Ethylene Vinyl Acetate and Its Role in Sustainable Manufacturing

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile and significant material in the realm of sustainable manufacturing. This copolymer, composed of ethylene and vinyl acetate, has a rich history dating back to the 1930s when it was first developed. Over the decades, EVA has evolved from a niche product to a widely used material across various industries, owing to its unique combination of properties.

The development of EVA technology has been driven by the increasing demand for materials that offer flexibility, durability, and environmental compatibility. As global awareness of sustainability issues has grown, EVA has gained prominence due to its potential to contribute to more eco-friendly manufacturing processes and products. The material's low toxicity, recyclability, and energy-efficient production methods align well with the principles of sustainable manufacturing.

In recent years, the focus on EVA has intensified as industries seek alternatives to traditional plastics and rubber materials. The automotive, footwear, solar panel, and packaging sectors have been at the forefront of adopting EVA in their manufacturing processes. This shift is largely attributed to EVA's ability to reduce carbon footprints and enhance product performance simultaneously.

The primary objective in the field of EVA research and development is to further optimize its properties for sustainable applications. This includes improving its biodegradability, enhancing its recycling efficiency, and expanding its use in renewable energy technologies. Researchers are also exploring ways to increase the renewable content in EVA formulations, potentially incorporating bio-based feedstocks to reduce reliance on fossil fuels.

Another key goal is to develop EVA composites that can replace less sustainable materials in various applications. This involves creating blends with other polymers or incorporating additives to enhance specific properties while maintaining EVA's core benefits. The aim is to broaden the material's applicability in sustainable manufacturing without compromising its environmental advantages.

As we look towards the future, the trajectory of EVA in sustainable manufacturing is poised for significant growth. The technology is expected to play a crucial role in the transition towards a circular economy, where materials are designed for reuse and recycling. Innovations in EVA technology are likely to focus on improving its end-of-life management, reducing its environmental impact throughout its lifecycle, and expanding its use in cutting-edge sustainable technologies.

The development of EVA technology has been driven by the increasing demand for materials that offer flexibility, durability, and environmental compatibility. As global awareness of sustainability issues has grown, EVA has gained prominence due to its potential to contribute to more eco-friendly manufacturing processes and products. The material's low toxicity, recyclability, and energy-efficient production methods align well with the principles of sustainable manufacturing.

In recent years, the focus on EVA has intensified as industries seek alternatives to traditional plastics and rubber materials. The automotive, footwear, solar panel, and packaging sectors have been at the forefront of adopting EVA in their manufacturing processes. This shift is largely attributed to EVA's ability to reduce carbon footprints and enhance product performance simultaneously.

The primary objective in the field of EVA research and development is to further optimize its properties for sustainable applications. This includes improving its biodegradability, enhancing its recycling efficiency, and expanding its use in renewable energy technologies. Researchers are also exploring ways to increase the renewable content in EVA formulations, potentially incorporating bio-based feedstocks to reduce reliance on fossil fuels.

Another key goal is to develop EVA composites that can replace less sustainable materials in various applications. This involves creating blends with other polymers or incorporating additives to enhance specific properties while maintaining EVA's core benefits. The aim is to broaden the material's applicability in sustainable manufacturing without compromising its environmental advantages.

As we look towards the future, the trajectory of EVA in sustainable manufacturing is poised for significant growth. The technology is expected to play a crucial role in the transition towards a circular economy, where materials are designed for reuse and recycling. Innovations in EVA technology are likely to focus on improving its end-of-life management, reducing its environmental impact throughout its lifecycle, and expanding its use in cutting-edge sustainable technologies.

Market Demand Analysis for EVA

The market demand for Ethylene Vinyl Acetate (EVA) has been steadily growing, driven by its versatile properties and increasing applications in sustainable manufacturing. EVA's unique combination of flexibility, durability, and low-temperature toughness has made it a preferred material in various industries, including packaging, footwear, solar panels, and automotive components.

In the packaging sector, EVA's excellent barrier properties and heat-sealing capabilities have led to its widespread use in flexible packaging solutions. The global shift towards sustainable packaging has further boosted EVA demand, as it can be easily recycled and offers reduced material usage compared to traditional packaging materials.

The footwear industry has also significantly contributed to the rising demand for EVA. Its lightweight nature, shock-absorption properties, and resistance to water and UV radiation make it an ideal material for shoe soles and insoles. Major sportswear brands have increasingly incorporated EVA into their product lines, driving market growth.

The renewable energy sector, particularly solar panel manufacturing, has emerged as a key driver for EVA demand. EVA is used as an encapsulant material in photovoltaic modules, providing protection against environmental factors and enhancing the overall efficiency of solar panels. With the global push towards clean energy, the demand for EVA in this sector is expected to continue its upward trajectory.

In the automotive industry, EVA's application in interior components, wire and cable insulation, and gaskets has been growing. The material's ability to reduce vehicle weight while maintaining performance aligns well with the industry's focus on fuel efficiency and sustainability.

The construction sector has also shown increased interest in EVA-based products, particularly in flooring, roofing membranes, and adhesives. EVA's weather resistance and durability make it suitable for both indoor and outdoor applications, contributing to its market growth in this sector.

Geographically, Asia-Pacific has emerged as the largest market for EVA, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs. North America and Europe follow, with growing demand in sustainable packaging and renewable energy applications.

The market trend indicates a shift towards bio-based EVA alternatives, as manufacturers seek to reduce their carbon footprint and meet stringent environmental regulations. This trend is likely to shape the future of EVA production and consumption, potentially opening new avenues for sustainable manufacturing practices.

In the packaging sector, EVA's excellent barrier properties and heat-sealing capabilities have led to its widespread use in flexible packaging solutions. The global shift towards sustainable packaging has further boosted EVA demand, as it can be easily recycled and offers reduced material usage compared to traditional packaging materials.

The footwear industry has also significantly contributed to the rising demand for EVA. Its lightweight nature, shock-absorption properties, and resistance to water and UV radiation make it an ideal material for shoe soles and insoles. Major sportswear brands have increasingly incorporated EVA into their product lines, driving market growth.

The renewable energy sector, particularly solar panel manufacturing, has emerged as a key driver for EVA demand. EVA is used as an encapsulant material in photovoltaic modules, providing protection against environmental factors and enhancing the overall efficiency of solar panels. With the global push towards clean energy, the demand for EVA in this sector is expected to continue its upward trajectory.

In the automotive industry, EVA's application in interior components, wire and cable insulation, and gaskets has been growing. The material's ability to reduce vehicle weight while maintaining performance aligns well with the industry's focus on fuel efficiency and sustainability.

The construction sector has also shown increased interest in EVA-based products, particularly in flooring, roofing membranes, and adhesives. EVA's weather resistance and durability make it suitable for both indoor and outdoor applications, contributing to its market growth in this sector.

Geographically, Asia-Pacific has emerged as the largest market for EVA, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs. North America and Europe follow, with growing demand in sustainable packaging and renewable energy applications.

The market trend indicates a shift towards bio-based EVA alternatives, as manufacturers seek to reduce their carbon footprint and meet stringent environmental regulations. This trend is likely to shape the future of EVA production and consumption, potentially opening new avenues for sustainable manufacturing practices.

EVA Technology Status and Challenges

Ethylene Vinyl Acetate (EVA) has emerged as a significant material in sustainable manufacturing, yet its current technological status presents both advancements and challenges. The global EVA market has witnessed substantial growth, driven by increasing demand in various industries such as solar panel encapsulation, packaging, and footwear. However, the technology faces several hurdles in its quest for sustainability.

One of the primary challenges in EVA production is the reliance on fossil fuel-based raw materials. The ethylene and vinyl acetate monomers used in EVA synthesis are typically derived from petroleum sources, which raises concerns about long-term sustainability and environmental impact. This dependence on non-renewable resources has prompted research into bio-based alternatives, but scalable solutions remain elusive.

The production process of EVA also presents environmental challenges. Traditional manufacturing methods often involve high energy consumption and the use of potentially harmful solvents. Efforts to develop more energy-efficient processes and environmentally friendly catalysts are ongoing, but widespread implementation is yet to be achieved. Additionally, the variability in EVA properties based on vinyl acetate content necessitates precise control during production, which can be technologically demanding.

Recycling EVA products poses another significant challenge. The cross-linked structure of EVA, particularly in applications like solar panel encapsulation, makes it difficult to recycle using conventional methods. This has led to increased landfill waste and environmental concerns. Research into advanced recycling technologies, such as chemical recycling and depolymerization, shows promise but is still in early stages of development.

The geographical distribution of EVA technology and production capabilities is uneven, with Asia-Pacific dominating the market. This concentration raises concerns about supply chain resilience and technology transfer. Efforts to diversify production and enhance technological capabilities in other regions are underway but face economic and infrastructural barriers.

In terms of technological advancements, recent years have seen improvements in EVA copolymer design, allowing for better tailoring of properties for specific applications. Innovations in crosslinking technologies have led to EVA materials with enhanced thermal and mechanical properties. However, these advancements often come at the cost of increased complexity in processing and potential challenges in end-of-life management.

The integration of EVA into sustainable manufacturing practices also faces regulatory challenges. Evolving environmental regulations and sustainability standards require continuous adaptation of EVA technology. This includes developing formulations with reduced volatile organic compound (VOC) emissions and improving the overall life cycle assessment of EVA products.

One of the primary challenges in EVA production is the reliance on fossil fuel-based raw materials. The ethylene and vinyl acetate monomers used in EVA synthesis are typically derived from petroleum sources, which raises concerns about long-term sustainability and environmental impact. This dependence on non-renewable resources has prompted research into bio-based alternatives, but scalable solutions remain elusive.

The production process of EVA also presents environmental challenges. Traditional manufacturing methods often involve high energy consumption and the use of potentially harmful solvents. Efforts to develop more energy-efficient processes and environmentally friendly catalysts are ongoing, but widespread implementation is yet to be achieved. Additionally, the variability in EVA properties based on vinyl acetate content necessitates precise control during production, which can be technologically demanding.

Recycling EVA products poses another significant challenge. The cross-linked structure of EVA, particularly in applications like solar panel encapsulation, makes it difficult to recycle using conventional methods. This has led to increased landfill waste and environmental concerns. Research into advanced recycling technologies, such as chemical recycling and depolymerization, shows promise but is still in early stages of development.

The geographical distribution of EVA technology and production capabilities is uneven, with Asia-Pacific dominating the market. This concentration raises concerns about supply chain resilience and technology transfer. Efforts to diversify production and enhance technological capabilities in other regions are underway but face economic and infrastructural barriers.

In terms of technological advancements, recent years have seen improvements in EVA copolymer design, allowing for better tailoring of properties for specific applications. Innovations in crosslinking technologies have led to EVA materials with enhanced thermal and mechanical properties. However, these advancements often come at the cost of increased complexity in processing and potential challenges in end-of-life management.

The integration of EVA into sustainable manufacturing practices also faces regulatory challenges. Evolving environmental regulations and sustainability standards require continuous adaptation of EVA technology. This includes developing formulations with reduced volatile organic compound (VOC) emissions and improving the overall life cycle assessment of EVA products.

Current EVA Manufacturing Solutions

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The vinyl acetate content can be varied to modify the properties of the material, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base for other adhesive systems. The material's low melting point and good flow characteristics make it suitable for bonding applications in industries such as packaging and woodworking.

- EVA in foam and insulation products: EVA is utilized in the production of foam and insulation materials due to its closed-cell structure and low thermal conductivity. It can be processed into sheets, rolls, or molded shapes for applications in footwear, sports equipment, and building insulation. The material's lightweight nature and shock-absorbing properties make it ideal for protective padding and cushioning.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. The material helps protect solar cells from environmental factors and ensures long-term performance of the solar panels. Research focuses on improving EVA formulations to enhance UV stability and reduce yellowing over time.

- EVA in wire and cable applications: EVA is used in the production of wire and cable insulation and jacketing materials. Its flexibility, flame retardancy, and resistance to environmental stress cracking make it suitable for both indoor and outdoor cable applications. EVA compounds can be formulated to meet specific industry standards for electrical and physical properties in various cable types.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends for packaging, bookbinding, and other industrial applications.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear soles, sports equipment padding, and building insulation. EVA foams can be crosslinked to improve their properties.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a key material in the production of solar panels, where it is used as an encapsulant. It provides excellent transparency, weather resistance, and adhesion to both glass and solar cells, protecting the photovoltaic components from environmental factors and enhancing the overall performance and durability of solar modules.Expand Specific Solutions05 EVA in film and packaging applications

EVA is extensively used in the production of flexible films and packaging materials. Its properties such as clarity, flexibility, and impact resistance make it suitable for food packaging, agricultural films, and stretch wrap applications. EVA can be blended with other polymers to enhance specific properties for different packaging needs.Expand Specific Solutions

Key Players in EVA Industry

The Ethylene Vinyl Acetate (EVA) market is in a mature growth stage, with a global market size expected to reach $12.2 billion by 2027. The technology's maturity is evident in its widespread adoption across various industries, including sustainable manufacturing. Key players like China Petroleum & Chemical Corp., Celanese International Corp., and Hanwha Chemical Co., Ltd. have established strong positions in the market. Companies such as Wacker Chemie AG and LyondellBasell Industries NV are driving innovation in EVA technology, focusing on enhancing sustainability and performance. The competitive landscape is characterized by ongoing research and development efforts, with institutions like Tianjin University contributing to technological advancements. As the demand for sustainable materials grows, companies are increasingly investing in eco-friendly EVA production methods and applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to sustainable EVA production. They utilize a high-pressure tubular reactor system with improved heat transfer and mixing capabilities[1]. This allows for more precise control of the polymerization process, resulting in EVA with consistent quality and reduced energy consumption. Sinopec has also implemented a solvent-free production method, eliminating the need for harmful organic solvents[2]. Their process incorporates advanced catalyst systems that enable lower reaction temperatures and pressures, further enhancing energy efficiency[3]. Additionally, Sinopec has integrated renewable feedstocks, such as bio-ethylene, into their EVA production, reducing reliance on fossil-based raw materials and decreasing the overall carbon footprint[4].

Strengths: Advanced reactor design for improved efficiency, solvent-free production reducing environmental impact, use of renewable feedstocks. Weaknesses: High initial investment costs for new technology implementation, potential challenges in scaling up bio-based feedstock supply.

Celanese International Corp.

Technical Solution: Celanese has developed a proprietary EVA production process focusing on sustainability and product customization. Their technology utilizes a continuous solution polymerization method with advanced process control systems[1]. This allows for real-time adjustments to reaction parameters, ensuring consistent product quality while minimizing waste and energy consumption. Celanese has also implemented a closed-loop recycling system for unreacted monomers and solvents, significantly reducing raw material usage and emissions[2]. Their EVA grades are tailored for specific applications, such as solar panel encapsulation, where they have developed formulations with enhanced UV resistance and durability[3]. Furthermore, Celanese has invested in bio-based feedstock integration, with up to 25% of ethylene content derived from renewable sources in select EVA grades[4].

Strengths: Highly efficient continuous production process, closed-loop recycling system, customized EVA formulations for specific applications. Weaknesses: Dependence on petroleum-based feedstocks for the majority of production, potential limitations in bio-based content due to availability and cost of renewable raw materials.

Key EVA Innovations

Vinyl acetate having a natural abundance of carbon-14 from non-fossil resources

PatentPendingEP4553060A1

Innovation

- A process for producing vinyl acetate from biomass, involving the reaction of ethylene and acetic acid, where both ethylene and acetic acid are derived from biomass or captured CO2, using various electrochemical and biochemical methods.

Method for preparing ethylene-vinyl acetate with low melt index

PatentWO2014181991A1

Innovation

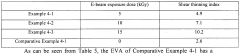

- Applying an electron beam with a defined exposure dose to an ethylene-vinyl acetate resin composition with a vinyl acetate content of 15 to 50 wt% to reduce the melt index to 10 g/10 min or less, thereby enhancing mechanical properties and processability without the need for additional modifiers like peroxides.

Environmental Impact of EVA

Ethylene Vinyl Acetate (EVA) has gained significant attention in sustainable manufacturing due to its versatile properties and potential for eco-friendly applications. However, the environmental impact of EVA production and usage requires careful consideration to ensure its role in sustainability is truly beneficial.

The production of EVA involves the copolymerization of ethylene and vinyl acetate, which are derived from fossil fuels. This process consumes energy and releases greenhouse gases, contributing to carbon emissions. However, compared to some alternative materials, EVA production generally has a lower environmental footprint, particularly in terms of energy consumption and water usage.

One of the key environmental advantages of EVA is its recyclability. EVA can be recycled multiple times without significant degradation of its properties, reducing the need for virgin material production and minimizing waste. This characteristic aligns well with circular economy principles, promoting resource efficiency and waste reduction in manufacturing processes.

EVA's durability and long lifespan also contribute to its environmental benefits. Products made with EVA often have extended use periods, reducing the frequency of replacement and associated resource consumption. This is particularly evident in applications such as solar panel encapsulation, where EVA's weather resistance and UV stability enhance the longevity of renewable energy systems.

However, the disposal of EVA products at the end of their life cycle presents environmental challenges. While recyclable, not all EVA waste is properly collected and processed, leading to potential accumulation in landfills or natural environments. Improper disposal can result in microplastic pollution, as EVA may break down into smaller particles over time.

In terms of toxicity, EVA is generally considered safe and non-toxic, with minimal leaching of harmful substances. This makes it suitable for various applications, including food packaging and medical devices, without posing significant risks to human health or ecosystems.

The use of EVA in sustainable manufacturing also extends to its potential as a carrier for bio-based additives and fillers. Researchers are exploring ways to incorporate natural fibers and biodegradable components into EVA matrices, creating composite materials with improved environmental profiles while maintaining desirable mechanical properties.

As industries strive for more sustainable practices, the role of EVA in reducing environmental impact becomes increasingly important. Its ability to replace less eco-friendly materials in various applications, coupled with ongoing research into bio-based alternatives and improved recycling technologies, positions EVA as a material with significant potential for advancing sustainable manufacturing practices.

The production of EVA involves the copolymerization of ethylene and vinyl acetate, which are derived from fossil fuels. This process consumes energy and releases greenhouse gases, contributing to carbon emissions. However, compared to some alternative materials, EVA production generally has a lower environmental footprint, particularly in terms of energy consumption and water usage.

One of the key environmental advantages of EVA is its recyclability. EVA can be recycled multiple times without significant degradation of its properties, reducing the need for virgin material production and minimizing waste. This characteristic aligns well with circular economy principles, promoting resource efficiency and waste reduction in manufacturing processes.

EVA's durability and long lifespan also contribute to its environmental benefits. Products made with EVA often have extended use periods, reducing the frequency of replacement and associated resource consumption. This is particularly evident in applications such as solar panel encapsulation, where EVA's weather resistance and UV stability enhance the longevity of renewable energy systems.

However, the disposal of EVA products at the end of their life cycle presents environmental challenges. While recyclable, not all EVA waste is properly collected and processed, leading to potential accumulation in landfills or natural environments. Improper disposal can result in microplastic pollution, as EVA may break down into smaller particles over time.

In terms of toxicity, EVA is generally considered safe and non-toxic, with minimal leaching of harmful substances. This makes it suitable for various applications, including food packaging and medical devices, without posing significant risks to human health or ecosystems.

The use of EVA in sustainable manufacturing also extends to its potential as a carrier for bio-based additives and fillers. Researchers are exploring ways to incorporate natural fibers and biodegradable components into EVA matrices, creating composite materials with improved environmental profiles while maintaining desirable mechanical properties.

As industries strive for more sustainable practices, the role of EVA in reducing environmental impact becomes increasingly important. Its ability to replace less eco-friendly materials in various applications, coupled with ongoing research into bio-based alternatives and improved recycling technologies, positions EVA as a material with significant potential for advancing sustainable manufacturing practices.

Regulatory Framework for EVA

The regulatory framework for Ethylene Vinyl Acetate (EVA) plays a crucial role in shaping its use and development in sustainable manufacturing. As a versatile copolymer with applications across various industries, EVA is subject to a complex web of regulations that aim to ensure its safe production, use, and disposal while promoting environmental sustainability.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and recommendations for the handling and use of polymers like EVA. These guidelines often focus on reducing environmental impact and ensuring worker safety throughout the product lifecycle.

In the United States, the Environmental Protection Agency (EPA) regulates EVA under the Toxic Substances Control Act (TSCA). The FDA also oversees EVA's use in food packaging and medical devices, ensuring compliance with safety standards. The Occupational Safety and Health Administration (OSHA) sets workplace safety guidelines for EVA manufacturing and handling.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which apply to EVA and its components. These regulations require manufacturers and importers to assess and manage the risks associated with EVA, promoting safer alternatives where possible.

Many countries have adopted specific regulations for EVA in sustainable manufacturing contexts. For instance, Japan's Ministry of Economy, Trade, and Industry (METI) has established guidelines for recycling and waste management of EVA-containing products, particularly in the solar panel industry where EVA is widely used as an encapsulant.

Regulatory frameworks also address the end-of-life management of EVA products. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, sets collection, recycling, and recovery targets for electronic waste, including EVA-containing components.

As sustainability becomes increasingly important, regulations are evolving to encourage the use of bio-based and recycled EVA. Initiatives such as the EU's Circular Economy Action Plan are driving the development of standards for recycled content and biodegradability in polymer products, including EVA.

Compliance with these diverse regulatory frameworks presents both challenges and opportunities for manufacturers. While adherence to stringent standards can increase production costs, it also drives innovation in sustainable manufacturing processes and product design, potentially leading to competitive advantages in environmentally conscious markets.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and recommendations for the handling and use of polymers like EVA. These guidelines often focus on reducing environmental impact and ensuring worker safety throughout the product lifecycle.

In the United States, the Environmental Protection Agency (EPA) regulates EVA under the Toxic Substances Control Act (TSCA). The FDA also oversees EVA's use in food packaging and medical devices, ensuring compliance with safety standards. The Occupational Safety and Health Administration (OSHA) sets workplace safety guidelines for EVA manufacturing and handling.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which apply to EVA and its components. These regulations require manufacturers and importers to assess and manage the risks associated with EVA, promoting safer alternatives where possible.

Many countries have adopted specific regulations for EVA in sustainable manufacturing contexts. For instance, Japan's Ministry of Economy, Trade, and Industry (METI) has established guidelines for recycling and waste management of EVA-containing products, particularly in the solar panel industry where EVA is widely used as an encapsulant.

Regulatory frameworks also address the end-of-life management of EVA products. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, sets collection, recycling, and recovery targets for electronic waste, including EVA-containing components.

As sustainability becomes increasingly important, regulations are evolving to encourage the use of bio-based and recycled EVA. Initiatives such as the EU's Circular Economy Action Plan are driving the development of standards for recycled content and biodegradability in polymer products, including EVA.

Compliance with these diverse regulatory frameworks presents both challenges and opportunities for manufacturers. While adherence to stringent standards can increase production costs, it also drives innovation in sustainable manufacturing processes and product design, potentially leading to competitive advantages in environmentally conscious markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!