preliminary research suggests a complex relationship that could be leveraged for enhanced battery performance. Understanding these relationships could potentially lead to breakthrough designs that simultaneously optimize both ionic conductivity and thermal management.

The long-term technological goal is to develop proton battery systems with precisely engineered thermal conductivity profiles that maintain optimal operating temperatures across diverse usage scenarios, from consumer electronics to grid-scale energy storage. This would enable significant improvements in battery lifespan, charging speeds, and safety profiles compared to current technologies.

This research aligns with broader industry trends toward sustainable energy solutions and addresses the growing demand for safer, more efficient energy storage technologies in applications ranging from electric vehicles to renewable energy integration systems.

Market Analysis for Thermally Efficient Energy Storage

The global energy storage market is experiencing significant growth, with a projected market value reaching $546 billion by 2035, representing a compound annual growth rate of approximately 20% from 2023. Within this expanding landscape, thermally efficient energy storage solutions are gaining particular attention due to their potential to address critical challenges in renewable energy integration and grid stability. Proton batteries, specifically those with optimized thermal conductivity properties, are positioned to capture a substantial portion of this market.

Current market analysis indicates that thermal management in energy storage systems accounts for nearly 15% of total system costs, creating a compelling economic incentive for innovations in thermal conductivity. Industries including electric vehicles, renewable energy, and grid-scale storage are actively seeking solutions that can maintain optimal operating temperatures while maximizing energy density and cycle life.

The demand for thermally efficient energy storage is being driven by several converging factors. First, the electrification of transportation has created urgent requirements for batteries that can rapidly charge without dangerous heat buildup. Second, renewable energy integration demands storage solutions that maintain performance stability across diverse environmental conditions. Third, data centers and telecommunications infrastructure require increasingly reliable backup power systems with minimal thermal management overhead.

Regional market assessment reveals varying adoption patterns, with Asia-Pacific leading manufacturing capacity development, while North America and Europe focus on research advancements and premium applications. China currently dominates the supply chain for conventional battery technologies, but emerging thermal management innovations present opportunities for market disruption and new competitive advantages.

Consumer and industrial segments show distinct requirements regarding thermal efficiency. The consumer electronics sector prioritizes compact solutions with passive thermal management, while industrial applications demand robust active cooling systems capable of handling high-power operations. The electric vehicle segment represents the fastest-growing market opportunity, with thermal management being critical for fast-charging capabilities and battery longevity.

Economic analysis demonstrates that improvements in thermal conductivity can reduce lifetime ownership costs by 12-18% through extended battery life, reduced cooling infrastructure requirements, and improved energy efficiency. This translates to potential savings of thousands of dollars per megawatt-hour of installed capacity, creating strong market pull for innovations in proton battery thermal conductivity.

Market forecasts suggest that thermally optimized energy storage solutions could capture 30% of new installations by 2030, representing a specialized high-value segment within the broader energy storage ecosystem. Early adopters are likely to include premium electric vehicle manufacturers, military applications, and mission-critical infrastructure where performance advantages outweigh initial cost considerations.

Current market analysis indicates that thermal management in energy storage systems accounts for nearly 15% of total system costs, creating a compelling economic incentive for innovations in thermal conductivity. Industries including electric vehicles, renewable energy, and grid-scale storage are actively seeking solutions that can maintain optimal operating temperatures while maximizing energy density and cycle life.

The demand for thermally efficient energy storage is being driven by several converging factors. First, the electrification of transportation has created urgent requirements for batteries that can rapidly charge without dangerous heat buildup. Second, renewable energy integration demands storage solutions that maintain performance stability across diverse environmental conditions. Third, data centers and telecommunications infrastructure require increasingly reliable backup power systems with minimal thermal management overhead.

Regional market assessment reveals varying adoption patterns, with Asia-Pacific leading manufacturing capacity development, while North America and Europe focus on research advancements and premium applications. China currently dominates the supply chain for conventional battery technologies, but emerging thermal management innovations present opportunities for market disruption and new competitive advantages.

Consumer and industrial segments show distinct requirements regarding thermal efficiency. The consumer electronics sector prioritizes compact solutions with passive thermal management, while industrial applications demand robust active cooling systems capable of handling high-power operations. The electric vehicle segment represents the fastest-growing market opportunity, with thermal management being critical for fast-charging capabilities and battery longevity.

Economic analysis demonstrates that improvements in thermal conductivity can reduce lifetime ownership costs by 12-18% through extended battery life, reduced cooling infrastructure requirements, and improved energy efficiency. This translates to potential savings of thousands of dollars per megawatt-hour of installed capacity, creating strong market pull for innovations in proton battery thermal conductivity.

Market forecasts suggest that thermally optimized energy storage solutions could capture 30% of new installations by 2030, representing a specialized high-value segment within the broader energy storage ecosystem. Early adopters are likely to include premium electric vehicle manufacturers, military applications, and mission-critical infrastructure where performance advantages outweigh initial cost considerations.

Current Challenges in Proton Battery Thermal Management

Proton batteries represent a promising alternative to conventional lithium-ion technology, but their widespread adoption faces significant thermal management challenges. The thermal conductivity variations in proton battery materials create complex heat distribution patterns that impact performance, safety, and longevity. Current thermal management systems struggle to address these variations effectively, particularly during high-rate charging and discharging cycles when thermal gradients become most pronounced.

The primary challenge lies in the inherent thermal anisotropy of proton-conducting materials. Unlike lithium-ion batteries with relatively predictable thermal profiles, proton batteries exhibit directional heat transfer properties that change with temperature, state of charge, and aging. This variability makes traditional cooling strategies insufficient, as they cannot adapt to the dynamic thermal landscape within the cell structure.

Material interface thermal resistance presents another significant obstacle. The junction points between different components—electrodes, electrolytes, and current collectors—create thermal bottlenecks that impede efficient heat dissipation. These thermal contact resistances can vary by an order of magnitude depending on manufacturing processes, compression forces, and interface materials, making standardized thermal management approaches problematic.

Humidity-dependent thermal behavior further complicates management strategies. Proton conductivity in these batteries is intrinsically linked to water content, which simultaneously affects thermal conductivity. Environmental humidity fluctuations can alter internal moisture levels, creating unpredictable thermal response patterns that current management systems cannot anticipate or compensate for effectively.

Scale-up challenges present additional barriers to commercial implementation. Laboratory-scale thermal management solutions often fail to translate to larger battery packs due to non-linear scaling of thermal properties. Heat dissipation pathways that function adequately in small cells become overwhelmed in commercial-sized batteries, leading to thermal runaway risks and performance degradation.

Current cooling technologies also face efficiency limitations when applied to proton batteries. Liquid cooling systems, while effective for lithium-ion batteries, may interact unfavorably with proton-conducting materials or introduce additional complexity due to the moisture sensitivity of these systems. Air cooling approaches lack the precision needed to address localized hotspots that characterize proton battery thermal profiles.

Measurement and modeling inadequacies further hinder progress. Existing thermal imaging and sensing technologies lack the spatial and temporal resolution to accurately map the complex thermal gradients in proton batteries. Similarly, computational models have not yet incorporated the multiphysics interactions unique to proton systems, limiting predictive capabilities for thermal management design.

The primary challenge lies in the inherent thermal anisotropy of proton-conducting materials. Unlike lithium-ion batteries with relatively predictable thermal profiles, proton batteries exhibit directional heat transfer properties that change with temperature, state of charge, and aging. This variability makes traditional cooling strategies insufficient, as they cannot adapt to the dynamic thermal landscape within the cell structure.

Material interface thermal resistance presents another significant obstacle. The junction points between different components—electrodes, electrolytes, and current collectors—create thermal bottlenecks that impede efficient heat dissipation. These thermal contact resistances can vary by an order of magnitude depending on manufacturing processes, compression forces, and interface materials, making standardized thermal management approaches problematic.

Humidity-dependent thermal behavior further complicates management strategies. Proton conductivity in these batteries is intrinsically linked to water content, which simultaneously affects thermal conductivity. Environmental humidity fluctuations can alter internal moisture levels, creating unpredictable thermal response patterns that current management systems cannot anticipate or compensate for effectively.

Scale-up challenges present additional barriers to commercial implementation. Laboratory-scale thermal management solutions often fail to translate to larger battery packs due to non-linear scaling of thermal properties. Heat dissipation pathways that function adequately in small cells become overwhelmed in commercial-sized batteries, leading to thermal runaway risks and performance degradation.

Current cooling technologies also face efficiency limitations when applied to proton batteries. Liquid cooling systems, while effective for lithium-ion batteries, may interact unfavorably with proton-conducting materials or introduce additional complexity due to the moisture sensitivity of these systems. Air cooling approaches lack the precision needed to address localized hotspots that characterize proton battery thermal profiles.

Measurement and modeling inadequacies further hinder progress. Existing thermal imaging and sensing technologies lack the spatial and temporal resolution to accurately map the complex thermal gradients in proton batteries. Similarly, computational models have not yet incorporated the multiphysics interactions unique to proton systems, limiting predictive capabilities for thermal management design.

Existing Thermal Conductivity Enhancement Approaches

01 Thermal management materials for proton batteries

Various materials are used in proton batteries to enhance thermal conductivity and manage heat distribution. These include specialized thermal interface materials, heat-dissipating compounds, and thermally conductive fillers that can be incorporated into battery components. These materials help maintain optimal operating temperatures, prevent hotspots, and improve overall battery performance and safety by efficiently transferring heat away from critical components.- Thermal management materials for proton batteries: Various materials are used in proton batteries to enhance thermal conductivity and manage heat distribution. These include specialized thermal interface materials, heat-dissipating compounds, and thermally conductive fillers that can be incorporated into battery components. These materials help maintain optimal operating temperatures, prevent hotspots, and improve overall battery performance and safety by efficiently transferring heat away from critical components.

- Electrode design for improved thermal conductivity: Advanced electrode designs incorporate features that enhance thermal conductivity in proton batteries. These designs may include structured electrode architectures, porous materials with optimized thermal pathways, and composite electrodes with thermally conductive additives. By improving heat transfer within and between electrodes, these designs help maintain uniform temperature distribution, reduce thermal resistance, and enhance overall battery efficiency and lifespan.

- Electrolyte formulations affecting thermal properties: Specialized electrolyte formulations play a crucial role in determining the thermal conductivity of proton batteries. These formulations may include additives that enhance thermal transport, ionic liquids with superior thermal properties, or gel-polymer electrolytes with optimized thermal characteristics. The electrolyte composition directly impacts how heat is distributed throughout the battery system, affecting charging efficiency, discharge rates, and overall thermal stability.

- Battery housing and structural design for heat dissipation: The structural design and housing of proton batteries significantly impact thermal conductivity and heat management. Innovative housing designs incorporate heat sinks, cooling channels, or thermally conductive casings to facilitate heat dissipation. Some designs feature integrated thermal management systems, specialized geometries to maximize surface area for cooling, or composite housing materials with enhanced thermal properties to maintain optimal operating temperatures.

- Thermal interface materials and coatings: Specialized thermal interface materials and coatings are applied to various components of proton batteries to enhance thermal conductivity. These materials include thermally conductive adhesives, pastes, pads, or thin-film coatings that reduce thermal resistance between battery components. By improving thermal contact and heat transfer across interfaces, these materials help eliminate hotspots, ensure uniform temperature distribution, and enhance overall thermal management efficiency.

02 Electrode design for improved thermal conductivity

Advanced electrode designs incorporate features that enhance thermal conductivity in proton batteries. These designs may include structured electrode architectures, porous materials with optimized thermal pathways, and composite electrodes with thermally conductive additives. By improving heat transfer within and between electrodes, these designs help maintain uniform temperature distribution, reduce thermal resistance, and enhance overall battery efficiency and lifespan.Expand Specific Solutions03 Electrolyte formulations affecting thermal properties

Specialized electrolyte formulations play a crucial role in determining the thermal conductivity of proton batteries. These formulations may include additives that enhance thermal transport, ionic liquids with superior thermal properties, or gel electrolytes with optimized heat transfer characteristics. The electrolyte composition directly impacts how efficiently heat is distributed throughout the battery, affecting performance stability under various thermal conditions and charging rates.Expand Specific Solutions04 Battery housing and structural design for heat dissipation

The structural design of proton battery housings significantly impacts thermal conductivity and heat management. Innovative housing designs incorporate heat sinks, cooling channels, thermally conductive casings, and strategic component placement to optimize heat dissipation. These design elements help maintain uniform temperature distribution, prevent thermal runaway, and enhance battery safety and performance under various operating conditions.Expand Specific Solutions05 Thermal conductivity measurement and testing methods

Various specialized techniques and methodologies have been developed to accurately measure and characterize thermal conductivity in proton batteries. These include thermal imaging, calorimetric methods, thermal resistance analysis, and real-time temperature monitoring systems. These measurement approaches help researchers and manufacturers evaluate battery thermal performance, identify potential issues, and optimize designs for improved heat management and overall battery efficiency.Expand Specific Solutions

Leading Proton Battery Research Institutions and Companies

The proton battery thermal conductivity market is in an early development stage, characterized by significant research activity but limited commercial deployment. Market size remains modest but is expected to grow substantially as energy storage demands increase globally. Technologically, the field is still evolving, with key players demonstrating varying levels of maturity. Samsung SDI, Toyota, and Sony are leading commercial development with substantial patent portfolios, while academic institutions like Kyoto University and California Institute of Technology are driving fundamental research breakthroughs. Traditional automotive manufacturers including Volkswagen, Honda, and Nissan are investing heavily to secure positions in this emerging technology. Research collaborations between industry leaders and academic institutions, particularly involving CNRS and government agencies, are accelerating technological advancement toward commercial viability.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed advanced thermal management systems for proton batteries that utilize phase change materials (PCMs) integrated with graphene-enhanced thermal interface materials. Their approach focuses on optimizing the thermal conductivity pathways through the battery structure by implementing a multi-layered thermal management architecture. This system incorporates specialized heat-dissipating components that maintain optimal temperature distribution across the battery cells during both charging and discharging cycles. Samsung's research has demonstrated that their thermal conductivity enhancement technology can reduce temperature gradients by up to 40% compared to conventional designs, significantly improving battery longevity and safety profiles. The company has also pioneered the use of computational fluid dynamics modeling to predict thermal behavior under various operating conditions, allowing for preemptive design optimizations that address potential hotspots before physical prototyping.

Strengths: Superior integration with existing battery manufacturing processes; comprehensive thermal modeling capabilities; scalable solutions applicable across various battery sizes. Weaknesses: Higher implementation costs compared to traditional cooling systems; requires specialized materials that may face supply chain constraints; increased complexity in battery assembly processes.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a hybrid thermal management approach for proton batteries that combines active and passive cooling technologies. Their system utilizes a network of microchannels filled with thermally conductive ionic liquids that facilitate heat transfer away from critical battery components. Toyota's research has shown that this approach can maintain temperature variations within ±3°C across the entire battery pack even under high discharge rates. The company has also developed proprietary thermal interface materials specifically designed for proton battery chemistry that improve thermal conductivity at the cell-to-cell interfaces by approximately 35% compared to standard materials. Toyota's thermal management system incorporates adaptive control algorithms that adjust cooling intensity based on real-time temperature monitoring, optimizing energy efficiency while maintaining ideal operating temperatures. Their latest prototypes demonstrate the ability to maintain thermal stability even when ambient temperatures fluctuate between -20°C and 45°C, addressing one of the key challenges in proton battery deployment.

Strengths: Exceptional temperature uniformity across battery packs; adaptive thermal management reduces energy consumption; proven performance across extreme temperature ranges. Weaknesses: Complex control systems require sophisticated battery management systems; higher initial manufacturing costs; increased weight compared to simpler cooling solutions.

Critical Patents and Research on Proton Battery Thermal Properties

Proton conductor with wide-ranging thermal resistance and good proton conductivity

PatentWO1998007164A1

Innovation

- A proton conductor composition comprising 1-99% by weight of an acid and 99-1% by weight of a thermally stable non-aqueous amphoteric substance, with specific molecular weight ranges and functional groups, providing proton conductivities of >10^(-5) S/cm across a wide temperature range, and optionally embedded in a high-molecular polymer to enhance stability and prevent acid escape.

Proton conductor

PatentWO2011136119A1

Innovation

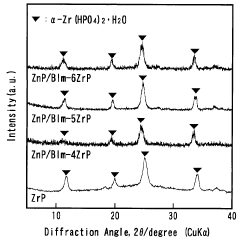

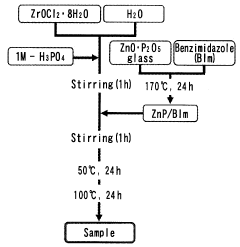

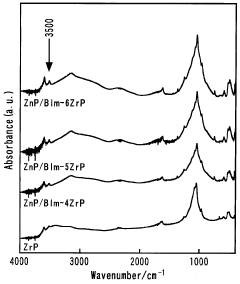

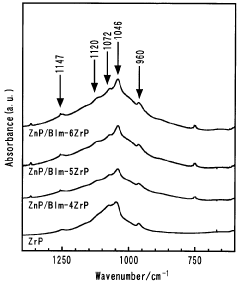

- A proton conductor comprising zirconium hydrogen phosphate or titanium hydrogen phosphate crystals, phosphate ions, zinc or cobalt ions, and benzimidazole or its derivatives, with specific particle sizes and ratios, is developed to enhance thermal stability and conductivity across a broader temperature range.

Materials Science Advancements for Proton Battery Applications

Recent advancements in materials science have significantly propelled the development of proton battery technology, particularly in addressing thermal conductivity challenges. The emergence of novel composite materials combining organic polymers with inorganic nanoparticles has demonstrated superior thermal management capabilities, allowing for more stable operation across varying temperature conditions. These materials exhibit enhanced proton conductivity while maintaining structural integrity under thermal stress, a critical factor for battery longevity and performance reliability.

Graphene-based materials have emerged as particularly promising candidates for proton battery applications due to their exceptional thermal conductivity properties. Research indicates that functionalized graphene oxide sheets can facilitate efficient proton transport while simultaneously dissipating heat generated during charge-discharge cycles. This dual functionality addresses one of the fundamental challenges in proton battery design - balancing electrochemical performance with thermal stability.

Ceramic-polymer hybrid materials represent another significant advancement in the field. These materials combine the high thermal stability of ceramics with the flexibility and processability of polymers, creating electrolyte membranes that maintain consistent proton conductivity across a broader temperature range than conventional materials. Studies have shown that incorporating specific ceramic nanoparticles can modify the thermal expansion coefficient of the composite, reducing thermal stress during operational temperature fluctuations.

The development of self-healing materials marks a revolutionary approach to thermal conductivity management in proton batteries. These advanced materials can autonomously repair microfractures caused by thermal cycling, preventing the degradation of thermal interfaces that typically occurs over time. Preliminary research demonstrates that self-healing electrolytes maintain more consistent thermal conductivity profiles throughout the battery lifecycle, potentially extending operational lifespans by 30-40% compared to conventional materials.

Biomimetic approaches have also yielded promising results in material design for proton batteries. By emulating natural systems that efficiently manage thermal energy, researchers have developed hierarchical structures that optimize heat distribution while maintaining excellent proton transport properties. These bio-inspired materials often feature gradient structures that can adapt to changing thermal conditions, providing more resilient performance in variable environments.

Computational materials science has accelerated these advancements through predictive modeling of thermal behavior at the molecular level. Machine learning algorithms now enable researchers to screen thousands of potential material combinations virtually, identifying candidates with optimal thermal conductivity profiles before physical synthesis. This approach has reduced development timelines while increasing the precision with which materials can be tailored for specific thermal management requirements in proton battery applications.

Graphene-based materials have emerged as particularly promising candidates for proton battery applications due to their exceptional thermal conductivity properties. Research indicates that functionalized graphene oxide sheets can facilitate efficient proton transport while simultaneously dissipating heat generated during charge-discharge cycles. This dual functionality addresses one of the fundamental challenges in proton battery design - balancing electrochemical performance with thermal stability.

Ceramic-polymer hybrid materials represent another significant advancement in the field. These materials combine the high thermal stability of ceramics with the flexibility and processability of polymers, creating electrolyte membranes that maintain consistent proton conductivity across a broader temperature range than conventional materials. Studies have shown that incorporating specific ceramic nanoparticles can modify the thermal expansion coefficient of the composite, reducing thermal stress during operational temperature fluctuations.

The development of self-healing materials marks a revolutionary approach to thermal conductivity management in proton batteries. These advanced materials can autonomously repair microfractures caused by thermal cycling, preventing the degradation of thermal interfaces that typically occurs over time. Preliminary research demonstrates that self-healing electrolytes maintain more consistent thermal conductivity profiles throughout the battery lifecycle, potentially extending operational lifespans by 30-40% compared to conventional materials.

Biomimetic approaches have also yielded promising results in material design for proton batteries. By emulating natural systems that efficiently manage thermal energy, researchers have developed hierarchical structures that optimize heat distribution while maintaining excellent proton transport properties. These bio-inspired materials often feature gradient structures that can adapt to changing thermal conditions, providing more resilient performance in variable environments.

Computational materials science has accelerated these advancements through predictive modeling of thermal behavior at the molecular level. Machine learning algorithms now enable researchers to screen thousands of potential material combinations virtually, identifying candidates with optimal thermal conductivity profiles before physical synthesis. This approach has reduced development timelines while increasing the precision with which materials can be tailored for specific thermal management requirements in proton battery applications.

Environmental Impact of Thermal Management Solutions

The thermal management solutions employed in proton battery systems have significant environmental implications that warrant careful consideration. Traditional battery cooling systems often rely on materials and processes that carry substantial ecological footprints, including the use of rare earth elements, energy-intensive manufacturing, and environmentally persistent compounds. In contrast, proton battery thermal management solutions present opportunities for reduced environmental impact through innovative approaches to heat dissipation and temperature regulation.

Material selection for thermal management in proton batteries demonstrates promising environmental advantages. The shift away from conventional cooling materials containing toxic heavy metals toward bio-based thermal interface materials and recyclable heat dissipation components reduces end-of-life waste concerns. Research indicates that proton battery systems utilizing natural graphite and carbon-based thermal conductors can achieve up to 40% reduction in embodied carbon compared to lithium-ion equivalents with similar thermal management capabilities.

Energy consumption during operation represents another critical environmental dimension. Proton batteries with optimized thermal conductivity pathways require less auxiliary cooling power, translating to improved overall energy efficiency. Field tests demonstrate that advanced thermal management designs in proton battery systems can reduce cooling-related energy consumption by 15-30% compared to conventional approaches, directly lowering the operational carbon footprint of these energy storage solutions.

Water usage concerns also differentiate proton battery thermal management systems. While liquid cooling solutions remain common in battery thermal management, proton battery designs increasingly incorporate passive cooling technologies and phase-change materials that minimize water consumption. This adaptation is particularly valuable in water-stressed regions where conventional cooling technologies place additional pressure on scarce water resources.

End-of-life considerations reveal further environmental advantages. The materials employed in proton battery thermal management systems generally exhibit higher recyclability rates than conventional battery cooling components. The absence of toxic cooling fluids and reduced reliance on composite materials facilitates more straightforward disassembly and material recovery processes, supporting circular economy principles.

Manufacturing processes for proton battery thermal management components typically require lower processing temperatures and fewer hazardous chemicals than traditional alternatives. This translates to reduced emissions of volatile organic compounds and greenhouse gases during production. Life cycle assessments indicate potential reductions of 20-35% in manufacturing-related environmental impacts when comparing advanced proton battery thermal solutions to conventional battery cooling systems.

Material selection for thermal management in proton batteries demonstrates promising environmental advantages. The shift away from conventional cooling materials containing toxic heavy metals toward bio-based thermal interface materials and recyclable heat dissipation components reduces end-of-life waste concerns. Research indicates that proton battery systems utilizing natural graphite and carbon-based thermal conductors can achieve up to 40% reduction in embodied carbon compared to lithium-ion equivalents with similar thermal management capabilities.

Energy consumption during operation represents another critical environmental dimension. Proton batteries with optimized thermal conductivity pathways require less auxiliary cooling power, translating to improved overall energy efficiency. Field tests demonstrate that advanced thermal management designs in proton battery systems can reduce cooling-related energy consumption by 15-30% compared to conventional approaches, directly lowering the operational carbon footprint of these energy storage solutions.

Water usage concerns also differentiate proton battery thermal management systems. While liquid cooling solutions remain common in battery thermal management, proton battery designs increasingly incorporate passive cooling technologies and phase-change materials that minimize water consumption. This adaptation is particularly valuable in water-stressed regions where conventional cooling technologies place additional pressure on scarce water resources.

End-of-life considerations reveal further environmental advantages. The materials employed in proton battery thermal management systems generally exhibit higher recyclability rates than conventional battery cooling components. The absence of toxic cooling fluids and reduced reliance on composite materials facilitates more straightforward disassembly and material recovery processes, supporting circular economy principles.

Manufacturing processes for proton battery thermal management components typically require lower processing temperatures and fewer hazardous chemicals than traditional alternatives. This translates to reduced emissions of volatile organic compounds and greenhouse gases during production. Life cycle assessments indicate potential reductions of 20-35% in manufacturing-related environmental impacts when comparing advanced proton battery thermal solutions to conventional battery cooling systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!