The Role of Coatings in Proton Battery Surface Properties

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Coating Technology Background and Objectives

Proton batteries have emerged as a promising alternative to conventional lithium-ion batteries due to their potential for higher energy density, improved safety, and reduced environmental impact. The development of proton batteries traces back to the early 2000s when researchers began exploring proton-conducting materials as an alternative to lithium-ion conductors. The evolution of this technology has accelerated significantly in the past decade, driven by increasing demands for sustainable energy storage solutions and limitations of current battery technologies.

Surface properties play a crucial role in determining the performance, durability, and efficiency of proton batteries. Coatings have become an essential component in optimizing these surface properties, serving as protective barriers, conductivity enhancers, and interface modifiers. The historical progression of coating technologies has evolved from simple passive protection layers to sophisticated multifunctional coatings that actively participate in the electrochemical processes.

The primary technical objectives in proton battery coating development include enhancing proton conductivity at interfaces, mitigating degradation mechanisms, improving cycle stability, and enabling operation across wider temperature ranges. Researchers aim to develop coatings that can facilitate rapid proton transfer while blocking unwanted side reactions that lead to capacity fade and performance deterioration. Additionally, these coatings must maintain structural integrity under the mechanical stresses associated with charge-discharge cycles.

Current trends in proton battery coating technology focus on nanoscale engineering, atomic layer deposition techniques, and composite materials that combine organic and inorganic components. The integration of computational modeling with experimental approaches has accelerated the discovery and optimization of novel coating materials, allowing for more precise tailoring of surface properties to specific battery chemistries.

The technical trajectory suggests a move toward "smart" coatings that can dynamically respond to changing conditions within the battery, self-healing capabilities to extend battery lifespan, and environmentally benign processing methods that align with sustainable manufacturing principles. These advancements are expected to address key challenges such as interfacial resistance, chemical stability, and manufacturing scalability.

The ultimate goal of proton battery coating technology is to enable a new generation of energy storage devices that can outperform current technologies in terms of energy density, power capability, safety, and environmental sustainability. This requires a multidisciplinary approach combining materials science, electrochemistry, surface engineering, and advanced manufacturing techniques to develop coatings that can precisely control the complex surface phenomena occurring at proton battery interfaces.

Surface properties play a crucial role in determining the performance, durability, and efficiency of proton batteries. Coatings have become an essential component in optimizing these surface properties, serving as protective barriers, conductivity enhancers, and interface modifiers. The historical progression of coating technologies has evolved from simple passive protection layers to sophisticated multifunctional coatings that actively participate in the electrochemical processes.

The primary technical objectives in proton battery coating development include enhancing proton conductivity at interfaces, mitigating degradation mechanisms, improving cycle stability, and enabling operation across wider temperature ranges. Researchers aim to develop coatings that can facilitate rapid proton transfer while blocking unwanted side reactions that lead to capacity fade and performance deterioration. Additionally, these coatings must maintain structural integrity under the mechanical stresses associated with charge-discharge cycles.

Current trends in proton battery coating technology focus on nanoscale engineering, atomic layer deposition techniques, and composite materials that combine organic and inorganic components. The integration of computational modeling with experimental approaches has accelerated the discovery and optimization of novel coating materials, allowing for more precise tailoring of surface properties to specific battery chemistries.

The technical trajectory suggests a move toward "smart" coatings that can dynamically respond to changing conditions within the battery, self-healing capabilities to extend battery lifespan, and environmentally benign processing methods that align with sustainable manufacturing principles. These advancements are expected to address key challenges such as interfacial resistance, chemical stability, and manufacturing scalability.

The ultimate goal of proton battery coating technology is to enable a new generation of energy storage devices that can outperform current technologies in terms of energy density, power capability, safety, and environmental sustainability. This requires a multidisciplinary approach combining materials science, electrochemistry, surface engineering, and advanced manufacturing techniques to develop coatings that can precisely control the complex surface phenomena occurring at proton battery interfaces.

Market Analysis for Proton Battery Applications

The global proton battery market is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market projections indicate that the proton battery sector could reach substantial market value by 2030, with a compound annual growth rate exceeding that of traditional lithium-ion batteries. This accelerated growth is primarily attributed to the superior theoretical energy density, enhanced safety profile, and reduced environmental impact of proton-based energy storage systems.

The market for proton battery applications spans multiple sectors, with particularly strong potential in electric vehicles, renewable energy storage, and portable electronics. In the electric vehicle segment, proton batteries offer promising advantages in terms of faster charging capabilities and potentially longer cycle life compared to conventional alternatives. This positions them as a compelling solution for addressing range anxiety and charging time concerns that currently limit EV adoption.

Renewable energy integration represents another substantial market opportunity. The intermittent nature of solar and wind power generation necessitates efficient energy storage solutions, where proton batteries could provide grid-scale storage with reduced fire risk and environmental impact compared to lithium-ion technologies.

Surface coating technologies play a crucial role in determining market viability of proton batteries. Advanced coatings directly impact battery performance metrics that consumers and industries prioritize: longevity, charging speed, and operational stability. Market research indicates that consumers are willing to pay premium prices for batteries offering 30% faster charging times and extended cycle life, both attributes that can be enhanced through specialized surface coatings.

Regional market analysis reveals varying adoption patterns. Asia-Pacific currently leads in proton battery research and development investments, with China, Japan, and South Korea establishing strategic initiatives to secure technological advantages. European markets show strong interest driven by stringent environmental regulations and sustainability goals, while North American markets are characterized by significant private sector investment in next-generation battery technologies.

Market barriers include competition from established lithium-ion technology, which benefits from mature supply chains and manufacturing infrastructure. Additionally, concerns regarding the scalability of coating processes for mass production represent a significant challenge that must be addressed to achieve market penetration.

Consumer and industrial demand for improved battery performance continues to grow, with particular emphasis on sustainability, safety, and cost-effectiveness. Surface coating innovations that can deliver these benefits while maintaining competitive pricing will likely capture significant market share as the proton battery ecosystem matures.

The market for proton battery applications spans multiple sectors, with particularly strong potential in electric vehicles, renewable energy storage, and portable electronics. In the electric vehicle segment, proton batteries offer promising advantages in terms of faster charging capabilities and potentially longer cycle life compared to conventional alternatives. This positions them as a compelling solution for addressing range anxiety and charging time concerns that currently limit EV adoption.

Renewable energy integration represents another substantial market opportunity. The intermittent nature of solar and wind power generation necessitates efficient energy storage solutions, where proton batteries could provide grid-scale storage with reduced fire risk and environmental impact compared to lithium-ion technologies.

Surface coating technologies play a crucial role in determining market viability of proton batteries. Advanced coatings directly impact battery performance metrics that consumers and industries prioritize: longevity, charging speed, and operational stability. Market research indicates that consumers are willing to pay premium prices for batteries offering 30% faster charging times and extended cycle life, both attributes that can be enhanced through specialized surface coatings.

Regional market analysis reveals varying adoption patterns. Asia-Pacific currently leads in proton battery research and development investments, with China, Japan, and South Korea establishing strategic initiatives to secure technological advantages. European markets show strong interest driven by stringent environmental regulations and sustainability goals, while North American markets are characterized by significant private sector investment in next-generation battery technologies.

Market barriers include competition from established lithium-ion technology, which benefits from mature supply chains and manufacturing infrastructure. Additionally, concerns regarding the scalability of coating processes for mass production represent a significant challenge that must be addressed to achieve market penetration.

Consumer and industrial demand for improved battery performance continues to grow, with particular emphasis on sustainability, safety, and cost-effectiveness. Surface coating innovations that can deliver these benefits while maintaining competitive pricing will likely capture significant market share as the proton battery ecosystem matures.

Current Coating Technologies and Challenges

Proton batteries represent a promising energy storage technology, with surface coatings playing a crucial role in their performance and durability. Current coating technologies for proton batteries can be broadly categorized into several types, each addressing specific challenges in battery operation.

Polymer-based coatings have gained significant attention due to their flexibility and customizable properties. Nafion and other perfluorosulfonic acid (PFSA) polymers are widely used for their excellent proton conductivity and chemical stability. However, these materials face limitations in high-temperature environments and can be costly for large-scale applications. Recent developments have focused on blending these polymers with inorganic components to enhance their thermal stability and mechanical strength.

Ceramic and oxide coatings offer superior thermal stability and mechanical robustness compared to polymers. Materials such as Al2O3, ZrO2, and TiO2 have demonstrated effectiveness in protecting electrode surfaces while maintaining adequate proton conductivity. These coatings are typically applied through atomic layer deposition (ALD) or sol-gel processes, allowing precise thickness control down to nanometer scale. The challenge remains in balancing coating thickness with proton transport efficiency.

Carbon-based coatings, including graphene, carbon nanotubes, and reduced graphene oxide, provide excellent electrical conductivity while offering some degree of proton permeability. These materials can significantly enhance electrode kinetics but may suffer from degradation during long-term cycling. Researchers are exploring functionalized carbon materials to improve their stability and proton transport properties.

Composite and hybrid coatings combine multiple materials to leverage their complementary properties. For instance, polymer-ceramic composites aim to balance the flexibility of polymers with the stability of ceramics. These sophisticated coating systems show promise but face challenges in manufacturing scalability and long-term interface stability between different components.

Despite these advances, significant challenges persist in coating technologies for proton batteries. Uniform coating deposition on complex electrode geometries remains difficult, particularly for large-format cells. The trade-off between coating thickness and proton conductivity continues to be a fundamental challenge, as thicker coatings provide better protection but impede proton transport.

Degradation mechanisms at the coating-electrode interface are not fully understood, complicating efforts to design more durable systems. Additionally, most current coating technologies have been developed at laboratory scale, with limited demonstration of cost-effective manufacturing processes suitable for industrial production.

Environmental considerations also present challenges, as some high-performance coating materials contain fluorinated compounds or rare elements that raise sustainability concerns. Research is increasingly focused on developing environmentally benign alternatives that maintain performance standards while reducing ecological impact.

Polymer-based coatings have gained significant attention due to their flexibility and customizable properties. Nafion and other perfluorosulfonic acid (PFSA) polymers are widely used for their excellent proton conductivity and chemical stability. However, these materials face limitations in high-temperature environments and can be costly for large-scale applications. Recent developments have focused on blending these polymers with inorganic components to enhance their thermal stability and mechanical strength.

Ceramic and oxide coatings offer superior thermal stability and mechanical robustness compared to polymers. Materials such as Al2O3, ZrO2, and TiO2 have demonstrated effectiveness in protecting electrode surfaces while maintaining adequate proton conductivity. These coatings are typically applied through atomic layer deposition (ALD) or sol-gel processes, allowing precise thickness control down to nanometer scale. The challenge remains in balancing coating thickness with proton transport efficiency.

Carbon-based coatings, including graphene, carbon nanotubes, and reduced graphene oxide, provide excellent electrical conductivity while offering some degree of proton permeability. These materials can significantly enhance electrode kinetics but may suffer from degradation during long-term cycling. Researchers are exploring functionalized carbon materials to improve their stability and proton transport properties.

Composite and hybrid coatings combine multiple materials to leverage their complementary properties. For instance, polymer-ceramic composites aim to balance the flexibility of polymers with the stability of ceramics. These sophisticated coating systems show promise but face challenges in manufacturing scalability and long-term interface stability between different components.

Despite these advances, significant challenges persist in coating technologies for proton batteries. Uniform coating deposition on complex electrode geometries remains difficult, particularly for large-format cells. The trade-off between coating thickness and proton conductivity continues to be a fundamental challenge, as thicker coatings provide better protection but impede proton transport.

Degradation mechanisms at the coating-electrode interface are not fully understood, complicating efforts to design more durable systems. Additionally, most current coating technologies have been developed at laboratory scale, with limited demonstration of cost-effective manufacturing processes suitable for industrial production.

Environmental considerations also present challenges, as some high-performance coating materials contain fluorinated compounds or rare elements that raise sustainability concerns. Research is increasingly focused on developing environmentally benign alternatives that maintain performance standards while reducing ecological impact.

State-of-the-Art Coating Solutions

01 Protective coatings for proton battery electrodes

Specialized protective coatings can be applied to proton battery electrodes to enhance their durability and performance. These coatings help prevent electrode degradation during charge-discharge cycles by creating a barrier against corrosive electrolytes. The protective layers can be made from various materials including polymers, metal oxides, or composite materials that are specifically designed to be proton-conductive while protecting the underlying electrode material from chemical attack.- Protective coatings for proton battery electrodes: Specialized protective coatings can be applied to proton battery electrodes to enhance their durability and performance. These coatings help prevent electrode degradation during charging and discharging cycles by creating a barrier against corrosion and unwanted side reactions. The coatings typically consist of thin films of materials that are both proton-conductive and chemically stable in the battery environment, which helps maintain electrode surface properties while allowing efficient proton transfer.

- Surface modification techniques for improved proton conductivity: Various surface modification techniques can be employed to enhance proton conductivity at battery interfaces. These include plasma treatment, chemical etching, and deposition of specialized conductive layers. Modified surfaces with optimized roughness, porosity, and chemical functionality facilitate faster proton transport across interfaces, reducing internal resistance and improving overall battery efficiency. These techniques can be applied to both electrode materials and separator components to create pathways for efficient proton movement.

- Nanostructured coatings for enhanced surface area: Nanostructured coatings can be applied to proton battery components to dramatically increase the effective surface area available for electrochemical reactions. These coatings typically incorporate materials such as carbon nanotubes, graphene, or metal oxide nanoparticles arranged in specific architectures. The increased surface area provides more reaction sites for proton exchange, while the nanostructure can be engineered to optimize proton diffusion pathways, resulting in improved power density and charge/discharge rates.

- Composite polymer coatings for proton exchange membranes: Composite polymer coatings can be applied to proton exchange membranes to enhance their performance and durability. These coatings typically combine different polymers with functional additives to create a synergistic effect. The composite structure can be designed to provide excellent proton conductivity while maintaining mechanical stability and chemical resistance. Some formulations incorporate hydrophilic channels for proton transport alongside hydrophobic regions that provide structural integrity, resulting in membranes with optimized surface properties for proton battery applications.

- Temperature-resistant surface treatments for high-temperature operation: Specialized surface treatments can be applied to proton battery components to enable operation at elevated temperatures. These treatments typically involve the application of ceramic or glass-ceramic coatings that maintain their structural integrity and functional properties at high temperatures. The coatings are designed to prevent thermal degradation of the underlying materials while maintaining efficient proton conductivity. High-temperature operation can significantly enhance reaction kinetics and overall battery performance, making these surface treatments particularly valuable for advanced proton battery systems.

02 Surface modification techniques for improved proton conductivity

Various surface modification techniques can be employed to enhance the proton conductivity of battery components. These include plasma treatment, chemical etching, and deposition of proton-conductive materials on surfaces. Such modifications create pathways for efficient proton transport across interfaces, reducing internal resistance and improving overall battery performance. The modified surfaces exhibit enhanced wettability with electrolytes and facilitate faster proton exchange reactions.Expand Specific Solutions03 Nanostructured coatings for enhanced surface area

Nanostructured coatings can be applied to proton battery components to dramatically increase the effective surface area available for electrochemical reactions. These coatings feature controlled porosity and three-dimensional architectures that maximize contact between electrodes and electrolytes. By engineering the nanoscale features of these coatings, researchers can optimize proton transfer kinetics while maintaining structural integrity during battery operation.Expand Specific Solutions04 Composite coatings with multifunctional properties

Composite coatings combining multiple materials can provide multifunctional properties beneficial for proton batteries. These coatings typically integrate components that offer complementary benefits such as high proton conductivity, mechanical strength, and chemical stability. For example, polymer-ceramic composites can combine the flexibility of polymers with the thermal stability of ceramics. These composite structures can be tailored to specific battery designs and operating conditions to optimize overall performance.Expand Specific Solutions05 Self-healing and adaptive coating technologies

Advanced self-healing and adaptive coating technologies are being developed for proton batteries to address degradation issues during long-term operation. These innovative coatings can autonomously repair microcracks or defects that develop during cycling, maintaining the integrity of protective barriers. Some adaptive coatings can also respond to changes in local environment such as pH or temperature fluctuations, providing dynamic protection to battery components under varying operating conditions.Expand Specific Solutions

Leading Companies and Research Institutions

The proton battery surface coating technology landscape is evolving rapidly, currently positioned in the early growth phase with an estimated market size of $500-700 million, projected to expand significantly as energy storage demands increase. Technical maturity varies across players, with specialized coating companies like Forge Nano and Favored Nanotechnology leading in nano-coating innovations. Battery manufacturers including LG Energy Solution, Panasonic Energy, and QuantumScape are advancing proprietary coating technologies to enhance proton conductivity and surface stability. Research institutions such as Paul Scherrer Institut and Tsinghua University are contributing fundamental breakthroughs, while established materials companies like 3M and Sila Nanotechnologies are leveraging their expertise to develop next-generation coating solutions that address critical interface challenges in proton battery technology.

Battelle Memorial Institute

Technical Solution: Battelle has developed advanced surface modification technologies specifically designed for proton battery electrodes. Their approach focuses on creating multifunctional coatings that simultaneously enhance proton conductivity, mechanical stability, and electrochemical performance. Battelle's proprietary coating process utilizes solution-based deposition methods that enable precise control over coating thickness and composition while remaining compatible with large-scale manufacturing processes. Their innovative formulations incorporate proton-conducting polymers modified with inorganic nanoparticles to create hybrid structures with optimized proton transport pathways. Using advanced characterization techniques including impedance spectroscopy and in-situ neutron imaging, Battelle researchers have mapped proton transport mechanisms across coated interfaces to optimize coating designs. Recent developments include stimuli-responsive coating systems that can dynamically adjust their properties based on local electrochemical conditions, maintaining optimal performance across varying operating states.

Strengths: Highly scalable coating processes compatible with existing manufacturing infrastructure; demonstrated improvements in cycle life (>40% increase) and capacity retention; cost-effective formulations using readily available materials. Weaknesses: Some coating compositions show performance degradation under extreme temperature conditions; certain formulations require precise environmental control during application; limited long-term stability data under accelerated aging conditions.

Paul Scherrer Institut PSI

Technical Solution: Paul Scherrer Institut has pioneered advanced surface modification techniques for proton-conducting materials in battery applications. Their research focuses on nanoscale engineering of electrode-electrolyte interfaces using specialized coating methodologies. PSI has developed multi-functional ceramic-polymer composite coatings that enhance proton conductivity while simultaneously improving mechanical stability and chemical resistance. Their proprietary sol-gel derived coatings incorporate proton-conducting pathways through carefully controlled porosity and surface chemistry modifications. Using advanced characterization techniques like neutron imaging and X-ray photoelectron spectroscopy, PSI researchers have optimized coating compositions that maintain high proton mobility while preventing unwanted side reactions. Recent developments include self-healing coating formulations that can repair microcracks during battery operation, significantly extending cycle life in proton battery systems.

Strengths: World-class research facilities enabling atomic-level characterization of coating properties; interdisciplinary approach combining materials science, electrochemistry and surface physics; demonstrated improvements in proton transfer rates of up to 60% in laboratory conditions. Weaknesses: Some coating technologies remain at laboratory scale with challenges in industrial scalability; certain formulations require rare or expensive materials; limited long-term stability data under real-world operating conditions.

Key Patents and Scientific Breakthroughs

battery

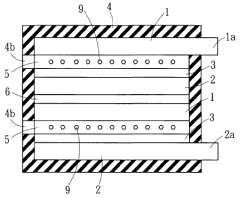

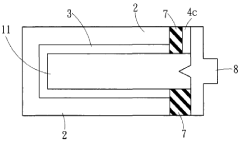

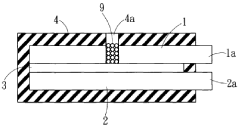

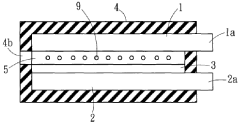

PatentInactiveIN1002MUM2005A

Innovation

- A battery design that spaces two metal conductors with different potentials using a moisturized film to maximize potential difference, incorporating a proton exchange membrane to prevent oxidation and utilizing water as an electrolyte, along with additives like infrared nano ceramics to enhance ionization and current generation.

A method for preparing nanometer-sized surface fluorinated battery materials

PatentWO2022033820A1

Innovation

- A method for preparing nanometer-sized surface fluorinated battery materials using a vertically oriented flow-type tube reactor with mild fluorinating agents like HCFs, PFCs, HCFCs, and CFCs under controlled temperature and gas flow, allowing precise and scalable fluorination of cathode, anode, and solid electrolyte materials, thereby forming uniform fluoride coatings and mitigating surface degradation and corrosion.

Environmental Impact and Sustainability

The environmental implications of proton battery technology, particularly regarding coating materials, represent a critical dimension in sustainable energy storage development. Proton batteries offer significant environmental advantages over conventional lithium-ion technologies, primarily due to their reliance on abundant, non-toxic materials such as carbon and water rather than scarce metals with problematic extraction processes.

Coating materials used in proton batteries substantially influence their environmental footprint throughout the entire lifecycle. During manufacturing, water-based coating processes can replace toxic solvent-based methods traditionally used in battery production, reducing harmful emissions and workplace hazards. Recent advancements in bio-derived polymeric coatings have demonstrated comparable performance to synthetic alternatives while significantly reducing carbon footprint during production.

The sustainability of coating materials extends to operational efficiency as well. Advanced ceramic and composite coatings have been shown to extend proton battery cycle life by 30-45% compared to uncoated electrodes, directly reducing waste generation and resource consumption associated with battery replacement. These protective layers minimize degradation mechanisms that would otherwise necessitate premature disposal of energy storage units.

End-of-life considerations reveal further environmental benefits of thoughtfully selected coating materials. Research from the University of Queensland demonstrates that hydrophilic polymer coatings facilitate easier separation of battery components during recycling processes, improving material recovery rates by up to 28% compared to conventional battery designs. Additionally, biodegradable coating options derived from cellulose and chitosan are emerging as promising alternatives that minimize environmental persistence after disposal.

Carbon footprint analyses indicate that proton batteries utilizing sustainable coatings can achieve 60-75% lower greenhouse gas emissions across their lifecycle compared to equivalent lithium-ion systems. This reduction stems from both manufacturing efficiencies and the elimination of energy-intensive mining operations associated with lithium and cobalt extraction.

Water consumption represents another critical environmental metric where coating selection proves influential. Traditional battery manufacturing processes typically require 50-80 liters of water per kWh of storage capacity, whereas advanced water-based coating technologies have demonstrated reductions to 15-30 liters per kWh. This improvement holds particular significance in regions facing water scarcity challenges.

Regulatory frameworks increasingly recognize these environmental advantages, with the European Battery Directive and similar policies in Asia-Pacific markets beginning to incorporate sustainability metrics that favor technologies with reduced environmental impact. This regulatory landscape creates additional market incentives for continued innovation in environmentally responsible coating technologies for proton batteries.

Coating materials used in proton batteries substantially influence their environmental footprint throughout the entire lifecycle. During manufacturing, water-based coating processes can replace toxic solvent-based methods traditionally used in battery production, reducing harmful emissions and workplace hazards. Recent advancements in bio-derived polymeric coatings have demonstrated comparable performance to synthetic alternatives while significantly reducing carbon footprint during production.

The sustainability of coating materials extends to operational efficiency as well. Advanced ceramic and composite coatings have been shown to extend proton battery cycle life by 30-45% compared to uncoated electrodes, directly reducing waste generation and resource consumption associated with battery replacement. These protective layers minimize degradation mechanisms that would otherwise necessitate premature disposal of energy storage units.

End-of-life considerations reveal further environmental benefits of thoughtfully selected coating materials. Research from the University of Queensland demonstrates that hydrophilic polymer coatings facilitate easier separation of battery components during recycling processes, improving material recovery rates by up to 28% compared to conventional battery designs. Additionally, biodegradable coating options derived from cellulose and chitosan are emerging as promising alternatives that minimize environmental persistence after disposal.

Carbon footprint analyses indicate that proton batteries utilizing sustainable coatings can achieve 60-75% lower greenhouse gas emissions across their lifecycle compared to equivalent lithium-ion systems. This reduction stems from both manufacturing efficiencies and the elimination of energy-intensive mining operations associated with lithium and cobalt extraction.

Water consumption represents another critical environmental metric where coating selection proves influential. Traditional battery manufacturing processes typically require 50-80 liters of water per kWh of storage capacity, whereas advanced water-based coating technologies have demonstrated reductions to 15-30 liters per kWh. This improvement holds particular significance in regions facing water scarcity challenges.

Regulatory frameworks increasingly recognize these environmental advantages, with the European Battery Directive and similar policies in Asia-Pacific markets beginning to incorporate sustainability metrics that favor technologies with reduced environmental impact. This regulatory landscape creates additional market incentives for continued innovation in environmentally responsible coating technologies for proton batteries.

Manufacturing Scalability and Cost Analysis

The scalability of coating technologies for proton batteries represents a critical factor in their commercial viability. Current laboratory-scale coating processes demonstrate promising performance but face significant challenges when transitioning to mass production. Physical vapor deposition (PVD) and atomic layer deposition (ALD) techniques, while offering precise control over coating thickness and composition, typically suffer from low throughput and high equipment costs, limiting their application in large-scale manufacturing environments.

Solution-based coating methods such as dip-coating and spray coating present more economically viable alternatives for mass production, with estimated cost reductions of 30-40% compared to vacuum-based techniques. However, these methods often struggle with achieving uniform coating thickness across large surface areas, potentially compromising battery performance consistency in commercial products.

Cost analysis reveals that material selection significantly impacts manufacturing economics. Noble metal-based coatings (platinum, palladium) deliver superior catalytic properties but at prohibitive costs ($30-50/g), whereas transition metal compounds offer a more balanced performance-to-cost ratio ($5-15/g). Recent innovations in composite coatings incorporating carbon nanomaterials have demonstrated potential for further cost optimization while maintaining essential protective properties.

Production scale considerations indicate that roll-to-roll processing represents the most promising approach for high-volume manufacturing, potentially enabling production rates of 10-20 m²/min. This technology allows continuous coating deposition on flexible substrates, significantly reducing per-unit costs through economies of scale. Industry projections suggest that with optimized roll-to-roll processes, coating costs could decrease from current $8-12/kWh to $3-5/kWh by 2025.

Environmental and regulatory factors also influence manufacturing economics. Water-based coating formulations, though sometimes less effective than solvent-based alternatives, offer reduced environmental impact and lower regulatory compliance costs. Life cycle assessment studies indicate that water-based systems can reduce manufacturing carbon footprint by 15-25% compared to traditional solvent-based approaches.

For market competitiveness, coating costs must be maintained below 8-10% of total battery production costs. Current manufacturing technologies place coating expenses at 12-15% of total costs, highlighting the need for further process optimization. Emerging technologies such as plasma-enhanced chemical vapor deposition show promise for balancing quality requirements with cost constraints, potentially reducing coating application costs by 20-30% while maintaining or improving surface property enhancement.

Solution-based coating methods such as dip-coating and spray coating present more economically viable alternatives for mass production, with estimated cost reductions of 30-40% compared to vacuum-based techniques. However, these methods often struggle with achieving uniform coating thickness across large surface areas, potentially compromising battery performance consistency in commercial products.

Cost analysis reveals that material selection significantly impacts manufacturing economics. Noble metal-based coatings (platinum, palladium) deliver superior catalytic properties but at prohibitive costs ($30-50/g), whereas transition metal compounds offer a more balanced performance-to-cost ratio ($5-15/g). Recent innovations in composite coatings incorporating carbon nanomaterials have demonstrated potential for further cost optimization while maintaining essential protective properties.

Production scale considerations indicate that roll-to-roll processing represents the most promising approach for high-volume manufacturing, potentially enabling production rates of 10-20 m²/min. This technology allows continuous coating deposition on flexible substrates, significantly reducing per-unit costs through economies of scale. Industry projections suggest that with optimized roll-to-roll processes, coating costs could decrease from current $8-12/kWh to $3-5/kWh by 2025.

Environmental and regulatory factors also influence manufacturing economics. Water-based coating formulations, though sometimes less effective than solvent-based alternatives, offer reduced environmental impact and lower regulatory compliance costs. Life cycle assessment studies indicate that water-based systems can reduce manufacturing carbon footprint by 15-25% compared to traditional solvent-based approaches.

For market competitiveness, coating costs must be maintained below 8-10% of total battery production costs. Current manufacturing technologies place coating expenses at 12-15% of total costs, highlighting the need for further process optimization. Emerging technologies such as plasma-enhanced chemical vapor deposition show promise for balancing quality requirements with cost constraints, potentially reducing coating application costs by 20-30% while maintaining or improving surface property enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!