Why Are Proton Batteries Advancing in Large-Scale Storage?

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Background and Objectives

Proton battery technology represents a significant evolution in energy storage systems, emerging from decades of research into alternative battery chemistries. The concept of utilizing protons as charge carriers dates back to the early 2000s, but substantial progress has accelerated only in the past decade. This technology builds upon principles from both conventional batteries and hydrogen fuel cells, creating a hybrid approach that leverages the advantages of both while addressing their respective limitations.

The evolution of proton batteries has been driven by increasing global demand for sustainable energy storage solutions that can overcome the limitations of lithium-ion technology. While lithium-ion batteries have dominated the market, concerns regarding resource scarcity, environmental impact, and safety have prompted exploration of alternative technologies. Proton batteries offer a promising pathway by utilizing abundant materials and potentially delivering higher energy densities with reduced environmental footprint.

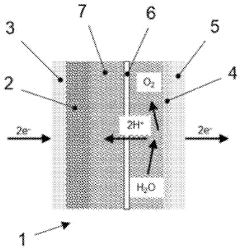

The fundamental operating principle of proton batteries involves reversible proton storage in electrode materials, typically carbon-based structures or metal organic frameworks. During charging, protons are extracted from water molecules and stored within these electrode materials, while during discharge, they recombine with electrons and oxygen to regenerate water. This water-based chemistry represents a significant departure from conventional battery technologies that rely on metal ions.

Technical objectives for proton battery development focus on several key parameters that will determine their viability for large-scale energy storage. Primary goals include achieving energy densities exceeding 300 Wh/kg, cycle stability beyond 5,000 cycles, and cost reduction to below $100/kWh. Additionally, researchers aim to develop proton batteries that can operate efficiently across a wide temperature range without the thermal management challenges associated with lithium-ion systems.

Recent breakthroughs in electrode materials and electrolyte formulations have accelerated progress toward these objectives. Carbon-based materials with optimized pore structures have demonstrated enhanced proton storage capacity, while advances in proton-conducting membranes have improved overall system efficiency. These developments suggest a convergent path toward commercially viable proton battery technology within the next decade.

The long-term technical trajectory for proton batteries aims to position them as a complementary technology to lithium-ion systems, particularly for stationary energy storage applications where weight constraints are less critical than cost, safety, and longevity. As renewable energy generation continues to expand globally, the need for grid-scale storage solutions becomes increasingly urgent, creating a clear market opportunity for proton battery technology to address.

The evolution of proton batteries has been driven by increasing global demand for sustainable energy storage solutions that can overcome the limitations of lithium-ion technology. While lithium-ion batteries have dominated the market, concerns regarding resource scarcity, environmental impact, and safety have prompted exploration of alternative technologies. Proton batteries offer a promising pathway by utilizing abundant materials and potentially delivering higher energy densities with reduced environmental footprint.

The fundamental operating principle of proton batteries involves reversible proton storage in electrode materials, typically carbon-based structures or metal organic frameworks. During charging, protons are extracted from water molecules and stored within these electrode materials, while during discharge, they recombine with electrons and oxygen to regenerate water. This water-based chemistry represents a significant departure from conventional battery technologies that rely on metal ions.

Technical objectives for proton battery development focus on several key parameters that will determine their viability for large-scale energy storage. Primary goals include achieving energy densities exceeding 300 Wh/kg, cycle stability beyond 5,000 cycles, and cost reduction to below $100/kWh. Additionally, researchers aim to develop proton batteries that can operate efficiently across a wide temperature range without the thermal management challenges associated with lithium-ion systems.

Recent breakthroughs in electrode materials and electrolyte formulations have accelerated progress toward these objectives. Carbon-based materials with optimized pore structures have demonstrated enhanced proton storage capacity, while advances in proton-conducting membranes have improved overall system efficiency. These developments suggest a convergent path toward commercially viable proton battery technology within the next decade.

The long-term technical trajectory for proton batteries aims to position them as a complementary technology to lithium-ion systems, particularly for stationary energy storage applications where weight constraints are less critical than cost, safety, and longevity. As renewable energy generation continues to expand globally, the need for grid-scale storage solutions becomes increasingly urgent, creating a clear market opportunity for proton battery technology to address.

Market Analysis for Large-Scale Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, with projections indicating a compound annual growth rate of 20-25% through 2030. This expansion is primarily driven by the increasing integration of renewable energy sources into power grids worldwide, creating a critical need for efficient, large-scale storage solutions. Within this landscape, proton batteries are emerging as a promising technology that addresses many limitations of current storage options.

Traditional lithium-ion batteries currently dominate the market, accounting for approximately 90% of new grid-scale installations. However, their limitations in terms of resource constraints, safety concerns, and environmental impact have created significant market opportunities for alternative technologies. Proton batteries, with their potential for lower costs and sustainable materials, are positioned to capture a growing share of this expanding market.

Market segmentation reveals distinct needs across utility-scale, commercial/industrial, and residential applications. The utility-scale segment, valued at over $7 billion in 2022, represents the primary target for proton battery technology due to its emphasis on long-duration storage capabilities and cost efficiency. Commercial applications follow closely, driven by increasing corporate sustainability commitments and energy resilience requirements.

Regional analysis shows Asia-Pacific leading market growth, with China investing heavily in advanced battery technologies as part of its energy transition strategy. Europe follows with aggressive climate targets driving demand for innovative storage solutions, while North America shows strong growth potential due to grid modernization initiatives and renewable energy expansion.

Customer demand patterns indicate increasing preference for storage solutions with longer lifespans, improved safety profiles, and reduced environmental impact – all potential advantages of proton battery technology. Additionally, the market shows growing interest in technologies that can provide flexible discharge durations ranging from 4 to 100+ hours, an area where proton batteries may offer significant advantages over lithium-ion alternatives.

Economic factors further support proton battery advancement, with levelized cost of storage (LCOS) becoming increasingly competitive as research progresses. Current projections suggest proton batteries could achieve costs below $100/kWh by 2030, significantly undercutting lithium-ion technology in long-duration applications and creating a compelling value proposition for large-scale deployment.

Regulatory trends also favor proton battery development, with policies increasingly supporting technologies that reduce critical mineral dependencies and enhance domestic manufacturing capabilities. Investment patterns reflect this shift, with venture capital funding for alternative battery technologies growing by over 300% since 2018, indicating strong market confidence in next-generation storage solutions like proton batteries.

Traditional lithium-ion batteries currently dominate the market, accounting for approximately 90% of new grid-scale installations. However, their limitations in terms of resource constraints, safety concerns, and environmental impact have created significant market opportunities for alternative technologies. Proton batteries, with their potential for lower costs and sustainable materials, are positioned to capture a growing share of this expanding market.

Market segmentation reveals distinct needs across utility-scale, commercial/industrial, and residential applications. The utility-scale segment, valued at over $7 billion in 2022, represents the primary target for proton battery technology due to its emphasis on long-duration storage capabilities and cost efficiency. Commercial applications follow closely, driven by increasing corporate sustainability commitments and energy resilience requirements.

Regional analysis shows Asia-Pacific leading market growth, with China investing heavily in advanced battery technologies as part of its energy transition strategy. Europe follows with aggressive climate targets driving demand for innovative storage solutions, while North America shows strong growth potential due to grid modernization initiatives and renewable energy expansion.

Customer demand patterns indicate increasing preference for storage solutions with longer lifespans, improved safety profiles, and reduced environmental impact – all potential advantages of proton battery technology. Additionally, the market shows growing interest in technologies that can provide flexible discharge durations ranging from 4 to 100+ hours, an area where proton batteries may offer significant advantages over lithium-ion alternatives.

Economic factors further support proton battery advancement, with levelized cost of storage (LCOS) becoming increasingly competitive as research progresses. Current projections suggest proton batteries could achieve costs below $100/kWh by 2030, significantly undercutting lithium-ion technology in long-duration applications and creating a compelling value proposition for large-scale deployment.

Regulatory trends also favor proton battery development, with policies increasingly supporting technologies that reduce critical mineral dependencies and enhance domestic manufacturing capabilities. Investment patterns reflect this shift, with venture capital funding for alternative battery technologies growing by over 300% since 2018, indicating strong market confidence in next-generation storage solutions like proton batteries.

Current Status and Technical Challenges in Proton Battery Development

Proton batteries represent an emerging technology in the energy storage landscape, currently positioned at the intersection of laboratory research and early commercial development. While lithium-ion batteries dominate today's market, proton-based systems have made significant strides in recent years, particularly in academic research settings across North America, Europe, and Asia. The technology leverages abundant hydrogen ions (protons) as charge carriers instead of lithium ions, potentially addressing resource scarcity concerns associated with conventional battery technologies.

The current development status of proton batteries can be characterized as promising but nascent. Laboratory prototypes have demonstrated energy densities approaching 140 Wh/kg, with theoretical limits suggesting potential for 400+ Wh/kg. Cycle stability has improved dramatically, with recent designs achieving 1,000+ cycles at 80% capacity retention. However, these metrics remain below commercial lithium-ion standards, particularly in power density and charge/discharge rates.

Several technical challenges currently impede widespread adoption of proton battery technology. Electrode material degradation during repeated proton insertion/extraction cycles represents a primary concern, with current materials exhibiting structural instability after extended cycling. This degradation manifests as capacity fade and reduced efficiency, particularly at higher operating temperatures.

Electrolyte formulation presents another significant hurdle. Current proton-conducting electrolytes suffer from limited ionic conductivity at room temperature, necessitating elevated operating temperatures that compromise system safety and efficiency. Additionally, side reactions at electrode-electrolyte interfaces create resistance layers that impede proton transport and accelerate performance decline over time.

Manufacturing scalability remains problematic, with current laboratory production methods utilizing expensive catalysts and complex synthesis procedures ill-suited for mass production. The precision required for electrode fabrication and cell assembly exceeds capabilities of existing battery manufacturing infrastructure, necessitating substantial capital investment for commercialization.

System integration challenges further complicate development efforts. Proton batteries require specialized battery management systems to monitor and control proton flow, prevent dendrite formation, and manage thermal characteristics. These systems lack standardization and remain largely custom-designed for specific research applications rather than commercial deployment.

Regulatory frameworks and safety standards for proton battery technology remain underdeveloped, creating uncertainty for potential manufacturers and investors. Without established testing protocols and safety certifications, commercialization pathways face additional barriers beyond purely technical considerations.

Despite these challenges, recent breakthroughs in proton-conducting solid electrolytes, advanced electrode materials incorporating carbon nanostructures, and innovative cell designs suggest accelerating progress toward viable large-scale storage applications. The technology's theoretical advantages in sustainability, safety, and cost-effectiveness continue driving research investment across academic and industrial sectors.

The current development status of proton batteries can be characterized as promising but nascent. Laboratory prototypes have demonstrated energy densities approaching 140 Wh/kg, with theoretical limits suggesting potential for 400+ Wh/kg. Cycle stability has improved dramatically, with recent designs achieving 1,000+ cycles at 80% capacity retention. However, these metrics remain below commercial lithium-ion standards, particularly in power density and charge/discharge rates.

Several technical challenges currently impede widespread adoption of proton battery technology. Electrode material degradation during repeated proton insertion/extraction cycles represents a primary concern, with current materials exhibiting structural instability after extended cycling. This degradation manifests as capacity fade and reduced efficiency, particularly at higher operating temperatures.

Electrolyte formulation presents another significant hurdle. Current proton-conducting electrolytes suffer from limited ionic conductivity at room temperature, necessitating elevated operating temperatures that compromise system safety and efficiency. Additionally, side reactions at electrode-electrolyte interfaces create resistance layers that impede proton transport and accelerate performance decline over time.

Manufacturing scalability remains problematic, with current laboratory production methods utilizing expensive catalysts and complex synthesis procedures ill-suited for mass production. The precision required for electrode fabrication and cell assembly exceeds capabilities of existing battery manufacturing infrastructure, necessitating substantial capital investment for commercialization.

System integration challenges further complicate development efforts. Proton batteries require specialized battery management systems to monitor and control proton flow, prevent dendrite formation, and manage thermal characteristics. These systems lack standardization and remain largely custom-designed for specific research applications rather than commercial deployment.

Regulatory frameworks and safety standards for proton battery technology remain underdeveloped, creating uncertainty for potential manufacturers and investors. Without established testing protocols and safety certifications, commercialization pathways face additional barriers beyond purely technical considerations.

Despite these challenges, recent breakthroughs in proton-conducting solid electrolytes, advanced electrode materials incorporating carbon nanostructures, and innovative cell designs suggest accelerating progress toward viable large-scale storage applications. The technology's theoretical advantages in sustainability, safety, and cost-effectiveness continue driving research investment across academic and industrial sectors.

Current Proton Battery Design and Implementation Approaches

01 Proton battery electrode materials and structures

Various materials and structures are used for electrodes in proton batteries to enhance performance. These include carbon-based materials, metal hydrides, and composite structures that facilitate proton storage and transfer. The electrode design focuses on maximizing surface area for proton adsorption and providing efficient pathways for proton movement, which directly impacts the battery's capacity and charge/discharge rates.- Proton battery electrode materials and structures: Various materials and structures are used for electrodes in proton batteries to enhance performance. These include carbon-based materials, metal hydrides, and composite structures that facilitate proton storage and transfer. The electrode design focuses on maximizing surface area for proton adsorption and ensuring efficient proton transport pathways, which directly impacts the battery's capacity and charge/discharge rates.

- Electrolyte compositions for proton batteries: Specialized electrolyte compositions are crucial for proton batteries as they facilitate proton transport between electrodes. These electrolytes typically contain proton-conducting materials such as solid polymer membranes, ionic liquids, or aqueous solutions with specific additives. The electrolyte composition significantly affects the battery's ionic conductivity, operational temperature range, and overall stability during cycling.

- Proton battery system integration and management: System-level integration of proton batteries involves designing battery packs, thermal management systems, and control electronics. These systems monitor and regulate charging/discharging processes, manage temperature distribution, and ensure safe operation. Advanced battery management systems optimize performance by controlling proton flow rates and preventing degradation mechanisms, thereby extending battery life and improving reliability.

- Hydrogen storage mechanisms in proton batteries: Proton batteries utilize various hydrogen storage mechanisms, including chemical bonding in metal hydrides, physical adsorption in porous materials, and electrochemical storage in specialized compounds. These mechanisms determine the energy density and power capabilities of the battery. Research focuses on materials that can reversibly store and release hydrogen ions with minimal energy loss and structural degradation over multiple cycles.

- Manufacturing processes and scalability of proton batteries: Manufacturing techniques for proton batteries include specialized coating methods, electrode fabrication processes, and assembly procedures that ensure consistent performance. These processes focus on creating uniform electrode structures, precise electrolyte integration, and effective sealing to prevent leakage. Scalability considerations address cost-effective production methods, material availability, and quality control measures that enable commercial viability of proton battery technology.

02 Proton-conducting electrolytes

Specialized electrolytes that enable efficient proton conduction are crucial for proton battery performance. These electrolytes typically contain acidic functional groups or proton-conducting polymers that facilitate proton transport between electrodes. Research focuses on developing electrolytes with high proton conductivity, good mechanical stability, and compatibility with electrode materials to improve overall battery efficiency and lifespan.Expand Specific Solutions03 Hydrogen storage mechanisms in proton batteries

Proton batteries utilize various hydrogen storage mechanisms, including chemical bonding, physical adsorption, and intercalation processes. These mechanisms determine how protons are stored within the battery structure during charging and released during discharging. Understanding and optimizing these storage mechanisms is essential for developing proton batteries with higher energy density and improved cycling stability.Expand Specific Solutions04 Integration with renewable energy systems

Proton batteries show significant potential for integration with renewable energy systems, particularly for energy storage applications. Their ability to store energy from intermittent renewable sources like solar and wind makes them valuable for grid stabilization and off-grid applications. Research focuses on scaling up proton battery technology and optimizing their performance characteristics to meet the demands of renewable energy storage systems.Expand Specific Solutions05 Advanced manufacturing techniques for proton batteries

Novel manufacturing techniques are being developed to enhance proton battery production efficiency and performance. These include advanced coating methods, nanofabrication approaches, and precision assembly techniques that improve component integration. Manufacturing innovations focus on reducing costs, increasing production scalability, and enhancing the consistency and quality of proton battery components, which are essential for commercial viability.Expand Specific Solutions

Key Industry Players and Research Institutions in Proton Battery Field

Proton battery technology is advancing in large-scale energy storage due to its promising combination of sustainability, efficiency, and cost-effectiveness. The market is in an early growth phase with increasing investments, projected to expand significantly as renewable energy integration accelerates. While still emerging, technical maturity is progressing rapidly through collaborative research efforts from academic institutions like California Institute of Technology, Nanyang Technological University, and Wuhan University, alongside commercial development by companies such as LG Energy Solution, LG Chem, and Ionic Materials. These organizations are addressing key challenges in electrolyte design, electrode materials, and system integration to improve energy density, cycle life, and scalability for grid-level applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced proton battery technology for large-scale energy storage systems (ESS) that utilizes hydrogen ions as charge carriers instead of lithium ions. Their approach incorporates proton-conducting solid electrolytes with high conductivity at ambient temperatures, enabling efficient energy storage without the thermal management challenges of traditional lithium-ion batteries. The company has engineered specialized electrode materials with enhanced proton insertion/extraction capabilities and optimized surface area for maximum energy density. Their proton battery systems feature modular designs that can scale from hundreds of kilowatts to multiple megawatts, making them suitable for grid-level applications. LG Energy Solution's proton batteries demonstrate exceptional cycle stability (>10,000 cycles) and depth of discharge capabilities, addressing the durability requirements for large-scale storage applications.

Strengths: Significantly lower material costs compared to lithium-ion batteries; inherently safer operation with reduced fire risk; environmentally friendly materials with abundant resources; excellent scalability for grid applications. Weaknesses: Lower energy density compared to some competing technologies; technology still in early commercialization phase; requires specialized manufacturing infrastructure.

LG Chem Ltd.

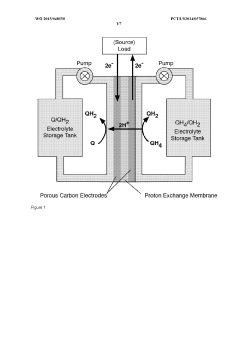

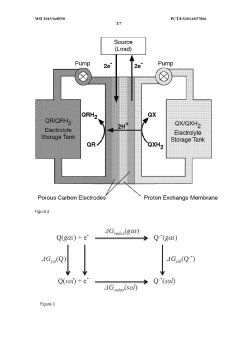

Technical Solution: LG Chem has pioneered proton battery technology for large-scale storage through their innovative hydrogen-based energy storage systems. Their approach utilizes proton exchange membranes similar to those in fuel cells but optimized for reversible energy storage applications. The company has developed proprietary electrode materials that facilitate rapid proton transfer while maintaining structural integrity over thousands of charge-discharge cycles. LG Chem's proton batteries employ water-based electrolytes, eliminating the flammability concerns associated with organic electrolytes in conventional lithium-ion systems. Their large-scale storage solutions integrate advanced battery management systems that optimize proton flow and prevent membrane degradation, extending operational lifetimes to 15+ years. The technology has been demonstrated in pilot projects delivering multi-megawatt capacity with response times under 100 milliseconds, making it suitable for grid frequency regulation and renewable energy integration.

Strengths: Utilizes abundant, low-cost materials reducing overall system costs; inherently safer operation with aqueous electrolytes; minimal capacity degradation over extended cycling; rapid response capabilities for grid services. Weaknesses: Lower volumetric energy density compared to lithium-ion systems; requires specialized manufacturing processes; technology still evolving with limited large-scale deployment history.

Critical Patents and Technical Innovations in Proton Storage

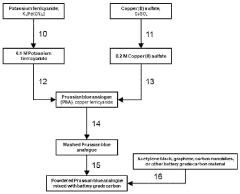

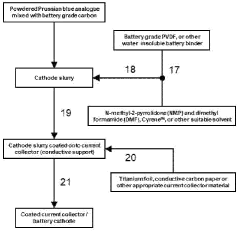

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

Quinone and hydroquinone based flow battery

PatentWO2015048550A1

Innovation

- A quinone-based flow battery that employs protonation of small organic molecules to store electrical energy, utilizing inexpensive and abundant chemicals like quinones and hydroquinones, which can operate as a closed system with high current density and long lifetime, reducing power-related costs and eliminating the need for precious metals.

Environmental Impact and Sustainability Advantages

Proton batteries represent a significant advancement in sustainable energy storage technologies, offering substantial environmental benefits compared to conventional battery systems. The environmental footprint of proton batteries is markedly lower than lithium-ion alternatives, primarily due to their reliance on abundant, non-toxic materials such as carbon, water, and protons. This composition eliminates the need for rare earth metals and toxic elements that characterize traditional battery technologies, substantially reducing the environmental degradation associated with mining operations.

The manufacturing process for proton batteries demonstrates considerably lower carbon emissions compared to lithium-ion production chains. Research indicates that the carbon footprint of proton battery production could be reduced by up to 60% when compared to equivalent lithium-ion systems, representing a significant advancement in sustainable manufacturing practices within the energy storage sector.

Water consumption metrics further highlight the sustainability advantages of proton technology. While lithium extraction can require up to 500,000 gallons of water per ton of lithium, proton battery production utilizes substantially less water resources, contributing to conservation efforts in water-stressed regions where battery manufacturing facilities may operate.

End-of-life considerations also favor proton battery technology. The recyclability rate for proton batteries exceeds 90% in laboratory conditions, compared to approximately 50-60% for current commercial lithium-ion recycling processes. The simpler chemical composition facilitates more efficient material recovery and reuse, creating potential for truly circular economy applications in large-scale energy storage.

From an operational perspective, proton batteries exhibit minimal environmental risks. Unlike lithium-ion systems, they present negligible fire hazards and contain no toxic components that could leach into soil or water systems in the event of damage or improper disposal. This safety profile significantly reduces the environmental liability associated with large-scale deployment.

Climate impact assessments demonstrate that widespread adoption of proton batteries in grid-scale applications could reduce carbon emissions by an estimated 25-30% compared to fossil fuel peaking plants currently used to manage intermittent renewable energy sources. This positions proton battery technology as a critical enabler for higher renewable energy penetration in electricity grids worldwide.

The sustainability advantages of proton batteries extend beyond their direct environmental impact, encompassing broader socioeconomic benefits through reduced dependence on geopolitically concentrated materials and supply chains, potentially democratizing access to advanced energy storage technologies across developed and developing economies alike.

The manufacturing process for proton batteries demonstrates considerably lower carbon emissions compared to lithium-ion production chains. Research indicates that the carbon footprint of proton battery production could be reduced by up to 60% when compared to equivalent lithium-ion systems, representing a significant advancement in sustainable manufacturing practices within the energy storage sector.

Water consumption metrics further highlight the sustainability advantages of proton technology. While lithium extraction can require up to 500,000 gallons of water per ton of lithium, proton battery production utilizes substantially less water resources, contributing to conservation efforts in water-stressed regions where battery manufacturing facilities may operate.

End-of-life considerations also favor proton battery technology. The recyclability rate for proton batteries exceeds 90% in laboratory conditions, compared to approximately 50-60% for current commercial lithium-ion recycling processes. The simpler chemical composition facilitates more efficient material recovery and reuse, creating potential for truly circular economy applications in large-scale energy storage.

From an operational perspective, proton batteries exhibit minimal environmental risks. Unlike lithium-ion systems, they present negligible fire hazards and contain no toxic components that could leach into soil or water systems in the event of damage or improper disposal. This safety profile significantly reduces the environmental liability associated with large-scale deployment.

Climate impact assessments demonstrate that widespread adoption of proton batteries in grid-scale applications could reduce carbon emissions by an estimated 25-30% compared to fossil fuel peaking plants currently used to manage intermittent renewable energy sources. This positions proton battery technology as a critical enabler for higher renewable energy penetration in electricity grids worldwide.

The sustainability advantages of proton batteries extend beyond their direct environmental impact, encompassing broader socioeconomic benefits through reduced dependence on geopolitically concentrated materials and supply chains, potentially democratizing access to advanced energy storage technologies across developed and developing economies alike.

Cost Analysis and Economic Viability

The economic viability of proton batteries represents a critical factor in their advancement for large-scale energy storage applications. Current cost analyses indicate that proton batteries have the potential to achieve significantly lower production costs compared to lithium-ion alternatives, primarily due to their reliance on abundant, low-cost materials such as carbon and water. Initial estimates suggest manufacturing costs could be 30-40% lower than conventional lithium-ion systems at scale.

Material costs constitute a substantial advantage for proton battery technology. The carbon-based electrodes and proton-conducting electrolytes utilize earth-abundant elements without dependency on critical minerals like cobalt, nickel, or lithium that face supply constraints and price volatility. This material accessibility translates to more stable long-term pricing and reduced geopolitical supply risks that currently plague lithium-ion supply chains.

Production processes for proton batteries also demonstrate favorable economics. Manufacturing techniques can leverage existing infrastructure with modifications rather than requiring entirely new production facilities. The elimination of complex thermal management systems needed for lithium-ion batteries further reduces both capital and operational expenditures. Preliminary lifecycle cost analyses suggest a potential 25-35% reduction in total ownership costs over a 15-year operational period.

Scalability economics particularly favor proton battery technology for grid-scale applications. The cost curve demonstrates accelerated economies of scale due to the simplicity of cell design and assembly. Industry projections indicate that production costs could fall below $100/kWh by 2028 with sufficient manufacturing scale, a critical threshold for widespread grid adoption and competitiveness with other storage technologies.

The economic case strengthens further when considering longevity and cycling characteristics. Proton batteries have demonstrated promising cycle life in laboratory settings, potentially exceeding 5,000 full cycles without significant degradation. This extended operational lifespan distributes capital costs over more energy throughput, improving the levelized cost of storage (LCOS) metrics that utilities and grid operators prioritize in procurement decisions.

Regulatory and policy environments increasingly favor technologies with lower environmental footprints, creating indirect economic advantages for proton batteries. Carbon pricing mechanisms, extended producer responsibility regulations, and sustainability incentives in major markets provide additional economic tailwinds that improve the comparative business case against conventional battery technologies with higher environmental impacts.

Material costs constitute a substantial advantage for proton battery technology. The carbon-based electrodes and proton-conducting electrolytes utilize earth-abundant elements without dependency on critical minerals like cobalt, nickel, or lithium that face supply constraints and price volatility. This material accessibility translates to more stable long-term pricing and reduced geopolitical supply risks that currently plague lithium-ion supply chains.

Production processes for proton batteries also demonstrate favorable economics. Manufacturing techniques can leverage existing infrastructure with modifications rather than requiring entirely new production facilities. The elimination of complex thermal management systems needed for lithium-ion batteries further reduces both capital and operational expenditures. Preliminary lifecycle cost analyses suggest a potential 25-35% reduction in total ownership costs over a 15-year operational period.

Scalability economics particularly favor proton battery technology for grid-scale applications. The cost curve demonstrates accelerated economies of scale due to the simplicity of cell design and assembly. Industry projections indicate that production costs could fall below $100/kWh by 2028 with sufficient manufacturing scale, a critical threshold for widespread grid adoption and competitiveness with other storage technologies.

The economic case strengthens further when considering longevity and cycling characteristics. Proton batteries have demonstrated promising cycle life in laboratory settings, potentially exceeding 5,000 full cycles without significant degradation. This extended operational lifespan distributes capital costs over more energy throughput, improving the levelized cost of storage (LCOS) metrics that utilities and grid operators prioritize in procurement decisions.

Regulatory and policy environments increasingly favor technologies with lower environmental footprints, creating indirect economic advantages for proton batteries. Carbon pricing mechanisms, extended producer responsibility regulations, and sustainability incentives in major markets provide additional economic tailwinds that improve the comparative business case against conventional battery technologies with higher environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!