Ethylene Vinyl Acetate: Bridging the Gap in Polymer Technology

EVA Technology Evolution

The evolution of Ethylene Vinyl Acetate (EVA) technology represents a significant milestone in polymer science. Initially developed in the 1950s, EVA has undergone continuous refinement and expansion of its applications over the decades. The early stages of EVA development focused primarily on its use as a flexible packaging material, leveraging its unique combination of flexibility and toughness.

In the 1960s and 1970s, researchers began to explore EVA's potential in footwear applications, particularly in the production of midsoles for athletic shoes. This period marked a crucial turning point in EVA technology, as manufacturers started to optimize the polymer's properties for specific end-use requirements. The development of foaming techniques for EVA during this era led to the creation of lightweight, cushioning materials that revolutionized the footwear industry.

The 1980s saw a significant expansion in EVA's application range. The polymer found its way into the solar panel industry as an encapsulant material, thanks to its excellent transparency, weather resistance, and electrical insulation properties. This decade also witnessed advancements in EVA's use in the automotive sector, particularly in wire and cable insulation.

The 1990s and early 2000s brought about further innovations in EVA technology. Researchers focused on enhancing the polymer's thermal stability and UV resistance, expanding its potential in outdoor applications. During this period, EVA also gained traction in the medical field, with the development of biocompatible grades suitable for various medical devices and packaging.

In recent years, the evolution of EVA technology has been driven by sustainability concerns and the need for high-performance materials. Manufacturers have been working on developing bio-based EVA variants, aiming to reduce the polymer's environmental footprint. Additionally, there has been a push towards creating EVA grades with improved recyclability and biodegradability.

The latest advancements in EVA technology include the development of nanocomposites, where EVA is combined with nanoparticles to enhance its mechanical, thermal, and barrier properties. This has opened up new possibilities in areas such as advanced packaging and high-performance sporting goods. Furthermore, researchers are exploring the potential of EVA in 3D printing applications, which could revolutionize rapid prototyping and customized manufacturing processes.

As we look to the future, the evolution of EVA technology is likely to continue along several key trajectories. These include further improvements in sustainability, the development of smart EVA materials with responsive properties, and the exploration of new applications in emerging fields such as flexible electronics and energy storage. The ongoing research and development in EVA technology underscore its enduring importance in bridging gaps in polymer science and meeting evolving industrial needs.

Market Demand Analysis

The market demand for Ethylene Vinyl Acetate (EVA) has been experiencing significant growth across various industries, driven by its versatile properties and wide range of applications. As a copolymer of ethylene and vinyl acetate, EVA offers a unique combination of flexibility, toughness, and adhesion, making it highly sought after in sectors such as packaging, footwear, solar panels, and automotive.

In the packaging industry, EVA has gained traction due to its excellent sealing properties and resistance to puncture and tear. The increasing demand for flexible and durable packaging solutions in the food and beverage sector has been a key driver for EVA market growth. Additionally, the rise of e-commerce has further boosted the need for protective packaging materials, where EVA's shock-absorbing qualities make it an ideal choice.

The footwear industry has also been a significant contributor to the growing demand for EVA. Its lightweight nature, coupled with superior cushioning and impact resistance, has made EVA a preferred material for shoe soles and insoles. The expanding sports and leisure footwear market, particularly in developing economies, has further fueled this demand.

In the renewable energy sector, EVA has found a crucial application in the manufacturing of solar panels. As the global push for clean energy intensifies, the demand for photovoltaic modules has surged, consequently driving up the need for EVA as an encapsulant material. The material's excellent transparency, weather resistance, and adhesion properties make it indispensable in ensuring the longevity and efficiency of solar panels.

The automotive industry has also contributed to the increasing market demand for EVA. Its use in gaskets, seals, and wire and cable insulation has grown due to its durability and resistance to chemicals and weathering. As vehicle manufacturers focus on lightweight materials to improve fuel efficiency, EVA's low density makes it an attractive option for various automotive components.

Geographically, Asia-Pacific has emerged as the largest market for EVA, driven by rapid industrialization, urbanization, and the growth of end-use industries in countries like China and India. North America and Europe follow, with steady demand from established industries and increasing adoption in innovative applications.

The market trend indicates a shift towards higher vinyl acetate content EVA grades, which offer enhanced properties for specific applications. This trend is particularly evident in the solar panel and high-performance packaging sectors, where improved adhesion and transparency are crucial.

As environmental concerns gain prominence, there is a growing demand for bio-based and recyclable EVA alternatives. This shift presents both challenges and opportunities for manufacturers to innovate and develop sustainable EVA products that meet market demands while addressing environmental considerations.

Technical Challenges

Ethylene Vinyl Acetate (EVA) copolymers face several technical challenges that hinder their widespread adoption and limit their potential applications. One of the primary issues is the difficulty in achieving a consistent and uniform distribution of vinyl acetate (VA) content throughout the polymer matrix. This non-uniformity can lead to variations in physical properties and performance characteristics, making it challenging to produce EVA materials with predictable and reliable behavior.

Another significant challenge lies in the thermal stability of EVA copolymers. At elevated temperatures, EVA tends to undergo degradation, resulting in the release of acetic acid. This thermal instability not only affects the material's long-term performance but also poses environmental and safety concerns in certain applications. Improving the heat resistance of EVA without compromising its desirable properties remains a key area of focus for researchers and manufacturers.

The processing of EVA copolymers presents its own set of challenges. The material's low melting point and tendency to stick to processing equipment can lead to difficulties in extrusion, molding, and other manufacturing processes. This can result in reduced production efficiency and increased costs. Additionally, achieving optimal adhesion between EVA and other materials in multi-layer structures or composites can be problematic, limiting its use in certain high-performance applications.

EVA copolymers also face challenges in terms of their mechanical properties. While they offer excellent flexibility and impact resistance, they often lack the strength and rigidity required for certain structural applications. Balancing these properties to meet the demands of diverse industries remains an ongoing challenge for polymer scientists and engineers.

The weatherability of EVA copolymers is another area of concern, particularly in outdoor applications. Exposure to UV radiation and environmental factors can lead to degradation, discoloration, and loss of mechanical properties over time. Developing effective stabilization strategies to enhance the long-term durability of EVA materials in harsh environments is crucial for expanding their use in sectors such as solar panel encapsulation and outdoor construction.

Lastly, the recyclability and end-of-life management of EVA products pose significant environmental challenges. The cross-linked nature of many EVA formulations makes them difficult to recycle through conventional methods. Developing eco-friendly alternatives or improved recycling technologies for EVA materials is essential to address growing sustainability concerns and meet increasingly stringent environmental regulations.

Current EVA Solutions

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and thermal properties can be tailored by adjusting the EVA composition and additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be crosslinked or expanded to create closed-cell foams for applications such as footwear, sports equipment, and building insulation.

- EVA in solar panel encapsulation: EVA is a popular material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells from environmental factors. It helps to improve the durability and efficiency of photovoltaic modules by providing a protective barrier against moisture and UV radiation.

- EVA in packaging and film applications: EVA is used in various packaging and film applications due to its flexibility, clarity, and barrier properties. It can be used to produce stretch films, shrink films, and laminated packaging materials. The material's properties can be modified to enhance oxygen barrier, moisture resistance, and sealability for specific packaging requirements.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and performance can be tailored by adjusting the EVA composition and incorporating additives.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be crosslinked or expanded to create closed-cell foams for applications such as footwear, packaging, and construction insulation.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and protection against moisture and UV radiation. The material helps to enhance the durability and performance of solar panels by encapsulating the solar cells and other components.Expand Specific Solutions05 Modification and blending of EVA

EVA can be modified or blended with other polymers and additives to enhance its properties or create new materials with specific characteristics. This includes crosslinking, grafting, and compounding with fillers or other polymers to improve mechanical properties, flame retardancy, or compatibility with other materials.Expand Specific Solutions

Key Industry Players

The Ethylene Vinyl Acetate (EVA) market is in a mature growth stage, characterized by steady demand across various industries. The global market size for EVA is substantial, driven by its versatile applications in sectors such as packaging, footwear, and solar panels. Technologically, EVA production is well-established, with major players like DuPont, Celanese, and Dow Global Technologies continuously innovating to improve product performance and manufacturing efficiency. Chinese companies, including Sinopec and Tianjin University, are also making significant contributions to EVA research and development. The competitive landscape is diverse, with both multinational corporations and regional players vying for market share through product differentiation and cost optimization strategies.

China Petroleum & Chemical Corp.

Celanese International Corp.

EVA Patent Landscape

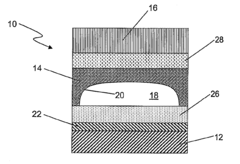

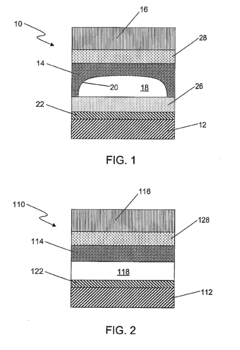

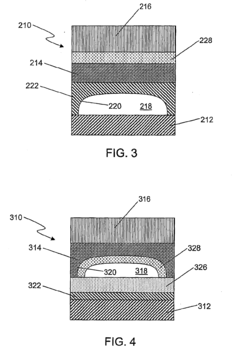

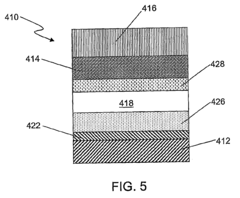

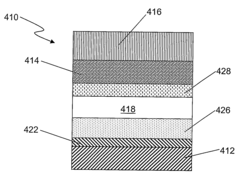

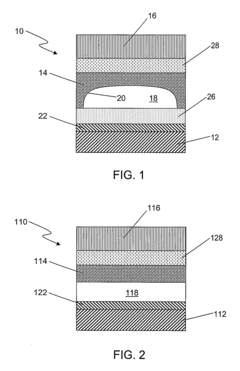

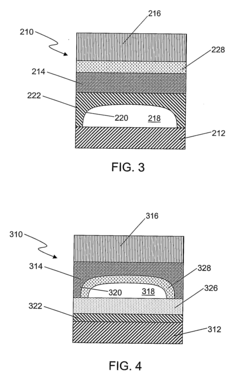

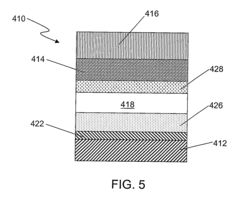

- A composite film structure with a containment layer having between 0 and 15 wt % vinyl acetate content, combined with a polyester film layer less than 20 μm in thickness, and an ethylene-vinyl acetate component with an ABA block copolymer, allowing for rapid drug transfer and minimizing interactions with the drug.

- A composite structure with a containment layer having between 0 and 15 wt % vinyl acetate repeating units, combined with a polyester film layer less than 20 μm in thickness, and an ethylene-vinyl acetate component with an ABA block copolymer, allowing for rapid drug transfer and minimizing interactions.

Environmental Impact

Ethylene Vinyl Acetate (EVA) has gained significant attention in polymer technology due to its versatile properties and wide range of applications. However, its environmental impact is a crucial aspect that requires careful consideration. The production and use of EVA have both positive and negative effects on the environment, which need to be thoroughly evaluated.

One of the primary environmental concerns associated with EVA is its non-biodegradability. Like many synthetic polymers, EVA does not naturally decompose in the environment, contributing to the global issue of plastic pollution. This persistence in ecosystems can lead to long-term environmental damage, particularly in marine environments where plastic waste accumulates.

However, EVA's durability also offers environmental benefits in certain applications. For instance, in solar panel encapsulation, EVA's long lifespan contributes to the overall sustainability of renewable energy systems. By protecting solar cells from environmental factors, EVA helps extend the operational life of solar panels, reducing the need for frequent replacements and the associated environmental costs of manufacturing new panels.

The production process of EVA also has environmental implications. The synthesis of EVA involves the use of petrochemical feedstocks, which are derived from non-renewable resources. This reliance on fossil fuels contributes to carbon emissions and the depletion of finite resources. However, advancements in production technologies have led to more efficient processes, reducing energy consumption and emissions associated with EVA manufacturing.

Recycling of EVA presents both challenges and opportunities. While EVA can be recycled, the process is often complex due to the material's cross-linked structure in many applications. This complexity can lead to downcycling rather than true recycling, where the material is repurposed for lower-value applications. However, innovative recycling technologies are being developed to improve the recyclability of EVA, potentially reducing its environmental footprint.

In terms of energy efficiency, EVA's use in building materials, such as insulation and weatherproofing, contributes to improved energy performance in structures. This indirect environmental benefit helps reduce overall energy consumption and associated greenhouse gas emissions in the built environment.

The environmental impact of EVA also extends to its end-of-life disposal. Incineration of EVA waste can release harmful emissions, while landfilling contributes to long-term environmental pollution. These issues highlight the need for improved waste management strategies and the development of more sustainable alternatives or biodegradable versions of EVA.

Regulatory Framework

The regulatory framework surrounding Ethylene Vinyl Acetate (EVA) plays a crucial role in its development, production, and application across various industries. As a polymer with diverse uses, EVA is subject to a complex web of regulations that vary depending on the intended use and geographical location.

In the United States, the Food and Drug Administration (FDA) oversees the use of EVA in food contact materials and medical devices. The FDA has established specific guidelines for EVA's use in packaging and food contact applications, ensuring that it meets safety standards for migration and overall composition. For medical devices, EVA must comply with biocompatibility requirements outlined in ISO 10993 and other relevant standards.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects EVA production and use. Manufacturers and importers of EVA must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information. Additionally, the EU's Restriction of Hazardous Substances (RoHS) directive impacts the use of EVA in electrical and electronic equipment.

In the automotive sector, EVA must adhere to strict regulations regarding emissions and safety. The Global Automotive Declarable Substance List (GADSL) provides guidelines for the use of EVA in automotive applications, ensuring compliance with environmental and safety standards across different markets.

The construction industry also imposes specific regulations on EVA-based products. Building codes and fire safety standards often dictate the use of flame-retardant additives in EVA formulations for applications such as wire and cable insulation or roofing materials.

Environmental regulations play an increasingly important role in shaping the EVA industry. Many countries have implemented policies to promote the recycling and proper disposal of EVA-based products. For instance, the EU's Circular Economy Action Plan aims to increase the recyclability and reusability of plastics, including EVA.

As sustainability concerns grow, regulations are evolving to address the environmental impact of EVA throughout its lifecycle. This includes initiatives to reduce greenhouse gas emissions during production, promote the use of bio-based alternatives, and improve end-of-life management of EVA products.

The global nature of the EVA market necessitates a harmonized approach to regulations. International standards organizations, such as ISO and ASTM, play a crucial role in developing standardized testing methods and specifications for EVA, facilitating global trade and ensuring consistent quality across different regions.