Emerging Research Trends in Ethylene Vinyl Acetate Applications

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Applications Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile polymer with a wide range of applications across various industries. The development of EVA can be traced back to the 1950s when it was first synthesized by DuPont. Since then, its unique properties, including flexibility, toughness, and excellent adhesion, have led to its widespread adoption in diverse sectors.

The evolution of EVA technology has been driven by the increasing demand for advanced materials with specific performance characteristics. Over the years, researchers and manufacturers have focused on enhancing EVA's properties through modifications in its composition, processing techniques, and blending with other materials. This continuous improvement has expanded its applicability and opened up new market opportunities.

In recent years, the global EVA market has experienced significant growth, propelled by the rising demand in industries such as packaging, footwear, solar panels, and automotive. The versatility of EVA has made it an attractive choice for manufacturers seeking cost-effective and high-performance materials. As a result, research efforts have intensified to explore novel applications and improve existing ones.

The current technological landscape for EVA applications is characterized by a focus on sustainability, enhanced performance, and customization. Researchers are exploring bio-based alternatives to traditional EVA formulations, aiming to reduce the environmental impact of polymer production. Additionally, there is a growing interest in developing EVA composites with improved mechanical, thermal, and barrier properties to meet the evolving needs of various industries.

The primary objectives of current research trends in EVA applications include:

1. Developing eco-friendly EVA formulations with reduced carbon footprint

2. Enhancing the thermal and mechanical properties of EVA for high-performance applications

3. Exploring new applications in emerging industries, such as renewable energy and 3D printing

4. Improving the processing techniques to increase production efficiency and reduce costs

5. Investigating the potential of EVA in advanced medical and pharmaceutical applications

As the demand for specialized materials continues to grow, the future of EVA applications looks promising. Researchers are expected to focus on tailoring EVA properties for specific end-use requirements, exploring novel blending and modification techniques, and addressing the challenges associated with recycling and sustainability. The ongoing technological advancements in EVA applications are likely to drive innovation across multiple industries, contributing to the development of next-generation products and solutions.

The evolution of EVA technology has been driven by the increasing demand for advanced materials with specific performance characteristics. Over the years, researchers and manufacturers have focused on enhancing EVA's properties through modifications in its composition, processing techniques, and blending with other materials. This continuous improvement has expanded its applicability and opened up new market opportunities.

In recent years, the global EVA market has experienced significant growth, propelled by the rising demand in industries such as packaging, footwear, solar panels, and automotive. The versatility of EVA has made it an attractive choice for manufacturers seeking cost-effective and high-performance materials. As a result, research efforts have intensified to explore novel applications and improve existing ones.

The current technological landscape for EVA applications is characterized by a focus on sustainability, enhanced performance, and customization. Researchers are exploring bio-based alternatives to traditional EVA formulations, aiming to reduce the environmental impact of polymer production. Additionally, there is a growing interest in developing EVA composites with improved mechanical, thermal, and barrier properties to meet the evolving needs of various industries.

The primary objectives of current research trends in EVA applications include:

1. Developing eco-friendly EVA formulations with reduced carbon footprint

2. Enhancing the thermal and mechanical properties of EVA for high-performance applications

3. Exploring new applications in emerging industries, such as renewable energy and 3D printing

4. Improving the processing techniques to increase production efficiency and reduce costs

5. Investigating the potential of EVA in advanced medical and pharmaceutical applications

As the demand for specialized materials continues to grow, the future of EVA applications looks promising. Researchers are expected to focus on tailoring EVA properties for specific end-use requirements, exploring novel blending and modification techniques, and addressing the challenges associated with recycling and sustainability. The ongoing technological advancements in EVA applications are likely to drive innovation across multiple industries, contributing to the development of next-generation products and solutions.

Market Analysis for EVA Products

The global market for Ethylene Vinyl Acetate (EVA) products has shown significant growth in recent years, driven by increasing demand across various industries. The versatility of EVA, with its unique combination of flexibility, toughness, and adhesion properties, has led to its widespread adoption in sectors such as packaging, footwear, solar panels, and automotive.

In the packaging industry, EVA is extensively used for flexible packaging solutions, particularly in food and beverage applications. The material's excellent sealing properties and resistance to moisture make it ideal for preserving product freshness. The growing emphasis on sustainable packaging has also boosted the demand for EVA-based biodegradable films.

The footwear sector represents another major market for EVA products. The material's lightweight nature, shock absorption capabilities, and durability have made it a popular choice for shoe soles and insoles. The rising health consciousness among consumers and the growing sports and fitness industry have further propelled the demand for EVA in athletic footwear.

The solar energy sector has emerged as a significant driver for EVA market growth. EVA encapsulants are crucial components in photovoltaic modules, providing protection against environmental factors and enhancing the longevity of solar panels. With the global push towards renewable energy sources, the demand for EVA in solar applications is expected to continue its upward trajectory.

In the automotive industry, EVA finds applications in various components, including gaskets, seals, and interior trims. The material's ability to withstand extreme temperatures and its sound-dampening properties make it valuable in automotive manufacturing. The trend towards electric vehicles has also opened new avenues for EVA applications in battery components.

Geographically, Asia-Pacific dominates the EVA market, with China and India being the major contributors. The region's robust manufacturing sector, coupled with increasing urbanization and disposable income, has fueled the demand for EVA products. North America and Europe follow, with steady growth driven by technological advancements and stringent regulations promoting sustainable materials.

The market landscape is characterized by intense competition among key players, leading to continuous innovation and product development. Major manufacturers are focusing on expanding their production capacities and developing specialized grades of EVA to cater to specific industry requirements. The trend towards bio-based and recyclable EVA products is gaining traction, aligning with the global shift towards sustainability.

In the packaging industry, EVA is extensively used for flexible packaging solutions, particularly in food and beverage applications. The material's excellent sealing properties and resistance to moisture make it ideal for preserving product freshness. The growing emphasis on sustainable packaging has also boosted the demand for EVA-based biodegradable films.

The footwear sector represents another major market for EVA products. The material's lightweight nature, shock absorption capabilities, and durability have made it a popular choice for shoe soles and insoles. The rising health consciousness among consumers and the growing sports and fitness industry have further propelled the demand for EVA in athletic footwear.

The solar energy sector has emerged as a significant driver for EVA market growth. EVA encapsulants are crucial components in photovoltaic modules, providing protection against environmental factors and enhancing the longevity of solar panels. With the global push towards renewable energy sources, the demand for EVA in solar applications is expected to continue its upward trajectory.

In the automotive industry, EVA finds applications in various components, including gaskets, seals, and interior trims. The material's ability to withstand extreme temperatures and its sound-dampening properties make it valuable in automotive manufacturing. The trend towards electric vehicles has also opened new avenues for EVA applications in battery components.

Geographically, Asia-Pacific dominates the EVA market, with China and India being the major contributors. The region's robust manufacturing sector, coupled with increasing urbanization and disposable income, has fueled the demand for EVA products. North America and Europe follow, with steady growth driven by technological advancements and stringent regulations promoting sustainable materials.

The market landscape is characterized by intense competition among key players, leading to continuous innovation and product development. Major manufacturers are focusing on expanding their production capacities and developing specialized grades of EVA to cater to specific industry requirements. The trend towards bio-based and recyclable EVA products is gaining traction, aligning with the global shift towards sustainability.

Current EVA Technology Challenges

Ethylene Vinyl Acetate (EVA) has gained significant traction in various industries due to its versatile properties. However, as applications expand and requirements become more stringent, several technological challenges have emerged. One of the primary issues is the limited thermal stability of EVA, particularly at higher temperatures. This constraint restricts its use in applications requiring prolonged exposure to elevated temperatures, such as certain solar panel encapsulations or high-temperature wire and cable insulations.

Another significant challenge lies in improving the barrier properties of EVA. While it offers good flexibility and clarity, its permeability to gases and moisture remains a concern in packaging and medical applications. This limitation often necessitates the use of additional barrier layers, increasing production complexity and costs.

The adhesion properties of EVA, while generally good, still present challenges in specific applications. Improving its adhesion to polar substrates without compromising other desirable properties is an ongoing area of research. This is particularly crucial in multi-layer packaging and composite materials where strong interfacial bonding is essential.

EVA's susceptibility to weathering and UV degradation poses another significant challenge, especially in outdoor applications. Enhancing its resistance to environmental factors without altering its core properties remains a key focus area for researchers and manufacturers alike.

The control of vinyl acetate (VA) content and its distribution within the polymer chain is another technical hurdle. Achieving a precise and uniform VA distribution is crucial for maintaining consistent product quality and performance across various applications. This challenge becomes more pronounced as the demand for specialized grades of EVA with specific property profiles increases.

Furthermore, the processability of EVA, particularly in terms of melt strength and thermal stability during processing, presents challenges in certain manufacturing processes. Improving these aspects without compromising the final product properties is a delicate balance that researchers are striving to achieve.

Lastly, there's an growing emphasis on developing more sustainable and environmentally friendly EVA formulations. This includes challenges in recycling EVA-based products, reducing the carbon footprint of EVA production, and exploring bio-based alternatives. The industry is grappling with finding solutions that maintain the performance characteristics of traditional EVA while meeting increasingly stringent environmental regulations and consumer demands for greener products.

Another significant challenge lies in improving the barrier properties of EVA. While it offers good flexibility and clarity, its permeability to gases and moisture remains a concern in packaging and medical applications. This limitation often necessitates the use of additional barrier layers, increasing production complexity and costs.

The adhesion properties of EVA, while generally good, still present challenges in specific applications. Improving its adhesion to polar substrates without compromising other desirable properties is an ongoing area of research. This is particularly crucial in multi-layer packaging and composite materials where strong interfacial bonding is essential.

EVA's susceptibility to weathering and UV degradation poses another significant challenge, especially in outdoor applications. Enhancing its resistance to environmental factors without altering its core properties remains a key focus area for researchers and manufacturers alike.

The control of vinyl acetate (VA) content and its distribution within the polymer chain is another technical hurdle. Achieving a precise and uniform VA distribution is crucial for maintaining consistent product quality and performance across various applications. This challenge becomes more pronounced as the demand for specialized grades of EVA with specific property profiles increases.

Furthermore, the processability of EVA, particularly in terms of melt strength and thermal stability during processing, presents challenges in certain manufacturing processes. Improving these aspects without compromising the final product properties is a delicate balance that researchers are striving to achieve.

Lastly, there's an growing emphasis on developing more sustainable and environmentally friendly EVA formulations. This includes challenges in recycling EVA-based products, reducing the carbon footprint of EVA production, and exploring bio-based alternatives. The industry is grappling with finding solutions that maintain the performance characteristics of traditional EVA while meeting increasingly stringent environmental regulations and consumer demands for greener products.

Current EVA Application Solutions

01 Composition and properties of EVA

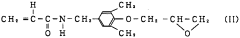

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and performance can be tailored by adjusting the EVA composition and additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It can be processed into closed-cell foams for applications such as footwear, sports equipment, and building insulation. The foam properties can be modified by adjusting the EVA grade and foaming agents.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and protection for solar cells. The material can be formulated with UV stabilizers and crosslinking agents to enhance its long-term performance in outdoor environments.

- EVA in wire and cable applications: EVA is employed in wire and cable insulation and jacketing due to its electrical insulation properties, flexibility, and resistance to environmental factors. It can be compounded with various additives to improve flame retardancy, UV resistance, and mechanical properties for specific cable applications.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and performance can be tailored by adjusting the EVA composition and additives.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It can be processed into closed-cell foams for applications such as footwear, sports equipment, and building insulation. The foam density and mechanical properties can be controlled through formulation and processing techniques.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a popular material for solar panel encapsulation due to its transparency, weatherability, and electrical insulation properties. It protects solar cells from environmental factors and ensures long-term performance. The EVA formulation can be optimized for UV resistance, adhesion to glass and backsheet materials, and crosslinking efficiency.Expand Specific Solutions05 EVA blends and composites

EVA can be blended with other polymers or filled with various additives to create composites with enhanced properties. These blends and composites find applications in areas such as wire and cable insulation, automotive parts, and packaging materials. The incorporation of fillers, reinforcing agents, or other polymers can improve mechanical strength, flame retardancy, or specific functional properties of EVA-based materials.Expand Specific Solutions

Key EVA Industry Players

The ethylene vinyl acetate (EVA) market is in a mature growth stage, characterized by steady demand across various industries. The global market size is projected to reach significant value, driven by applications in packaging, solar panels, and footwear. Technologically, EVA production is well-established, with major players like DuPont, Celanese, and China Petroleum & Chemical Corp. (Sinopec) continuously innovating to improve product performance and sustainability. Research institutions such as Shanghai Petrochemical Research Institute and Tianjin University are contributing to advancements in EVA applications. Emerging trends focus on developing bio-based EVA and enhancing its properties for specialized applications, indicating ongoing technological evolution in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) is at the forefront of Ethylene Vinyl Acetate (EVA) research and applications. Their approach focuses on developing high-performance EVA copolymers for various industries. They have made significant strides in improving EVA's thermal and mechanical properties through advanced polymerization techniques and the incorporation of nanofillers[1]. Sinopec has also been exploring the use of renewable feedstocks to produce bio-based EVA, aligning with global sustainability trends[2]. Their research extends to enhancing EVA's compatibility with other polymers for advanced composite materials, particularly in the photovoltaic industry for solar panel encapsulation[3].

Strengths: Extensive R&D capabilities, vertically integrated production, and a strong market presence in Asia. Weaknesses: Potential environmental concerns associated with petrochemical production and dependency on oil prices.

Celanese International Corp.

Technical Solution: Celanese International Corp. is pioneering research in EVA applications, particularly in the medical and pharmaceutical sectors. Their focus is on developing specialized EVA grades with enhanced biocompatibility and controlled release properties for drug delivery systems[4]. Celanese has made significant progress in creating EVA formulations with improved barrier properties for packaging applications, addressing the growing demand for sustainable and high-performance materials[5]. The company is also exploring the use of EVA in 3D printing filaments, leveraging its unique properties to create flexible and durable printed objects[6]. Their research extends to developing EVA-based adhesives with improved thermal stability and bonding strength for automotive and construction industries.

Strengths: Strong expertise in specialty polymers, global manufacturing capabilities, and diverse application portfolio. Weaknesses: Intense competition in specialty chemicals and potential regulatory challenges in medical applications.

Key EVA Research Breakthroughs

Graft ethylene-vinyl acetate copolymer and resin composition containing the same

PatentWO1997002302A1

Innovation

- A graft-modified ethylene-vinyl acetate copolymer is developed by incorporating a glycidyl group-containing compound and unsaturated glycidyl ester, along with a radical initiator, to enhance thermal stability and adhesion, and is blended with polyamide or polyester resins to improve mechanical and thermal properties.

Modified support materials for catalysts

PatentInactiveUS7518014B2

Innovation

- A method involving a modified support material with a gold to palladium atomic ratio between 0.3 and 0.9, where palladium and gold catalytic components are reduced and activated using a reducing environment and an activating agent like KOAc, forming a catalyst that improves EA selectivity while maintaining or enhancing CO2 selectivity and activity.

Environmental Impact of EVA

The environmental impact of Ethylene Vinyl Acetate (EVA) has become a significant focus in recent research trends. As the use of EVA continues to expand across various industries, understanding its ecological footprint has gained paramount importance. One of the primary concerns is the end-of-life disposal of EVA products, particularly in the context of waste management and recycling.

EVA, being a thermoplastic polymer, offers potential for recycling. However, the process is not without challenges. The presence of various additives and cross-linking agents in EVA formulations can complicate recycling efforts. Recent studies have explored innovative recycling techniques, including chemical recycling and advanced mechanical recycling processes, to address these issues and improve the recyclability of EVA-based products.

The production of EVA also raises environmental concerns, particularly regarding energy consumption and greenhouse gas emissions. Researchers are investigating more sustainable production methods, such as the use of renewable energy sources in manufacturing processes and the development of bio-based alternatives to traditional EVA formulations. These efforts aim to reduce the carbon footprint associated with EVA production.

Water pollution is another area of environmental concern related to EVA. Studies have shown that EVA can release microplastics into aquatic ecosystems, contributing to the growing problem of plastic pollution in oceans and waterways. Ongoing research is focused on developing EVA formulations that are less prone to degradation and microplastic release, as well as exploring biodegradable alternatives that maintain similar performance characteristics.

The use of EVA in agriculture, particularly in greenhouse films and mulch films, has led to investigations into its impact on soil health. While EVA films offer benefits in terms of crop yield and water conservation, concerns about soil contamination and long-term effects on soil microbiota have prompted research into more environmentally friendly alternatives and improved degradation mechanisms for agricultural EVA products.

Emerging research is also exploring the potential of EVA in environmental remediation applications. Studies have shown promise in using EVA-based materials for the removal of pollutants from water and air, leveraging the polymer's adsorption properties. This dual approach of mitigating EVA's environmental impact while harnessing its potential for environmental cleanup represents an exciting frontier in EVA research.

As sustainability becomes increasingly crucial in material science, the environmental impact of EVA continues to be a key driver of innovation and research. The development of more sustainable EVA formulations, improved recycling technologies, and novel applications in environmental protection are shaping the future of this versatile polymer, aiming to balance its industrial utility with ecological responsibility.

EVA, being a thermoplastic polymer, offers potential for recycling. However, the process is not without challenges. The presence of various additives and cross-linking agents in EVA formulations can complicate recycling efforts. Recent studies have explored innovative recycling techniques, including chemical recycling and advanced mechanical recycling processes, to address these issues and improve the recyclability of EVA-based products.

The production of EVA also raises environmental concerns, particularly regarding energy consumption and greenhouse gas emissions. Researchers are investigating more sustainable production methods, such as the use of renewable energy sources in manufacturing processes and the development of bio-based alternatives to traditional EVA formulations. These efforts aim to reduce the carbon footprint associated with EVA production.

Water pollution is another area of environmental concern related to EVA. Studies have shown that EVA can release microplastics into aquatic ecosystems, contributing to the growing problem of plastic pollution in oceans and waterways. Ongoing research is focused on developing EVA formulations that are less prone to degradation and microplastic release, as well as exploring biodegradable alternatives that maintain similar performance characteristics.

The use of EVA in agriculture, particularly in greenhouse films and mulch films, has led to investigations into its impact on soil health. While EVA films offer benefits in terms of crop yield and water conservation, concerns about soil contamination and long-term effects on soil microbiota have prompted research into more environmentally friendly alternatives and improved degradation mechanisms for agricultural EVA products.

Emerging research is also exploring the potential of EVA in environmental remediation applications. Studies have shown promise in using EVA-based materials for the removal of pollutants from water and air, leveraging the polymer's adsorption properties. This dual approach of mitigating EVA's environmental impact while harnessing its potential for environmental cleanup represents an exciting frontier in EVA research.

As sustainability becomes increasingly crucial in material science, the environmental impact of EVA continues to be a key driver of innovation and research. The development of more sustainable EVA formulations, improved recycling technologies, and novel applications in environmental protection are shaping the future of this versatile polymer, aiming to balance its industrial utility with ecological responsibility.

EVA Regulatory Landscape

The regulatory landscape for Ethylene Vinyl Acetate (EVA) is complex and evolving, reflecting the material's widespread use across various industries. Globally, EVA is subject to a range of regulations that primarily focus on its safety, environmental impact, and specific applications.

In the United States, the Food and Drug Administration (FDA) regulates EVA in food contact applications. The material must comply with specific regulations outlined in 21 CFR 177.1350, which details the conditions under which EVA can be safely used in food packaging and processing equipment. The Environmental Protection Agency (EPA) also oversees EVA production and use under the Toxic Substances Control Act (TSCA), ensuring environmental and health safety standards are met.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, manufacturers and importers of EVA must register the substance and provide detailed safety information. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive impacts EVA use in electrical and electronic equipment, requiring compliance with limits on certain hazardous substances.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees EVA production and use, with a focus on environmental protection and sustainable development. Japan's regulatory approach includes the Chemical Substances Control Law, which requires manufacturers and importers to evaluate the safety of chemical substances, including EVA.

Emerging research trends in EVA applications are influencing regulatory developments. As new applications in fields such as renewable energy (solar panels) and medical devices emerge, regulatory bodies are adapting their frameworks to address potential risks and ensure safety. For instance, the use of EVA in photovoltaic modules has led to increased scrutiny of its long-term durability and potential environmental impact at the end of the product lifecycle.

The growing emphasis on sustainability and circular economy principles is also shaping the regulatory landscape for EVA. Regulations are increasingly focusing on recyclability, biodegradability, and overall environmental footprint. This trend is particularly evident in packaging applications, where many countries are implementing stricter regulations on plastic use and disposal.

As research continues to uncover new properties and applications of EVA, regulatory bodies are likely to refine and expand their oversight. This dynamic regulatory environment necessitates ongoing vigilance and adaptation from manufacturers, importers, and end-users of EVA to ensure compliance and responsible use of the material across its diverse applications.

In the United States, the Food and Drug Administration (FDA) regulates EVA in food contact applications. The material must comply with specific regulations outlined in 21 CFR 177.1350, which details the conditions under which EVA can be safely used in food packaging and processing equipment. The Environmental Protection Agency (EPA) also oversees EVA production and use under the Toxic Substances Control Act (TSCA), ensuring environmental and health safety standards are met.

The European Union has implemented stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. Under REACH, manufacturers and importers of EVA must register the substance and provide detailed safety information. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive impacts EVA use in electrical and electronic equipment, requiring compliance with limits on certain hazardous substances.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees EVA production and use, with a focus on environmental protection and sustainable development. Japan's regulatory approach includes the Chemical Substances Control Law, which requires manufacturers and importers to evaluate the safety of chemical substances, including EVA.

Emerging research trends in EVA applications are influencing regulatory developments. As new applications in fields such as renewable energy (solar panels) and medical devices emerge, regulatory bodies are adapting their frameworks to address potential risks and ensure safety. For instance, the use of EVA in photovoltaic modules has led to increased scrutiny of its long-term durability and potential environmental impact at the end of the product lifecycle.

The growing emphasis on sustainability and circular economy principles is also shaping the regulatory landscape for EVA. Regulations are increasingly focusing on recyclability, biodegradability, and overall environmental footprint. This trend is particularly evident in packaging applications, where many countries are implementing stricter regulations on plastic use and disposal.

As research continues to uncover new properties and applications of EVA, regulatory bodies are likely to refine and expand their oversight. This dynamic regulatory environment necessitates ongoing vigilance and adaptation from manufacturers, importers, and end-users of EVA to ensure compliance and responsible use of the material across its diverse applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!