Environmental Impact Assessment of Electrolytic Cell Operations in Industrial Scales

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Tech Evolution and Objectives

Electrolytic cell technology has undergone significant evolution since its inception in the early 19th century. The fundamental principle of using electrical energy to drive non-spontaneous chemical reactions has remained constant, but the efficiency, scale, and environmental impact of these processes have dramatically improved over time.

The initial development of electrolytic cells focused primarily on small-scale laboratory applications, with limited consideration for environmental consequences. As industrial applications emerged in the late 19th and early 20th centuries, the emphasis shifted towards increasing production capacity and reducing energy consumption. This period saw the introduction of larger cells and improved electrode materials, but environmental concerns were still largely overlooked.

The mid-20th century marked a turning point in electrolytic cell technology, with growing awareness of environmental issues. Researchers began to explore ways to minimize harmful emissions and improve overall process efficiency. This led to the development of more advanced membrane technologies and the introduction of catalysts to enhance reaction rates while reducing energy requirements.

In recent decades, the objectives of electrolytic cell technology have expanded to include not only production efficiency but also environmental sustainability. Modern research focuses on developing cells that operate at lower temperatures, use less corrosive electrolytes, and produce fewer byproducts. Additionally, there is a growing interest in utilizing renewable energy sources to power electrolytic processes, further reducing their carbon footprint.

The current technological landscape is characterized by a push towards miniaturization and modularization of electrolytic cells. This approach allows for more flexible and scalable industrial applications while also facilitating better control over environmental impacts. Researchers are also exploring novel materials for electrodes and membranes that can improve selectivity and reduce unwanted side reactions.

Looking forward, the primary objectives for electrolytic cell technology include further reducing energy consumption, minimizing waste generation, and improving the overall environmental footprint of industrial-scale operations. There is a particular emphasis on developing closed-loop systems that can recycle byproducts and minimize resource consumption. Additionally, researchers are exploring the integration of advanced monitoring and control systems to optimize cell performance in real-time, ensuring consistent output while minimizing environmental impact.

The initial development of electrolytic cells focused primarily on small-scale laboratory applications, with limited consideration for environmental consequences. As industrial applications emerged in the late 19th and early 20th centuries, the emphasis shifted towards increasing production capacity and reducing energy consumption. This period saw the introduction of larger cells and improved electrode materials, but environmental concerns were still largely overlooked.

The mid-20th century marked a turning point in electrolytic cell technology, with growing awareness of environmental issues. Researchers began to explore ways to minimize harmful emissions and improve overall process efficiency. This led to the development of more advanced membrane technologies and the introduction of catalysts to enhance reaction rates while reducing energy requirements.

In recent decades, the objectives of electrolytic cell technology have expanded to include not only production efficiency but also environmental sustainability. Modern research focuses on developing cells that operate at lower temperatures, use less corrosive electrolytes, and produce fewer byproducts. Additionally, there is a growing interest in utilizing renewable energy sources to power electrolytic processes, further reducing their carbon footprint.

The current technological landscape is characterized by a push towards miniaturization and modularization of electrolytic cells. This approach allows for more flexible and scalable industrial applications while also facilitating better control over environmental impacts. Researchers are also exploring novel materials for electrodes and membranes that can improve selectivity and reduce unwanted side reactions.

Looking forward, the primary objectives for electrolytic cell technology include further reducing energy consumption, minimizing waste generation, and improving the overall environmental footprint of industrial-scale operations. There is a particular emphasis on developing closed-loop systems that can recycle byproducts and minimize resource consumption. Additionally, researchers are exploring the integration of advanced monitoring and control systems to optimize cell performance in real-time, ensuring consistent output while minimizing environmental impact.

Market Demand for Sustainable Electrolysis

The market demand for sustainable electrolysis has been steadily growing in recent years, driven by the increasing focus on environmental sustainability and the transition towards cleaner energy sources. This trend is particularly evident in industries that rely heavily on electrolytic processes, such as chlor-alkali production, water treatment, and hydrogen generation.

In the chlor-alkali industry, which produces essential chemicals like chlorine, caustic soda, and hydrogen, there is a significant push towards more sustainable electrolysis methods. Traditional mercury-cell and diaphragm-cell technologies are being phased out in favor of membrane-cell technology, which offers improved energy efficiency and reduced environmental impact. This shift is driven by both regulatory pressures and market demands for greener production processes.

The water treatment sector is another area where sustainable electrolysis is gaining traction. Electrochemical water treatment methods, such as electrocoagulation and electrooxidation, are becoming increasingly popular due to their effectiveness in removing contaminants without the need for additional chemicals. These technologies are particularly in demand for industrial wastewater treatment, where stringent environmental regulations are driving the adoption of more sustainable solutions.

Hydrogen production through water electrolysis is experiencing a surge in demand, particularly in the context of the growing hydrogen economy. Green hydrogen, produced using renewable energy sources, is seen as a key component in decarbonizing various sectors, including transportation, industry, and power generation. This has led to increased investment in electrolysis technologies, with a focus on improving efficiency and scalability.

The market for sustainable electrolysis is also being driven by the broader trend of industrial decarbonization. Many companies are setting ambitious carbon reduction targets and are looking for ways to minimize the environmental impact of their operations. Sustainable electrolysis technologies offer a pathway to reduce carbon emissions in various industrial processes, making them attractive to companies seeking to improve their environmental performance.

Furthermore, government policies and incentives aimed at promoting clean energy and reducing greenhouse gas emissions are creating a favorable environment for sustainable electrolysis technologies. Subsidies, tax incentives, and research grants are encouraging innovation and adoption in this field, further stimulating market demand.

As the global focus on sustainability intensifies, the market for sustainable electrolysis is expected to continue its growth trajectory. Industries are increasingly recognizing the long-term benefits of adopting cleaner technologies, not only in terms of environmental impact but also in terms of operational efficiency and regulatory compliance. This growing awareness is likely to drive further investment and innovation in sustainable electrolysis solutions across various industrial applications.

In the chlor-alkali industry, which produces essential chemicals like chlorine, caustic soda, and hydrogen, there is a significant push towards more sustainable electrolysis methods. Traditional mercury-cell and diaphragm-cell technologies are being phased out in favor of membrane-cell technology, which offers improved energy efficiency and reduced environmental impact. This shift is driven by both regulatory pressures and market demands for greener production processes.

The water treatment sector is another area where sustainable electrolysis is gaining traction. Electrochemical water treatment methods, such as electrocoagulation and electrooxidation, are becoming increasingly popular due to their effectiveness in removing contaminants without the need for additional chemicals. These technologies are particularly in demand for industrial wastewater treatment, where stringent environmental regulations are driving the adoption of more sustainable solutions.

Hydrogen production through water electrolysis is experiencing a surge in demand, particularly in the context of the growing hydrogen economy. Green hydrogen, produced using renewable energy sources, is seen as a key component in decarbonizing various sectors, including transportation, industry, and power generation. This has led to increased investment in electrolysis technologies, with a focus on improving efficiency and scalability.

The market for sustainable electrolysis is also being driven by the broader trend of industrial decarbonization. Many companies are setting ambitious carbon reduction targets and are looking for ways to minimize the environmental impact of their operations. Sustainable electrolysis technologies offer a pathway to reduce carbon emissions in various industrial processes, making them attractive to companies seeking to improve their environmental performance.

Furthermore, government policies and incentives aimed at promoting clean energy and reducing greenhouse gas emissions are creating a favorable environment for sustainable electrolysis technologies. Subsidies, tax incentives, and research grants are encouraging innovation and adoption in this field, further stimulating market demand.

As the global focus on sustainability intensifies, the market for sustainable electrolysis is expected to continue its growth trajectory. Industries are increasingly recognizing the long-term benefits of adopting cleaner technologies, not only in terms of environmental impact but also in terms of operational efficiency and regulatory compliance. This growing awareness is likely to drive further investment and innovation in sustainable electrolysis solutions across various industrial applications.

Current Challenges in Industrial Electrolysis

Industrial electrolysis faces several significant challenges that hinder its efficiency, sustainability, and widespread adoption. One of the primary concerns is the high energy consumption associated with electrolytic processes. The substantial electrical input required for large-scale operations contributes to increased operational costs and carbon footprints, making it difficult to align with global sustainability goals.

Material degradation and corrosion present another major hurdle in industrial electrolysis. The harsh chemical environments within electrolytic cells often lead to accelerated wear of electrodes and other components. This not only increases maintenance costs but also affects the purity of the final products and the overall efficiency of the process.

The management of byproducts and waste streams poses a significant environmental challenge. Many electrolytic processes generate unwanted side products or toxic substances that require careful handling and disposal. Developing effective methods for treating or valorizing these byproducts is crucial for improving the environmental profile of industrial electrolysis.

Scaling up laboratory processes to industrial levels introduces complexities in maintaining uniform current distribution and electrolyte composition. Achieving consistent product quality across large-scale operations remains a persistent challenge, often requiring sophisticated control systems and innovative cell designs.

The limited availability and high cost of certain electrode materials, particularly for specialized applications, constrain the economic viability of some electrolytic processes. Research into alternative, more abundant materials that can match or exceed the performance of traditional electrodes is an ongoing area of focus.

Safety concerns, especially in processes involving flammable or explosive gases like hydrogen, necessitate rigorous safety protocols and equipment. Balancing safety requirements with operational efficiency adds another layer of complexity to industrial electrolysis operations.

Water management and purification represent critical challenges, particularly in water-intensive electrolytic processes. Ensuring a consistent supply of high-purity water while minimizing water consumption and managing wastewater is essential for sustainable operations.

The integration of renewable energy sources into electrolytic processes presents both opportunities and challenges. While it offers the potential to reduce the carbon footprint of operations, the intermittent nature of many renewable sources complicates process control and efficiency optimization.

Addressing these multifaceted challenges requires interdisciplinary approaches, combining advances in materials science, process engineering, and environmental technology. Innovations in electrode materials, cell design, and process control systems are crucial for overcoming these hurdles and enhancing the sustainability and efficiency of industrial electrolysis.

Material degradation and corrosion present another major hurdle in industrial electrolysis. The harsh chemical environments within electrolytic cells often lead to accelerated wear of electrodes and other components. This not only increases maintenance costs but also affects the purity of the final products and the overall efficiency of the process.

The management of byproducts and waste streams poses a significant environmental challenge. Many electrolytic processes generate unwanted side products or toxic substances that require careful handling and disposal. Developing effective methods for treating or valorizing these byproducts is crucial for improving the environmental profile of industrial electrolysis.

Scaling up laboratory processes to industrial levels introduces complexities in maintaining uniform current distribution and electrolyte composition. Achieving consistent product quality across large-scale operations remains a persistent challenge, often requiring sophisticated control systems and innovative cell designs.

The limited availability and high cost of certain electrode materials, particularly for specialized applications, constrain the economic viability of some electrolytic processes. Research into alternative, more abundant materials that can match or exceed the performance of traditional electrodes is an ongoing area of focus.

Safety concerns, especially in processes involving flammable or explosive gases like hydrogen, necessitate rigorous safety protocols and equipment. Balancing safety requirements with operational efficiency adds another layer of complexity to industrial electrolysis operations.

Water management and purification represent critical challenges, particularly in water-intensive electrolytic processes. Ensuring a consistent supply of high-purity water while minimizing water consumption and managing wastewater is essential for sustainable operations.

The integration of renewable energy sources into electrolytic processes presents both opportunities and challenges. While it offers the potential to reduce the carbon footprint of operations, the intermittent nature of many renewable sources complicates process control and efficiency optimization.

Addressing these multifaceted challenges requires interdisciplinary approaches, combining advances in materials science, process engineering, and environmental technology. Innovations in electrode materials, cell design, and process control systems are crucial for overcoming these hurdles and enhancing the sustainability and efficiency of industrial electrolysis.

Existing Environmental Solutions for Electrolysis

01 Reduction of greenhouse gas emissions

Electrolytic cells can be designed to reduce greenhouse gas emissions in industrial processes. By utilizing renewable energy sources and optimizing the electrolysis process, these cells can contribute to lowering the carbon footprint of various industries, including chemical manufacturing and metal production.- Reduction of greenhouse gas emissions: Electrolytic cells can be designed to reduce greenhouse gas emissions in industrial processes. By utilizing renewable energy sources and optimizing the electrolysis process, these cells can contribute to lowering the carbon footprint of various industries, including chemical manufacturing and metal production.

- Water treatment and purification: Electrolytic cells play a crucial role in water treatment and purification systems. They can effectively remove contaminants, disinfect water, and reduce the need for chemical additives, thus minimizing the environmental impact of water treatment processes and improving overall water quality.

- Energy efficiency and renewable integration: Advanced electrolytic cell designs focus on improving energy efficiency and integrating renewable energy sources. This approach reduces the overall energy consumption and promotes the use of clean energy in industrial processes, leading to a more sustainable and environmentally friendly operation.

- Waste reduction and resource recovery: Electrolytic cells can be utilized for waste reduction and resource recovery in various industries. By implementing these cells in recycling processes, valuable materials can be extracted from waste streams, reducing the amount of waste sent to landfills and conserving natural resources.

- Life cycle assessment and environmental monitoring: Implementing life cycle assessment tools and environmental monitoring systems for electrolytic cell operations helps in identifying and mitigating potential environmental impacts. This approach enables continuous improvement in the environmental performance of electrolytic processes and ensures compliance with environmental regulations.

02 Water treatment and purification

Electrolytic cells play a crucial role in water treatment and purification systems. They can effectively remove contaminants, disinfect water, and reduce the need for chemical additives, thus minimizing the environmental impact of water treatment processes and improving overall water quality.Expand Specific Solutions03 Energy efficiency and renewable energy integration

Advanced electrolytic cell designs focus on improving energy efficiency and integrating renewable energy sources. This approach reduces the overall energy consumption and promotes the use of clean energy in industrial processes, leading to a more sustainable and environmentally friendly operation.Expand Specific Solutions04 Waste reduction and resource recovery

Electrolytic cells can be utilized for waste reduction and resource recovery in various industries. By employing electrochemical processes, these cells can treat industrial effluents, recover valuable materials, and minimize the environmental impact of waste disposal.Expand Specific Solutions05 Life cycle assessment and environmental monitoring

Implementing life cycle assessment and environmental monitoring systems for electrolytic cell operations helps identify and mitigate potential environmental impacts. This approach enables continuous improvement in environmental performance and ensures compliance with regulatory standards.Expand Specific Solutions

Key Players in Industrial Electrolysis

The environmental impact assessment of electrolytic cell operations in industrial scales is currently in a growth phase, with increasing market size due to rising environmental concerns and regulatory pressures. The technology's maturity varies across companies, with established players like Ecolab USA, Inc. and Industrie De Nora SpA demonstrating advanced capabilities. Emerging companies such as Axine Water Technologies and Electric Hydrogen Co. are driving innovation in this field. The competitive landscape is diverse, featuring both traditional industrial giants and specialized environmental technology firms. As the industry evolves, there's a growing focus on developing more efficient and sustainable electrolytic processes to minimize environmental impact in large-scale industrial operations.

Axine Water Technologies, Inc.

Technical Solution: Axine Water Technologies, Inc. specializes in electrochemical treatment solutions for industrial wastewater, with a particular focus on pharmaceutical and chemical manufacturing effluents. Their proprietary electrolytic cell technology utilizes advanced catalysts and electrode materials to achieve high pollutant removal rates while minimizing energy consumption[8]. Axine's systems incorporate real-time monitoring and adaptive control algorithms that optimize treatment processes based on influent characteristics, reducing chemical usage by up to 50% compared to conventional treatment methods[9]. The company has developed a comprehensive environmental impact assessment framework that considers not only direct emissions but also the avoided environmental burden from reduced chemical manufacturing and transportation.

Strengths: Highly effective for treating complex industrial wastewaters, reduced chemical usage, and adaptive process control. Weaknesses: Specialized application may limit broader industrial adoption, potential high initial investment costs.

Electric Hydrogen Co.

Technical Solution: Electric Hydrogen Co. has pioneered large-scale electrolysis systems for green hydrogen production with a strong focus on environmental sustainability. Their proprietary electrolytic cell design incorporates advanced materials that increase efficiency by up to 30% compared to conventional alkaline electrolyzers[6]. The company has developed a modular approach to electrolysis, allowing for scalable installations that can be optimized for specific industrial requirements. Electric Hydrogen's systems include integrated heat recovery mechanisms, which capture and repurpose waste heat, improving overall system efficiency by an additional 10-15%[7]. Their environmental impact assessment includes a comprehensive life cycle analysis, considering factors such as raw material sourcing, manufacturing processes, and end-of-life recycling.

Strengths: High efficiency in green hydrogen production, modular and scalable design, integrated heat recovery. Weaknesses: Limited to hydrogen production applications, potentially high capital costs for large-scale implementations.

Innovations in Green Electrolytic Processes

Electrolytic cell for the production of aluminum

PatentInactiveEP0517100A3

Innovation

- The electrolytic cell design incorporates enlarged active anode and cathode surfaces, reduced current densities, centralized oxide feeding, inclined anode surfaces, a continuous anode system with pre-fired blocks, and a cathode structure that minimizes magnetic interference and heat dissipation, along with optimized gas management to reduce energy consumption and emissions.

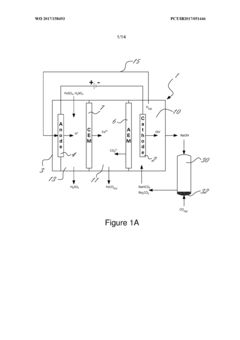

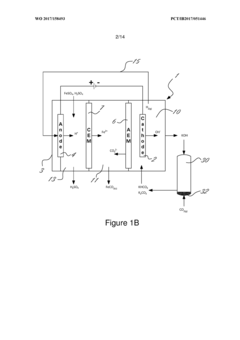

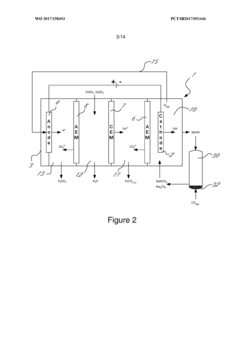

Electrolytic cells and uses thereof for the treatment of acid mine drainage and for sequestering co 2

PatentWO2017158493A1

Innovation

- The use of multi-chamber electrolytic cells with cationic and anionic exchange membranes, coupled with a C02 absorption reactor, to electrochemically convert metal sulfate compounds into stable metal carbonate compounds while sequestering C02, utilizing a hydrogen-oxidizing anode and cathode to manage pH and ion exchange efficiently.

Environmental Regulations for Electrolytic Industries

Environmental regulations for electrolytic industries have become increasingly stringent in recent years, reflecting growing concerns about the environmental impact of industrial processes. These regulations aim to minimize the ecological footprint of electrolytic cell operations while ensuring sustainable industrial growth. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Bank have established guidelines for environmental protection in industrial settings, including specific provisions for electrolytic industries.

In the United States, the Environmental Protection Agency (EPA) oversees the implementation of regulations pertaining to electrolytic industries. The Clean Air Act and Clean Water Act are two primary pieces of legislation that directly impact these industries. The National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically addresses emissions from electrolytic processes, setting limits on the release of pollutants such as chlorine, hydrogen chloride, and mercury.

The European Union has implemented the Industrial Emissions Directive (IED), which applies to various industrial activities, including electrolytic processes. This directive mandates the use of Best Available Techniques (BAT) to prevent and control emissions. The BAT Reference Documents (BREFs) for the non-ferrous metals industries provide specific guidance for electrolytic operations, covering aspects such as energy efficiency, waste management, and emission control.

In China, the Ministry of Ecology and Environment has issued a series of regulations and standards for electrolytic industries, focusing on pollution prevention and control. These include the Emission Standard of Pollutants for the Aluminum Industry and the Integrated Emission Standard of Air Pollutants, which set specific limits for various pollutants associated with electrolytic processes.

Many countries have also implemented regulations regarding the disposal of spent electrolytes and other waste products from electrolytic operations. These regulations often require proper treatment and disposal methods to prevent soil and groundwater contamination. Additionally, there is a growing emphasis on the recycling and recovery of valuable materials from electrolytic waste streams, driven by both environmental concerns and resource conservation goals.

Compliance with these regulations often requires significant investments in pollution control technologies and process improvements. However, many industries have found that adherence to environmental regulations can lead to long-term cost savings through improved efficiency and reduced liability. As global environmental awareness continues to grow, it is likely that regulations for electrolytic industries will become even more comprehensive and stringent in the future, necessitating ongoing adaptation and innovation in industrial practices.

In the United States, the Environmental Protection Agency (EPA) oversees the implementation of regulations pertaining to electrolytic industries. The Clean Air Act and Clean Water Act are two primary pieces of legislation that directly impact these industries. The National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically addresses emissions from electrolytic processes, setting limits on the release of pollutants such as chlorine, hydrogen chloride, and mercury.

The European Union has implemented the Industrial Emissions Directive (IED), which applies to various industrial activities, including electrolytic processes. This directive mandates the use of Best Available Techniques (BAT) to prevent and control emissions. The BAT Reference Documents (BREFs) for the non-ferrous metals industries provide specific guidance for electrolytic operations, covering aspects such as energy efficiency, waste management, and emission control.

In China, the Ministry of Ecology and Environment has issued a series of regulations and standards for electrolytic industries, focusing on pollution prevention and control. These include the Emission Standard of Pollutants for the Aluminum Industry and the Integrated Emission Standard of Air Pollutants, which set specific limits for various pollutants associated with electrolytic processes.

Many countries have also implemented regulations regarding the disposal of spent electrolytes and other waste products from electrolytic operations. These regulations often require proper treatment and disposal methods to prevent soil and groundwater contamination. Additionally, there is a growing emphasis on the recycling and recovery of valuable materials from electrolytic waste streams, driven by both environmental concerns and resource conservation goals.

Compliance with these regulations often requires significant investments in pollution control technologies and process improvements. However, many industries have found that adherence to environmental regulations can lead to long-term cost savings through improved efficiency and reduced liability. As global environmental awareness continues to grow, it is likely that regulations for electrolytic industries will become even more comprehensive and stringent in the future, necessitating ongoing adaptation and innovation in industrial practices.

Life Cycle Assessment of Electrolytic Operations

Life Cycle Assessment (LCA) of electrolytic operations is a comprehensive approach to evaluating the environmental impacts associated with all stages of the electrolytic process, from raw material extraction to end-of-life disposal. This assessment is crucial for understanding the full environmental footprint of industrial-scale electrolytic cell operations and identifying opportunities for improvement.

The LCA process typically begins with a detailed inventory of inputs and outputs for each stage of the electrolytic operation. This includes energy consumption, raw material usage, water requirements, and emissions to air, water, and soil. For electrolytic cells, key inputs often include electricity, electrodes, electrolytes, and process water. Outputs may encompass the desired product, waste heat, spent electrolytes, and various byproducts or emissions.

One of the primary focus areas in LCA for electrolytic operations is energy consumption. Electrolytic processes are often energy-intensive, and the environmental impact can vary significantly depending on the source of electricity. Renewable energy sources can substantially reduce the carbon footprint compared to fossil fuel-based electricity. The assessment also considers the production and transportation of raw materials, which can contribute significantly to the overall environmental impact.

Water usage and management are critical aspects of the LCA for electrolytic operations. Many electrolytic processes require large volumes of water for cooling, cleaning, or as part of the electrolyte solution. The assessment evaluates both the quantity of water used and the potential for water pollution through the release of process chemicals or byproducts.

The LCA also examines the lifespan and disposal of equipment used in electrolytic operations. This includes the environmental impacts associated with the production of electrodes, cell components, and other infrastructure, as well as their eventual disposal or recycling. The durability and recyclability of these components can significantly influence the overall environmental profile of the operation.

Emissions and waste management form another crucial part of the assessment. This involves quantifying and characterizing air emissions, liquid effluents, and solid waste generated throughout the electrolytic process. The potential for recycling or reusing byproducts and waste streams is evaluated to identify opportunities for reducing environmental impact and improving resource efficiency.

By conducting a thorough LCA, industries can identify hotspots in their electrolytic operations where environmental impacts are most significant. This information can guide targeted improvements, such as implementing more efficient technologies, optimizing processes, or exploring alternative materials. The results of an LCA can also inform decision-making regarding technology selection, process design, and sustainability strategies for electrolytic operations at industrial scales.

The LCA process typically begins with a detailed inventory of inputs and outputs for each stage of the electrolytic operation. This includes energy consumption, raw material usage, water requirements, and emissions to air, water, and soil. For electrolytic cells, key inputs often include electricity, electrodes, electrolytes, and process water. Outputs may encompass the desired product, waste heat, spent electrolytes, and various byproducts or emissions.

One of the primary focus areas in LCA for electrolytic operations is energy consumption. Electrolytic processes are often energy-intensive, and the environmental impact can vary significantly depending on the source of electricity. Renewable energy sources can substantially reduce the carbon footprint compared to fossil fuel-based electricity. The assessment also considers the production and transportation of raw materials, which can contribute significantly to the overall environmental impact.

Water usage and management are critical aspects of the LCA for electrolytic operations. Many electrolytic processes require large volumes of water for cooling, cleaning, or as part of the electrolyte solution. The assessment evaluates both the quantity of water used and the potential for water pollution through the release of process chemicals or byproducts.

The LCA also examines the lifespan and disposal of equipment used in electrolytic operations. This includes the environmental impacts associated with the production of electrodes, cell components, and other infrastructure, as well as their eventual disposal or recycling. The durability and recyclability of these components can significantly influence the overall environmental profile of the operation.

Emissions and waste management form another crucial part of the assessment. This involves quantifying and characterizing air emissions, liquid effluents, and solid waste generated throughout the electrolytic process. The potential for recycling or reusing byproducts and waste streams is evaluated to identify opportunities for reducing environmental impact and improving resource efficiency.

By conducting a thorough LCA, industries can identify hotspots in their electrolytic operations where environmental impacts are most significant. This information can guide targeted improvements, such as implementing more efficient technologies, optimizing processes, or exploring alternative materials. The results of an LCA can also inform decision-making regarding technology selection, process design, and sustainability strategies for electrolytic operations at industrial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!