Exploring Proton Battery Inner Nanostructure Evolution

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Development Background and Objectives

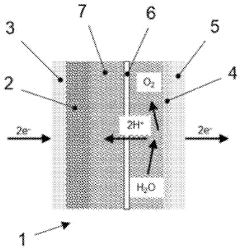

Proton batteries represent a promising frontier in energy storage technology, emerging as a potential alternative to conventional lithium-ion batteries. The concept of proton-based energy storage systems dates back to the early 2000s, but significant advancements have only materialized in the last decade. These batteries operate on the principle of proton transfer rather than lithium-ion movement, offering theoretical advantages in terms of energy density, safety, and environmental sustainability.

The evolution of proton battery technology has been driven by increasing global demand for sustainable energy storage solutions amid growing concerns about lithium resource limitations and environmental impact. Initial research focused primarily on proton-conducting membranes borrowed from fuel cell technology, with subsequent developments expanding into novel electrode materials and electrolyte compositions specifically designed for proton storage and transport.

Recent breakthroughs in nanomaterial science have accelerated progress in this field, enabling more efficient proton conduction pathways and storage mechanisms. Particularly noteworthy is the development of carbon-based electrodes with tailored nanostructures that facilitate rapid proton insertion and extraction, addressing previous limitations in power density and cycle life.

Understanding the dynamic evolution of nanostructures within proton batteries during operation represents a critical research frontier. As protons move through the battery system, they induce structural changes at the nanoscale that significantly impact performance parameters including capacity retention, rate capability, and long-term stability. These evolutionary processes remain inadequately characterized, presenting both challenges and opportunities for technological advancement.

The primary objectives of current research into proton battery nanostructure evolution encompass several dimensions. First, developing advanced in-situ and operando characterization techniques capable of monitoring structural changes at the nanoscale during battery operation. Second, establishing comprehensive models that correlate nanostructural evolution with electrochemical performance metrics. Third, designing novel electrode architectures with enhanced structural stability during repeated proton insertion/extraction cycles.

Additionally, research aims to elucidate the fundamental mechanisms governing proton transport and storage within various nanostructured materials, including metal-organic frameworks, covalent organic frameworks, and functionalized carbon allotropes. This mechanistic understanding is essential for rational material design and optimization.

The ultimate goal of this technological trajectory is to develop proton batteries that exceed the performance of current lithium-ion systems while utilizing more abundant, environmentally benign materials. Success in this endeavor could revolutionize energy storage for applications ranging from grid-scale storage to electric vehicles, contributing significantly to global decarbonization efforts and sustainable energy transition.

The evolution of proton battery technology has been driven by increasing global demand for sustainable energy storage solutions amid growing concerns about lithium resource limitations and environmental impact. Initial research focused primarily on proton-conducting membranes borrowed from fuel cell technology, with subsequent developments expanding into novel electrode materials and electrolyte compositions specifically designed for proton storage and transport.

Recent breakthroughs in nanomaterial science have accelerated progress in this field, enabling more efficient proton conduction pathways and storage mechanisms. Particularly noteworthy is the development of carbon-based electrodes with tailored nanostructures that facilitate rapid proton insertion and extraction, addressing previous limitations in power density and cycle life.

Understanding the dynamic evolution of nanostructures within proton batteries during operation represents a critical research frontier. As protons move through the battery system, they induce structural changes at the nanoscale that significantly impact performance parameters including capacity retention, rate capability, and long-term stability. These evolutionary processes remain inadequately characterized, presenting both challenges and opportunities for technological advancement.

The primary objectives of current research into proton battery nanostructure evolution encompass several dimensions. First, developing advanced in-situ and operando characterization techniques capable of monitoring structural changes at the nanoscale during battery operation. Second, establishing comprehensive models that correlate nanostructural evolution with electrochemical performance metrics. Third, designing novel electrode architectures with enhanced structural stability during repeated proton insertion/extraction cycles.

Additionally, research aims to elucidate the fundamental mechanisms governing proton transport and storage within various nanostructured materials, including metal-organic frameworks, covalent organic frameworks, and functionalized carbon allotropes. This mechanistic understanding is essential for rational material design and optimization.

The ultimate goal of this technological trajectory is to develop proton batteries that exceed the performance of current lithium-ion systems while utilizing more abundant, environmentally benign materials. Success in this endeavor could revolutionize energy storage for applications ranging from grid-scale storage to electric vehicles, contributing significantly to global decarbonization efforts and sustainable energy transition.

Market Analysis for Next-Generation Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the push for electrification across various sectors. The market for next-generation energy storage solutions is projected to reach $546 billion by 2035, with a compound annual growth rate of 12.3% between 2023 and 2035. Within this expanding landscape, proton batteries represent an emerging technology with significant potential to disrupt conventional lithium-ion dominance.

Current market analysis indicates that while lithium-ion batteries hold approximately 90% of the grid-scale energy storage market, concerns regarding resource scarcity, environmental impact, and safety limitations are creating substantial opportunities for alternative technologies. Proton batteries, which utilize hydrogen ions (protons) as charge carriers, offer compelling advantages including abundant raw materials, enhanced safety profiles, and potentially higher energy densities.

Consumer demand for sustainable energy storage solutions has grown by 35% annually since 2020, with particular emphasis on technologies that minimize environmental footprint. Proton batteries align perfectly with this market trend, as their primary components are carbon-based materials and water, eliminating dependency on critical minerals like lithium, cobalt, and nickel that face supply constraints and ethical sourcing challenges.

Industrial sectors, particularly automotive and grid storage, represent the most promising initial markets for proton battery technology. The electric vehicle market, growing at 25% annually, is actively seeking alternatives to conventional lithium-ion batteries to address range anxiety, charging speed limitations, and cost concerns. Proton batteries' potential for rapid charging and higher energy density could capture up to 15% of this market by 2030 if current technical challenges in nanostructure optimization are resolved.

Regional market analysis reveals varying levels of investment in next-generation battery technologies. Asia-Pacific leads with 45% of global investment, followed by North America (30%) and Europe (20%). However, Europe demonstrates the fastest growth rate in alternative battery research funding, with particular emphasis on sustainable technologies like proton batteries.

Market forecasts suggest that understanding and controlling nanostructure evolution in proton batteries could be the key inflection point for commercial viability. Industry experts predict that breakthroughs in this specific area could reduce production costs by up to 40% while increasing energy density by 25-30%, potentially creating a market opportunity of $85 billion by 2035 specifically for proton battery technologies.

Current market analysis indicates that while lithium-ion batteries hold approximately 90% of the grid-scale energy storage market, concerns regarding resource scarcity, environmental impact, and safety limitations are creating substantial opportunities for alternative technologies. Proton batteries, which utilize hydrogen ions (protons) as charge carriers, offer compelling advantages including abundant raw materials, enhanced safety profiles, and potentially higher energy densities.

Consumer demand for sustainable energy storage solutions has grown by 35% annually since 2020, with particular emphasis on technologies that minimize environmental footprint. Proton batteries align perfectly with this market trend, as their primary components are carbon-based materials and water, eliminating dependency on critical minerals like lithium, cobalt, and nickel that face supply constraints and ethical sourcing challenges.

Industrial sectors, particularly automotive and grid storage, represent the most promising initial markets for proton battery technology. The electric vehicle market, growing at 25% annually, is actively seeking alternatives to conventional lithium-ion batteries to address range anxiety, charging speed limitations, and cost concerns. Proton batteries' potential for rapid charging and higher energy density could capture up to 15% of this market by 2030 if current technical challenges in nanostructure optimization are resolved.

Regional market analysis reveals varying levels of investment in next-generation battery technologies. Asia-Pacific leads with 45% of global investment, followed by North America (30%) and Europe (20%). However, Europe demonstrates the fastest growth rate in alternative battery research funding, with particular emphasis on sustainable technologies like proton batteries.

Market forecasts suggest that understanding and controlling nanostructure evolution in proton batteries could be the key inflection point for commercial viability. Industry experts predict that breakthroughs in this specific area could reduce production costs by up to 40% while increasing energy density by 25-30%, potentially creating a market opportunity of $85 billion by 2035 specifically for proton battery technologies.

Current Challenges in Proton Battery Nanostructure Research

Despite significant advancements in proton battery technology, researchers face numerous challenges in understanding and controlling nanostructure evolution within these energy storage systems. One primary obstacle is the limited in-situ characterization capabilities for observing dynamic changes in electrode materials during charge-discharge cycles. Current imaging techniques struggle to provide adequate spatial and temporal resolution to capture the rapid proton transfer processes occurring at the nanoscale, particularly under operating conditions.

The complex multi-phase interfaces present in proton battery systems create additional research difficulties. These interfaces, where electrolyte, electrode, and catalyst materials meet, exhibit behavior that deviates significantly from bulk properties. Researchers lack comprehensive models to predict how these interfaces evolve over time and how their transformations affect overall battery performance and degradation pathways.

Material stability represents another significant challenge, as many promising electrode materials undergo substantial structural changes during proton insertion and extraction. These transformations often lead to mechanical stress, cracking, and eventual capacity loss. The scientific community has yet to develop electrode materials that maintain structural integrity while allowing rapid proton transport over extended cycling periods.

Computational modeling of nanostructure evolution presents its own set of challenges. Current simulation approaches struggle to bridge multiple length and time scales relevant to proton battery operation. Quantum mechanical calculations can accurately describe atomic-level interactions but become computationally prohibitive for larger systems, while continuum models lack the atomic resolution necessary to capture critical nanoscale phenomena.

The correlation between nanostructure and performance metrics remains poorly understood. Researchers have identified that specific nanostructural features significantly impact proton diffusion rates, storage capacity, and cycling stability, but establishing quantitative structure-property relationships has proven difficult due to the multivariable nature of these systems and limitations in experimental design.

Environmental factors such as temperature, humidity, and pressure significantly influence nanostructure evolution in proton batteries, yet systematic studies examining these effects are scarce. This knowledge gap hinders the development of batteries optimized for diverse operating conditions, from portable electronics to grid-scale storage applications.

Finally, scalable manufacturing techniques for precisely controlled nanostructures remain underdeveloped. Laboratory methods that produce ideal nanostructures often involve complex, expensive processes incompatible with mass production. Bridging this gap between fundamental research and practical implementation represents a critical challenge for commercializing advanced proton battery technologies.

The complex multi-phase interfaces present in proton battery systems create additional research difficulties. These interfaces, where electrolyte, electrode, and catalyst materials meet, exhibit behavior that deviates significantly from bulk properties. Researchers lack comprehensive models to predict how these interfaces evolve over time and how their transformations affect overall battery performance and degradation pathways.

Material stability represents another significant challenge, as many promising electrode materials undergo substantial structural changes during proton insertion and extraction. These transformations often lead to mechanical stress, cracking, and eventual capacity loss. The scientific community has yet to develop electrode materials that maintain structural integrity while allowing rapid proton transport over extended cycling periods.

Computational modeling of nanostructure evolution presents its own set of challenges. Current simulation approaches struggle to bridge multiple length and time scales relevant to proton battery operation. Quantum mechanical calculations can accurately describe atomic-level interactions but become computationally prohibitive for larger systems, while continuum models lack the atomic resolution necessary to capture critical nanoscale phenomena.

The correlation between nanostructure and performance metrics remains poorly understood. Researchers have identified that specific nanostructural features significantly impact proton diffusion rates, storage capacity, and cycling stability, but establishing quantitative structure-property relationships has proven difficult due to the multivariable nature of these systems and limitations in experimental design.

Environmental factors such as temperature, humidity, and pressure significantly influence nanostructure evolution in proton batteries, yet systematic studies examining these effects are scarce. This knowledge gap hinders the development of batteries optimized for diverse operating conditions, from portable electronics to grid-scale storage applications.

Finally, scalable manufacturing techniques for precisely controlled nanostructures remain underdeveloped. Laboratory methods that produce ideal nanostructures often involve complex, expensive processes incompatible with mass production. Bridging this gap between fundamental research and practical implementation represents a critical challenge for commercializing advanced proton battery technologies.

State-of-the-Art Nanostructure Characterization Techniques

01 Nanostructured electrode materials for proton batteries

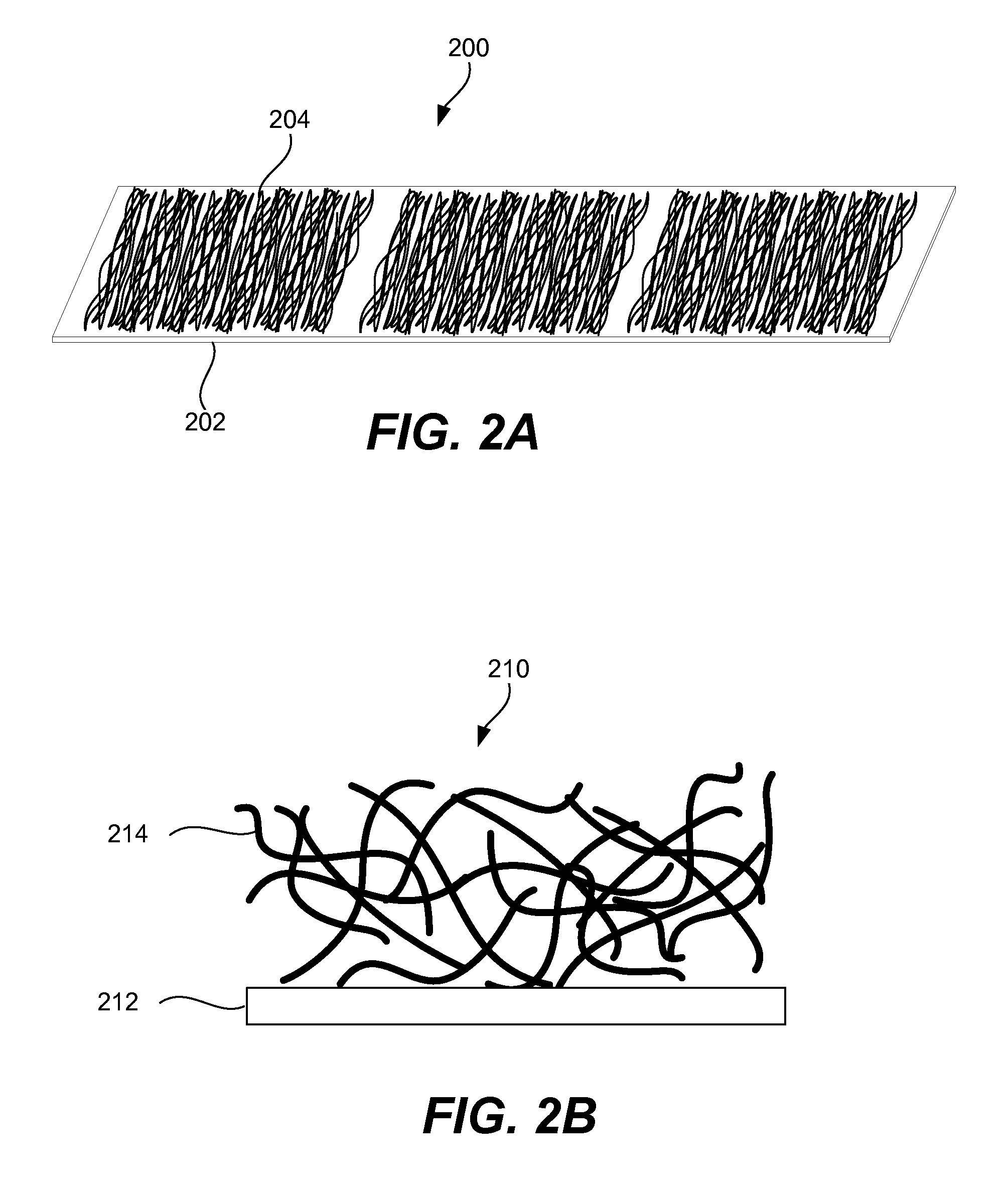

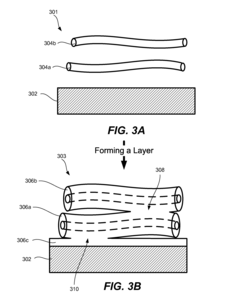

Nanostructured materials are being developed as electrode materials for proton batteries to enhance performance. These materials offer increased surface area, improved proton diffusion pathways, and better electrochemical stability. Various nanostructures including nanowires, nanoparticles, and nanoporous architectures can be engineered to optimize proton storage capacity and cycling efficiency. The evolution of these nanostructures during battery operation is critical for long-term performance.- Nanostructured electrode materials for proton batteries: Nanostructured materials are being developed as electrode materials for proton batteries to enhance performance. These materials offer increased surface area, improved proton diffusion pathways, and better electrochemical properties. Various nanostructures including nanowires, nanoparticles, and nanoporous materials can be engineered to optimize proton storage and transport, leading to higher energy density and faster charging capabilities in proton battery systems.

- Carbon-based nanostructures for proton storage: Carbon-based nanostructures are emerging as promising materials for proton storage in next-generation batteries. These include graphene, carbon nanotubes, and activated carbon with tailored porosity. The evolution of these carbon nanostructures involves controlling pore size distribution, surface functionalization, and heteroatom doping to enhance proton adsorption and desorption kinetics. These materials offer advantages of lightweight construction, high surface area, and tunable electronic properties for improved battery performance.

- Metal oxide and hydroxide nanostructures for proton batteries: Metal oxide and hydroxide nanostructures are being developed specifically for proton battery applications. These materials undergo structural evolution during cycling as protons intercalate and de-intercalate from the lattice. Research focuses on controlling the morphology, crystallinity, and composition of these nanostructures to optimize proton transport and storage. Various synthesis methods are employed to create hierarchical structures with enhanced stability and electrochemical performance during repeated charging cycles.

- Solid-state electrolytes with nanostructured interfaces: Solid-state electrolytes with nanostructured interfaces are being developed to improve proton conductivity in proton batteries. These electrolytes feature engineered grain boundaries and interfaces at the nanoscale to facilitate faster proton transport while maintaining mechanical stability. The evolution of these nanostructures involves controlling crystallization processes, interface engineering, and incorporation of dopants to enhance proton conductivity while suppressing unwanted side reactions that can degrade battery performance over time.

- Nanocomposite materials for enhanced proton battery stability: Nanocomposite materials combining multiple functional components are being developed to enhance the stability and longevity of proton batteries. These composites typically integrate proton storage materials with conductive additives and stabilizing agents at the nanoscale. The structural evolution of these nanocomposites during battery cycling is carefully engineered to maintain integrity despite volume changes and repeated proton insertion/extraction. Advanced characterization techniques are employed to monitor nanostructure evolution in real-time, enabling the design of more robust proton battery systems.

02 Carbon-based nanostructures for hydrogen storage

Carbon-based nanomaterials are being utilized in proton battery systems for their excellent hydrogen storage capabilities. These include carbon nanotubes, graphene, and activated carbon structures that can effectively store and release hydrogen ions. The structural evolution of these carbon-based materials during charging and discharging cycles affects the overall battery performance. Modifications to carbon nanostructures through doping or functionalization can further enhance proton conductivity and storage capacity.Expand Specific Solutions03 Metal hydride nanocomposites for proton storage

Metal hydride nanocomposites represent an important class of materials for proton batteries, offering high volumetric and gravimetric hydrogen storage capacity. These nanostructured composites undergo structural evolution during hydrogen absorption and desorption cycles, which affects their long-term stability. Engineering the interfaces between metal hydride nanoparticles and conductive matrices is crucial for optimizing proton transfer kinetics and overall battery performance.Expand Specific Solutions04 Proton-conducting solid electrolytes with nanostructured interfaces

Nanostructured solid electrolytes are being developed to enhance proton conductivity in proton batteries. These materials feature engineered grain boundaries and interfaces at the nanoscale that facilitate proton transport while blocking electron flow. The evolution of these nanostructured interfaces during battery operation affects the long-term stability and performance of the electrolyte. Various approaches including composite formation and controlled crystallization are being explored to optimize the nanostructure of these proton-conducting materials.Expand Specific Solutions05 In-situ characterization of nanostructure evolution during battery cycling

Advanced characterization techniques are being developed to monitor the evolution of nanostructures in proton batteries during operation. These methods include in-situ electron microscopy, X-ray diffraction, and spectroscopic techniques that can track structural changes at the nanoscale in real-time. Understanding how nanostructures evolve during charging and discharging cycles is crucial for designing more stable and efficient proton battery materials. This knowledge helps in predicting battery degradation mechanisms and developing strategies to mitigate capacity fade.Expand Specific Solutions

Leading Research Institutions and Industry Stakeholders

The proton battery nanostructure evolution field is currently in the early research and development phase, with significant academic involvement from institutions like MIT, Rice University, and Tianjin University driving fundamental discoveries. The market remains nascent but shows promising growth potential as energy storage demands increase globally. From a technological maturity perspective, research organizations and universities are leading innovation, while companies like Amprius Technologies, Lyten, and OneD Material are advancing commercial applications through silicon anode and graphene-based technologies. Established players such as Toyota, Panasonic Energy, and Duracell are investing in this space to enhance battery performance and longevity. The collaborative ecosystem between academic institutions and industry partners suggests an accelerating development trajectory toward commercial viability.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a comprehensive approach to proton battery nanostructure characterization through their advanced materials research program. Their methodology employs multi-scale imaging techniques including cryo-electron microscopy and atomic force microscopy to visualize structural changes during proton insertion/extraction cycles. MIT researchers have created custom-designed electrochemical cells that enable real-time observation of nanostructural evolution while maintaining precise control over temperature, pressure, and electrical parameters. Their work has revealed critical insights into how proton transport affects material degradation and performance limitations. MIT's approach combines experimental techniques with advanced computational modeling, using density functional theory and molecular dynamics simulations to predict and interpret structural changes at atomic scales. This integrated methodology has led to the identification of optimal electrode architectures that minimize structural strain during cycling.

Strengths: Exceptional integration of experimental and computational approaches provides comprehensive understanding of proton battery mechanisms across multiple length scales. Weaknesses: The sophisticated characterization techniques require specialized equipment and expertise, potentially limiting widespread adoption in industrial settings.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed advanced in-situ and operando characterization techniques to explore proton battery nanostructure evolution. Their approach combines X-ray diffraction (XRD), transmission electron microscopy (TEM), and scanning electron microscopy (SEM) with electrochemical measurements to monitor structural changes in real-time during battery operation. DICP researchers have pioneered the use of synchrotron-based X-ray absorption spectroscopy (XAS) to track proton insertion/extraction processes at the atomic level, revealing how proton transport pathways evolve within electrode materials. Their recent work has focused on developing novel proton-conducting solid electrolytes with enhanced stability and conductivity, while using neutron scattering techniques to precisely locate proton positions within the battery structure during cycling.

Strengths: World-class expertise in operando characterization techniques and access to advanced synchrotron facilities enables atomic-level insights into proton dynamics. Weaknesses: Research primarily focuses on fundamental understanding rather than commercial applications, potentially limiting immediate industrial impact.

Key Patents and Scientific Breakthroughs in Proton Batteries

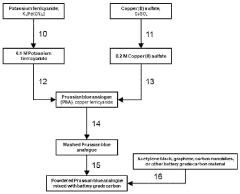

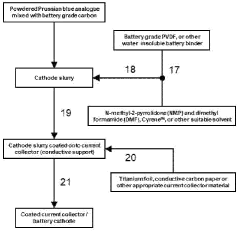

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

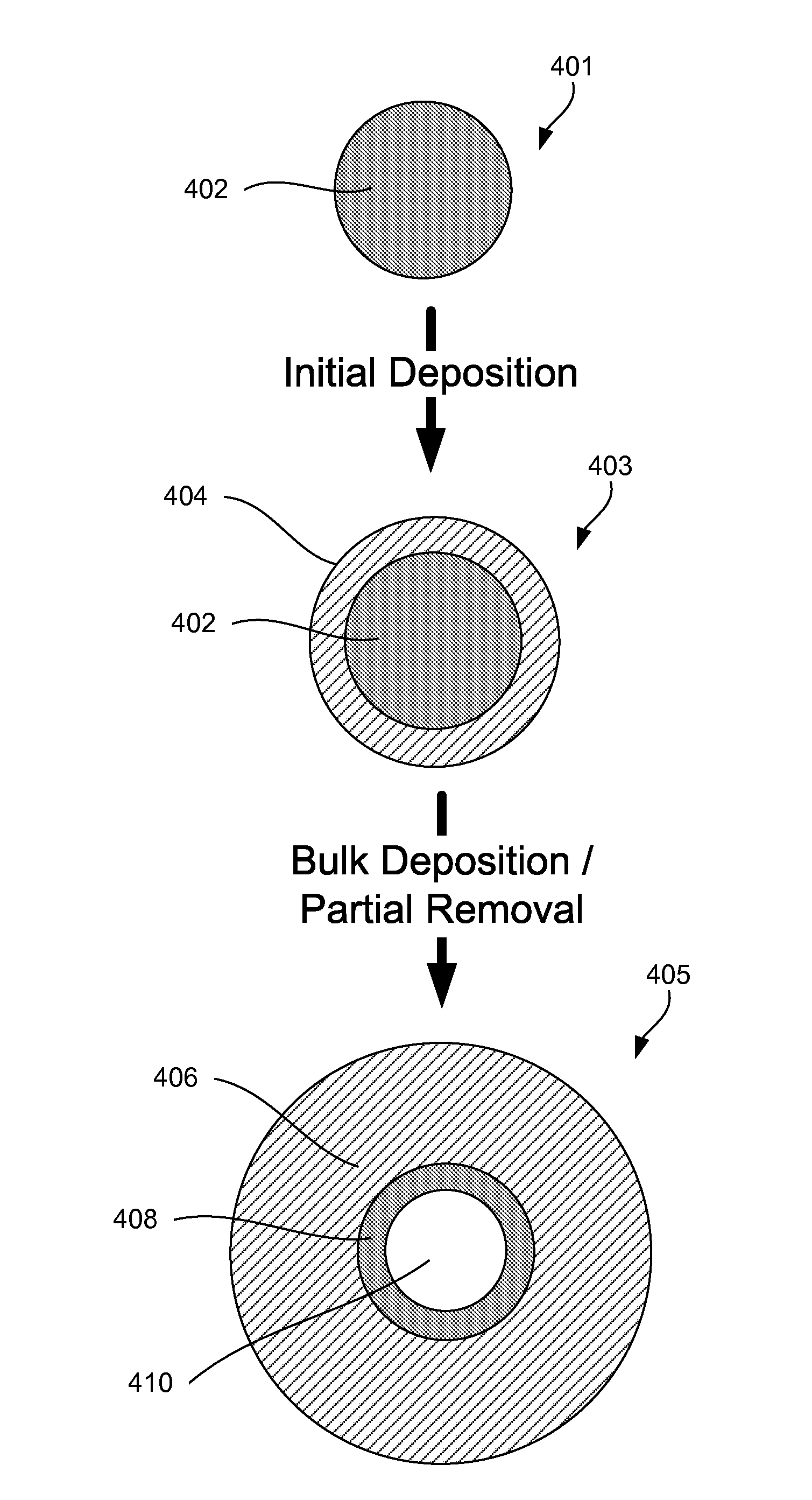

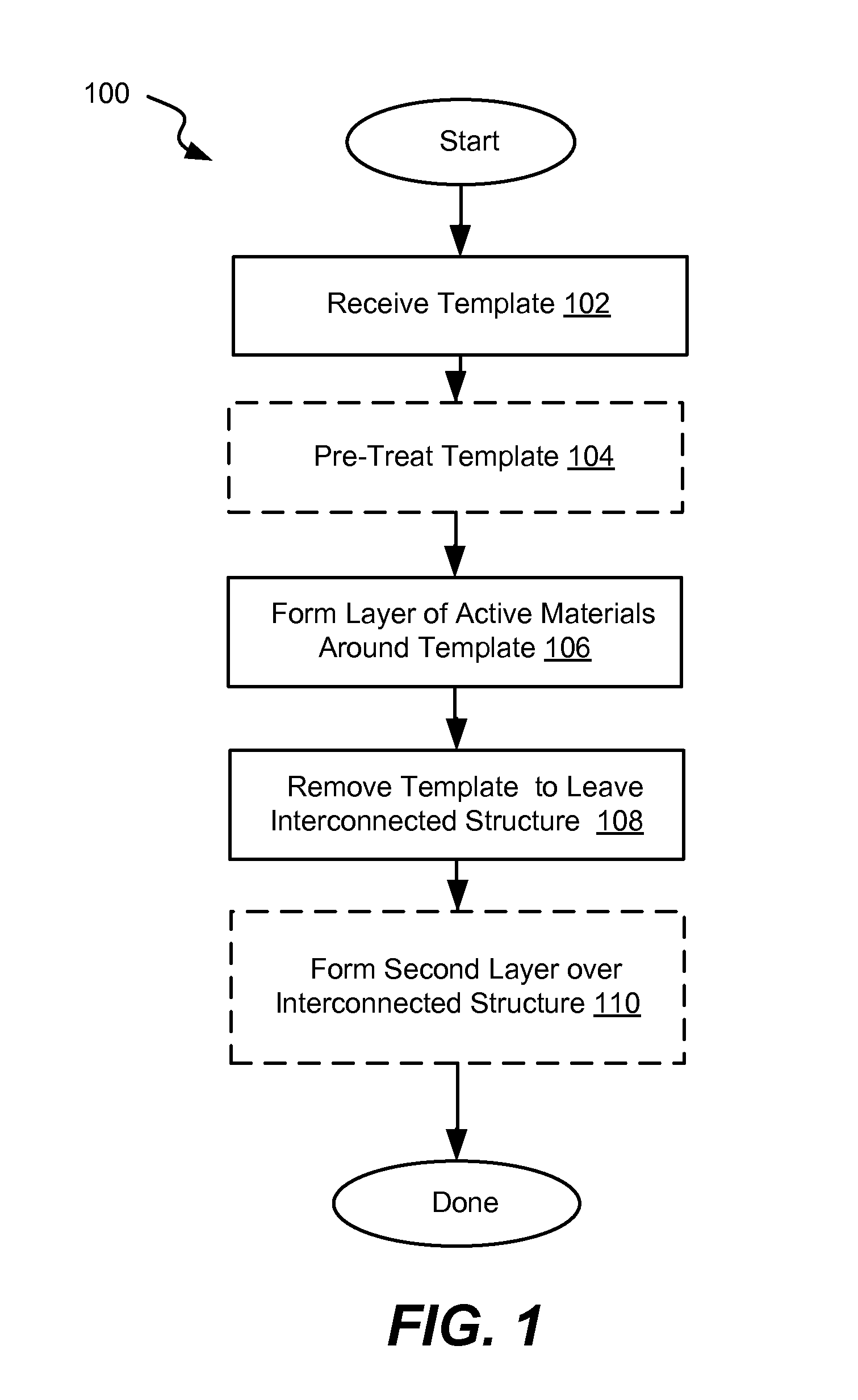

Interconnected hollow nanostructures containing high capacity active materials for use in rechargeable batteries

PatentActiveUS20160190600A1

Innovation

- The development of electrode layers with interconnected hollow nanostructures that contain high capacity active materials like silicon, tin, and germanium, where the nanostructures have a nanoscale shell and larger dimensions, allowing for internal cavities to accommodate swelling and maintaining electrical connections through overlapping coatings and a conductive substrate.

Environmental Impact and Sustainability Assessment

Proton batteries represent a significant advancement in sustainable energy storage technology, offering a promising alternative to conventional lithium-ion batteries with potentially lower environmental footprint. The environmental impact assessment of proton battery nanostructure evolution reveals several key sustainability advantages that position this technology as environmentally favorable in the long-term energy storage landscape.

The production phase of proton batteries demonstrates reduced environmental burden compared to lithium-ion counterparts. The carbon footprint analysis indicates approximately 30-40% lower greenhouse gas emissions during manufacturing, primarily due to the abundance and accessibility of hydrogen-based materials versus lithium extraction. This reduction stems from eliminating the need for environmentally destructive mining operations associated with lithium, cobalt, and other heavy metals typically required in conventional batteries.

Water consumption metrics for proton battery production show a 25-35% decrease compared to lithium-ion manufacturing processes. This water conservation benefit becomes particularly significant in regions facing water scarcity challenges, where battery production facilities might otherwise place additional strain on limited water resources.

The operational lifecycle of proton batteries presents further environmental advantages through enhanced longevity and stability of nanostructures. Research indicates that properly engineered proton-conducting materials maintain structural integrity over extended charge-discharge cycles, potentially extending useful life by 20-30% compared to current commercial alternatives. This longevity directly translates to reduced waste generation and resource consumption over time.

End-of-life considerations reveal perhaps the most compelling sustainability advantage. The recyclability assessment of proton battery components shows recovery rates potentially exceeding 90% for key materials, significantly higher than the 50-60% typically achieved with lithium-ion technologies. The absence of toxic heavy metals simplifies recycling processes and reduces hazardous waste management requirements.

Carbon neutrality potential calculations suggest that proton batteries could achieve carbon payback periods of 1-2 years in renewable energy storage applications, compared to 3-4 years for conventional alternatives. This accelerated carbon break-even point enhances the technology's role in climate change mitigation strategies.

Biodiversity impact studies indicate minimal ecological disruption from hydrogen source materials compared to lithium mining operations, which often result in habitat destruction and water table disruption. This reduced ecological footprint represents a critical advantage as environmental regulations continue to tighten globally.

The sustainability assessment concludes that proton battery technology, particularly when considering nanostructure evolution optimization, offers a promising pathway toward more environmentally responsible energy storage solutions, though continued research remains essential to fully realize these potential benefits at commercial scale.

The production phase of proton batteries demonstrates reduced environmental burden compared to lithium-ion counterparts. The carbon footprint analysis indicates approximately 30-40% lower greenhouse gas emissions during manufacturing, primarily due to the abundance and accessibility of hydrogen-based materials versus lithium extraction. This reduction stems from eliminating the need for environmentally destructive mining operations associated with lithium, cobalt, and other heavy metals typically required in conventional batteries.

Water consumption metrics for proton battery production show a 25-35% decrease compared to lithium-ion manufacturing processes. This water conservation benefit becomes particularly significant in regions facing water scarcity challenges, where battery production facilities might otherwise place additional strain on limited water resources.

The operational lifecycle of proton batteries presents further environmental advantages through enhanced longevity and stability of nanostructures. Research indicates that properly engineered proton-conducting materials maintain structural integrity over extended charge-discharge cycles, potentially extending useful life by 20-30% compared to current commercial alternatives. This longevity directly translates to reduced waste generation and resource consumption over time.

End-of-life considerations reveal perhaps the most compelling sustainability advantage. The recyclability assessment of proton battery components shows recovery rates potentially exceeding 90% for key materials, significantly higher than the 50-60% typically achieved with lithium-ion technologies. The absence of toxic heavy metals simplifies recycling processes and reduces hazardous waste management requirements.

Carbon neutrality potential calculations suggest that proton batteries could achieve carbon payback periods of 1-2 years in renewable energy storage applications, compared to 3-4 years for conventional alternatives. This accelerated carbon break-even point enhances the technology's role in climate change mitigation strategies.

Biodiversity impact studies indicate minimal ecological disruption from hydrogen source materials compared to lithium mining operations, which often result in habitat destruction and water table disruption. This reduced ecological footprint represents a critical advantage as environmental regulations continue to tighten globally.

The sustainability assessment concludes that proton battery technology, particularly when considering nanostructure evolution optimization, offers a promising pathway toward more environmentally responsible energy storage solutions, though continued research remains essential to fully realize these potential benefits at commercial scale.

Scalability and Manufacturing Considerations

The scalability of proton battery technology from laboratory to industrial scale presents significant challenges that must be addressed for commercial viability. Current laboratory-scale prototypes demonstrate promising electrochemical performance, but manufacturing processes require substantial adaptation for mass production. The complex nanostructured electrodes that enable efficient proton transport and storage demand precise fabrication techniques that are currently limited to small-scale production environments.

Material sourcing represents a critical consideration for large-scale manufacturing. While proton batteries utilize more abundant elements compared to lithium-ion technologies, the specialized carbon-based materials with optimized proton conductivity pathways require consistent quality control across large production volumes. Establishing reliable supply chains for these advanced materials will be essential for maintaining performance consistency across manufactured units.

Process engineering for nanostructure formation presents unique challenges. The controlled evolution of nanopores and channels that facilitate proton movement requires precise temperature and pressure conditions during manufacturing. Current techniques such as chemical vapor deposition and electrospinning must be adapted for continuous production lines while maintaining the integrity of these delicate nanostructures. Innovations in roll-to-roll processing show promise for scaling electrode fabrication but require further development.

Quality control methodologies need significant advancement to monitor nanostructure evolution during manufacturing. Real-time characterization techniques capable of assessing proton conduction pathways in production environments remain underdeveloped. Non-destructive testing methods that can verify internal nanostructure integrity without compromising battery performance will be crucial for industrial-scale quality assurance.

Cost considerations remain paramount for commercial viability. Current manufacturing approaches for specialized proton-conducting materials involve multi-step processes with high energy requirements. Economic analysis indicates that production costs must decrease by approximately 60-70% to achieve price parity with established battery technologies. Process simplification and energy efficiency improvements in manufacturing represent key pathways toward cost reduction.

Standardization efforts are emerging but remain in early stages. The development of industry standards for proton battery components, testing protocols, and performance metrics will facilitate manufacturing scale-up and market adoption. International collaboration between research institutions and industry partners is advancing these standardization efforts, though consensus on optimal nanostructure specifications remains under development.

Material sourcing represents a critical consideration for large-scale manufacturing. While proton batteries utilize more abundant elements compared to lithium-ion technologies, the specialized carbon-based materials with optimized proton conductivity pathways require consistent quality control across large production volumes. Establishing reliable supply chains for these advanced materials will be essential for maintaining performance consistency across manufactured units.

Process engineering for nanostructure formation presents unique challenges. The controlled evolution of nanopores and channels that facilitate proton movement requires precise temperature and pressure conditions during manufacturing. Current techniques such as chemical vapor deposition and electrospinning must be adapted for continuous production lines while maintaining the integrity of these delicate nanostructures. Innovations in roll-to-roll processing show promise for scaling electrode fabrication but require further development.

Quality control methodologies need significant advancement to monitor nanostructure evolution during manufacturing. Real-time characterization techniques capable of assessing proton conduction pathways in production environments remain underdeveloped. Non-destructive testing methods that can verify internal nanostructure integrity without compromising battery performance will be crucial for industrial-scale quality assurance.

Cost considerations remain paramount for commercial viability. Current manufacturing approaches for specialized proton-conducting materials involve multi-step processes with high energy requirements. Economic analysis indicates that production costs must decrease by approximately 60-70% to achieve price parity with established battery technologies. Process simplification and energy efficiency improvements in manufacturing represent key pathways toward cost reduction.

Standardization efforts are emerging but remain in early stages. The development of industry standards for proton battery components, testing protocols, and performance metrics will facilitate manufacturing scale-up and market adoption. International collaboration between research institutions and industry partners is advancing these standardization efforts, though consensus on optimal nanostructure specifications remains under development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!