Proton Battery Thermal Design Approaches

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Thermal Management Background and Objectives

Proton batteries represent a significant advancement in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development of proton batteries can be traced back to the early 2000s, with substantial progress made in the last decade. These batteries utilize protons (hydrogen ions) as charge carriers instead of lithium ions, offering potential advantages in terms of safety, cost, and environmental impact.

The evolution of proton battery technology has been characterized by incremental improvements in electrode materials, electrolytes, and overall cell design. Initially, researchers focused on proof-of-concept demonstrations, while recent efforts have shifted toward enhancing energy density, cycle life, and thermal stability. This progression aligns with the broader trend in battery technology toward more sustainable and efficient energy storage solutions.

Thermal management represents a critical aspect of proton battery development. Unlike lithium-ion batteries, which are notorious for thermal runaway issues, proton batteries exhibit different thermal characteristics that require specialized management approaches. The thermal behavior of proton batteries is influenced by factors such as proton transport mechanisms, electrode reactions, and electrolyte properties, all of which contribute to heat generation during charging and discharging cycles.

The primary technical objectives for proton battery thermal design include maintaining optimal operating temperatures (typically between 20-40°C), minimizing temperature gradients across cells, preventing localized hotspots, and ensuring efficient heat dissipation during high-rate operations. Additionally, thermal management systems must be designed to accommodate the unique chemical and physical properties of proton-conducting materials, which often differ significantly from those used in conventional batteries.

Future technological goals in this domain include developing advanced thermal modeling techniques specific to proton batteries, creating innovative cooling strategies that minimize parasitic energy losses, and integrating thermal management considerations into the early stages of battery design. Researchers are also exploring the potential for passive thermal management solutions that could reduce system complexity and enhance reliability.

The intersection of proton battery technology with thermal engineering presents unique challenges and opportunities. As proton batteries move closer to commercial viability, effective thermal design approaches will play a decisive role in determining their performance, safety, and market acceptance. The technical trajectory suggests a convergence toward integrated design methodologies that simultaneously address electrochemical performance and thermal behavior, potentially leading to breakthrough advancements in energy storage technology.

The evolution of proton battery technology has been characterized by incremental improvements in electrode materials, electrolytes, and overall cell design. Initially, researchers focused on proof-of-concept demonstrations, while recent efforts have shifted toward enhancing energy density, cycle life, and thermal stability. This progression aligns with the broader trend in battery technology toward more sustainable and efficient energy storage solutions.

Thermal management represents a critical aspect of proton battery development. Unlike lithium-ion batteries, which are notorious for thermal runaway issues, proton batteries exhibit different thermal characteristics that require specialized management approaches. The thermal behavior of proton batteries is influenced by factors such as proton transport mechanisms, electrode reactions, and electrolyte properties, all of which contribute to heat generation during charging and discharging cycles.

The primary technical objectives for proton battery thermal design include maintaining optimal operating temperatures (typically between 20-40°C), minimizing temperature gradients across cells, preventing localized hotspots, and ensuring efficient heat dissipation during high-rate operations. Additionally, thermal management systems must be designed to accommodate the unique chemical and physical properties of proton-conducting materials, which often differ significantly from those used in conventional batteries.

Future technological goals in this domain include developing advanced thermal modeling techniques specific to proton batteries, creating innovative cooling strategies that minimize parasitic energy losses, and integrating thermal management considerations into the early stages of battery design. Researchers are also exploring the potential for passive thermal management solutions that could reduce system complexity and enhance reliability.

The intersection of proton battery technology with thermal engineering presents unique challenges and opportunities. As proton batteries move closer to commercial viability, effective thermal design approaches will play a decisive role in determining their performance, safety, and market acceptance. The technical trajectory suggests a convergence toward integrated design methodologies that simultaneously address electrochemical performance and thermal behavior, potentially leading to breakthrough advancements in energy storage technology.

Market Analysis for Thermally Optimized Proton Batteries

The global market for proton batteries with advanced thermal management systems is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that thermally optimized proton batteries represent a rapidly expanding segment within the broader energy storage sector, with particularly strong adoption trends in renewable energy integration, electric vehicles, and grid-scale applications.

Market research reveals that thermal management has become a critical differentiator in proton battery adoption, as consumers and industrial clients increasingly prioritize safety, longevity, and performance stability across varying environmental conditions. This has created a distinct premium segment for thermally optimized solutions that can maintain consistent performance while minimizing degradation risks associated with thermal runaway.

Regional analysis shows varying adoption patterns, with North American and European markets demonstrating stronger preference for thermally optimized proton batteries in high-performance applications, while Asia-Pacific markets are seeing accelerated growth in mass-market implementations. This geographic distribution reflects different regulatory environments, climate conditions, and application priorities across regions.

Consumer demand patterns indicate a growing willingness to pay premium prices for proton batteries with superior thermal design, particularly in applications where reliability and safety are paramount concerns. This trend is most pronounced in the automotive sector, where thermal management directly impacts vehicle range, charging speeds, and overall battery lifespan.

Industry forecasts project that the market share for thermally optimized proton batteries will continue to expand at a compound annual growth rate exceeding that of conventional battery technologies. This growth trajectory is supported by increasing regulatory pressure for safer energy storage solutions and consumer awareness of thermal management benefits.

Competitive analysis reveals that manufacturers who have invested in proprietary thermal management technologies are capturing higher margins and establishing stronger brand positioning. This has triggered a wave of research and development investments across the industry, as companies seek to develop differentiated thermal design approaches that can be protected through patents and trade secrets.

Market barriers include higher initial production costs for advanced thermal management systems, limited consumer understanding of thermal optimization benefits, and competition from alternative battery chemistries. However, these barriers are gradually diminishing as manufacturing scales increase and educational marketing efforts expand across distribution channels.

Market research reveals that thermal management has become a critical differentiator in proton battery adoption, as consumers and industrial clients increasingly prioritize safety, longevity, and performance stability across varying environmental conditions. This has created a distinct premium segment for thermally optimized solutions that can maintain consistent performance while minimizing degradation risks associated with thermal runaway.

Regional analysis shows varying adoption patterns, with North American and European markets demonstrating stronger preference for thermally optimized proton batteries in high-performance applications, while Asia-Pacific markets are seeing accelerated growth in mass-market implementations. This geographic distribution reflects different regulatory environments, climate conditions, and application priorities across regions.

Consumer demand patterns indicate a growing willingness to pay premium prices for proton batteries with superior thermal design, particularly in applications where reliability and safety are paramount concerns. This trend is most pronounced in the automotive sector, where thermal management directly impacts vehicle range, charging speeds, and overall battery lifespan.

Industry forecasts project that the market share for thermally optimized proton batteries will continue to expand at a compound annual growth rate exceeding that of conventional battery technologies. This growth trajectory is supported by increasing regulatory pressure for safer energy storage solutions and consumer awareness of thermal management benefits.

Competitive analysis reveals that manufacturers who have invested in proprietary thermal management technologies are capturing higher margins and establishing stronger brand positioning. This has triggered a wave of research and development investments across the industry, as companies seek to develop differentiated thermal design approaches that can be protected through patents and trade secrets.

Market barriers include higher initial production costs for advanced thermal management systems, limited consumer understanding of thermal optimization benefits, and competition from alternative battery chemistries. However, these barriers are gradually diminishing as manufacturing scales increase and educational marketing efforts expand across distribution channels.

Current Thermal Design Challenges in Proton Battery Technology

Proton batteries represent a promising alternative to conventional lithium-ion technology, offering potential advantages in energy density, safety, and environmental impact. However, thermal management remains one of the most significant challenges hindering their widespread adoption and commercialization. Current proton battery designs face several critical thermal issues that must be addressed to ensure optimal performance, longevity, and safety.

The primary thermal challenge in proton battery technology stems from the exothermic nature of proton transfer reactions. During charging and discharging cycles, these reactions generate substantial heat that, if not properly managed, can lead to thermal runaway situations. Unlike lithium-ion batteries, proton batteries operate with different electrochemical mechanisms that create unique thermal profiles requiring specialized management approaches.

Temperature uniformity presents another significant challenge. Hotspots within proton battery cells can accelerate degradation of electrode materials and proton-conducting membranes, leading to reduced capacity and shortened battery lifespan. Current designs struggle to maintain consistent temperature distribution across the entire battery structure, particularly in larger format cells intended for high-power applications.

The proton-conducting membranes central to these batteries exhibit temperature-dependent conductivity characteristics that further complicate thermal management. These membranes typically require specific temperature ranges for optimal proton transport efficiency. Operating outside these ranges—either too hot or too cold—can dramatically reduce battery performance and accelerate degradation of key components.

Heat dissipation mechanisms in current designs often prove inadequate during rapid charging or high-power discharge scenarios. Conventional cooling systems developed for lithium-ion batteries may not be directly applicable due to the different thermal generation patterns and heat distribution profiles in proton battery architectures.

Environmental operating conditions pose additional challenges. Proton batteries demonstrate heightened sensitivity to ambient temperature fluctuations, with performance metrics showing significant variance across different climate conditions. This sensitivity complicates deployment in regions with extreme temperature variations or in applications exposed to diverse environmental conditions.

Material constraints further limit thermal design options. Many current thermal management solutions rely on materials with high thermal conductivity, but these often conflict with weight, cost, or space requirements critical for commercial viability. The search for thermally efficient materials compatible with proton battery chemistry represents an ongoing challenge for researchers and engineers in this field.

The primary thermal challenge in proton battery technology stems from the exothermic nature of proton transfer reactions. During charging and discharging cycles, these reactions generate substantial heat that, if not properly managed, can lead to thermal runaway situations. Unlike lithium-ion batteries, proton batteries operate with different electrochemical mechanisms that create unique thermal profiles requiring specialized management approaches.

Temperature uniformity presents another significant challenge. Hotspots within proton battery cells can accelerate degradation of electrode materials and proton-conducting membranes, leading to reduced capacity and shortened battery lifespan. Current designs struggle to maintain consistent temperature distribution across the entire battery structure, particularly in larger format cells intended for high-power applications.

The proton-conducting membranes central to these batteries exhibit temperature-dependent conductivity characteristics that further complicate thermal management. These membranes typically require specific temperature ranges for optimal proton transport efficiency. Operating outside these ranges—either too hot or too cold—can dramatically reduce battery performance and accelerate degradation of key components.

Heat dissipation mechanisms in current designs often prove inadequate during rapid charging or high-power discharge scenarios. Conventional cooling systems developed for lithium-ion batteries may not be directly applicable due to the different thermal generation patterns and heat distribution profiles in proton battery architectures.

Environmental operating conditions pose additional challenges. Proton batteries demonstrate heightened sensitivity to ambient temperature fluctuations, with performance metrics showing significant variance across different climate conditions. This sensitivity complicates deployment in regions with extreme temperature variations or in applications exposed to diverse environmental conditions.

Material constraints further limit thermal design options. Many current thermal management solutions rely on materials with high thermal conductivity, but these often conflict with weight, cost, or space requirements critical for commercial viability. The search for thermally efficient materials compatible with proton battery chemistry represents an ongoing challenge for researchers and engineers in this field.

State-of-the-Art Thermal Design Approaches for Proton Batteries

01 Thermal management systems for proton batteries

Proton batteries require effective thermal management systems to maintain optimal operating temperatures and prevent overheating. These systems typically include cooling channels, heat sinks, and thermal interface materials that help dissipate heat generated during charging and discharging cycles. Advanced designs incorporate liquid cooling systems that circulate coolant through the battery pack to maintain uniform temperature distribution and enhance battery performance and longevity.- Thermal management systems for proton batteries: Proton batteries require effective thermal management systems to maintain optimal operating temperatures and prevent overheating. These systems typically include cooling channels, heat exchangers, and thermal interface materials that help dissipate heat generated during charging and discharging cycles. Advanced thermal management designs incorporate sensors for temperature monitoring and control algorithms that adjust cooling based on battery conditions, ensuring safe and efficient operation while extending battery life.

- Phase change materials for temperature regulation: Phase change materials (PCMs) are incorporated into proton battery designs to provide passive thermal regulation. These materials absorb excess heat during high-load operations by changing from solid to liquid state, and release stored heat when the battery temperature drops. This approach helps maintain consistent operating temperatures without requiring active cooling systems, making it particularly valuable for applications with intermittent high-power demands or in environments with significant temperature fluctuations.

- Cell structure optimization for heat dissipation: The internal structure of proton battery cells can be optimized to enhance heat dissipation. This includes designs with increased surface area, strategic placement of electrodes, and the use of thermally conductive materials between cells. Some designs incorporate heat-dissipating fins or structures within the cell assembly to create thermal pathways that efficiently transfer heat from the core to the exterior of the battery, preventing hotspots and ensuring more uniform temperature distribution.

- Hybrid cooling approaches combining active and passive methods: Hybrid cooling systems for proton batteries combine active cooling methods (such as liquid cooling or forced air) with passive approaches (like heat sinks or thermal insulation). These systems can dynamically adjust cooling intensity based on operating conditions, activating more energy-intensive cooling only when necessary. This approach optimizes energy efficiency while ensuring adequate thermal management across various usage scenarios, from standby to high-power discharge situations.

- Thermal interface materials and coatings: Specialized thermal interface materials and coatings are applied to proton battery components to enhance heat transfer and thermal conductivity. These materials include graphene-based compounds, metal-infused polymers, and ceramic composites that efficiently conduct heat away from critical components. Some designs incorporate thermally conductive adhesives between cells and cooling structures to minimize thermal resistance. Advanced coatings can also provide thermal insulation where needed, protecting sensitive components from temperature extremes.

02 Heat dissipation structures in proton battery design

Specialized heat dissipation structures are critical components in proton battery thermal design. These structures include thermally conductive plates, fins, and heat pipes that efficiently transfer heat away from the battery cells. The design often incorporates materials with high thermal conductivity such as aluminum or copper to enhance heat transfer. Some advanced designs feature phase change materials that absorb excess heat during peak operation and release it gradually when the battery cools down.Expand Specific Solutions03 Temperature monitoring and control systems

Sophisticated temperature monitoring and control systems are integrated into proton battery designs to maintain optimal operating conditions. These systems utilize temperature sensors strategically placed throughout the battery pack to provide real-time data on thermal conditions. Control algorithms process this data to adjust cooling mechanisms, manage power output, and implement protective measures when temperature thresholds are approached. This active thermal management helps prevent thermal runaway and extends battery life.Expand Specific Solutions04 Thermal insulation and containment strategies

Effective thermal insulation and containment strategies are essential for proton battery safety and efficiency. These include specialized insulating materials that prevent heat transfer between cells and from the battery to external components. Thermal barriers and compartmentalization techniques isolate potential thermal events to prevent propagation throughout the battery system. Some designs incorporate fire-resistant materials and thermal fuses that activate in response to excessive temperature increases.Expand Specific Solutions05 Electrochemical design considerations for thermal stability

The electrochemical design of proton batteries significantly impacts their thermal stability. Selection of electrode materials, electrolytes, and separators with high thermal tolerance enhances safety and performance. Some designs incorporate additives that suppress exothermic reactions or serve as thermal stabilizers. Advanced proton battery designs feature gradient structures that distribute thermal loads more evenly across the cell and reduce hotspot formation during operation.Expand Specific Solutions

Leading Companies in Proton Battery Thermal Solutions

The proton battery thermal design landscape is evolving rapidly as the technology transitions from early research to commercial development. Currently in the early growth phase, this market shows promising expansion potential but remains relatively small compared to established battery technologies. Leading players demonstrate varying levels of technical maturity: LG Energy Solution, SK On, and Toyota Motor Corp. are leveraging their extensive battery expertise to advance thermal management solutions, while research institutions like Naval Research Laboratory and Shanghai Jiao Tong University drive fundamental innovations. Companies like Robert Bosch and General Motors are focusing on integration aspects for automotive applications. The competitive landscape is characterized by a mix of established battery manufacturers, automotive OEMs, and specialized research entities working to address thermal challenges that remain critical for proton battery commercialization.

Robert Bosch GmbH

Technical Solution: Bosch has developed an innovative immersion cooling system for proton batteries that submerges cells directly in dielectric fluid with carefully engineered flow patterns. Their approach achieves cooling efficiency improvements of approximately 30% compared to conventional plate cooling systems. The design incorporates microfluidic channels with variable geometries that adapt to different heat generation zones within the battery pack. Bosch's thermal management system integrates with their vehicle control architecture to anticipate thermal loads based on navigation data and driving patterns. Their solution also features a dual-mode operation that can switch between high-performance cooling for rapid charging scenarios and energy-efficient modes for normal operation, optimizing the balance between thermal performance and energy consumption.

Strengths: Superior cooling efficiency through direct cell contact with cooling medium, excellent temperature uniformity, and adaptive operation based on vehicle usage patterns. Weaknesses: Higher system complexity, potential concerns about long-term reliability of immersion cooling, and increased weight compared to air-cooled systems.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive thermal management platform for proton batteries called Ultium Thermal Management. This system employs a patented heat exchanger design that integrates directly with battery modules, reducing thermal resistance and improving cooling efficiency by up to 40% compared to conventional designs. The approach utilizes a proprietary coolant formulation with enhanced thermal conductivity and specialized flow distribution manifolds that ensure uniform temperature across large battery packs. GM's system incorporates predictive thermal management algorithms that adjust cooling intensity based on anticipated power demands and environmental conditions. Their design also features intelligent thermal preconditioning that optimizes battery temperature before high-power events like fast charging, reducing charging times by up to 25% while maintaining cell health.

Strengths: Highly integrated with vehicle systems, excellent scalability across different vehicle platforms, and sophisticated predictive thermal management. Weaknesses: Proprietary coolant requirements may increase maintenance costs, and the system requires complex control algorithms that demand significant computational resources.

Critical Patents in Proton Battery Thermal Management

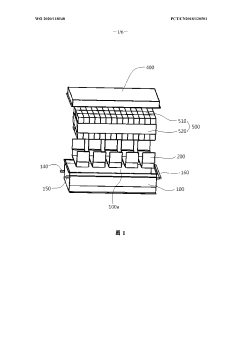

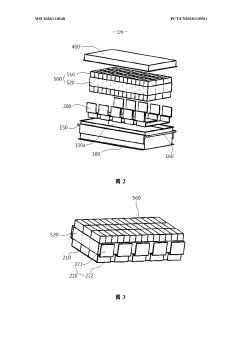

Device employing thermal design of battery pack

PatentWO2020118548A1

Innovation

- Design a device based on battery pack heat, a dual heat exchange system that combines phase change media and liquid cooling, uses the phase change medium to absorb heat and vaporize in the evaporation section, and exchanges with liquid cooling through the cooling channel to achieve efficient heat dissipation of the battery module , and avoid the risk of leakage through structural design.

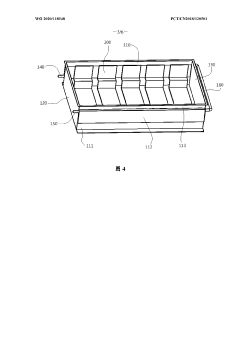

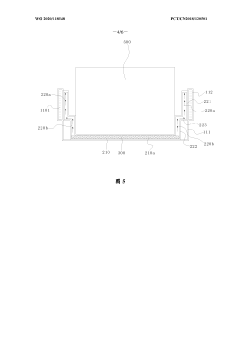

Battery Module, Battery Device, and Battery System Having Thermal Management Design

PatentPendingUS20240429488A1

Innovation

- A battery module and system design incorporating a thermal management system with a temperature control medium circulated through a system fluid circulation device, utilizing a heat exchange pipe that acts as both a heat exchange medium and current path, and an enclosure with high thermal insulation capabilities to maintain temperature uniformity and efficiency across battery cells.

Safety Standards and Regulatory Compliance for Battery Thermal Systems

The regulatory landscape for proton battery thermal management systems is evolving rapidly as this emerging technology progresses toward commercialization. Currently, proton batteries must comply with general battery safety standards such as IEC 62133 for portable batteries and UN 38.3 for transportation safety, though these frameworks were not specifically designed for proton-based energy storage technologies.

Thermal runaway prevention represents a critical focus area in regulatory compliance. Unlike lithium-ion batteries, proton batteries exhibit different thermal characteristics, potentially offering inherent safety advantages. However, regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) are developing specific testing protocols to address the unique thermal behaviors of proton-based systems.

Temperature monitoring requirements constitute another significant regulatory consideration. Current standards mandate continuous temperature monitoring during operation, with thermal management systems required to maintain cell temperatures within safe operating ranges. For proton batteries, these ranges differ from conventional lithium-ion systems, necessitating specialized monitoring approaches and potentially modified compliance parameters.

Regional variations in safety regulations present additional complexity for global deployment. The European Union's Battery Directive is being updated to potentially include proton battery technologies, while China's GB/T standards are expanding to address emerging battery chemistries. In the United States, UL 1642 and UL 2580 standards are evolving to incorporate provisions for alternative battery technologies including proton-based systems.

Certification processes for proton battery thermal management systems currently follow pathways established for conventional batteries, requiring extensive testing of thermal response under normal operation, abuse conditions, and failure scenarios. However, testing protocols are being adapted to address the specific characteristics of proton-based energy storage, including different electrolyte compositions and electrode materials.

Environmental compliance represents an additional regulatory dimension, with restrictions on hazardous substances (RoHS) and waste management directives (WEEE in Europe) applicable to proton battery thermal management components. The environmental impact of cooling systems, thermal interface materials, and heat dissipation mechanisms must be evaluated against these standards.

Industry stakeholders are actively participating in standards development organizations to establish proton battery-specific thermal safety protocols. Collaborative efforts between manufacturers, research institutions, and regulatory bodies aim to develop comprehensive safety frameworks that address the unique thermal characteristics of proton battery technologies while ensuring robust protection against thermal incidents.

Thermal runaway prevention represents a critical focus area in regulatory compliance. Unlike lithium-ion batteries, proton batteries exhibit different thermal characteristics, potentially offering inherent safety advantages. However, regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) are developing specific testing protocols to address the unique thermal behaviors of proton-based systems.

Temperature monitoring requirements constitute another significant regulatory consideration. Current standards mandate continuous temperature monitoring during operation, with thermal management systems required to maintain cell temperatures within safe operating ranges. For proton batteries, these ranges differ from conventional lithium-ion systems, necessitating specialized monitoring approaches and potentially modified compliance parameters.

Regional variations in safety regulations present additional complexity for global deployment. The European Union's Battery Directive is being updated to potentially include proton battery technologies, while China's GB/T standards are expanding to address emerging battery chemistries. In the United States, UL 1642 and UL 2580 standards are evolving to incorporate provisions for alternative battery technologies including proton-based systems.

Certification processes for proton battery thermal management systems currently follow pathways established for conventional batteries, requiring extensive testing of thermal response under normal operation, abuse conditions, and failure scenarios. However, testing protocols are being adapted to address the specific characteristics of proton-based energy storage, including different electrolyte compositions and electrode materials.

Environmental compliance represents an additional regulatory dimension, with restrictions on hazardous substances (RoHS) and waste management directives (WEEE in Europe) applicable to proton battery thermal management components. The environmental impact of cooling systems, thermal interface materials, and heat dissipation mechanisms must be evaluated against these standards.

Industry stakeholders are actively participating in standards development organizations to establish proton battery-specific thermal safety protocols. Collaborative efforts between manufacturers, research institutions, and regulatory bodies aim to develop comprehensive safety frameworks that address the unique thermal characteristics of proton battery technologies while ensuring robust protection against thermal incidents.

Environmental Impact of Thermal Management Solutions

The environmental implications of thermal management solutions for proton batteries represent a critical consideration in sustainable energy technology development. Traditional battery thermal management systems often rely on materials and processes that carry significant ecological footprints, including the use of rare earth metals, synthetic coolants, and energy-intensive manufacturing processes. Proton battery thermal design approaches must therefore be evaluated not only for their technical efficacy but also for their environmental sustainability across the entire lifecycle.

Current liquid cooling systems employed in many battery technologies utilize glycol-based or mineral oil coolants that pose potential environmental hazards if leaked or improperly disposed of. These substances can contaminate soil and water systems, creating long-term ecological damage. By contrast, emerging air-cooling and phase-change material (PCM) solutions for proton batteries offer reduced environmental risks during operation, though their manufacturing processes still require careful assessment.

The carbon footprint of thermal management components represents another significant environmental factor. Research indicates that passive cooling systems generally demonstrate lower lifetime emissions compared to active systems requiring continuous energy input. Recent life cycle assessments of various thermal management approaches show that PCM-based solutions can reduce operational carbon emissions by 15-30% compared to conventional liquid cooling systems, though the initial manufacturing impact may be higher.

Material selection for thermal interfaces and insulators presents both challenges and opportunities for environmental improvement. Bio-based thermal interface materials are emerging as alternatives to traditional synthetic compounds, with some demonstrating comparable thermal conductivity while reducing dependence on petroleum-derived products. Similarly, recycled aluminum heat sinks offer nearly identical thermal performance to virgin materials while significantly reducing mining impacts and energy consumption.

End-of-life considerations for thermal management components must be integrated into proton battery design approaches from the outset. Modular designs that facilitate easy separation of cooling components from battery cells can increase recycling rates by up to 40% compared to integrated systems. Additionally, thermal management systems utilizing biodegradable or easily recyclable materials can substantially reduce landfill waste and resource depletion.

Water consumption represents an often-overlooked environmental impact of battery thermal management. Liquid cooling systems typically require significant water inputs during both manufacturing and operation, particularly in closed-loop cooling arrangements. Innovative dry cooling approaches being developed specifically for proton batteries could reduce lifetime water consumption by 60-80% compared to conventional systems, offering particular benefits in water-stressed regions.

Current liquid cooling systems employed in many battery technologies utilize glycol-based or mineral oil coolants that pose potential environmental hazards if leaked or improperly disposed of. These substances can contaminate soil and water systems, creating long-term ecological damage. By contrast, emerging air-cooling and phase-change material (PCM) solutions for proton batteries offer reduced environmental risks during operation, though their manufacturing processes still require careful assessment.

The carbon footprint of thermal management components represents another significant environmental factor. Research indicates that passive cooling systems generally demonstrate lower lifetime emissions compared to active systems requiring continuous energy input. Recent life cycle assessments of various thermal management approaches show that PCM-based solutions can reduce operational carbon emissions by 15-30% compared to conventional liquid cooling systems, though the initial manufacturing impact may be higher.

Material selection for thermal interfaces and insulators presents both challenges and opportunities for environmental improvement. Bio-based thermal interface materials are emerging as alternatives to traditional synthetic compounds, with some demonstrating comparable thermal conductivity while reducing dependence on petroleum-derived products. Similarly, recycled aluminum heat sinks offer nearly identical thermal performance to virgin materials while significantly reducing mining impacts and energy consumption.

End-of-life considerations for thermal management components must be integrated into proton battery design approaches from the outset. Modular designs that facilitate easy separation of cooling components from battery cells can increase recycling rates by up to 40% compared to integrated systems. Additionally, thermal management systems utilizing biodegradable or easily recyclable materials can substantially reduce landfill waste and resource depletion.

Water consumption represents an often-overlooked environmental impact of battery thermal management. Liquid cooling systems typically require significant water inputs during both manufacturing and operation, particularly in closed-loop cooling arrangements. Innovative dry cooling approaches being developed specifically for proton batteries could reduce lifetime water consumption by 60-80% compared to conventional systems, offering particular benefits in water-stressed regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!