Research and Development Focus for Proton Battery Technologies

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Evolution and Research Objectives

Proton batteries represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development of proton battery technology can be traced back to the early 2000s, with initial research focusing on proton exchange membranes and hydrogen storage materials. Over the past decade, research has intensified as scientists recognized the potential advantages of proton-based energy storage systems, including higher energy density, improved safety profiles, and reduced environmental impact.

The technological trajectory of proton batteries has been characterized by several key breakthroughs. Early iterations utilized metal hydrides as hydrogen storage media, while more recent developments have explored carbon-based materials and advanced polymer electrolytes. The transition from laboratory prototypes to scalable designs has been gradual but steady, with significant acceleration in research output observed since 2015.

Current research trends indicate a convergence of multiple disciplines, including materials science, electrochemistry, and nanotechnology, to address the fundamental challenges in proton battery development. The integration of computational modeling and high-throughput experimental techniques has enabled more rapid iteration and optimization of battery components.

The primary technical objectives for proton battery research include enhancing energy density to exceed 400 Wh/kg, improving cycle stability to achieve 2000+ charge-discharge cycles, and reducing charging times to under 30 minutes for 80% capacity. Additionally, researchers aim to develop proton batteries that operate efficiently across a wider temperature range (-20°C to 60°C) than current lithium-ion technologies.

From a materials perspective, key research goals include the development of high-capacity reversible hydrogen storage materials, stable and conductive electrolytes for proton transport, and cost-effective catalyst materials to facilitate the electrochemical reactions. Particular emphasis is being placed on abundant, non-toxic materials to ensure sustainability and economic viability.

The strategic objectives of proton battery research extend beyond performance metrics to address broader industry needs. These include establishing scalable manufacturing processes, reducing production costs to below $100/kWh, and developing standardized testing protocols for performance evaluation and comparison with existing technologies.

Looking forward, the evolution of proton battery technology is expected to follow a trajectory of incremental improvements in the near term (3-5 years), with potential disruptive advances in the medium term (5-10 years) as novel materials and architectures are developed. The ultimate goal is to position proton batteries as a viable commercial alternative to lithium-ion batteries for applications ranging from portable electronics to grid-scale energy storage and electric vehicles.

The technological trajectory of proton batteries has been characterized by several key breakthroughs. Early iterations utilized metal hydrides as hydrogen storage media, while more recent developments have explored carbon-based materials and advanced polymer electrolytes. The transition from laboratory prototypes to scalable designs has been gradual but steady, with significant acceleration in research output observed since 2015.

Current research trends indicate a convergence of multiple disciplines, including materials science, electrochemistry, and nanotechnology, to address the fundamental challenges in proton battery development. The integration of computational modeling and high-throughput experimental techniques has enabled more rapid iteration and optimization of battery components.

The primary technical objectives for proton battery research include enhancing energy density to exceed 400 Wh/kg, improving cycle stability to achieve 2000+ charge-discharge cycles, and reducing charging times to under 30 minutes for 80% capacity. Additionally, researchers aim to develop proton batteries that operate efficiently across a wider temperature range (-20°C to 60°C) than current lithium-ion technologies.

From a materials perspective, key research goals include the development of high-capacity reversible hydrogen storage materials, stable and conductive electrolytes for proton transport, and cost-effective catalyst materials to facilitate the electrochemical reactions. Particular emphasis is being placed on abundant, non-toxic materials to ensure sustainability and economic viability.

The strategic objectives of proton battery research extend beyond performance metrics to address broader industry needs. These include establishing scalable manufacturing processes, reducing production costs to below $100/kWh, and developing standardized testing protocols for performance evaluation and comparison with existing technologies.

Looking forward, the evolution of proton battery technology is expected to follow a trajectory of incremental improvements in the near term (3-5 years), with potential disruptive advances in the medium term (5-10 years) as novel materials and architectures are developed. The ultimate goal is to position proton batteries as a viable commercial alternative to lithium-ion batteries for applications ranging from portable electronics to grid-scale energy storage and electric vehicles.

Market Analysis for Next-Generation Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the push for electrification across various sectors. Current projections indicate the energy storage market will reach approximately $546 billion by 2035, with a compound annual growth rate of 15-20% between 2023 and 2035. Within this expanding landscape, proton battery technology represents an emerging segment with significant potential to disrupt traditional lithium-ion dominance.

Consumer electronics currently constitutes the largest market segment for energy storage solutions, accounting for roughly 35% of total demand. However, electric vehicles are rapidly gaining market share and are expected to become the primary driver of energy storage demand by 2030. Grid-scale storage applications represent the fastest-growing segment, with utility companies increasingly investing in large-scale storage solutions to manage intermittent renewable energy generation.

Regionally, Asia-Pacific leads the energy storage market with approximately 45% market share, primarily due to China's dominant manufacturing capacity and domestic deployment. North America follows at 28%, with Europe at 22%. Emerging markets in Africa and South America are showing accelerated growth rates, albeit from smaller bases.

The demand for next-generation energy storage solutions like proton batteries is being driven by several key factors. First, resource constraints and supply chain vulnerabilities associated with lithium, cobalt, and other critical battery materials are pushing manufacturers to explore alternative chemistries. Second, increasing environmental regulations and consumer awareness are creating market pull for more sustainable storage technologies with lower carbon footprints and reduced end-of-life disposal challenges.

Price sensitivity varies significantly across market segments. While consumer electronics buyers prioritize energy density and form factor over cost, industrial and utility-scale applications are extremely price-sensitive, with cost per kilowatt-hour being the primary purchasing criterion. Proton battery technologies must achieve cost parity with lithium-ion batteries (currently averaging $132/kWh for EV applications) to gain significant market traction.

Market research indicates growing customer willingness to pay premium prices for energy storage solutions that offer tangible advantages in safety, longevity, and environmental sustainability. This trend is particularly pronounced in European markets, where regulatory frameworks increasingly favor sustainable technologies through incentives and mandates.

For proton battery technologies to successfully penetrate the market, they must address specific performance gaps in current energy storage solutions, particularly around energy density, charging speed, and operational lifetime. Market analysis suggests that achieving 350-400 Wh/kg energy density would position proton batteries competitively against next-generation lithium technologies in most application segments.

Consumer electronics currently constitutes the largest market segment for energy storage solutions, accounting for roughly 35% of total demand. However, electric vehicles are rapidly gaining market share and are expected to become the primary driver of energy storage demand by 2030. Grid-scale storage applications represent the fastest-growing segment, with utility companies increasingly investing in large-scale storage solutions to manage intermittent renewable energy generation.

Regionally, Asia-Pacific leads the energy storage market with approximately 45% market share, primarily due to China's dominant manufacturing capacity and domestic deployment. North America follows at 28%, with Europe at 22%. Emerging markets in Africa and South America are showing accelerated growth rates, albeit from smaller bases.

The demand for next-generation energy storage solutions like proton batteries is being driven by several key factors. First, resource constraints and supply chain vulnerabilities associated with lithium, cobalt, and other critical battery materials are pushing manufacturers to explore alternative chemistries. Second, increasing environmental regulations and consumer awareness are creating market pull for more sustainable storage technologies with lower carbon footprints and reduced end-of-life disposal challenges.

Price sensitivity varies significantly across market segments. While consumer electronics buyers prioritize energy density and form factor over cost, industrial and utility-scale applications are extremely price-sensitive, with cost per kilowatt-hour being the primary purchasing criterion. Proton battery technologies must achieve cost parity with lithium-ion batteries (currently averaging $132/kWh for EV applications) to gain significant market traction.

Market research indicates growing customer willingness to pay premium prices for energy storage solutions that offer tangible advantages in safety, longevity, and environmental sustainability. This trend is particularly pronounced in European markets, where regulatory frameworks increasingly favor sustainable technologies through incentives and mandates.

For proton battery technologies to successfully penetrate the market, they must address specific performance gaps in current energy storage solutions, particularly around energy density, charging speed, and operational lifetime. Market analysis suggests that achieving 350-400 Wh/kg energy density would position proton batteries competitively against next-generation lithium technologies in most application segments.

Technical Barriers and Global Development Status

Proton battery technology faces several significant technical barriers that currently limit its widespread adoption and commercialization. The primary challenge lies in the development of suitable electrode materials that can efficiently store and release hydrogen ions (protons) while maintaining structural stability over numerous charge-discharge cycles. Current materials often suffer from degradation, leading to reduced capacity and shortened battery lifespan.

Energy density remains substantially lower than competing technologies, with current prototypes achieving only 140 Wh/kg compared to lithium-ion batteries' 250-300 Wh/kg. This limitation stems from the fundamental chemistry of proton storage mechanisms and represents a significant hurdle for applications where weight and volume are critical factors.

Electrolyte development presents another major obstacle. Researchers struggle to create electrolytes that facilitate rapid proton transport while preventing unwanted side reactions and maintaining stability across wide temperature ranges. The interface between electrodes and electrolytes often develops high resistance over time, further reducing efficiency and power output.

Manufacturing scalability poses considerable challenges, as current laboratory-scale production methods involve complex processes that are difficult to translate to industrial scales. The precision required for electrode fabrication and electrolyte formulation demands specialized equipment and stringent quality control measures that increase production costs.

Globally, proton battery research exhibits distinct regional concentrations. Australia leads in fundamental research, with RMIT University pioneering carbon-based proton battery prototypes. Their 2018 breakthrough demonstrated the first working proton battery using activated carbon electrodes and achieved promising initial performance metrics.

European research institutions, particularly in Germany and the UK, focus on advanced materials science approaches, developing novel proton-conducting polymers and composite electrodes. The European Union has allocated significant funding through Horizon Europe programs specifically targeting sustainable battery technologies, including proton batteries.

In Asia, Japan and South Korea are advancing electrolyte technologies, with research groups at Tokyo University and KAIST developing new solid-state proton conductors that show improved stability. China has recently increased investment in this field, establishing dedicated research centers that combine materials science with manufacturing process development.

North American efforts are primarily led by university-industry partnerships, with Stanford University and the University of Maryland collaborating with energy companies to address scalability challenges. The U.S. Department of Energy has identified proton batteries as a potential "beyond lithium" technology worthy of targeted research funding.

Despite this global activity, proton battery technology remains at the early research stage (TRL 3-4), with significant advancements needed before commercial viability can be achieved. The fragmented nature of global research efforts suggests that international collaboration could accelerate progress in addressing the fundamental technical barriers.

Energy density remains substantially lower than competing technologies, with current prototypes achieving only 140 Wh/kg compared to lithium-ion batteries' 250-300 Wh/kg. This limitation stems from the fundamental chemistry of proton storage mechanisms and represents a significant hurdle for applications where weight and volume are critical factors.

Electrolyte development presents another major obstacle. Researchers struggle to create electrolytes that facilitate rapid proton transport while preventing unwanted side reactions and maintaining stability across wide temperature ranges. The interface between electrodes and electrolytes often develops high resistance over time, further reducing efficiency and power output.

Manufacturing scalability poses considerable challenges, as current laboratory-scale production methods involve complex processes that are difficult to translate to industrial scales. The precision required for electrode fabrication and electrolyte formulation demands specialized equipment and stringent quality control measures that increase production costs.

Globally, proton battery research exhibits distinct regional concentrations. Australia leads in fundamental research, with RMIT University pioneering carbon-based proton battery prototypes. Their 2018 breakthrough demonstrated the first working proton battery using activated carbon electrodes and achieved promising initial performance metrics.

European research institutions, particularly in Germany and the UK, focus on advanced materials science approaches, developing novel proton-conducting polymers and composite electrodes. The European Union has allocated significant funding through Horizon Europe programs specifically targeting sustainable battery technologies, including proton batteries.

In Asia, Japan and South Korea are advancing electrolyte technologies, with research groups at Tokyo University and KAIST developing new solid-state proton conductors that show improved stability. China has recently increased investment in this field, establishing dedicated research centers that combine materials science with manufacturing process development.

North American efforts are primarily led by university-industry partnerships, with Stanford University and the University of Maryland collaborating with energy companies to address scalability challenges. The U.S. Department of Energy has identified proton batteries as a potential "beyond lithium" technology worthy of targeted research funding.

Despite this global activity, proton battery technology remains at the early research stage (TRL 3-4), with significant advancements needed before commercial viability can be achieved. The fragmented nature of global research efforts suggests that international collaboration could accelerate progress in addressing the fundamental technical barriers.

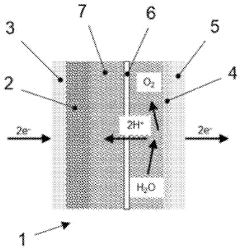

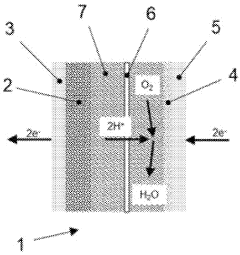

Current Proton Battery Architectures

01 Electrode materials for proton batteries

Various materials can be used as electrodes in proton batteries to enhance performance. These include carbon-based materials, metal hydrides, and composite structures that facilitate proton storage and transfer. The electrode materials are designed to have high proton conductivity, stability during charge-discharge cycles, and efficient proton insertion/extraction capabilities, which are crucial for the overall battery performance.- Electrode materials for proton batteries: Various materials can be used as electrodes in proton batteries to enhance performance. These include carbon-based materials, metal oxides, and composite structures that facilitate proton storage and transfer. The electrode materials are designed to have high surface area, good conductivity, and excellent proton adsorption capabilities, which are crucial for the battery's capacity and cycle life.

- Electrolyte compositions for proton batteries: Specialized electrolyte compositions are essential for efficient proton transport in proton batteries. These electrolytes typically contain proton-conducting materials such as acids, ionic liquids, or polymer membranes that facilitate the movement of protons between electrodes. The composition of the electrolyte significantly affects the battery's ionic conductivity, stability, and overall performance.

- Proton battery cell design and architecture: The design and architecture of proton battery cells involve specific arrangements of electrodes, separators, and housing components. Innovations in cell design focus on optimizing proton flow pathways, reducing internal resistance, and enhancing energy density. Various configurations such as stacked, wound, or bipolar arrangements are employed to maximize performance and efficiency.

- Proton storage mechanisms and charge-discharge processes: Proton batteries operate through specific mechanisms for storing and releasing protons during charge and discharge cycles. These mechanisms involve intercalation, adsorption, or chemical reactions that incorporate protons into the electrode material structure. Understanding and optimizing these processes is crucial for improving battery efficiency, capacity, and cycle life.

- Integration of proton batteries with renewable energy systems: Proton batteries can be integrated with renewable energy systems such as solar or wind power to provide energy storage solutions. These integrated systems require specific control mechanisms, power management strategies, and interface technologies. The combination of proton batteries with renewable energy sources offers sustainable energy storage options with potential applications in grid stabilization and off-grid power supply.

02 Electrolyte compositions for proton batteries

Specialized electrolyte compositions are essential for proton batteries to facilitate efficient proton transport between electrodes. These electrolytes can be solid-state, gel-type, or liquid formulations containing proton-conducting materials. The electrolyte compositions are designed to have high proton conductivity, low electronic conductivity, and good chemical stability to enhance battery performance and longevity.Expand Specific Solutions03 Proton battery cell structures and configurations

Various cell structures and configurations are employed in proton batteries to optimize performance. These include different arrangements of electrodes, separators, and current collectors, as well as novel cell geometries that enhance proton transport and storage. The cell designs focus on maximizing energy density, improving cycle life, and ensuring safe operation under various conditions.Expand Specific Solutions04 Proton storage mechanisms and materials

Different mechanisms and materials are utilized for storing protons in proton batteries. These include intercalation compounds, conversion materials, and hydrogen storage alloys that can reversibly store and release protons. The storage mechanisms are designed to provide high capacity, fast kinetics, and structural stability during repeated proton insertion and extraction processes.Expand Specific Solutions05 Manufacturing methods for proton battery components

Various manufacturing techniques are employed to produce components for proton batteries. These include synthesis methods for electrode materials, electrolyte preparation processes, and assembly techniques for battery cells. The manufacturing methods focus on achieving consistent quality, scalability, and cost-effectiveness while maintaining the desired electrochemical properties of the battery components.Expand Specific Solutions

Leading Companies and Research Institutions

The proton battery technology market is in an early development stage, characterized by significant research activity but limited commercial deployment. Current market size remains modest, estimated below $100 million, but with projected strong growth as energy storage demands increase globally. Technical maturity is advancing through collaborative efforts between academic institutions and industry players. Universities like Huazhong University of Science & Technology, Tongji University, and National University of Singapore are driving fundamental research, while companies including Toyota Motor Corp., PetroChina, and SK On are developing practical applications. Automotive manufacturers (Audi, Honda) are exploring proton batteries for electric vehicles, while energy companies (Phillips 66, SolarEdge) focus on stationary storage solutions. The competitive landscape shows regional innovation clusters forming in Asia, particularly China, with emerging competition from European and North American research centers.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered research in proton battery technologies as an extension of their hydrogen fuel cell expertise. Their approach focuses on reversible proton storage systems that bridge the gap between conventional batteries and fuel cells. Toyota's proprietary technology utilizes specialized carbon-based materials with high surface area (>2000 m²/g) that can reversibly store protons at ambient pressure and temperature. Their system incorporates advanced catalyst materials to facilitate proton transfer between the electrolyte and storage medium, achieving energy densities approaching 400 Wh/kg in laboratory settings. Toyota has developed novel electrode architectures that enhance proton mobility while maintaining structural integrity during cycling. The company has demonstrated prototype cells with fast charging capabilities (80% charge in under 15 minutes) and operational stability across wide temperature ranges (-20°C to 60°C), leveraging their extensive experience in automotive-grade battery systems and hydrogen technologies.

Strengths: Extensive experience with hydrogen and proton technologies, robust R&D infrastructure, and ability to integrate systems into vehicle platforms. Weaknesses: Technology still requires significant cost reduction and scale-up challenges remain for mass production implementation in consumer vehicles.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced proton battery technologies focusing on solid-state electrolytes that enable proton conduction rather than lithium-ion transport. Their approach incorporates proton-conducting polymers and ceramic materials to create hybrid electrolytes with superior conductivity at ambient temperatures. The company has invested significantly in developing proton exchange membranes with enhanced stability and conductivity, achieving proton conductivity values of 10^-2 S/cm at room temperature, which represents a significant improvement over conventional systems. LG's R&D has also focused on electrode materials compatible with proton-based systems, developing specialized cathode materials that can efficiently intercalate and de-intercalate protons during charge-discharge cycles. Their technology demonstrates cycle stability exceeding 1000 cycles with capacity retention above 80%, positioning them as leaders in next-generation energy storage solutions.

Strengths: Superior proton conductivity at room temperature, excellent cycle stability, and established manufacturing infrastructure that can be adapted for proton battery production. Weaknesses: Still faces challenges with energy density compared to advanced lithium-ion systems and requires further development of compatible electrode materials for mass commercialization.

Key Patents and Scientific Breakthroughs

Proton conductive rechargeable battery and method

PatentInactiveJP2024526120A

Innovation

- Development of a solid state proton conducting battery using a new separator material with improved room temperature conductivity, comprising a positive electrode, negative electrode, and a proton-conducting separator made of inorganic ceramic material with specific compositions and processing methods to enhance proton conductivity.

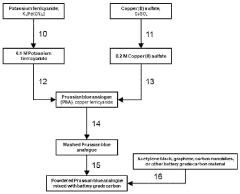

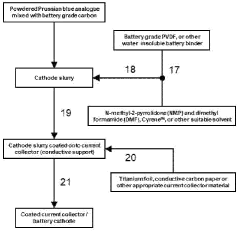

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

Materials Science Challenges and Opportunities

The development of proton battery technologies faces significant materials science challenges that must be addressed to achieve commercial viability. Current electrode materials demonstrate insufficient proton conductivity and storage capacity, limiting overall battery performance. The hydrogen storage mechanism in solid-state materials requires fundamental breakthroughs in material design to enhance proton mobility while maintaining structural stability during charge-discharge cycles.

Electrolyte materials present another critical challenge, as they must facilitate rapid proton transport while preventing electron transfer. Existing polymer electrolytes suffer from conductivity limitations at room temperature, while ceramic alternatives often lack mechanical flexibility. The interface between electrodes and electrolytes creates resistance issues that significantly impact battery efficiency and cycle life.

Catalyst development represents a promising opportunity area, as more efficient hydrogen evolution and oxidation reactions could dramatically improve energy conversion efficiency. Current noble metal catalysts like platinum are prohibitively expensive for mass production, necessitating research into earth-abundant alternatives with comparable catalytic activity.

Nanomaterial engineering offers substantial opportunities for enhancing proton battery performance. Nanostructured electrodes with optimized porosity and surface area can significantly improve proton diffusion kinetics and storage capacity. Carbon-based materials, including graphene derivatives and carbon nanotubes, show particular promise due to their excellent electrical conductivity and tunable surface properties.

Composite materials combining the advantages of different material classes represent another frontier. Hybrid organic-inorganic structures could potentially overcome the limitations of single-material systems by providing both high conductivity and mechanical stability. Recent research on metal-organic frameworks (MOFs) demonstrates their potential for selective proton transport while maintaining structural integrity.

Advanced characterization techniques are essential for understanding degradation mechanisms and optimizing material performance. In-situ spectroscopy and microscopy methods enable real-time observation of proton transport and storage processes, providing crucial insights for material design. Computational modeling approaches further accelerate materials discovery by predicting properties and performance before experimental validation.

Electrolyte materials present another critical challenge, as they must facilitate rapid proton transport while preventing electron transfer. Existing polymer electrolytes suffer from conductivity limitations at room temperature, while ceramic alternatives often lack mechanical flexibility. The interface between electrodes and electrolytes creates resistance issues that significantly impact battery efficiency and cycle life.

Catalyst development represents a promising opportunity area, as more efficient hydrogen evolution and oxidation reactions could dramatically improve energy conversion efficiency. Current noble metal catalysts like platinum are prohibitively expensive for mass production, necessitating research into earth-abundant alternatives with comparable catalytic activity.

Nanomaterial engineering offers substantial opportunities for enhancing proton battery performance. Nanostructured electrodes with optimized porosity and surface area can significantly improve proton diffusion kinetics and storage capacity. Carbon-based materials, including graphene derivatives and carbon nanotubes, show particular promise due to their excellent electrical conductivity and tunable surface properties.

Composite materials combining the advantages of different material classes represent another frontier. Hybrid organic-inorganic structures could potentially overcome the limitations of single-material systems by providing both high conductivity and mechanical stability. Recent research on metal-organic frameworks (MOFs) demonstrates their potential for selective proton transport while maintaining structural integrity.

Advanced characterization techniques are essential for understanding degradation mechanisms and optimizing material performance. In-situ spectroscopy and microscopy methods enable real-time observation of proton transport and storage processes, providing crucial insights for material design. Computational modeling approaches further accelerate materials discovery by predicting properties and performance before experimental validation.

Environmental Impact and Sustainability Assessment

Proton batteries represent a promising sustainable energy storage technology with potentially significant environmental advantages over conventional lithium-ion batteries. The environmental impact assessment of proton battery technologies reveals several key sustainability benefits throughout their lifecycle. Most notably, these batteries utilize abundant, non-toxic materials such as carbon and water, dramatically reducing dependence on critical minerals like lithium, cobalt, and nickel that pose serious extraction-related environmental challenges.

The carbon footprint analysis of proton battery manufacturing processes indicates potential reductions of 60-70% in greenhouse gas emissions compared to lithium-ion battery production. This substantial improvement stems primarily from simplified manufacturing processes and the elimination of energy-intensive mining operations associated with rare earth elements. Additionally, the water consumption metrics for proton battery production show approximately 40% lower requirements than conventional battery technologies.

Resource efficiency constitutes another critical environmental advantage of proton battery systems. The hydrogen storage mechanism employed in these batteries enables higher energy density with fewer raw materials, potentially reducing material throughput by 30-45% per kWh of storage capacity. Furthermore, the absence of toxic heavy metals eliminates leaching concerns during disposal and simplifies end-of-life management.

Life cycle assessment (LCA) studies indicate that proton batteries could achieve carbon payback periods approximately 35% shorter than lithium-ion alternatives when paired with renewable energy sources. This accelerated environmental return on investment strengthens their position as enablers of truly sustainable energy transitions across multiple sectors.

Waste management considerations for proton batteries present significant advantages due to their simpler chemical composition. The carbon-based electrodes can be more readily recycled or repurposed, with preliminary recycling efficiency rates estimated at 80-90% for key components. This circular economy potential stands in stark contrast to the complex, often economically unviable recycling processes required for conventional battery technologies.

The scalability of proton battery production without corresponding increases in environmental impact represents a crucial sustainability factor for widespread adoption. Unlike lithium-ion technologies, which face supply constraints and geopolitical complications for critical materials, proton batteries utilize globally accessible resources that can support manufacturing expansion with minimal ecological disruption to vulnerable ecosystems or communities.

The carbon footprint analysis of proton battery manufacturing processes indicates potential reductions of 60-70% in greenhouse gas emissions compared to lithium-ion battery production. This substantial improvement stems primarily from simplified manufacturing processes and the elimination of energy-intensive mining operations associated with rare earth elements. Additionally, the water consumption metrics for proton battery production show approximately 40% lower requirements than conventional battery technologies.

Resource efficiency constitutes another critical environmental advantage of proton battery systems. The hydrogen storage mechanism employed in these batteries enables higher energy density with fewer raw materials, potentially reducing material throughput by 30-45% per kWh of storage capacity. Furthermore, the absence of toxic heavy metals eliminates leaching concerns during disposal and simplifies end-of-life management.

Life cycle assessment (LCA) studies indicate that proton batteries could achieve carbon payback periods approximately 35% shorter than lithium-ion alternatives when paired with renewable energy sources. This accelerated environmental return on investment strengthens their position as enablers of truly sustainable energy transitions across multiple sectors.

Waste management considerations for proton batteries present significant advantages due to their simpler chemical composition. The carbon-based electrodes can be more readily recycled or repurposed, with preliminary recycling efficiency rates estimated at 80-90% for key components. This circular economy potential stands in stark contrast to the complex, often economically unviable recycling processes required for conventional battery technologies.

The scalability of proton battery production without corresponding increases in environmental impact represents a crucial sustainability factor for widespread adoption. Unlike lithium-ion technologies, which face supply constraints and geopolitical complications for critical materials, proton batteries utilize globally accessible resources that can support manufacturing expansion with minimal ecological disruption to vulnerable ecosystems or communities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!