Regulatory Framework for Proton Battery International Trade

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proton Battery Technology Evolution and Objectives

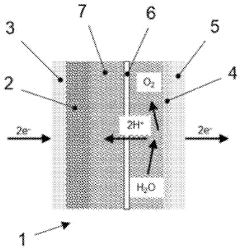

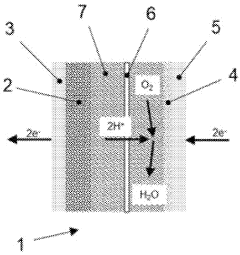

Proton battery technology has evolved significantly since its conceptual inception in the early 2000s, emerging as a promising alternative to conventional lithium-ion batteries. The fundamental principle behind proton batteries involves using protons (hydrogen ions) as charge carriers instead of lithium ions, offering potential advantages in energy density, safety, and environmental impact. Early research focused primarily on theoretical frameworks and laboratory-scale demonstrations, with limited practical applications.

The evolution accelerated around 2016 when researchers at RMIT University in Australia developed the first working prototype of a proton battery using carbon-based electrodes and a reversible fuel cell system. This breakthrough demonstrated the feasibility of storing hydrogen in carbon rather than as compressed gas, marking a significant milestone in proton battery development. By 2018, improved prototypes achieved energy densities comparable to commercial lithium-ion batteries, though still at laboratory scale.

Between 2019 and 2021, technological advancements focused on enhancing electrode materials, electrolyte compositions, and cell architectures to improve efficiency and cycle life. Research expanded to include various proton-conducting solid electrolytes and hybrid systems combining features of both batteries and hydrogen fuel cells. These developments addressed key challenges such as proton conductivity, electrode stability, and charge-discharge efficiency.

The regulatory landscape began taking shape around 2020, with initial discussions on classification standards for proton batteries in international trade. However, the absence of a comprehensive regulatory framework has been identified as a significant barrier to commercialization and global market adoption. Current objectives in this domain include establishing standardized testing protocols, safety certifications, and transportation regulations specific to proton battery technologies.

Looking forward, the technical objectives for proton battery development include achieving energy densities exceeding 300 Wh/kg (surpassing current lithium-ion technologies), extending cycle life beyond 2,000 cycles, and reducing production costs to below $100/kWh. These targets are considered essential for commercial viability across various applications, from portable electronics to grid-scale energy storage.

Parallel to these technical goals, regulatory objectives focus on creating harmonized international standards that facilitate safe and efficient cross-border trade of proton battery technologies. This includes developing classification codes within the Harmonized System (HS), establishing safety protocols for transportation under dangerous goods regulations, and creating certification standards that address the unique characteristics of proton-based energy storage systems.

The evolution accelerated around 2016 when researchers at RMIT University in Australia developed the first working prototype of a proton battery using carbon-based electrodes and a reversible fuel cell system. This breakthrough demonstrated the feasibility of storing hydrogen in carbon rather than as compressed gas, marking a significant milestone in proton battery development. By 2018, improved prototypes achieved energy densities comparable to commercial lithium-ion batteries, though still at laboratory scale.

Between 2019 and 2021, technological advancements focused on enhancing electrode materials, electrolyte compositions, and cell architectures to improve efficiency and cycle life. Research expanded to include various proton-conducting solid electrolytes and hybrid systems combining features of both batteries and hydrogen fuel cells. These developments addressed key challenges such as proton conductivity, electrode stability, and charge-discharge efficiency.

The regulatory landscape began taking shape around 2020, with initial discussions on classification standards for proton batteries in international trade. However, the absence of a comprehensive regulatory framework has been identified as a significant barrier to commercialization and global market adoption. Current objectives in this domain include establishing standardized testing protocols, safety certifications, and transportation regulations specific to proton battery technologies.

Looking forward, the technical objectives for proton battery development include achieving energy densities exceeding 300 Wh/kg (surpassing current lithium-ion technologies), extending cycle life beyond 2,000 cycles, and reducing production costs to below $100/kWh. These targets are considered essential for commercial viability across various applications, from portable electronics to grid-scale energy storage.

Parallel to these technical goals, regulatory objectives focus on creating harmonized international standards that facilitate safe and efficient cross-border trade of proton battery technologies. This includes developing classification codes within the Harmonized System (HS), establishing safety protocols for transportation under dangerous goods regulations, and creating certification standards that address the unique characteristics of proton-based energy storage systems.

Global Market Analysis for Proton Battery Trade

The global proton battery market is experiencing significant growth as countries worldwide seek sustainable energy storage solutions to meet climate goals. Current market projections indicate that the proton battery sector could reach a valuation of $7.5 billion by 2030, with a compound annual growth rate of 29.3% from 2023 to 2030. This remarkable growth trajectory is primarily driven by increasing governmental commitments to carbon neutrality and the rising demand for clean energy technologies across developed and emerging economies.

Asia-Pacific currently dominates the proton battery market landscape, with China, Japan, and South Korea leading in both production capacity and technological innovation. These countries collectively account for approximately 65% of global proton battery manufacturing. The European Union follows with roughly 22% market share, where countries like Germany, France, and the Netherlands are making substantial investments in proton battery research and development facilities.

North America represents about 10% of the global market, with the United States gradually increasing its footprint through strategic public-private partnerships and research grants. The remaining 3% is distributed across other regions, with notable growth potential in countries like Australia, which possesses abundant hydrogen resources essential for proton battery production.

Trade patterns for proton battery technologies reveal interesting dynamics. Major exporters include Japan, South Korea, and Germany, which leverage their advanced manufacturing capabilities and technological expertise. Meanwhile, countries with ambitious renewable energy targets such as India, Brazil, and several European nations are becoming significant importers of proton battery systems and components.

Market segmentation analysis indicates that transportation applications currently represent the largest end-use sector for proton batteries at 42%, followed by grid storage applications at 31%, portable electronics at 18%, and other industrial applications at 9%. This distribution reflects the versatility of proton battery technology across multiple sectors.

Consumer adoption trends vary significantly by region, with higher acceptance rates in countries offering substantial government incentives for clean energy technologies. Price sensitivity remains a critical factor influencing market penetration, particularly in developing economies where cost considerations often outweigh environmental benefits in purchasing decisions.

Supply chain analysis reveals potential vulnerabilities in the global proton battery trade ecosystem. Critical raw materials required for proton battery manufacturing, including specialized catalysts and membrane materials, are concentrated in specific geographic regions, creating potential bottlenecks and geopolitical dependencies that could impact future market growth and stability.

Asia-Pacific currently dominates the proton battery market landscape, with China, Japan, and South Korea leading in both production capacity and technological innovation. These countries collectively account for approximately 65% of global proton battery manufacturing. The European Union follows with roughly 22% market share, where countries like Germany, France, and the Netherlands are making substantial investments in proton battery research and development facilities.

North America represents about 10% of the global market, with the United States gradually increasing its footprint through strategic public-private partnerships and research grants. The remaining 3% is distributed across other regions, with notable growth potential in countries like Australia, which possesses abundant hydrogen resources essential for proton battery production.

Trade patterns for proton battery technologies reveal interesting dynamics. Major exporters include Japan, South Korea, and Germany, which leverage their advanced manufacturing capabilities and technological expertise. Meanwhile, countries with ambitious renewable energy targets such as India, Brazil, and several European nations are becoming significant importers of proton battery systems and components.

Market segmentation analysis indicates that transportation applications currently represent the largest end-use sector for proton batteries at 42%, followed by grid storage applications at 31%, portable electronics at 18%, and other industrial applications at 9%. This distribution reflects the versatility of proton battery technology across multiple sectors.

Consumer adoption trends vary significantly by region, with higher acceptance rates in countries offering substantial government incentives for clean energy technologies. Price sensitivity remains a critical factor influencing market penetration, particularly in developing economies where cost considerations often outweigh environmental benefits in purchasing decisions.

Supply chain analysis reveals potential vulnerabilities in the global proton battery trade ecosystem. Critical raw materials required for proton battery manufacturing, including specialized catalysts and membrane materials, are concentrated in specific geographic regions, creating potential bottlenecks and geopolitical dependencies that could impact future market growth and stability.

International Regulatory Landscape and Technical Barriers

The global regulatory landscape for proton battery technology remains in its nascent stages, with significant variations across different regions. Currently, no unified international framework specifically addresses proton battery trade, creating a complex environment for manufacturers and distributors. Most jurisdictions apply existing battery and energy storage regulations to this emerging technology, resulting in inconsistent standards and compliance requirements.

In North America, regulatory bodies like the U.S. Department of Energy and Environment Canada have begun preliminary assessments of proton battery safety protocols, but comprehensive regulations remain underdeveloped. The European Union has taken a more proactive approach through its Battery Directive framework, which is being updated to potentially include specific provisions for novel battery technologies including proton-based systems.

Asia-Pacific regions demonstrate the most significant regulatory disparities. Japan and South Korea have integrated proton battery considerations into their existing lithium battery frameworks, while China has established a specialized regulatory committee focused on hydrogen-based energy technologies, including proton batteries. These regional differences create substantial barriers for international trade and technology transfer.

Technical barriers to international trade primarily revolve around safety certification and standardization issues. The absence of internationally recognized testing protocols specifically designed for proton battery technology has resulted in manufacturers needing to undergo multiple certification processes to access different markets. This redundancy significantly increases compliance costs and extends time-to-market for innovative products.

Transportation regulations present another critical barrier. Current dangerous goods regulations for battery shipment were developed primarily for lithium-ion technologies and may not adequately address the unique characteristics of proton batteries. This regulatory gap has led to shipping delays, increased logistics costs, and limited market access for manufacturers.

Intellectual property protection frameworks also vary considerably across jurisdictions, with patent enforcement mechanisms for novel battery technologies showing significant inconsistency. This creates uncertainty for technology developers and potentially inhibits cross-border technology transfer and investment.

Tariff classifications represent an additional challenge, as most customs authorities have not established specific harmonized system codes for proton battery technologies. This classification ambiguity leads to inconsistent import duties and potential trade disputes, further complicating international commerce in this emerging sector.

In North America, regulatory bodies like the U.S. Department of Energy and Environment Canada have begun preliminary assessments of proton battery safety protocols, but comprehensive regulations remain underdeveloped. The European Union has taken a more proactive approach through its Battery Directive framework, which is being updated to potentially include specific provisions for novel battery technologies including proton-based systems.

Asia-Pacific regions demonstrate the most significant regulatory disparities. Japan and South Korea have integrated proton battery considerations into their existing lithium battery frameworks, while China has established a specialized regulatory committee focused on hydrogen-based energy technologies, including proton batteries. These regional differences create substantial barriers for international trade and technology transfer.

Technical barriers to international trade primarily revolve around safety certification and standardization issues. The absence of internationally recognized testing protocols specifically designed for proton battery technology has resulted in manufacturers needing to undergo multiple certification processes to access different markets. This redundancy significantly increases compliance costs and extends time-to-market for innovative products.

Transportation regulations present another critical barrier. Current dangerous goods regulations for battery shipment were developed primarily for lithium-ion technologies and may not adequately address the unique characteristics of proton batteries. This regulatory gap has led to shipping delays, increased logistics costs, and limited market access for manufacturers.

Intellectual property protection frameworks also vary considerably across jurisdictions, with patent enforcement mechanisms for novel battery technologies showing significant inconsistency. This creates uncertainty for technology developers and potentially inhibits cross-border technology transfer and investment.

Tariff classifications represent an additional challenge, as most customs authorities have not established specific harmonized system codes for proton battery technologies. This classification ambiguity leads to inconsistent import duties and potential trade disputes, further complicating international commerce in this emerging sector.

Current International Trade Compliance Solutions

01 Electrode materials for proton batteries

Various materials can be used as electrodes in proton batteries to enhance performance. These include carbon-based materials, metal hydrides, and composite structures that facilitate proton storage and transfer. The electrode materials are designed to efficiently store and release protons during charge-discharge cycles, improving energy density and cycle life of the battery.- Electrode materials for proton batteries: Various materials can be used as electrodes in proton batteries to enhance performance. These include carbon-based materials, metal hydrides, and composite structures that facilitate proton storage and transport. The electrode materials are designed to efficiently store and release protons during charging and discharging cycles, improving the overall energy density and cycle life of the battery.

- Electrolyte compositions for proton conduction: Specialized electrolyte compositions are crucial for efficient proton conduction in proton batteries. These electrolytes typically contain proton-conducting polymers, ionic liquids, or solid-state materials that facilitate the movement of protons between electrodes. The development of stable, highly conductive electrolytes is essential for improving battery performance, reducing internal resistance, and enhancing operational stability across various temperature ranges.

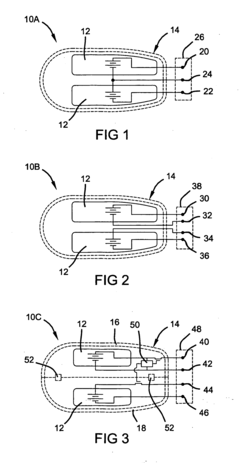

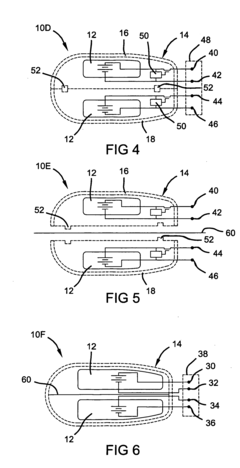

- Proton battery cell design and architecture: The structural design and architecture of proton battery cells significantly impact their performance. Innovations include novel cell configurations, membrane electrode assemblies, and integrated systems that optimize proton flow and storage. Advanced designs focus on maximizing active material utilization, improving thermal management, and enhancing mechanical stability to achieve higher energy density and longer operational lifetimes.

- Hydrogen storage mechanisms in proton batteries: Proton batteries utilize various hydrogen storage mechanisms to store energy. These include reversible hydrogen absorption in metal alloys, chemical bonding in complex hydrides, and physical adsorption in porous materials. The efficiency of hydrogen storage directly affects the energy density, charging speed, and overall performance of the battery system, making it a critical aspect of proton battery technology.

- Integration of proton batteries with renewable energy systems: Proton batteries can be effectively integrated with renewable energy systems to provide energy storage solutions. These batteries can store excess energy generated from intermittent renewable sources like solar and wind, and release it when needed. The integration involves specialized control systems, power management electronics, and grid interface technologies that optimize energy flow and maximize system efficiency while ensuring compatibility with existing infrastructure.

02 Electrolyte compositions for proton conduction

Specialized electrolyte compositions are crucial for efficient proton transport in proton batteries. These electrolytes typically contain proton-conducting materials such as solid polymer membranes, ionic liquids, or acid-based solutions that facilitate the movement of protons between electrodes while maintaining electrochemical stability. The composition of these electrolytes significantly affects the battery's power output and operational temperature range.Expand Specific Solutions03 Proton battery cell design and architecture

The structural design and architecture of proton battery cells impact their performance and efficiency. Innovations in cell configuration include layered structures, flow designs, and integrated systems that optimize proton movement and storage. Advanced cell designs also address issues such as thermal management, pressure regulation, and mechanical stability during operation.Expand Specific Solutions04 Hydrogen storage mechanisms in proton batteries

Proton batteries utilize various hydrogen storage mechanisms to achieve high energy density. These include chemical bonding in metal hydrides, physical adsorption in porous materials, and electrochemical storage in specialized compounds. The efficiency of hydrogen storage directly influences the battery's capacity, charging speed, and overall energy density.Expand Specific Solutions05 Integration of proton batteries with renewable energy systems

Proton batteries can be effectively integrated with renewable energy systems for energy storage applications. These batteries can store excess energy from intermittent renewable sources like solar and wind, providing a sustainable energy storage solution. The integration involves specialized control systems, power management electronics, and interface designs that optimize energy conversion efficiency and system reliability.Expand Specific Solutions

Key Industry Players and Global Competition

The regulatory framework for proton battery international trade is evolving within an emerging market characterized by early-stage development and limited commercial scale. Current global market size remains relatively small but shows promising growth potential as energy storage demands increase. From a technological maturity perspective, key players demonstrate varying levels of advancement: academic institutions like Tongji University and Rensselaer Polytechnic Institute are conducting foundational research, while commercial entities including Contemporary Amperex Technology, LG Chem, and Toyota are gradually integrating proton battery technologies into their R&D portfolios. Chinese companies like BTR New Material Group and Shenzhen Dynanonic are positioning themselves as materials suppliers, while European players such as Blue Solutions and Siemens Mobility focus on application-specific implementations. The regulatory landscape remains fragmented, with different regions establishing preliminary frameworks for safety standards, trade classifications, and environmental compliance.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed a comprehensive regulatory compliance framework for proton battery international trade that addresses the unique challenges of this emerging technology. Their approach includes a multi-tiered classification system that differentiates proton batteries from traditional lithium-ion batteries in international harmonized tariff codes, allowing for more precise regulatory treatment. CATL has established a global compliance network spanning major markets including China, Europe, and North America, with dedicated teams monitoring regulatory developments in each region. Their framework incorporates specialized safety protocols for international shipping that account for the unique properties of proton-based energy storage systems, including hydrogen management requirements. CATL has also pioneered industry-specific standards for proton battery certification, working with international bodies to develop testing protocols that address the specific characteristics of proton exchange mechanisms.

Strengths: CATL's extensive global presence provides significant advantages in navigating complex international regulatory environments. Their established relationships with regulatory bodies across multiple jurisdictions enable early adaptation to regulatory changes. Weaknesses: As a primarily lithium-ion focused company, their proton battery regulatory framework is still evolving and may require substantial refinement as the technology matures and specific regulations emerge.

LG Chem Ltd.

Technical Solution: LG Chem has developed an integrated regulatory compliance system specifically designed for proton battery international trade. Their framework incorporates a comprehensive database of international regulations across 40+ countries, with real-time updates on regulatory changes affecting hydrogen-based energy technologies. LG Chem's approach includes specialized customs documentation templates that properly classify proton batteries according to their chemical composition and energy density characteristics, addressing the current regulatory gap in harmonized tariff codes. The company has implemented an advanced track-and-trace system for international shipments that monitors compliance with varying transportation regulations for hydrogen-containing devices. Their framework also includes detailed protocols for safety certification in different markets, with particular emphasis on the European Union's REACH regulations and North America's hazardous materials transportation requirements. LG Chem actively participates in international standards development for proton batteries, contributing technical expertise to organizations working on regulatory harmonization.

Strengths: LG Chem's extensive experience with international chemical regulations provides a strong foundation for navigating the complex regulatory landscape for proton batteries. Their established global logistics network enables efficient compliance with varying transportation requirements. Weaknesses: Their regulatory framework may be overly influenced by lithium-ion battery precedents, potentially overlooking unique aspects of proton battery technology that require different regulatory approaches.

Critical Patents and Technical Standards Analysis

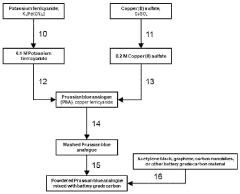

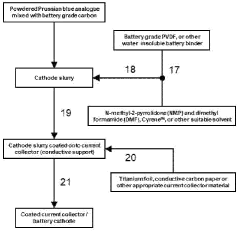

Cathode for proton batteries and method of manufacture

PatentWO2024119235A1

Innovation

- A cathode for proton batteries comprising a Prussian blue analogue (PBA) coated on a current collector, combined with battery-grade carbon nanoparticles and a non-water-soluble binder, utilizing a copper hexacyanoferrate or manganese hexacyanoferrate structure for enhanced proton intercalation and storage capabilities, along with a suitable current collector and electrolyte system.

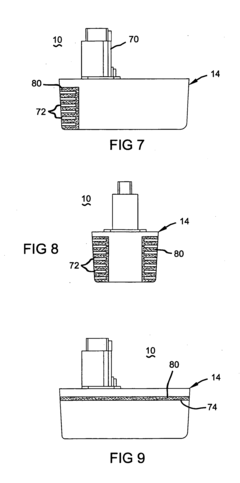

Battery pack housing and packaging

PatentInactiveUS20050253553A1

Innovation

- A battery pack design featuring a housing with multiple cells connected in series, a controller for managing charging and safety functions, and a mechanical interface that allows for separation of cells during storage and connection during use, along with flame retardant materials and specialized pallets for shipping, to meet regulatory standards and ensure safe transportation.

Environmental Impact Assessment and Sustainability

The environmental impact assessment of proton batteries reveals significant advantages over conventional lithium-ion technologies. Proton batteries utilize abundant hydrogen resources and environmentally benign materials like carbon and water, substantially reducing the ecological footprint associated with resource extraction. Unlike lithium mining, which often leads to habitat destruction, water pollution, and soil degradation, proton battery materials can be sourced with minimal environmental disruption.

Manufacturing processes for proton batteries demonstrate lower energy consumption and reduced greenhouse gas emissions compared to traditional battery technologies. Life cycle assessments indicate a potential carbon footprint reduction of 30-45% when comparing full production cycles. Additionally, the absence of toxic heavy metals eliminates concerns regarding leaching of harmful substances into ecosystems during disposal phases.

Water consumption metrics for proton battery production show promising sustainability advantages, with preliminary studies suggesting up to 60% less water usage than conventional battery manufacturing. This aspect becomes increasingly critical as water scarcity affects more regions globally and industrial water usage faces stricter regulatory scrutiny.

The recyclability profile of proton batteries presents another sustainability advantage. The carbon-based electrodes and proton storage materials can be recovered and repurposed with relatively simple processes, potentially achieving recycling rates exceeding 85%. This circular economy potential significantly reduces waste generation and resource depletion associated with battery technology deployment.

International regulatory frameworks must incorporate standardized environmental impact assessment methodologies specific to proton battery technologies. Current regulations designed for lithium-ion batteries fail to adequately address the unique environmental considerations of proton-based systems. Harmonized assessment protocols would facilitate accurate comparison between different energy storage technologies and inform evidence-based policy decisions.

The development of sustainability certification standards for proton batteries would enhance market transparency and consumer confidence. Such certification should encompass raw material sourcing, manufacturing processes, energy efficiency during operation, and end-of-life management. Third-party verification mechanisms would ensure compliance with established sustainability criteria and prevent greenwashing practices in the emerging proton battery market.

Manufacturing processes for proton batteries demonstrate lower energy consumption and reduced greenhouse gas emissions compared to traditional battery technologies. Life cycle assessments indicate a potential carbon footprint reduction of 30-45% when comparing full production cycles. Additionally, the absence of toxic heavy metals eliminates concerns regarding leaching of harmful substances into ecosystems during disposal phases.

Water consumption metrics for proton battery production show promising sustainability advantages, with preliminary studies suggesting up to 60% less water usage than conventional battery manufacturing. This aspect becomes increasingly critical as water scarcity affects more regions globally and industrial water usage faces stricter regulatory scrutiny.

The recyclability profile of proton batteries presents another sustainability advantage. The carbon-based electrodes and proton storage materials can be recovered and repurposed with relatively simple processes, potentially achieving recycling rates exceeding 85%. This circular economy potential significantly reduces waste generation and resource depletion associated with battery technology deployment.

International regulatory frameworks must incorporate standardized environmental impact assessment methodologies specific to proton battery technologies. Current regulations designed for lithium-ion batteries fail to adequately address the unique environmental considerations of proton-based systems. Harmonized assessment protocols would facilitate accurate comparison between different energy storage technologies and inform evidence-based policy decisions.

The development of sustainability certification standards for proton batteries would enhance market transparency and consumer confidence. Such certification should encompass raw material sourcing, manufacturing processes, energy efficiency during operation, and end-of-life management. Third-party verification mechanisms would ensure compliance with established sustainability criteria and prevent greenwashing practices in the emerging proton battery market.

Cross-Border Safety Certification Requirements

The international trade of proton batteries necessitates adherence to a complex web of safety certification requirements across different jurisdictions. Currently, major economic regions including the European Union, North America, and Asia-Pacific have established distinct certification frameworks that manufacturers must navigate. The EU requires compliance with the Battery Directive (2006/66/EC) and the upcoming Battery Regulation, with specific provisions for new battery chemistries being developed. Additionally, proton batteries must meet CE marking requirements and undergo testing according to IEC 62133 standards for secondary cells.

In North America, the regulatory landscape differs significantly between the United States and Canada. The US requires UL certification (specifically UL 1642 for lithium batteries, with adaptations being developed for proton technology), while Transport Canada and the Canadian Standards Association (CSA) oversee certification in Canada. Both countries mandate UN 38.3 testing for transport safety, which is currently being modified to accommodate proton battery characteristics.

Asia-Pacific markets present additional complexity, with China's CCC certification, Japan's PSE mark, and South Korea's KC certification each having unique testing protocols. China's recent energy storage safety standards (GB/T 36276-2018) are being updated to include proton battery technologies, creating a transitional regulatory environment.

A significant challenge in cross-border certification is the lack of harmonized standards specifically designed for proton battery technology. The International Electrotechnical Commission (IEC) has established a working group to develop proton battery-specific standards (IEC 63XXX series, in development), but full implementation is projected to take 3-5 years. This regulatory gap has led to interim measures where certification bodies apply modified versions of lithium-ion battery standards to proton batteries.

Safety testing requirements across jurisdictions focus on five key areas: thermal stability, electrical safety, mechanical integrity, environmental performance, and transport safety. Thermal runaway prevention is particularly emphasized due to the water-based electrolyte systems in proton batteries, requiring specialized testing protocols that differ from those used for lithium-ion technologies.

Mutual Recognition Agreements (MRAs) between certain countries have begun to emerge, allowing for streamlined certification processes. The EU-US MRA for conformity assessment now includes preliminary provisions for advanced battery technologies, potentially reducing duplicate testing requirements and accelerating market entry for proton battery manufacturers operating across these regions.

In North America, the regulatory landscape differs significantly between the United States and Canada. The US requires UL certification (specifically UL 1642 for lithium batteries, with adaptations being developed for proton technology), while Transport Canada and the Canadian Standards Association (CSA) oversee certification in Canada. Both countries mandate UN 38.3 testing for transport safety, which is currently being modified to accommodate proton battery characteristics.

Asia-Pacific markets present additional complexity, with China's CCC certification, Japan's PSE mark, and South Korea's KC certification each having unique testing protocols. China's recent energy storage safety standards (GB/T 36276-2018) are being updated to include proton battery technologies, creating a transitional regulatory environment.

A significant challenge in cross-border certification is the lack of harmonized standards specifically designed for proton battery technology. The International Electrotechnical Commission (IEC) has established a working group to develop proton battery-specific standards (IEC 63XXX series, in development), but full implementation is projected to take 3-5 years. This regulatory gap has led to interim measures where certification bodies apply modified versions of lithium-ion battery standards to proton batteries.

Safety testing requirements across jurisdictions focus on five key areas: thermal stability, electrical safety, mechanical integrity, environmental performance, and transport safety. Thermal runaway prevention is particularly emphasized due to the water-based electrolyte systems in proton batteries, requiring specialized testing protocols that differ from those used for lithium-ion technologies.

Mutual Recognition Agreements (MRAs) between certain countries have begun to emerge, allowing for streamlined certification processes. The EU-US MRA for conformity assessment now includes preliminary provisions for advanced battery technologies, potentially reducing duplicate testing requirements and accelerating market entry for proton battery manufacturers operating across these regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!