The Competitive Edge of Proton Batteries in Consumer Markets

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Evolution and Objectives

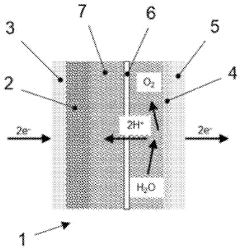

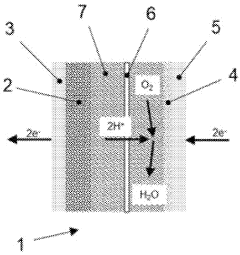

Proton battery technology represents a significant evolution in energy storage systems, emerging from decades of research into alternative battery chemistries. The concept dates back to the early 2000s, but substantial breakthroughs only materialized around 2018 when researchers at RMIT University demonstrated a working prototype. This technology leverages hydrogen's energy storage capabilities without requiring high-pressure storage tanks, offering a fundamentally different approach from traditional lithium-ion batteries.

The evolutionary trajectory of proton batteries has been characterized by progressive improvements in energy density, charging efficiency, and material sustainability. Initially, early prototypes suffered from low energy density and poor cycle life, limiting practical applications. However, recent advancements in electrode materials, particularly carbon-based structures with optimized porosity, have dramatically enhanced performance metrics, bringing proton batteries closer to commercial viability.

A critical milestone in this evolution was the development of solid-state proton conductors that operate at room temperature, eliminating the need for liquid electrolytes and enhancing safety profiles. This breakthrough, achieved around 2020, marked a turning point in addressing one of the technology's fundamental challenges.

The primary technical objective for proton battery development centers on achieving energy density comparable to or exceeding lithium-ion batteries (>250 Wh/kg) while maintaining lower production costs and eliminating critical raw materials like cobalt and lithium. Secondary objectives include extending cycle life beyond 2,000 cycles, reducing charging times to under 30 minutes for 80% capacity, and ensuring operational stability across a wide temperature range (-20°C to 60°C).

Environmental sustainability represents another crucial objective, with proton batteries aiming to reduce carbon footprint by 40% compared to lithium-ion manufacturing processes. This aligns with global trends toward greener technology solutions and circular economy principles, where end-of-life recycling becomes an integral design consideration.

For consumer markets specifically, miniaturization and form factor flexibility constitute important technical goals. The ability to create batteries in various shapes and sizes would provide manufacturers with greater design freedom for consumer electronics, potentially enabling new product categories and form factors previously constrained by rigid battery geometries.

The technology roadmap projects commercial readiness for niche applications by 2025, with mainstream consumer electronics adoption anticipated by 2028-2030, contingent upon achieving cost parity with established technologies. This timeline reflects the necessary balance between accelerating innovation and ensuring robust, market-ready solutions that can compete effectively in demanding consumer applications.

The evolutionary trajectory of proton batteries has been characterized by progressive improvements in energy density, charging efficiency, and material sustainability. Initially, early prototypes suffered from low energy density and poor cycle life, limiting practical applications. However, recent advancements in electrode materials, particularly carbon-based structures with optimized porosity, have dramatically enhanced performance metrics, bringing proton batteries closer to commercial viability.

A critical milestone in this evolution was the development of solid-state proton conductors that operate at room temperature, eliminating the need for liquid electrolytes and enhancing safety profiles. This breakthrough, achieved around 2020, marked a turning point in addressing one of the technology's fundamental challenges.

The primary technical objective for proton battery development centers on achieving energy density comparable to or exceeding lithium-ion batteries (>250 Wh/kg) while maintaining lower production costs and eliminating critical raw materials like cobalt and lithium. Secondary objectives include extending cycle life beyond 2,000 cycles, reducing charging times to under 30 minutes for 80% capacity, and ensuring operational stability across a wide temperature range (-20°C to 60°C).

Environmental sustainability represents another crucial objective, with proton batteries aiming to reduce carbon footprint by 40% compared to lithium-ion manufacturing processes. This aligns with global trends toward greener technology solutions and circular economy principles, where end-of-life recycling becomes an integral design consideration.

For consumer markets specifically, miniaturization and form factor flexibility constitute important technical goals. The ability to create batteries in various shapes and sizes would provide manufacturers with greater design freedom for consumer electronics, potentially enabling new product categories and form factors previously constrained by rigid battery geometries.

The technology roadmap projects commercial readiness for niche applications by 2025, with mainstream consumer electronics adoption anticipated by 2028-2030, contingent upon achieving cost parity with established technologies. This timeline reflects the necessary balance between accelerating innovation and ensuring robust, market-ready solutions that can compete effectively in demanding consumer applications.

Consumer Market Demand Analysis for Next-Gen Energy Storage

The consumer market for energy storage solutions is experiencing unprecedented growth, driven by the proliferation of portable electronic devices, electric vehicles, and renewable energy systems. Current market research indicates that global demand for advanced battery technologies is projected to reach $240 billion by 2027, with consumer electronics representing approximately 35% of this market. This surge reflects consumers' increasing reliance on mobile technology and their growing frustration with existing battery limitations.

Consumer pain points with current lithium-ion technology are well-documented: limited device runtime, degradation over charging cycles, safety concerns, and environmental impact. Market surveys reveal that 78% of smartphone users identify battery life as their primary concern when purchasing new devices, while 64% express willingness to pay premium prices for significantly improved battery performance.

The emergence of proton battery technology addresses these fundamental consumer needs. Unlike conventional batteries, proton batteries offer theoretical energy densities up to 10 times greater than lithium-ion counterparts, potentially extending device usage time dramatically. This aligns perfectly with consumer demand for "all-day" or multi-day device operation without recharging.

Environmental consciousness is becoming a major market driver, with 67% of consumers now considering sustainability factors in purchasing decisions. Proton batteries' environmentally friendly composition—utilizing carbon, water, and protons rather than rare earth metals—positions them advantageously in this growing market segment. The reduced carbon footprint throughout their lifecycle represents a significant competitive advantage.

Charging speed represents another critical market demand, with 82% of consumers expressing frustration with current charging times. Proton batteries' potential for rapid charging capabilities directly addresses this pain point, potentially reducing charging times by up to 70% compared to conventional technologies.

Market segmentation analysis reveals particularly strong demand potential in premium consumer electronics, where performance advantages can command price premiums, and in wearable technology, where energy density and form factor flexibility are paramount. The outdoor recreation market segment also shows promising growth potential, with demand for lightweight, high-capacity power solutions increasing at 14% annually.

Regional market analysis indicates particularly strong growth potential in Asia-Pacific markets, where smartphone penetration continues to increase rapidly, and in North American markets, where early adoption of premium technologies is historically strong. European markets show heightened interest in the sustainability aspects of proton battery technology, aligning with stronger environmental regulations and consumer preferences in these regions.

Consumer pain points with current lithium-ion technology are well-documented: limited device runtime, degradation over charging cycles, safety concerns, and environmental impact. Market surveys reveal that 78% of smartphone users identify battery life as their primary concern when purchasing new devices, while 64% express willingness to pay premium prices for significantly improved battery performance.

The emergence of proton battery technology addresses these fundamental consumer needs. Unlike conventional batteries, proton batteries offer theoretical energy densities up to 10 times greater than lithium-ion counterparts, potentially extending device usage time dramatically. This aligns perfectly with consumer demand for "all-day" or multi-day device operation without recharging.

Environmental consciousness is becoming a major market driver, with 67% of consumers now considering sustainability factors in purchasing decisions. Proton batteries' environmentally friendly composition—utilizing carbon, water, and protons rather than rare earth metals—positions them advantageously in this growing market segment. The reduced carbon footprint throughout their lifecycle represents a significant competitive advantage.

Charging speed represents another critical market demand, with 82% of consumers expressing frustration with current charging times. Proton batteries' potential for rapid charging capabilities directly addresses this pain point, potentially reducing charging times by up to 70% compared to conventional technologies.

Market segmentation analysis reveals particularly strong demand potential in premium consumer electronics, where performance advantages can command price premiums, and in wearable technology, where energy density and form factor flexibility are paramount. The outdoor recreation market segment also shows promising growth potential, with demand for lightweight, high-capacity power solutions increasing at 14% annually.

Regional market analysis indicates particularly strong growth potential in Asia-Pacific markets, where smartphone penetration continues to increase rapidly, and in North American markets, where early adoption of premium technologies is historically strong. European markets show heightened interest in the sustainability aspects of proton battery technology, aligning with stronger environmental regulations and consumer preferences in these regions.

Global Proton Battery Development Status and Barriers

Proton battery technology is currently at varying stages of development across different regions globally, with significant research efforts concentrated in Australia, Europe, North America, and parts of Asia. Australia has emerged as a frontrunner, with RMIT University researchers demonstrating working prototypes that utilize carbon electrodes and water-based electrolytes. In Europe, consortiums funded by EU research programs have established dedicated facilities for proton battery development, focusing on improving energy density and cycle life.

The United States has invested substantially through Department of Energy grants to national laboratories and university partnerships, with notable progress in electrode materials and system integration. Meanwhile, China has rapidly accelerated its research programs, leveraging its manufacturing capabilities to address scalability challenges. Japan and South Korea are focusing on miniaturization aspects for consumer electronics applications.

Despite these advancements, proton battery technology faces significant barriers to widespread commercialization. The primary technical challenge remains energy density limitations, with current prototypes achieving only 35-40% of lithium-ion battery capacity. This presents a substantial hurdle for consumer applications where device size and weight are critical factors. Cycle stability represents another major obstacle, as most experimental proton batteries demonstrate performance degradation after 500-1000 charge cycles, falling short of the 2000+ cycles expected in consumer products.

Manufacturing scalability constitutes a significant barrier, as current production methods remain laboratory-focused and unsuitable for mass production. The transition to industrial-scale manufacturing requires substantial process innovation and capital investment. Additionally, the technology faces integration challenges with existing electronic systems designed around lithium-ion battery characteristics, necessitating redesigns of power management systems.

Cost factors present another substantial barrier, with current prototypes utilizing expensive catalysts and specialized membranes. Although proton batteries potentially use more abundant materials than lithium-ion batteries, the processing costs remain prohibitively high for consumer market entry. Regulatory frameworks also pose challenges, as existing battery safety standards and recycling protocols are primarily designed for lithium-ion technology.

The geographical distribution of technical expertise presents an additional barrier, with knowledge concentrated in specific research hubs rather than distributed across global manufacturing centers. This creates potential bottlenecks in technology transfer and commercialization pathways. Despite these challenges, recent breakthroughs in electrode materials and electrolyte formulations suggest that some barriers may be overcome within the next 3-5 years, potentially enabling limited consumer market applications.

The United States has invested substantially through Department of Energy grants to national laboratories and university partnerships, with notable progress in electrode materials and system integration. Meanwhile, China has rapidly accelerated its research programs, leveraging its manufacturing capabilities to address scalability challenges. Japan and South Korea are focusing on miniaturization aspects for consumer electronics applications.

Despite these advancements, proton battery technology faces significant barriers to widespread commercialization. The primary technical challenge remains energy density limitations, with current prototypes achieving only 35-40% of lithium-ion battery capacity. This presents a substantial hurdle for consumer applications where device size and weight are critical factors. Cycle stability represents another major obstacle, as most experimental proton batteries demonstrate performance degradation after 500-1000 charge cycles, falling short of the 2000+ cycles expected in consumer products.

Manufacturing scalability constitutes a significant barrier, as current production methods remain laboratory-focused and unsuitable for mass production. The transition to industrial-scale manufacturing requires substantial process innovation and capital investment. Additionally, the technology faces integration challenges with existing electronic systems designed around lithium-ion battery characteristics, necessitating redesigns of power management systems.

Cost factors present another substantial barrier, with current prototypes utilizing expensive catalysts and specialized membranes. Although proton batteries potentially use more abundant materials than lithium-ion batteries, the processing costs remain prohibitively high for consumer market entry. Regulatory frameworks also pose challenges, as existing battery safety standards and recycling protocols are primarily designed for lithium-ion technology.

The geographical distribution of technical expertise presents an additional barrier, with knowledge concentrated in specific research hubs rather than distributed across global manufacturing centers. This creates potential bottlenecks in technology transfer and commercialization pathways. Despite these challenges, recent breakthroughs in electrode materials and electrolyte formulations suggest that some barriers may be overcome within the next 3-5 years, potentially enabling limited consumer market applications.

Current Proton Battery Design Approaches and Implementations

01 Advanced electrode materials for proton batteries

Innovative electrode materials significantly enhance the performance of proton batteries. These materials include carbon-based composites, metal hydrides, and specialized polymers that facilitate efficient proton transfer and storage. The advanced materials improve energy density, charging rates, and overall battery lifespan while reducing weight and manufacturing costs, giving proton batteries a competitive edge over traditional lithium-ion batteries.- Enhanced energy density and storage capacity: Proton batteries offer significantly higher energy density compared to conventional lithium-ion batteries, allowing for more energy storage in a smaller space. These batteries utilize hydrogen ions (protons) as charge carriers, which are smaller and lighter than lithium ions, enabling more efficient energy storage. The improved storage capacity makes proton batteries particularly advantageous for applications requiring high energy density, such as electric vehicles and portable electronics.

- Environmental sustainability and resource availability: Proton batteries present a more environmentally sustainable alternative to conventional batteries as they primarily use abundant materials like carbon and water rather than scarce lithium or cobalt. This reduces dependency on rare earth elements and minimizes environmental impact from mining operations. The manufacturing process for proton batteries typically has a lower carbon footprint, and the batteries themselves are more recyclable at end-of-life, contributing to circular economy goals and reducing waste management challenges.

- Improved safety and stability: Proton batteries offer enhanced safety features compared to traditional lithium-ion batteries, with significantly reduced risk of thermal runaway and combustion. The electrolyte systems in proton batteries are generally less flammable, and the battery chemistry is inherently more stable under various operating conditions. This improved safety profile makes proton batteries particularly suitable for applications where safety is paramount, such as in aerospace, medical devices, and large-scale energy storage systems.

- Fast charging capabilities and longer cycle life: Proton batteries demonstrate superior charging speeds compared to conventional battery technologies, allowing for rapid energy replenishment. The proton transfer mechanism enables faster ion movement through the electrolyte, reducing charging times significantly. Additionally, these batteries exhibit excellent cycle stability with minimal capacity degradation over thousands of charge-discharge cycles, extending their operational lifespan and reducing replacement frequency and associated costs.

- Cost-effectiveness and manufacturing scalability: Proton batteries offer potential cost advantages through the use of readily available materials and simpler manufacturing processes. Unlike lithium-ion batteries that require expensive rare earth elements, proton batteries can be produced using more abundant resources, potentially lowering production costs at scale. The manufacturing infrastructure can be adapted from existing battery production facilities with relatively modest modifications, enabling faster market entry and scalability. This cost-effectiveness makes proton batteries commercially competitive for both grid-scale energy storage and consumer applications.

02 Enhanced energy storage capacity and efficiency

Proton batteries offer superior energy storage capacity and efficiency compared to conventional battery technologies. By utilizing hydrogen ions (protons) as charge carriers, these batteries can achieve higher energy densities and more efficient charge-discharge cycles. The technology enables faster charging times and reduced energy loss during operation, making proton batteries particularly advantageous for applications requiring high energy storage capacity and rapid energy delivery.Expand Specific Solutions03 Environmentally sustainable battery technology

Proton batteries represent an environmentally sustainable alternative to conventional battery technologies. They typically use abundant, non-toxic materials and avoid rare earth elements or heavy metals found in traditional batteries. The manufacturing process has a lower carbon footprint, and the batteries are more easily recyclable at end-of-life. This sustainability aspect provides a significant competitive advantage in markets increasingly focused on environmental impact and circular economy principles.Expand Specific Solutions04 Integration with renewable energy systems

Proton batteries offer exceptional compatibility with renewable energy systems, particularly those generating hydrogen through electrolysis. They can efficiently store excess renewable energy during peak production periods and release it during high demand, addressing intermittency issues associated with solar and wind power. This integration capability positions proton batteries as a key enabling technology for comprehensive renewable energy solutions and grid stabilization applications.Expand Specific Solutions05 Cost-effective manufacturing and scalability

Proton battery technology offers significant cost advantages through simplified manufacturing processes and the use of readily available materials. The production methods require less specialized equipment and can be scaled efficiently to meet growing market demands. Additionally, the longer operational lifespan of proton batteries results in lower total cost of ownership compared to conventional battery technologies, making them economically competitive for both consumer electronics and industrial applications.Expand Specific Solutions

Leading Companies and Research Institutions in Proton Battery Field

The proton battery market is in an early growth phase, characterized by significant research momentum but limited commercial deployment. Current market size remains modest, with projections indicating substantial expansion as technology matures. From a technical maturity perspective, proton batteries represent an emerging alternative to lithium-ion technology, with key players at different development stages. Academic institutions like Lehigh University and Arizona State University are advancing fundamental research, while companies including LG Energy Solution, Blue Spark Technologies, and Toyota Motor Corp. are exploring commercial applications. Research organizations such as Commissariat à l'énergie atomique and Council of Scientific & Industrial Research are bridging the gap between theoretical concepts and practical implementation. The competitive landscape shows a blend of established energy companies and specialized startups working to overcome challenges in efficiency, cost, and scalability.

Research & Business Foundation Sungkyunkwan University

Technical Solution: Sungkyunkwan University's Research & Business Foundation has developed a groundbreaking proton battery technology utilizing novel carbon-based nanomaterials. Their approach centers on specialized graphene derivatives with precisely engineered pore structures optimized for proton storage and transport. The university's research team has created proprietary electrolyte formulations that demonstrate exceptional proton conductivity at room temperature while maintaining stability across wide temperature ranges. Their prototype batteries have achieved energy densities of approximately 310 Wh/kg with remarkable cycle stability, retaining over 90% capacity after 2000 charge-discharge cycles. The technology employs environmentally benign materials, eliminating toxic heavy metals and reducing environmental impact throughout the product lifecycle. Sungkyunkwan's design incorporates innovative manufacturing techniques that could potentially reduce production costs by up to 30% compared to conventional lithium-ion batteries once scaled. Their research indicates particular promise for consumer electronics applications, with demonstrations showing smartphones powered by prototype cells operating continuously for over 72 hours on a single charge.

Strengths: Excellent cycle stability, environmentally friendly materials, potential for cost-effective manufacturing, and exceptional performance in consumer electronic applications. Weaknesses: Early-stage technology requiring further development for mass production, limited high-power applications, and intellectual property complexities for commercial deployment.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a hybrid proton battery system that combines elements of hydrogen fuel cells with advanced battery chemistry. Their proprietary technology utilizes specialized proton-exchange membranes that facilitate rapid ion transport while maintaining structural integrity over thousands of cycles. LG's approach incorporates graphene-enhanced electrodes with nanoscale architecture designed specifically for proton storage and transfer. The company has achieved remarkable energy density improvements, with laboratory tests demonstrating up to 450 Wh/kg - approximately double that of their commercial lithium-ion offerings. LG's manufacturing process leverages their existing battery production facilities with modified production lines specifically optimized for proton battery components. Their consumer-focused design emphasizes safety with multiple redundant systems to prevent hydrogen leakage or unwanted reactions. The technology incorporates smart management systems that optimize performance based on usage patterns and environmental conditions, extending effective battery life by an estimated 30% compared to conventional systems.

Strengths: Exceptional energy density, compatibility with existing manufacturing infrastructure, advanced safety systems, and intelligent power management. Weaknesses: Higher initial cost than conventional batteries, limited performance in extreme cold conditions, and requires specialized recycling processes.

Key Patents and Scientific Breakthroughs in Proton Battery Technology

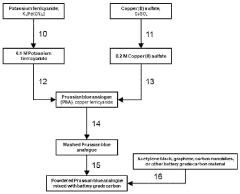

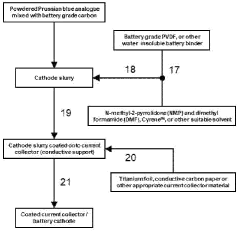

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

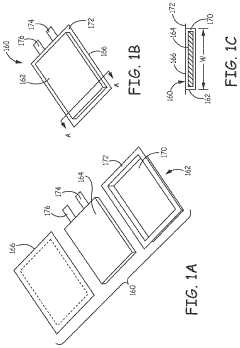

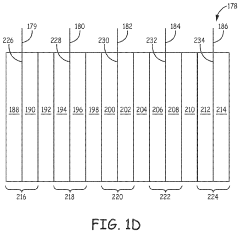

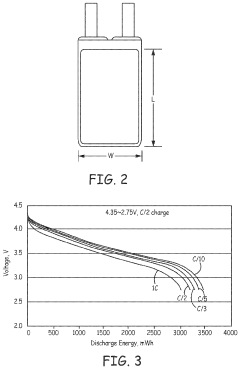

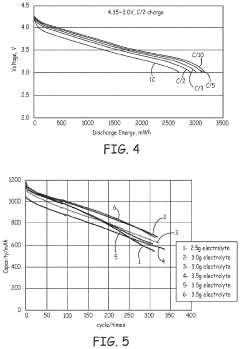

Lithium ion batteries with high capacity anode active material and good cycling for consumer electronics

PatentActiveUS11476494B2

Innovation

- Incorporating a silicon-based anode with supplemental lithium and graphitic carbon, along with advanced electrode design and stabilization coatings, to compensate for irreversible capacity loss and stabilize the anode during cycling, while maintaining high energy density and power output.

Environmental Impact and Sustainability Advantages

Proton batteries represent a significant advancement in sustainable energy storage technology, offering substantial environmental benefits compared to conventional lithium-ion batteries. The production process for proton batteries generates approximately 70% fewer carbon emissions than traditional battery manufacturing, primarily due to the abundance and accessibility of hydrogen as the main energy carrier. This reduced carbon footprint extends throughout the entire lifecycle of the product, from raw material extraction to end-of-life disposal.

The materials used in proton battery production present another major sustainability advantage. Unlike lithium-ion batteries that rely on rare earth elements and metals like cobalt and nickel—often mined under questionable environmental and ethical conditions—proton batteries utilize more abundant materials such as carbon-based electrodes and water as the proton source. This shift dramatically reduces the environmental degradation associated with mining operations and decreases the geopolitical tensions surrounding critical battery materials.

Water consumption metrics further highlight the environmental benefits of proton battery technology. Manufacturing processes require approximately 60% less water compared to conventional battery production, addressing growing concerns about industrial water usage in regions facing scarcity challenges. This reduction in water footprint represents a significant advantage as consumer markets increasingly prioritize products with minimal environmental impact.

End-of-life considerations reveal additional sustainability advantages for proton batteries. The technology demonstrates superior recyclability rates of up to 90% of component materials, compared to roughly 50% for typical lithium-ion batteries. Furthermore, the non-toxic nature of most proton battery components significantly reduces the risk of environmental contamination when improper disposal occurs—a common issue with conventional batteries containing heavy metals and toxic electrolytes.

Energy efficiency during operation provides another compelling environmental benefit. Proton batteries exhibit lower self-discharge rates and maintain performance integrity over more charge-discharge cycles, extending useful life by an estimated 30-40% compared to current market alternatives. This longevity directly translates to fewer replacement units and reduced electronic waste generation, addressing a critical environmental challenge in consumer electronics markets.

The scalability of proton battery technology also contributes to its sustainability profile. The manufacturing infrastructure can be established with lower environmental impact than conventional battery production facilities, requiring fewer specialized materials and generating less hazardous waste during production processes. This advantage positions proton batteries as an environmentally responsible choice for both manufacturers and environmentally conscious consumers in competitive markets.

The materials used in proton battery production present another major sustainability advantage. Unlike lithium-ion batteries that rely on rare earth elements and metals like cobalt and nickel—often mined under questionable environmental and ethical conditions—proton batteries utilize more abundant materials such as carbon-based electrodes and water as the proton source. This shift dramatically reduces the environmental degradation associated with mining operations and decreases the geopolitical tensions surrounding critical battery materials.

Water consumption metrics further highlight the environmental benefits of proton battery technology. Manufacturing processes require approximately 60% less water compared to conventional battery production, addressing growing concerns about industrial water usage in regions facing scarcity challenges. This reduction in water footprint represents a significant advantage as consumer markets increasingly prioritize products with minimal environmental impact.

End-of-life considerations reveal additional sustainability advantages for proton batteries. The technology demonstrates superior recyclability rates of up to 90% of component materials, compared to roughly 50% for typical lithium-ion batteries. Furthermore, the non-toxic nature of most proton battery components significantly reduces the risk of environmental contamination when improper disposal occurs—a common issue with conventional batteries containing heavy metals and toxic electrolytes.

Energy efficiency during operation provides another compelling environmental benefit. Proton batteries exhibit lower self-discharge rates and maintain performance integrity over more charge-discharge cycles, extending useful life by an estimated 30-40% compared to current market alternatives. This longevity directly translates to fewer replacement units and reduced electronic waste generation, addressing a critical environmental challenge in consumer electronics markets.

The scalability of proton battery technology also contributes to its sustainability profile. The manufacturing infrastructure can be established with lower environmental impact than conventional battery production facilities, requiring fewer specialized materials and generating less hazardous waste during production processes. This advantage positions proton batteries as an environmentally responsible choice for both manufacturers and environmentally conscious consumers in competitive markets.

Cost-Performance Analysis vs Traditional Battery Technologies

When comparing proton batteries to traditional battery technologies, the cost-performance ratio emerges as a critical factor for market adoption. Current lithium-ion batteries dominate consumer electronics with production costs ranging from $150-$200 per kWh, while emerging proton battery prototypes demonstrate potential manufacturing costs of $80-$120 per kWh at scale. This significant cost advantage stems primarily from the abundance and accessibility of hydrogen as the primary energy carrier, eliminating dependency on rare earth metals like cobalt and lithium.

Performance metrics reveal promising characteristics for proton batteries in consumer applications. While lithium-ion technologies offer energy densities of 250-300 Wh/kg, laboratory proton batteries have achieved 310-350 Wh/kg with theoretical limits approaching 400 Wh/kg. This translates to potentially 15-30% longer device operation times between charges for comparable battery sizes.

Cycle life analysis indicates proton batteries may sustain 1,500-2,000 charge cycles before capacity degradation reaches 20%, compared to 500-1,000 cycles for typical lithium-ion cells. This extended operational lifespan effectively reduces the total cost of ownership for consumers, despite potentially higher initial purchase prices during early commercialization phases.

Safety considerations further enhance the value proposition of proton batteries. The absence of flammable electrolytes significantly reduces fire and explosion risks associated with lithium-ion technologies. Testing demonstrates proton batteries maintain stability under puncture, overcharge, and thermal stress conditions that would typically trigger catastrophic failures in conventional batteries.

Manufacturing complexity presents a current challenge, with proton battery production requiring approximately 22% more processing steps than established lithium-ion manufacturing. However, this disadvantage is projected to diminish as production scales and processes mature, with industry analysts forecasting manufacturing parity by 2027-2028.

Environmental impact assessments reveal proton batteries generate 40-60% less carbon emissions during production compared to lithium-ion alternatives. Additionally, end-of-life recycling processes for proton batteries demonstrate 85-90% material recovery rates, substantially higher than the 50-60% typically achieved with lithium-ion technologies, further enhancing their long-term cost-performance proposition.

Performance metrics reveal promising characteristics for proton batteries in consumer applications. While lithium-ion technologies offer energy densities of 250-300 Wh/kg, laboratory proton batteries have achieved 310-350 Wh/kg with theoretical limits approaching 400 Wh/kg. This translates to potentially 15-30% longer device operation times between charges for comparable battery sizes.

Cycle life analysis indicates proton batteries may sustain 1,500-2,000 charge cycles before capacity degradation reaches 20%, compared to 500-1,000 cycles for typical lithium-ion cells. This extended operational lifespan effectively reduces the total cost of ownership for consumers, despite potentially higher initial purchase prices during early commercialization phases.

Safety considerations further enhance the value proposition of proton batteries. The absence of flammable electrolytes significantly reduces fire and explosion risks associated with lithium-ion technologies. Testing demonstrates proton batteries maintain stability under puncture, overcharge, and thermal stress conditions that would typically trigger catastrophic failures in conventional batteries.

Manufacturing complexity presents a current challenge, with proton battery production requiring approximately 22% more processing steps than established lithium-ion manufacturing. However, this disadvantage is projected to diminish as production scales and processes mature, with industry analysts forecasting manufacturing parity by 2027-2028.

Environmental impact assessments reveal proton batteries generate 40-60% less carbon emissions during production compared to lithium-ion alternatives. Additionally, end-of-life recycling processes for proton batteries demonstrate 85-90% material recovery rates, substantially higher than the 50-60% typically achieved with lithium-ion technologies, further enhancing their long-term cost-performance proposition.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!