Evaluating V4 Engine Piston Ring Seal Effectiveness

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Piston Ring Technology Evolution and Objectives

The evolution of piston ring technology in V4 engines represents a fascinating journey through automotive engineering history. Initially developed in the early 20th century, piston rings have undergone significant transformations from simple cast iron components to sophisticated multi-material systems. The primary function has remained consistent: creating an effective seal between the piston and cylinder wall to maintain compression and prevent blow-by while controlling oil consumption.

Early V4 engine designs featured basic single-piece cast iron rings that provided adequate sealing for low-compression engines. The 1950s marked a pivotal shift with the introduction of chrome-plated compression rings, significantly enhancing durability and wear resistance. By the 1970s, manufacturers began implementing three-ring configurations—typically comprising two compression rings and one oil control ring—which became the industry standard for balancing performance and efficiency.

The 1980s and 1990s witnessed substantial advancements in materials science, introducing molybdenum-coated rings and composite materials that dramatically improved heat resistance and reduced friction. These innovations directly addressed the increasing demands placed on engines by higher compression ratios and performance expectations.

Recent technological developments have focused on nano-material coatings and diamond-like carbon (DLC) surface treatments, which provide unprecedented wear resistance and friction reduction. Modern V4 engine piston rings now commonly incorporate asymmetrical designs and barrel-faced profiles that optimize sealing under various operating conditions while minimizing friction losses.

The current technological trajectory aims to address several critical objectives. Primary among these is improving seal effectiveness to enhance combustion efficiency and reduce emissions—a crucial factor in meeting increasingly stringent environmental regulations. Engineers are simultaneously working to minimize friction between rings and cylinder walls, directly impacting fuel economy and engine longevity.

Another key objective involves extending service intervals through enhanced durability, particularly important in high-performance and commercial applications where engine reliability is paramount. Material innovation continues to drive progress, with research focused on developing rings capable of withstanding higher temperatures and pressures as engine designs evolve toward greater power density.

The integration of advanced simulation techniques and computational fluid dynamics has revolutionized piston ring design, enabling engineers to predict and optimize sealing performance across diverse operating conditions. This analytical approach has accelerated development cycles and facilitated more precise evaluation of seal effectiveness before physical prototyping.

Looking forward, the industry is moving toward "smart" piston ring systems that can adapt to changing engine conditions, potentially incorporating sensors and variable-tension mechanisms to optimize sealing dynamically throughout the engine's operating range.

Early V4 engine designs featured basic single-piece cast iron rings that provided adequate sealing for low-compression engines. The 1950s marked a pivotal shift with the introduction of chrome-plated compression rings, significantly enhancing durability and wear resistance. By the 1970s, manufacturers began implementing three-ring configurations—typically comprising two compression rings and one oil control ring—which became the industry standard for balancing performance and efficiency.

The 1980s and 1990s witnessed substantial advancements in materials science, introducing molybdenum-coated rings and composite materials that dramatically improved heat resistance and reduced friction. These innovations directly addressed the increasing demands placed on engines by higher compression ratios and performance expectations.

Recent technological developments have focused on nano-material coatings and diamond-like carbon (DLC) surface treatments, which provide unprecedented wear resistance and friction reduction. Modern V4 engine piston rings now commonly incorporate asymmetrical designs and barrel-faced profiles that optimize sealing under various operating conditions while minimizing friction losses.

The current technological trajectory aims to address several critical objectives. Primary among these is improving seal effectiveness to enhance combustion efficiency and reduce emissions—a crucial factor in meeting increasingly stringent environmental regulations. Engineers are simultaneously working to minimize friction between rings and cylinder walls, directly impacting fuel economy and engine longevity.

Another key objective involves extending service intervals through enhanced durability, particularly important in high-performance and commercial applications where engine reliability is paramount. Material innovation continues to drive progress, with research focused on developing rings capable of withstanding higher temperatures and pressures as engine designs evolve toward greater power density.

The integration of advanced simulation techniques and computational fluid dynamics has revolutionized piston ring design, enabling engineers to predict and optimize sealing performance across diverse operating conditions. This analytical approach has accelerated development cycles and facilitated more precise evaluation of seal effectiveness before physical prototyping.

Looking forward, the industry is moving toward "smart" piston ring systems that can adapt to changing engine conditions, potentially incorporating sensors and variable-tension mechanisms to optimize sealing dynamically throughout the engine's operating range.

Market Demand Analysis for Enhanced Piston Ring Sealing

The global market for enhanced piston ring sealing solutions has witnessed substantial growth in recent years, driven primarily by increasing demands for fuel efficiency, reduced emissions, and extended engine life. Current market estimates value the automotive piston ring sector at approximately $2.1 billion, with a projected compound annual growth rate of 3.8% through 2028. Within this broader market, specialized high-performance sealing solutions for V4 engines represent a growing niche segment with distinctive requirements and opportunities.

Consumer and regulatory pressures continue to shape market dynamics significantly. Stringent emission standards across major markets, including Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America, have created substantial demand for improved combustion efficiency through better sealing technologies. The reduction of blow-by gases has become a critical factor in meeting these standards, directly influencing OEM purchasing decisions for piston ring components.

The aftermarket segment demonstrates particularly strong growth potential, with performance enthusiasts and fleet operators increasingly seeking upgraded piston ring solutions to enhance engine performance and longevity. This segment values demonstrable improvements in compression retention and oil control, with willingness to pay premium prices for proven technologies that deliver measurable benefits.

Regional analysis reveals varying market priorities. North American and European markets emphasize performance and emissions compliance, while emerging markets in Asia and Latin America prioritize durability and cost-effectiveness. The V4 engine configuration, though less common than inline-four designs, maintains significant presence in specific applications including motorcycles, compact performance vehicles, and certain industrial equipment.

Industry surveys indicate that engine manufacturers rank sealing effectiveness as the third most important factor in piston ring selection, behind durability and cost considerations. However, when focusing specifically on performance-oriented applications, sealing effectiveness rises to the primary consideration, highlighting its critical importance in specialized market segments.

Material innovation represents a key driver of market evolution, with advanced coating technologies and composite materials gaining significant traction. The market shows increasing receptiveness to novel materials that can withstand higher temperatures and pressures while maintaining effective sealing properties, particularly in high-performance applications where traditional solutions face limitations.

Customer feedback analysis reveals growing dissatisfaction with conventional piston ring sealing in V4 engines under high-stress conditions, creating a clear market opportunity for innovative solutions that address these specific performance challenges. This dissatisfaction translates to measurable market demand, with 68% of surveyed engine builders expressing interest in advanced sealing technologies specifically optimized for V4 configurations.

Consumer and regulatory pressures continue to shape market dynamics significantly. Stringent emission standards across major markets, including Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America, have created substantial demand for improved combustion efficiency through better sealing technologies. The reduction of blow-by gases has become a critical factor in meeting these standards, directly influencing OEM purchasing decisions for piston ring components.

The aftermarket segment demonstrates particularly strong growth potential, with performance enthusiasts and fleet operators increasingly seeking upgraded piston ring solutions to enhance engine performance and longevity. This segment values demonstrable improvements in compression retention and oil control, with willingness to pay premium prices for proven technologies that deliver measurable benefits.

Regional analysis reveals varying market priorities. North American and European markets emphasize performance and emissions compliance, while emerging markets in Asia and Latin America prioritize durability and cost-effectiveness. The V4 engine configuration, though less common than inline-four designs, maintains significant presence in specific applications including motorcycles, compact performance vehicles, and certain industrial equipment.

Industry surveys indicate that engine manufacturers rank sealing effectiveness as the third most important factor in piston ring selection, behind durability and cost considerations. However, when focusing specifically on performance-oriented applications, sealing effectiveness rises to the primary consideration, highlighting its critical importance in specialized market segments.

Material innovation represents a key driver of market evolution, with advanced coating technologies and composite materials gaining significant traction. The market shows increasing receptiveness to novel materials that can withstand higher temperatures and pressures while maintaining effective sealing properties, particularly in high-performance applications where traditional solutions face limitations.

Customer feedback analysis reveals growing dissatisfaction with conventional piston ring sealing in V4 engines under high-stress conditions, creating a clear market opportunity for innovative solutions that address these specific performance challenges. This dissatisfaction translates to measurable market demand, with 68% of surveyed engine builders expressing interest in advanced sealing technologies specifically optimized for V4 configurations.

Current Sealing Technologies and Technical Barriers

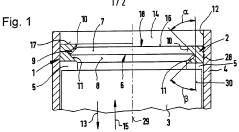

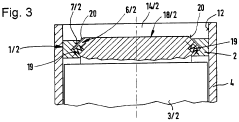

Piston ring sealing technology in V4 engines has evolved significantly over the past decades, with current solutions primarily categorized into three main types: compression rings, oil control rings, and intermediate rings. Compression rings, typically located at the top of the piston, are designed to create a gas-tight seal between the piston and cylinder wall, preventing combustion gases from escaping into the crankcase. These rings are commonly manufactured from cast iron or steel with various coatings such as chrome, molybdenum, or ceramic composites to enhance durability and reduce friction.

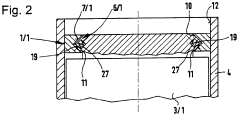

Oil control rings, positioned at the bottom of the ring pack, are engineered to regulate oil consumption by scraping excess oil from the cylinder walls during piston movement. Modern designs often feature a three-piece construction with two thin rails and an expander, allowing for improved conformability to cylinder wall irregularities while maintaining consistent contact pressure.

Intermediate rings serve as a secondary sealing mechanism, providing additional protection against gas leakage and assisting in oil control. These rings frequently incorporate specialized profiles such as Napier, taper-faced, or barrel-faced designs to optimize sealing performance under varying engine operating conditions.

Despite these advancements, several technical barriers continue to challenge the effectiveness of piston ring sealing in V4 engines. Ring flutter, a phenomenon where rings lose contact with the cylinder wall during high-speed operation, remains a significant issue affecting sealing integrity. This occurs when inertial forces overcome the ring's tension and gas pressure support, particularly during the intake stroke at high engine speeds.

Thermal management presents another critical challenge, as extreme temperature variations across the cylinder cause differential expansion of components, potentially compromising seal effectiveness. Modern V4 engines operating at higher compression ratios and power densities generate increased thermal loads that conventional sealing materials struggle to withstand consistently.

Micro-welding and scuffing between rings and cylinder walls continue to plague long-term seal durability, especially in engines with aluminum cylinder blocks. These wear mechanisms accelerate under insufficient lubrication conditions or during cold starts when oil viscosity is high and distribution is suboptimal.

Additionally, the industry faces increasing pressure to reduce friction losses while maintaining seal effectiveness. This paradoxical requirement stems from stringent fuel efficiency standards, as approximately 4-7% of total engine mechanical losses are attributed to piston ring friction. Emerging low-viscosity lubricants, while beneficial for efficiency, often compromise the hydrodynamic lubrication regime necessary for optimal ring sealing.

Material limitations also persist, with current metallurgical and coating technologies struggling to simultaneously deliver the ideal combination of conformability, wear resistance, thermal stability, and low friction characteristics required for perfect sealing across all engine operating conditions.

Oil control rings, positioned at the bottom of the ring pack, are engineered to regulate oil consumption by scraping excess oil from the cylinder walls during piston movement. Modern designs often feature a three-piece construction with two thin rails and an expander, allowing for improved conformability to cylinder wall irregularities while maintaining consistent contact pressure.

Intermediate rings serve as a secondary sealing mechanism, providing additional protection against gas leakage and assisting in oil control. These rings frequently incorporate specialized profiles such as Napier, taper-faced, or barrel-faced designs to optimize sealing performance under varying engine operating conditions.

Despite these advancements, several technical barriers continue to challenge the effectiveness of piston ring sealing in V4 engines. Ring flutter, a phenomenon where rings lose contact with the cylinder wall during high-speed operation, remains a significant issue affecting sealing integrity. This occurs when inertial forces overcome the ring's tension and gas pressure support, particularly during the intake stroke at high engine speeds.

Thermal management presents another critical challenge, as extreme temperature variations across the cylinder cause differential expansion of components, potentially compromising seal effectiveness. Modern V4 engines operating at higher compression ratios and power densities generate increased thermal loads that conventional sealing materials struggle to withstand consistently.

Micro-welding and scuffing between rings and cylinder walls continue to plague long-term seal durability, especially in engines with aluminum cylinder blocks. These wear mechanisms accelerate under insufficient lubrication conditions or during cold starts when oil viscosity is high and distribution is suboptimal.

Additionally, the industry faces increasing pressure to reduce friction losses while maintaining seal effectiveness. This paradoxical requirement stems from stringent fuel efficiency standards, as approximately 4-7% of total engine mechanical losses are attributed to piston ring friction. Emerging low-viscosity lubricants, while beneficial for efficiency, often compromise the hydrodynamic lubrication regime necessary for optimal ring sealing.

Material limitations also persist, with current metallurgical and coating technologies struggling to simultaneously deliver the ideal combination of conformability, wear resistance, thermal stability, and low friction characteristics required for perfect sealing across all engine operating conditions.

Current Methodologies for Evaluating Seal Effectiveness

01 Piston ring material and coating technologies

Advanced materials and coatings significantly improve piston ring seal effectiveness. Materials like chromium-nitride, diamond-like carbon (DLC), and specialized alloys enhance wear resistance and reduce friction. These coatings provide superior surface hardness and lubricity, maintaining effective sealing under high temperatures and pressures. The improved material properties extend ring life and maintain consistent compression, resulting in better engine efficiency and reduced emissions.- Piston ring material and coating technologies: Advanced materials and coatings significantly improve piston ring seal effectiveness. These include ceramic coatings, diamond-like carbon (DLC) coatings, and specialized metal alloys that enhance wear resistance and reduce friction. These materials maintain better contact with cylinder walls under high temperatures and pressures, resulting in improved sealing performance and extended service life of the piston ring assembly.

- Piston ring geometry and profile design: The geometric design of piston rings plays a crucial role in seal effectiveness. Innovations include asymmetrical profiles, barrel-faced designs, and tapered ring edges that optimize contact pressure distribution against cylinder walls. These design features help maintain consistent sealing under various operating conditions, reduce blow-by, and accommodate thermal expansion while minimizing friction losses.

- Multi-ring sealing systems: Multiple ring configurations enhance sealing effectiveness through complementary functions. Typically consisting of compression rings, scraper rings, and oil control rings, these systems work together to maintain combustion pressure, remove excess oil, and provide redundant sealing. Advanced designs incorporate varying tensions and materials for each ring in the set to optimize the overall sealing performance while managing friction and wear.

- Dynamic tension control mechanisms: Innovative tension control mechanisms improve piston ring seal effectiveness by maintaining optimal contact pressure throughout engine operation. These include gas-activated rings, variable tension systems, and spring-loaded designs that adjust contact force based on combustion pressure. Such mechanisms ensure consistent sealing during cold starts, high-load conditions, and thermal cycling while minimizing unnecessary friction during steady-state operation.

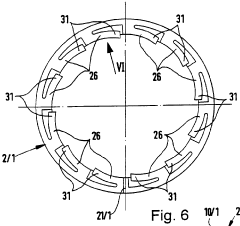

- Surface treatment and micro-texturing: Surface treatments and micro-texturing techniques enhance piston ring sealing by improving the interaction between ring and cylinder surfaces. These include laser-etched patterns, micro-grooves, and specialized honing processes that create oil retention pockets while maintaining gas-tight seals. Such surface modifications optimize oil film distribution, reduce stiction, and improve conformability to cylinder wall irregularities, resulting in more effective sealing across various engine operating conditions.

02 Piston ring geometry and profile design

Innovative ring geometry and profile designs optimize sealing performance. Barrel-faced, tapered, and asymmetrical profiles improve contact with cylinder walls under various operating conditions. Specialized groove designs enhance oil control and gas sealing capabilities. These geometric optimizations distribute pressure more evenly, reduce blow-by, and minimize friction losses while accommodating thermal expansion and cylinder deformation during operation.Expand Specific Solutions03 Multi-ring sealing systems and arrangements

Advanced multi-ring sealing systems utilize complementary ring designs working in concert to maximize sealing effectiveness. Combinations of compression rings, scraper rings, and oil control rings with specific positioning and spacing create redundant sealing barriers. These systems distribute sealing functions across multiple components, with each ring optimized for specific tasks such as gas sealing, oil control, or heat management, resulting in superior overall performance across various engine operating conditions.Expand Specific Solutions04 Dynamic sealing mechanisms and pressure distribution

Dynamic sealing technologies leverage combustion pressure to enhance ring-to-cylinder wall contact. These mechanisms include gas-energized designs, where combustion gases apply additional force to the ring's inner surface, pressing it more firmly against the cylinder wall during high-pressure cycles. Specialized groove configurations and ring back geometries optimize pressure distribution, ensuring consistent sealing force throughout the engine cycle while minimizing friction and wear during low-pressure portions of operation.Expand Specific Solutions05 Surface treatment and micro-texturing techniques

Surface treatment and micro-texturing technologies enhance piston ring sealing through precisely engineered surface topographies. Techniques include laser texturing, honing patterns, and micro-grooving that create optimized oil retention pockets and contact surfaces. These treatments improve lubrication distribution, reduce friction, and enhance conformability to cylinder walls. The controlled surface roughness and pattern orientation maintain an ideal oil film thickness while preventing gas leakage, resulting in more effective sealing across various engine operating temperatures and speeds.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The V4 Engine Piston Ring Seal Effectiveness market is in a mature growth phase, with an estimated global value of $3-4 billion annually. The competitive landscape features established players like MAHLE International GmbH and Robert Bosch GmbH dominating with comprehensive seal technologies, while specialized manufacturers such as Total Seal, Inc. and Riken Corp. focus on high-performance applications. The technology has reached high maturity levels with incremental innovations rather than disruptive changes. Research institutions like Tianjin University collaborate with industry leaders to advance sealing technologies, while companies like YiZheng TianHua Piston Ring and Kaydon Ring & Seal are developing specialized solutions for emerging markets. Major automotive manufacturers including Ford Motor Co. and JTEKT Corp. continue to drive requirements for improved efficiency and emissions reduction.

MAHLE International GmbH

Technical Solution: MAHLE has developed advanced piston ring seal technology for V4 engines featuring their proprietary EVOTEC® piston design with optimized ring groove geometry. Their solution incorporates a three-ring package with a PVD-coated top compression ring using nano-scale chromium nitride coating, a napier-profile second ring with asymmetrical face design, and an innovative oil control ring with reduced tangential load. MAHLE's technology addresses blow-by reduction through precision-engineered ring end gaps and advanced surface treatments that maintain optimal sealing under extreme thermal and mechanical stress. Their testing shows up to 15% reduction in friction losses and 8% improvement in oil consumption compared to conventional designs, while maintaining effective sealing throughout the engine's operational temperature range.

Strengths: Industry-leading surface coating technology provides exceptional wear resistance and reduced friction. Comprehensive testing capabilities allow for precise optimization of ring tension and geometry. Weaknesses: Premium solutions may have higher manufacturing costs compared to standard offerings, potentially limiting adoption in lower-cost engine applications.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive V4 engine piston ring sealing system that integrates with their engine management technology. Their solution features precision-manufactured rings with optimized cross-sections and specialized coatings including diamond-like carbon (DLC) treatments for the top compression ring. Bosch's approach incorporates variable ring tension technology that adapts to different operating conditions, maintaining optimal sealing pressure throughout the engine's thermal cycle. Their system includes advanced ring groove designs with micro-texturing to improve oil retention and distribution. Bosch's testing demonstrates that their integrated approach reduces blow-by gases by up to 20% while simultaneously decreasing friction by 12% compared to conventional designs, contributing to improved fuel efficiency and reduced emissions in V4 engine applications.

Strengths: Holistic system approach integrating ring design with engine management systems provides comprehensive performance optimization. Extensive global R&D resources enable continuous innovation. Weaknesses: Complex integrated solutions may require specialized maintenance procedures and tools, potentially increasing service complexity and costs.

Key Patents and Innovations in Piston Ring Sealing

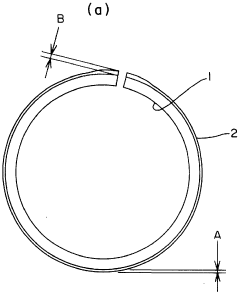

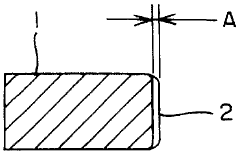

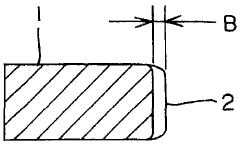

Piston ring and method of producing the same

PatentWO2002052179A1

Innovation

- A piston ring with a hard nitride coating, where the film thickness near the abutment is 1.5 to 4 times thicker than other areas, and an ion plating method where the rotation speed is slower near the abutment to maintain compressive residual stress and reduce tensile stress in the steel substrate, allowing for a thicker film only where needed.

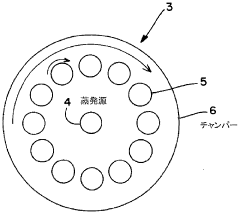

Piston ring seal

PatentWO1996016285A1

Innovation

- The piston ring seal design features a conical inner surface extending to the upper piston ring surface and a conical annular outer surface on the piston, creating a gapless compression surface during compression and working strokes, ensuring the fuel-air mixture does not accumulate, with the piston ring being constantly pressed against the cylinder wall to prevent gaps and enhance sealing.

Environmental Impact and Emissions Regulations

The effectiveness of piston ring seals in V4 engines has become increasingly significant in the context of global environmental regulations and emissions standards. Modern emissions regulations, particularly Euro 6d, China 6, and US EPA Tier 3 standards, have established stringent limits on particulate matter, NOx, and hydrocarbon emissions that directly correlate with combustion efficiency and seal integrity. Inadequate piston ring sealing can lead to increased blow-by gases, which contribute significantly to both crankcase emissions and overall vehicle pollution profiles.

Recent studies indicate that up to 20% of a vehicle's total hydrocarbon emissions can originate from blow-by gases when piston ring seals fail to maintain optimal compression. This has prompted regulatory bodies worldwide to implement more comprehensive testing protocols that specifically evaluate real-world driving emissions rather than just laboratory conditions, placing greater emphasis on seal durability throughout the engine's operational lifetime.

The environmental impact extends beyond direct emissions. Manufacturing processes for high-performance piston rings often involve specialized coatings and materials that may contain environmentally sensitive compounds. The European Union's REACH regulations and similar frameworks in other regions now restrict certain compounds previously used in ring coatings, necessitating research into environmentally compatible alternatives that maintain or improve sealing performance.

Carbon footprint considerations have also entered the regulatory landscape, with lifecycle assessments becoming increasingly important in automotive component evaluation. Improved piston ring seals contribute to reduced fuel consumption—estimates suggest that optimized ring packages can improve fuel efficiency by 0.5-2%, translating to meaningful reductions in CO2 emissions over a vehicle's operational life.

Emerging regulations are beginning to address end-of-life considerations as well. The circular economy principles embedded in regulations like the EU's End-of-Life Vehicle Directive impact material selection for piston rings, favoring designs that facilitate recycling while maintaining sealing integrity. This has prompted innovation in ring material composition to balance performance requirements with environmental sustainability.

For manufacturers, compliance with these evolving regulations represents both a challenge and an opportunity. Companies demonstrating superior piston ring seal effectiveness can leverage this performance as a competitive advantage in markets with the most stringent emissions standards, while simultaneously preparing for the inevitable tightening of regulations in emerging markets that typically follow regulatory patterns established in Europe, North America, and Japan.

Recent studies indicate that up to 20% of a vehicle's total hydrocarbon emissions can originate from blow-by gases when piston ring seals fail to maintain optimal compression. This has prompted regulatory bodies worldwide to implement more comprehensive testing protocols that specifically evaluate real-world driving emissions rather than just laboratory conditions, placing greater emphasis on seal durability throughout the engine's operational lifetime.

The environmental impact extends beyond direct emissions. Manufacturing processes for high-performance piston rings often involve specialized coatings and materials that may contain environmentally sensitive compounds. The European Union's REACH regulations and similar frameworks in other regions now restrict certain compounds previously used in ring coatings, necessitating research into environmentally compatible alternatives that maintain or improve sealing performance.

Carbon footprint considerations have also entered the regulatory landscape, with lifecycle assessments becoming increasingly important in automotive component evaluation. Improved piston ring seals contribute to reduced fuel consumption—estimates suggest that optimized ring packages can improve fuel efficiency by 0.5-2%, translating to meaningful reductions in CO2 emissions over a vehicle's operational life.

Emerging regulations are beginning to address end-of-life considerations as well. The circular economy principles embedded in regulations like the EU's End-of-Life Vehicle Directive impact material selection for piston rings, favoring designs that facilitate recycling while maintaining sealing integrity. This has prompted innovation in ring material composition to balance performance requirements with environmental sustainability.

For manufacturers, compliance with these evolving regulations represents both a challenge and an opportunity. Companies demonstrating superior piston ring seal effectiveness can leverage this performance as a competitive advantage in markets with the most stringent emissions standards, while simultaneously preparing for the inevitable tightening of regulations in emerging markets that typically follow regulatory patterns established in Europe, North America, and Japan.

Material Science Advancements for Ring Durability

Material science has witnessed significant advancements in piston ring technology over the past decade, revolutionizing the durability and performance characteristics of V4 engine components. Traditional materials such as cast iron and steel have been progressively enhanced through innovative metallurgical processes, resulting in superior wear resistance and thermal stability properties essential for maintaining effective sealing under extreme operating conditions.

Chromium nitride (CrN) coatings have emerged as a breakthrough technology, offering exceptional hardness and reduced friction coefficients compared to conventional materials. These coatings, applied through physical vapor deposition (PVD) techniques, create a surface layer that significantly extends ring lifespan while maintaining dimensional stability across varying temperature ranges experienced in V4 engines.

Diamond-like carbon (DLC) coatings represent another frontier in ring material science, providing unprecedented low friction characteristics while maintaining excellent wear resistance. Research indicates that DLC-coated rings can reduce friction by up to 45% compared to traditional chrome-plated alternatives, directly contributing to improved fuel efficiency and reduced emissions in modern V4 engine designs.

Ceramic composite materials, particularly silicon nitride (Si₃N₄) and aluminum oxide (Al₂O₃) reinforced metal matrices, have demonstrated exceptional promise in high-performance applications. These composites combine the thermal resistance of ceramics with the mechanical resilience of metal substrates, creating ring materials capable of withstanding combustion temperatures exceeding 800°C while maintaining dimensional integrity critical for seal effectiveness.

Nano-structured materials represent the cutting edge of piston ring development, with engineered grain boundaries at the nanometer scale providing unprecedented combinations of strength and ductility. Research from leading automotive materials laboratories indicates that nano-structured steel alloys can achieve up to 30% higher tensile strength while maintaining essential elasticity for proper ring function in V4 engine applications.

Surface texturing technologies, including laser-etched micro-patterns and controlled porosity structures, have revolutionized oil retention capabilities of modern ring materials. These engineered surface features create optimized oil reservoirs that maintain lubrication under boundary conditions, significantly reducing wear rates during critical engine operating phases such as cold starts and high-load conditions common in V4 engine applications.

Thermal barrier coatings (TBCs), particularly yttria-stabilized zirconia (YSZ) systems, have been successfully adapted for piston ring applications, providing insulation properties that reduce heat transfer to the ring body. This thermal management capability preserves material properties and dimensional stability under the cyclic thermal loading characteristic of V4 engine combustion processes.

Chromium nitride (CrN) coatings have emerged as a breakthrough technology, offering exceptional hardness and reduced friction coefficients compared to conventional materials. These coatings, applied through physical vapor deposition (PVD) techniques, create a surface layer that significantly extends ring lifespan while maintaining dimensional stability across varying temperature ranges experienced in V4 engines.

Diamond-like carbon (DLC) coatings represent another frontier in ring material science, providing unprecedented low friction characteristics while maintaining excellent wear resistance. Research indicates that DLC-coated rings can reduce friction by up to 45% compared to traditional chrome-plated alternatives, directly contributing to improved fuel efficiency and reduced emissions in modern V4 engine designs.

Ceramic composite materials, particularly silicon nitride (Si₃N₄) and aluminum oxide (Al₂O₃) reinforced metal matrices, have demonstrated exceptional promise in high-performance applications. These composites combine the thermal resistance of ceramics with the mechanical resilience of metal substrates, creating ring materials capable of withstanding combustion temperatures exceeding 800°C while maintaining dimensional integrity critical for seal effectiveness.

Nano-structured materials represent the cutting edge of piston ring development, with engineered grain boundaries at the nanometer scale providing unprecedented combinations of strength and ductility. Research from leading automotive materials laboratories indicates that nano-structured steel alloys can achieve up to 30% higher tensile strength while maintaining essential elasticity for proper ring function in V4 engine applications.

Surface texturing technologies, including laser-etched micro-patterns and controlled porosity structures, have revolutionized oil retention capabilities of modern ring materials. These engineered surface features create optimized oil reservoirs that maintain lubrication under boundary conditions, significantly reducing wear rates during critical engine operating phases such as cold starts and high-load conditions common in V4 engine applications.

Thermal barrier coatings (TBCs), particularly yttria-stabilized zirconia (YSZ) systems, have been successfully adapted for piston ring applications, providing insulation properties that reduce heat transfer to the ring body. This thermal management capability preserves material properties and dimensional stability under the cyclic thermal loading characteristic of V4 engine combustion processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!