Exploring AGM Battery Use in Stationary Applications

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in lead-acid battery technology, particularly in the context of stationary applications. Initially developed in the 1970s for military aircraft, AGM batteries have since found widespread use in various sectors due to their unique characteristics and advantages over traditional flooded lead-acid batteries.

The early stages of AGM battery development focused on addressing the limitations of conventional lead-acid batteries, such as electrolyte spillage and the need for regular maintenance. By immobilizing the electrolyte in a fiberglass mat separator, AGM batteries achieved a spill-proof design and improved safety. This innovation also allowed for a more compact and lightweight construction, making them ideal for applications where space and weight were critical factors.

Throughout the 1980s and 1990s, AGM technology continued to evolve, with manufacturers refining the production processes and materials used. These improvements led to enhanced performance characteristics, including better charge acceptance, longer cycle life, and improved deep discharge recovery. As a result, AGM batteries began to gain traction in telecommunications and uninterruptible power supply (UPS) systems, where reliability and maintenance-free operation were paramount.

The turn of the millennium saw a significant expansion in the use of AGM batteries for stationary applications. The growing demand for backup power solutions in data centers, coupled with the increasing adoption of renewable energy systems, created new opportunities for AGM technology. Manufacturers responded by developing larger-capacity AGM batteries specifically designed for these applications, offering improved energy density and cycle life.

In recent years, the evolution of AGM batteries has been driven by the need for more sustainable and efficient energy storage solutions. This has led to advancements in electrode design, separator materials, and manufacturing techniques. Modern AGM batteries now offer enhanced performance in partial state of charge (PSoC) operations, making them well-suited for renewable energy integration and grid stabilization applications.

The latest developments in AGM technology have focused on extending battery life and improving overall system efficiency. This includes the integration of smart battery management systems, which optimize charging and discharging cycles, and the use of advanced alloys to reduce grid corrosion and increase durability. These innovations have further solidified the position of AGM batteries in stationary applications, particularly in scenarios where long-term reliability and minimal maintenance are essential.

As the demand for stationary energy storage continues to grow, AGM batteries are evolving to meet new challenges. Research is ongoing into improving the energy density and cycle life of AGM batteries, with some manufacturers exploring hybrid designs that incorporate elements of other battery technologies. These efforts aim to enhance the competitiveness of AGM batteries in an increasingly diverse energy storage market, ensuring their continued relevance in stationary applications for years to come.

The early stages of AGM battery development focused on addressing the limitations of conventional lead-acid batteries, such as electrolyte spillage and the need for regular maintenance. By immobilizing the electrolyte in a fiberglass mat separator, AGM batteries achieved a spill-proof design and improved safety. This innovation also allowed for a more compact and lightweight construction, making them ideal for applications where space and weight were critical factors.

Throughout the 1980s and 1990s, AGM technology continued to evolve, with manufacturers refining the production processes and materials used. These improvements led to enhanced performance characteristics, including better charge acceptance, longer cycle life, and improved deep discharge recovery. As a result, AGM batteries began to gain traction in telecommunications and uninterruptible power supply (UPS) systems, where reliability and maintenance-free operation were paramount.

The turn of the millennium saw a significant expansion in the use of AGM batteries for stationary applications. The growing demand for backup power solutions in data centers, coupled with the increasing adoption of renewable energy systems, created new opportunities for AGM technology. Manufacturers responded by developing larger-capacity AGM batteries specifically designed for these applications, offering improved energy density and cycle life.

In recent years, the evolution of AGM batteries has been driven by the need for more sustainable and efficient energy storage solutions. This has led to advancements in electrode design, separator materials, and manufacturing techniques. Modern AGM batteries now offer enhanced performance in partial state of charge (PSoC) operations, making them well-suited for renewable energy integration and grid stabilization applications.

The latest developments in AGM technology have focused on extending battery life and improving overall system efficiency. This includes the integration of smart battery management systems, which optimize charging and discharging cycles, and the use of advanced alloys to reduce grid corrosion and increase durability. These innovations have further solidified the position of AGM batteries in stationary applications, particularly in scenarios where long-term reliability and minimal maintenance are essential.

As the demand for stationary energy storage continues to grow, AGM batteries are evolving to meet new challenges. Research is ongoing into improving the energy density and cycle life of AGM batteries, with some manufacturers exploring hybrid designs that incorporate elements of other battery technologies. These efforts aim to enhance the competitiveness of AGM batteries in an increasingly diverse energy storage market, ensuring their continued relevance in stationary applications for years to come.

Market Demand Analysis

The market demand for AGM (Absorbent Glass Mat) batteries in stationary applications has been steadily growing, driven by the increasing need for reliable backup power systems and the expansion of renewable energy installations. The stationary energy storage sector, which includes applications such as uninterruptible power supplies (UPS), telecom base stations, and grid stabilization, has shown significant potential for AGM battery adoption.

In the UPS market, AGM batteries are gaining traction due to their maintenance-free nature and ability to provide instant power during outages. The global UPS market is expected to grow substantially, with a particular emphasis on data centers and healthcare facilities, both of which require dependable backup power solutions. This growth directly translates to increased demand for AGM batteries in these critical infrastructure applications.

The telecommunications industry represents another major market for AGM batteries in stationary applications. As mobile networks expand and upgrade to 5G technology, the need for reliable backup power at base stations has intensified. AGM batteries are well-suited for this purpose due to their deep-cycle capabilities and resistance to extreme temperatures, making them ideal for remote and outdoor installations.

Renewable energy integration has also contributed to the rising demand for AGM batteries. As solar and wind power generation becomes more prevalent, the need for energy storage solutions to balance grid loads and provide power during non-generating hours has increased. AGM batteries offer a cost-effective and proven technology for small to medium-scale energy storage systems, particularly in residential and commercial solar installations.

The industrial sector presents additional opportunities for AGM battery adoption in stationary applications. Manufacturing facilities, warehouses, and other industrial sites require reliable backup power to prevent costly downtime and ensure safety systems remain operational during power interruptions. AGM batteries' low maintenance requirements and long service life make them an attractive option for these applications.

Geographically, the market demand for AGM batteries in stationary applications varies. Developed regions such as North America and Europe show strong demand driven by infrastructure upgrades and stringent reliability requirements. Emerging markets in Asia-Pacific and Africa are experiencing rapid growth in telecommunications and renewable energy sectors, creating new opportunities for AGM battery deployment.

Despite the positive market outlook, AGM batteries face competition from other energy storage technologies, such as lithium-ion batteries and flow batteries. However, AGM batteries maintain advantages in certain applications due to their lower upfront costs, established recycling infrastructure, and proven reliability in harsh environments. The market demand analysis suggests that AGM batteries will continue to play a significant role in stationary applications, particularly in sectors where their specific characteristics align well with operational requirements and cost considerations.

In the UPS market, AGM batteries are gaining traction due to their maintenance-free nature and ability to provide instant power during outages. The global UPS market is expected to grow substantially, with a particular emphasis on data centers and healthcare facilities, both of which require dependable backup power solutions. This growth directly translates to increased demand for AGM batteries in these critical infrastructure applications.

The telecommunications industry represents another major market for AGM batteries in stationary applications. As mobile networks expand and upgrade to 5G technology, the need for reliable backup power at base stations has intensified. AGM batteries are well-suited for this purpose due to their deep-cycle capabilities and resistance to extreme temperatures, making them ideal for remote and outdoor installations.

Renewable energy integration has also contributed to the rising demand for AGM batteries. As solar and wind power generation becomes more prevalent, the need for energy storage solutions to balance grid loads and provide power during non-generating hours has increased. AGM batteries offer a cost-effective and proven technology for small to medium-scale energy storage systems, particularly in residential and commercial solar installations.

The industrial sector presents additional opportunities for AGM battery adoption in stationary applications. Manufacturing facilities, warehouses, and other industrial sites require reliable backup power to prevent costly downtime and ensure safety systems remain operational during power interruptions. AGM batteries' low maintenance requirements and long service life make them an attractive option for these applications.

Geographically, the market demand for AGM batteries in stationary applications varies. Developed regions such as North America and Europe show strong demand driven by infrastructure upgrades and stringent reliability requirements. Emerging markets in Asia-Pacific and Africa are experiencing rapid growth in telecommunications and renewable energy sectors, creating new opportunities for AGM battery deployment.

Despite the positive market outlook, AGM batteries face competition from other energy storage technologies, such as lithium-ion batteries and flow batteries. However, AGM batteries maintain advantages in certain applications due to their lower upfront costs, established recycling infrastructure, and proven reliability in harsh environments. The market demand analysis suggests that AGM batteries will continue to play a significant role in stationary applications, particularly in sectors where their specific characteristics align well with operational requirements and cost considerations.

Technical Challenges

The adoption of AGM (Absorbent Glass Mat) batteries in stationary applications faces several technical challenges that need to be addressed for widespread implementation. One of the primary concerns is the limited cycle life of AGM batteries compared to other stationary energy storage technologies. While AGM batteries offer improved performance over traditional lead-acid batteries, they still fall short in terms of longevity when subjected to frequent deep discharge cycles, which is often required in stationary applications.

Another significant challenge is the temperature sensitivity of AGM batteries. These batteries are known to perform optimally within a narrow temperature range, typically between 20°C and 25°C. In stationary applications, where batteries may be exposed to varying environmental conditions, maintaining this optimal temperature range can be difficult and may require additional cooling or heating systems, increasing overall system complexity and cost.

The charging efficiency of AGM batteries also presents a technical hurdle. While they have better charge acceptance compared to flooded lead-acid batteries, AGM batteries still exhibit lower charging efficiencies than some alternative technologies, such as lithium-ion batteries. This lower efficiency can lead to increased energy losses during the charging process, potentially impacting the overall system performance and operating costs in stationary applications.

Scalability is another technical challenge for AGM batteries in stationary applications. As the demand for larger-scale energy storage systems grows, the ability to effectively scale up AGM battery installations while maintaining performance and safety becomes crucial. Issues such as voltage balancing across large battery banks and managing thermal runaway risks in scaled-up systems need to be carefully addressed.

Furthermore, the energy density of AGM batteries, while improved over traditional lead-acid batteries, is still lower than some competing technologies. This lower energy density can result in larger physical footprints for stationary energy storage systems, which may be a limiting factor in space-constrained applications or urban environments where real estate is at a premium.

Lastly, the environmental impact and end-of-life management of AGM batteries pose technical challenges. While these batteries are recyclable, the recycling process can be complex and energy-intensive. Developing more efficient and environmentally friendly recycling methods, as well as improving the overall lifecycle sustainability of AGM batteries, remains an important area for technical advancement in their application to stationary energy storage systems.

Another significant challenge is the temperature sensitivity of AGM batteries. These batteries are known to perform optimally within a narrow temperature range, typically between 20°C and 25°C. In stationary applications, where batteries may be exposed to varying environmental conditions, maintaining this optimal temperature range can be difficult and may require additional cooling or heating systems, increasing overall system complexity and cost.

The charging efficiency of AGM batteries also presents a technical hurdle. While they have better charge acceptance compared to flooded lead-acid batteries, AGM batteries still exhibit lower charging efficiencies than some alternative technologies, such as lithium-ion batteries. This lower efficiency can lead to increased energy losses during the charging process, potentially impacting the overall system performance and operating costs in stationary applications.

Scalability is another technical challenge for AGM batteries in stationary applications. As the demand for larger-scale energy storage systems grows, the ability to effectively scale up AGM battery installations while maintaining performance and safety becomes crucial. Issues such as voltage balancing across large battery banks and managing thermal runaway risks in scaled-up systems need to be carefully addressed.

Furthermore, the energy density of AGM batteries, while improved over traditional lead-acid batteries, is still lower than some competing technologies. This lower energy density can result in larger physical footprints for stationary energy storage systems, which may be a limiting factor in space-constrained applications or urban environments where real estate is at a premium.

Lastly, the environmental impact and end-of-life management of AGM batteries pose technical challenges. While these batteries are recyclable, the recycling process can be complex and energy-intensive. Developing more efficient and environmentally friendly recycling methods, as well as improving the overall lifecycle sustainability of AGM batteries, remains an important area for technical advancement in their application to stationary energy storage systems.

Current AGM Solutions

01 AGM battery structure and design

Innovations in the structure and design of AGM (Absorbent Glass Mat) batteries, including improvements in electrode arrangement, separator materials, and overall battery construction to enhance performance and efficiency.- AGM battery structure and design improvements: Advancements in AGM battery structure and design focus on enhancing performance and efficiency. These improvements include optimized electrode configurations, innovative separator materials, and refined internal component arrangements. Such enhancements aim to increase battery capacity, extend lifespan, and improve overall reliability.

- Charging and management systems for AGM batteries: Specialized charging and management systems are developed to optimize AGM battery performance. These systems incorporate advanced algorithms for charge control, temperature regulation, and state-of-charge monitoring. The goal is to maximize battery efficiency, prevent overcharging, and extend the operational life of AGM batteries.

- AGM battery applications in vehicles and energy storage: AGM batteries find extensive use in automotive and energy storage applications. Innovations in this area focus on adapting AGM technology for start-stop systems in vehicles, hybrid electric vehicles, and renewable energy storage solutions. These developments aim to improve energy density, cycle life, and overall system integration.

- Manufacturing processes and quality control for AGM batteries: Advancements in manufacturing processes and quality control techniques for AGM batteries are crucial for ensuring consistent performance and reliability. These innovations include automated assembly methods, precision control of electrolyte distribution, and advanced testing procedures to detect defects and optimize battery characteristics.

- Environmental and safety aspects of AGM batteries: Research and development efforts focus on improving the environmental sustainability and safety of AGM batteries. This includes developing recyclable materials, reducing harmful emissions during production and use, and implementing enhanced safety features to prevent thermal runaway and other potential hazards associated with battery operation.

02 Electrolyte management in AGM batteries

Advancements in electrolyte management systems for AGM batteries, focusing on optimizing electrolyte distribution, reducing electrolyte loss, and improving overall battery life and performance.Expand Specific Solutions03 Thermal management of AGM batteries

Development of thermal management solutions for AGM batteries, including heat dissipation mechanisms, temperature control systems, and thermal insulation techniques to maintain optimal operating conditions and extend battery lifespan.Expand Specific Solutions04 AGM battery manufacturing processes

Innovations in manufacturing processes for AGM batteries, including automated assembly techniques, quality control measures, and production optimization to improve efficiency and reduce costs.Expand Specific Solutions05 AGM battery monitoring and management systems

Development of advanced monitoring and management systems for AGM batteries, including state-of-charge estimation, fault detection, and remote monitoring capabilities to improve battery performance and maintenance.Expand Specific Solutions

Key Industry Players

The AGM battery market for stationary applications is in a growth phase, driven by increasing demand for reliable energy storage solutions. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, AGM batteries are relatively mature, offering a balance of performance and cost-effectiveness. Key players like Johnson Controls, Exide Technologies, and EnerSys are leading innovation in this space, while companies such as Fengfan Co., Ltd., Tianneng Battery Group, and Chaowei Power Group are expanding their presence. The competitive landscape is characterized by a mix of established global manufacturers and emerging regional players, with ongoing research focused on improving battery life, efficiency, and sustainability.

Hoppecke Batterien GmbH & Co. KG

Technical Solution: Hoppecke has developed a range of AGM batteries specifically designed for stationary applications, with a focus on telecommunications, renewable energy storage, and industrial backup power systems. Their AGM technology incorporates advanced lead-calcium alloy grids that enhance corrosion resistance and reduce water consumption, extending battery life in stationary settings. Hoppecke's AGM batteries feature a proprietary valve-regulated design that allows for efficient gas recombination, minimizing electrolyte loss and eliminating the need for regular watering[2]. The company has also implemented a unique plate design that optimizes current distribution and reduces internal resistance, resulting in improved charge acceptance and discharge performance in stationary applications[4]. Hoppecke's AGM batteries are equipped with flame-retardant separators and robust casings, enhancing safety and reliability in various stationary installations[6].

Strengths: Long service life, high cycling capability, and enhanced safety features. Weaknesses: Limited energy density compared to newer lithium-ion technologies, and sensitivity to high-temperature environments.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has developed advanced AGM (Absorbent Glass Mat) battery technology for stationary applications, focusing on improving energy density, cycle life, and reliability. Their AGM batteries utilize a highly absorbent microfiber glass separator that holds the electrolyte in place, reducing the risk of acid spills and allowing for flexible mounting orientations. The company has implemented enhanced grid designs and active material formulations to optimize performance in stationary applications such as uninterruptible power supplies (UPS) and renewable energy storage systems. Johnson Controls' AGM batteries feature a sealed design that minimizes gassing and water loss, resulting in maintenance-free operation and extended service life[1][3]. The company has also integrated smart monitoring capabilities into their AGM batteries, allowing for real-time performance tracking and predictive maintenance in stationary installations[5].

Strengths: Maintenance-free design, flexible mounting options, and integrated smart monitoring capabilities. Weaknesses: Higher initial cost compared to flooded lead-acid batteries, and potential for thermal runaway in extreme conditions.

Core AGM Innovations

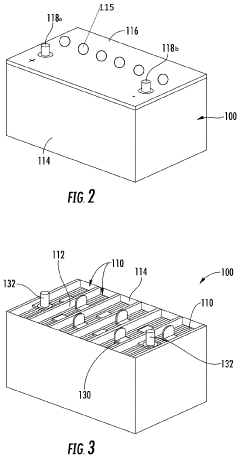

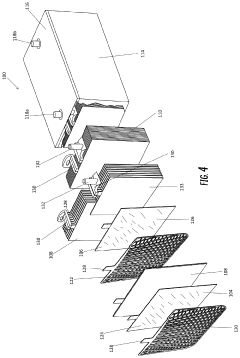

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

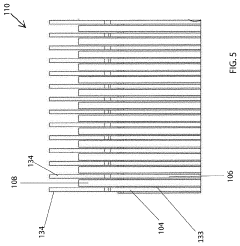

Over-Saturated Absorbed Glass Mat Valve Regulated Lead-Acid Battery Comprising Carbon Additives

PatentInactiveUS20140120386A1

Innovation

- An AGM VRLA battery design with a positive plate, negative plate containing a carbon additive, an AGM separator, and an electrolyte present in an amount ranging from 100 to 150% by volume based on the total pore volume of the separator, utilizing various carbon additives such as graphite, carbon black, activated carbon, and graphene to enhance charge acceptance and durability.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) batteries in stationary applications is a crucial consideration as the world moves towards more sustainable energy solutions. AGM batteries, known for their sealed design and high efficiency, offer several environmental advantages over traditional lead-acid batteries.

One of the primary environmental benefits of AGM batteries is their low gas emissions. Unlike flooded lead-acid batteries, AGM batteries do not release hydrogen gas during operation, reducing the risk of explosion and eliminating the need for special ventilation systems. This characteristic makes them safer for indoor use and reduces the overall environmental footprint of installations.

AGM batteries also have a longer lifespan compared to conventional lead-acid batteries, typically lasting 3-10 years depending on usage and maintenance. This extended life cycle translates to fewer battery replacements over time, reducing waste generation and the environmental impact associated with battery production and disposal.

The sealed construction of AGM batteries prevents electrolyte leakage, a common issue with flooded lead-acid batteries. This design feature minimizes the risk of soil and water contamination, making AGM batteries a more environmentally friendly option for stationary applications, particularly in sensitive ecological areas.

In terms of recyclability, AGM batteries are highly recyclable, with up to 99% of their components being recoverable. The lead, plastic, and other materials can be effectively separated and reused in the production of new batteries or other products. This high recycling rate significantly reduces the environmental impact of battery disposal and conserves valuable resources.

AGM batteries also contribute to energy efficiency in stationary applications. Their low internal resistance allows for faster charging and discharging, reducing energy losses during power conversion processes. This efficiency can lead to lower overall energy consumption in systems utilizing AGM batteries, indirectly reducing carbon emissions associated with power generation.

However, it is important to note that the production of AGM batteries still involves the use of lead, which can have environmental implications if not properly managed. Strict regulations and responsible manufacturing practices are essential to mitigate potential environmental risks during the production phase.

In conclusion, while AGM batteries are not without environmental considerations, their overall impact in stationary applications tends to be more positive compared to traditional battery technologies. Their long lifespan, high recyclability, and efficient performance contribute to a reduced environmental footprint, making them a viable option for sustainable energy storage solutions.

One of the primary environmental benefits of AGM batteries is their low gas emissions. Unlike flooded lead-acid batteries, AGM batteries do not release hydrogen gas during operation, reducing the risk of explosion and eliminating the need for special ventilation systems. This characteristic makes them safer for indoor use and reduces the overall environmental footprint of installations.

AGM batteries also have a longer lifespan compared to conventional lead-acid batteries, typically lasting 3-10 years depending on usage and maintenance. This extended life cycle translates to fewer battery replacements over time, reducing waste generation and the environmental impact associated with battery production and disposal.

The sealed construction of AGM batteries prevents electrolyte leakage, a common issue with flooded lead-acid batteries. This design feature minimizes the risk of soil and water contamination, making AGM batteries a more environmentally friendly option for stationary applications, particularly in sensitive ecological areas.

In terms of recyclability, AGM batteries are highly recyclable, with up to 99% of their components being recoverable. The lead, plastic, and other materials can be effectively separated and reused in the production of new batteries or other products. This high recycling rate significantly reduces the environmental impact of battery disposal and conserves valuable resources.

AGM batteries also contribute to energy efficiency in stationary applications. Their low internal resistance allows for faster charging and discharging, reducing energy losses during power conversion processes. This efficiency can lead to lower overall energy consumption in systems utilizing AGM batteries, indirectly reducing carbon emissions associated with power generation.

However, it is important to note that the production of AGM batteries still involves the use of lead, which can have environmental implications if not properly managed. Strict regulations and responsible manufacturing practices are essential to mitigate potential environmental risks during the production phase.

In conclusion, while AGM batteries are not without environmental considerations, their overall impact in stationary applications tends to be more positive compared to traditional battery technologies. Their long lifespan, high recyclability, and efficient performance contribute to a reduced environmental footprint, making them a viable option for sustainable energy storage solutions.

Safety Regulations

Safety regulations play a crucial role in the adoption and implementation of AGM (Absorbent Glass Mat) batteries for stationary applications. As these batteries gain popularity in various sectors, including telecommunications, renewable energy storage, and backup power systems, it is essential to establish and adhere to comprehensive safety guidelines.

The primary focus of safety regulations for AGM batteries in stationary applications is to mitigate potential risks associated with their operation, maintenance, and disposal. These regulations typically cover aspects such as installation requirements, ventilation standards, fire safety measures, and proper handling procedures.

One key area of safety regulation is the installation process. Guidelines often specify the need for proper enclosures, adequate spacing between battery units, and appropriate electrical connections. These measures help prevent short circuits, overheating, and other hazards that could lead to battery failure or accidents.

Ventilation requirements are another critical aspect of safety regulations. Although AGM batteries produce minimal gas emissions compared to flooded lead-acid batteries, proper ventilation is still necessary to dissipate any heat generated during charging and discharging cycles. Regulations may specify minimum airflow rates and ventilation system designs to ensure safe operation in enclosed spaces.

Fire safety is a paramount concern in stationary battery applications. Safety regulations often mandate the use of fire-resistant materials in battery enclosures and surrounding structures. Additionally, the installation of fire detection and suppression systems may be required in certain applications, particularly in large-scale installations or critical infrastructure settings.

Handling and maintenance procedures are also subject to safety regulations. These guidelines typically outline proper personal protective equipment (PPE) for technicians, safe methods for battery replacement and disposal, and protocols for addressing battery failures or accidents. Regular inspection and maintenance schedules may be mandated to ensure ongoing safety compliance.

Environmental considerations are increasingly incorporated into safety regulations for AGM batteries. This includes guidelines for the proper disposal of spent batteries, recycling requirements, and measures to prevent environmental contamination in case of battery leakage or damage.

As the technology and applications of AGM batteries continue to evolve, safety regulations are regularly updated to address new challenges and incorporate best practices. Compliance with these regulations is not only a legal requirement but also essential for ensuring the long-term reliability and safety of stationary AGM battery installations.

The primary focus of safety regulations for AGM batteries in stationary applications is to mitigate potential risks associated with their operation, maintenance, and disposal. These regulations typically cover aspects such as installation requirements, ventilation standards, fire safety measures, and proper handling procedures.

One key area of safety regulation is the installation process. Guidelines often specify the need for proper enclosures, adequate spacing between battery units, and appropriate electrical connections. These measures help prevent short circuits, overheating, and other hazards that could lead to battery failure or accidents.

Ventilation requirements are another critical aspect of safety regulations. Although AGM batteries produce minimal gas emissions compared to flooded lead-acid batteries, proper ventilation is still necessary to dissipate any heat generated during charging and discharging cycles. Regulations may specify minimum airflow rates and ventilation system designs to ensure safe operation in enclosed spaces.

Fire safety is a paramount concern in stationary battery applications. Safety regulations often mandate the use of fire-resistant materials in battery enclosures and surrounding structures. Additionally, the installation of fire detection and suppression systems may be required in certain applications, particularly in large-scale installations or critical infrastructure settings.

Handling and maintenance procedures are also subject to safety regulations. These guidelines typically outline proper personal protective equipment (PPE) for technicians, safe methods for battery replacement and disposal, and protocols for addressing battery failures or accidents. Regular inspection and maintenance schedules may be mandated to ensure ongoing safety compliance.

Environmental considerations are increasingly incorporated into safety regulations for AGM batteries. This includes guidelines for the proper disposal of spent batteries, recycling requirements, and measures to prevent environmental contamination in case of battery leakage or damage.

As the technology and applications of AGM batteries continue to evolve, safety regulations are regularly updated to address new challenges and incorporate best practices. Compliance with these regulations is not only a legal requirement but also essential for ensuring the long-term reliability and safety of stationary AGM battery installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!