Exploring Hydrochloric Acid's Versatility Across Industries

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Applications and Objectives

Hydrochloric acid (HCl) stands as a cornerstone in various industrial applications, showcasing remarkable versatility across multiple sectors. This strong mineral acid plays a pivotal role in numerous processes, from chemical manufacturing to food production. The primary objective of exploring HCl's applications is to optimize its usage, enhance efficiency, and develop innovative solutions for emerging challenges in diverse industries.

In the chemical industry, HCl serves as a crucial reagent and catalyst in the production of various compounds. Its ability to facilitate reactions and maintain pH levels makes it indispensable in processes such as chlorine production, polymer synthesis, and pharmaceutical manufacturing. The goal is to refine these processes, minimizing waste and improving yield while ensuring safety and environmental compliance.

The metal processing sector heavily relies on HCl for pickling and descaling operations. By removing rust and impurities from metal surfaces, HCl contributes to the production of high-quality steel and other metal products. Ongoing research aims to develop more efficient pickling techniques that reduce acid consumption and minimize environmental impact.

In water treatment, HCl is utilized for pH adjustment and neutralization of alkaline effluents. The objective is to enhance water purification methods, exploring novel applications of HCl in combination with other treatment technologies to address emerging contaminants and meet increasingly stringent environmental regulations.

The oil and gas industry employs HCl in well acidizing and hydraulic fracturing operations. Research efforts focus on optimizing acid formulations to improve oil and gas recovery rates while minimizing formation damage and environmental risks. Additionally, there is a growing interest in developing eco-friendly alternatives that maintain the effectiveness of HCl-based treatments.

HCl's role in the food industry extends to pH control, flavor enhancement, and food preservation. The goal is to refine its application in food processing, ensuring product safety and quality while meeting consumer demands for clean-label products. This includes exploring natural alternatives and minimizing HCl usage where possible.

In the pharmaceutical sector, HCl is essential in drug synthesis and formulation. Ongoing research aims to develop more efficient synthesis routes, improve drug stability, and enhance bioavailability through innovative HCl-based formulations. The objective is to accelerate drug development processes and reduce production costs while maintaining high quality standards.

As industries evolve, the exploration of HCl's versatility continues to uncover new applications and improve existing ones. The overarching goal is to harness its unique properties to drive innovation, enhance productivity, and address emerging challenges across various sectors, all while prioritizing safety, sustainability, and environmental stewardship.

In the chemical industry, HCl serves as a crucial reagent and catalyst in the production of various compounds. Its ability to facilitate reactions and maintain pH levels makes it indispensable in processes such as chlorine production, polymer synthesis, and pharmaceutical manufacturing. The goal is to refine these processes, minimizing waste and improving yield while ensuring safety and environmental compliance.

The metal processing sector heavily relies on HCl for pickling and descaling operations. By removing rust and impurities from metal surfaces, HCl contributes to the production of high-quality steel and other metal products. Ongoing research aims to develop more efficient pickling techniques that reduce acid consumption and minimize environmental impact.

In water treatment, HCl is utilized for pH adjustment and neutralization of alkaline effluents. The objective is to enhance water purification methods, exploring novel applications of HCl in combination with other treatment technologies to address emerging contaminants and meet increasingly stringent environmental regulations.

The oil and gas industry employs HCl in well acidizing and hydraulic fracturing operations. Research efforts focus on optimizing acid formulations to improve oil and gas recovery rates while minimizing formation damage and environmental risks. Additionally, there is a growing interest in developing eco-friendly alternatives that maintain the effectiveness of HCl-based treatments.

HCl's role in the food industry extends to pH control, flavor enhancement, and food preservation. The goal is to refine its application in food processing, ensuring product safety and quality while meeting consumer demands for clean-label products. This includes exploring natural alternatives and minimizing HCl usage where possible.

In the pharmaceutical sector, HCl is essential in drug synthesis and formulation. Ongoing research aims to develop more efficient synthesis routes, improve drug stability, and enhance bioavailability through innovative HCl-based formulations. The objective is to accelerate drug development processes and reduce production costs while maintaining high quality standards.

As industries evolve, the exploration of HCl's versatility continues to uncover new applications and improve existing ones. The overarching goal is to harness its unique properties to drive innovation, enhance productivity, and address emerging challenges across various sectors, all while prioritizing safety, sustainability, and environmental stewardship.

Market Analysis for HCl

The global hydrochloric acid (HCl) market has shown steady growth in recent years, driven by its widespread applications across various industries. The market size was valued at approximately 7.5 billion USD in 2020 and is projected to reach 9.2 billion USD by 2026, growing at a CAGR of 3.5% during the forecast period. This growth is primarily attributed to the increasing demand from key end-use industries such as chemicals, steel pickling, and oil well acidizing.

The chemical industry remains the largest consumer of hydrochloric acid, accounting for nearly 40% of the global market share. HCl is extensively used in the production of various chemicals, including vinyl chloride, dichloroethane, and chlorinated solvents. The steel industry follows closely, utilizing HCl for pickling and descaling processes, which contribute to about 30% of the market demand.

Geographically, Asia-Pacific dominates the hydrochloric acid market, with China being the largest producer and consumer. The region's rapid industrialization, particularly in countries like India and Southeast Asian nations, is expected to further boost demand. North America and Europe hold significant market shares, driven by established chemical and manufacturing sectors.

The oil and gas industry presents a growing opportunity for HCl usage, particularly in hydraulic fracturing and well acidizing operations. As unconventional oil and gas exploration activities increase, the demand for HCl in this sector is expected to rise, potentially reaching 15% of the global market share by 2025.

Environmental concerns and stringent regulations regarding the production and handling of hydrochloric acid pose challenges to market growth. However, these challenges also drive innovation in production methods and handling technologies, creating opportunities for companies to develop more sustainable and safer practices.

The market is characterized by the presence of several large-scale manufacturers and numerous regional players. Key market players include Dow Chemical Company, Covestro AG, Olin Corporation, and BASF SE. These companies are focusing on capacity expansion, technological advancements, and strategic partnerships to maintain their market positions and meet the growing demand.

Emerging trends in the HCl market include the development of high-purity grades for specialized applications in electronics and semiconductor industries, as well as the increasing adoption of byproduct hydrochloric acid from various chemical processes. This trend towards circular economy practices is expected to influence market dynamics in the coming years, potentially altering supply chains and pricing structures.

The chemical industry remains the largest consumer of hydrochloric acid, accounting for nearly 40% of the global market share. HCl is extensively used in the production of various chemicals, including vinyl chloride, dichloroethane, and chlorinated solvents. The steel industry follows closely, utilizing HCl for pickling and descaling processes, which contribute to about 30% of the market demand.

Geographically, Asia-Pacific dominates the hydrochloric acid market, with China being the largest producer and consumer. The region's rapid industrialization, particularly in countries like India and Southeast Asian nations, is expected to further boost demand. North America and Europe hold significant market shares, driven by established chemical and manufacturing sectors.

The oil and gas industry presents a growing opportunity for HCl usage, particularly in hydraulic fracturing and well acidizing operations. As unconventional oil and gas exploration activities increase, the demand for HCl in this sector is expected to rise, potentially reaching 15% of the global market share by 2025.

Environmental concerns and stringent regulations regarding the production and handling of hydrochloric acid pose challenges to market growth. However, these challenges also drive innovation in production methods and handling technologies, creating opportunities for companies to develop more sustainable and safer practices.

The market is characterized by the presence of several large-scale manufacturers and numerous regional players. Key market players include Dow Chemical Company, Covestro AG, Olin Corporation, and BASF SE. These companies are focusing on capacity expansion, technological advancements, and strategic partnerships to maintain their market positions and meet the growing demand.

Emerging trends in the HCl market include the development of high-purity grades for specialized applications in electronics and semiconductor industries, as well as the increasing adoption of byproduct hydrochloric acid from various chemical processes. This trend towards circular economy practices is expected to influence market dynamics in the coming years, potentially altering supply chains and pricing structures.

HCl Production Challenges

The production of hydrochloric acid (HCl) faces several significant challenges that impact its efficiency, cost-effectiveness, and environmental sustainability. One of the primary issues is the corrosive nature of HCl, which necessitates the use of specialized equipment and materials throughout the production process. This requirement not only increases capital costs but also leads to higher maintenance expenses and potential safety risks.

Another major challenge lies in the management of by-products and waste streams. Depending on the production method, various unwanted substances may be generated, such as chlorine gas or sulfuric acid. These by-products require careful handling and disposal, often involving additional processing steps or treatment facilities, which can significantly impact the overall production costs and environmental footprint.

Energy consumption is a critical concern in HCl production. Many processes, particularly those involving the reaction of hydrogen and chlorine, require substantial energy inputs. This not only contributes to higher operational costs but also raises environmental concerns due to increased carbon emissions. The industry is under pressure to develop more energy-efficient production methods to address these issues.

Raw material availability and price volatility present ongoing challenges. The production of HCl often relies on the availability of chlorine or hydrogen, which can be subject to market fluctuations. Ensuring a stable and cost-effective supply of these raw materials is crucial for maintaining consistent production and managing costs.

Environmental regulations pose significant challenges to HCl producers. Stringent emission controls and waste management requirements necessitate substantial investments in pollution control technologies and monitoring systems. Compliance with these regulations can be complex and costly, particularly for smaller producers.

Safety considerations are paramount in HCl production due to the hazardous nature of the chemicals involved. Implementing robust safety protocols, training programs, and emergency response systems is essential but adds to the operational complexity and costs.

The transportation and storage of HCl present logistical challenges. The corrosive nature of the acid requires specialized containers and handling procedures, which can increase distribution costs and limit storage options. This can impact the ability to respond to market demand fluctuations efficiently.

Lastly, the industry faces the challenge of developing more sustainable production methods. There is growing pressure to reduce the environmental impact of HCl production, including minimizing waste generation, improving energy efficiency, and exploring alternative raw materials or production routes that have a lower carbon footprint.

Another major challenge lies in the management of by-products and waste streams. Depending on the production method, various unwanted substances may be generated, such as chlorine gas or sulfuric acid. These by-products require careful handling and disposal, often involving additional processing steps or treatment facilities, which can significantly impact the overall production costs and environmental footprint.

Energy consumption is a critical concern in HCl production. Many processes, particularly those involving the reaction of hydrogen and chlorine, require substantial energy inputs. This not only contributes to higher operational costs but also raises environmental concerns due to increased carbon emissions. The industry is under pressure to develop more energy-efficient production methods to address these issues.

Raw material availability and price volatility present ongoing challenges. The production of HCl often relies on the availability of chlorine or hydrogen, which can be subject to market fluctuations. Ensuring a stable and cost-effective supply of these raw materials is crucial for maintaining consistent production and managing costs.

Environmental regulations pose significant challenges to HCl producers. Stringent emission controls and waste management requirements necessitate substantial investments in pollution control technologies and monitoring systems. Compliance with these regulations can be complex and costly, particularly for smaller producers.

Safety considerations are paramount in HCl production due to the hazardous nature of the chemicals involved. Implementing robust safety protocols, training programs, and emergency response systems is essential but adds to the operational complexity and costs.

The transportation and storage of HCl present logistical challenges. The corrosive nature of the acid requires specialized containers and handling procedures, which can increase distribution costs and limit storage options. This can impact the ability to respond to market demand fluctuations efficiently.

Lastly, the industry faces the challenge of developing more sustainable production methods. There is growing pressure to reduce the environmental impact of HCl production, including minimizing waste generation, improving energy efficiency, and exploring alternative raw materials or production routes that have a lower carbon footprint.

Current HCl Usage Solutions

01 Production methods of hydrochloric acid

Various methods are employed to produce hydrochloric acid, including the reaction of chlorine with hydrogen, the chlorination of organic compounds, and as a byproduct in chemical processes. These production methods aim to optimize yield, purity, and efficiency while minimizing environmental impact.- Production and purification of hydrochloric acid: Various methods and systems for producing and purifying hydrochloric acid are described. These include processes for manufacturing high-purity hydrochloric acid, as well as techniques for removing impurities and contaminants from the acid. The methods often involve distillation, absorption, or other separation processes to achieve the desired purity levels.

- Applications of hydrochloric acid in chemical processes: Hydrochloric acid is widely used in various chemical processes and industrial applications. It serves as a key reagent in the production of other chemicals, metal treatment, and as a pH regulator. The acid's properties make it valuable in processes such as ore processing, water treatment, and the manufacture of pharmaceuticals and food additives.

- Storage and handling of hydrochloric acid: Specialized equipment and methods for storing, transporting, and handling hydrochloric acid are crucial due to its corrosive nature. This includes the design of acid-resistant containers, safety measures for preventing leaks and spills, and systems for the controlled dispensing of the acid in industrial settings.

- Recovery and recycling of hydrochloric acid: Techniques for recovering and recycling hydrochloric acid from industrial processes are important for environmental and economic reasons. These methods often involve capturing HCl gas, absorbing it into water, or regenerating the acid from spent solutions. Such processes help reduce waste and improve the efficiency of chemical operations.

- Safety and environmental considerations in hydrochloric acid use: Given the hazardous nature of hydrochloric acid, safety protocols and environmental protection measures are critical. This includes methods for neutralizing acid spills, treating acid-containing wastewater, and implementing safety systems in facilities that use or produce hydrochloric acid. Proper handling and disposal techniques are essential to minimize risks to human health and the environment.

02 Purification and concentration of hydrochloric acid

Techniques for purifying and concentrating hydrochloric acid involve distillation, membrane separation, and adsorption processes. These methods aim to remove impurities and increase the acid concentration for various industrial applications, ensuring high-quality products for specific uses.Expand Specific Solutions03 Applications of hydrochloric acid in chemical processing

Hydrochloric acid is widely used in various chemical processes, including metal treatment, pH regulation, and as a reagent in organic synthesis. Its versatility makes it essential in industries such as metallurgy, pharmaceuticals, and food processing, where it plays a crucial role in numerous reactions and treatments.Expand Specific Solutions04 Safety and handling of hydrochloric acid

Proper safety measures and handling procedures are crucial when working with hydrochloric acid due to its corrosive nature. This includes the use of specialized storage containers, personal protective equipment, and neutralization techniques. Implementing these practices helps prevent accidents and ensures worker safety in industrial settings.Expand Specific Solutions05 Environmental considerations and waste management

Managing the environmental impact of hydrochloric acid production and use involves developing sustainable practices for waste treatment and disposal. This includes neutralization processes, recycling methods, and the implementation of closed-loop systems to minimize emissions and reduce the ecological footprint of industrial operations using hydrochloric acid.Expand Specific Solutions

Key HCl Industry Players

The exploration of hydrochloric acid's versatility across industries is in a mature stage, with a well-established market and diverse applications. The global hydrochloric acid market size is substantial, estimated to reach several billion dollars annually. Technologically, the production and application of hydrochloric acid are well-developed, with companies like Fluid Energy Group Ltd., Covestro Deutschland AG, and Dow Global Technologies LLC leading innovation in specialized formulations and sustainable production methods. Research institutions such as Nankai University and Tianjin University contribute to advancing the understanding and applications of hydrochloric acid in various sectors, including chemical manufacturing, pharmaceuticals, and environmental remediation.

Fluid Energy Group Ltd.

Technical Solution: Fluid Energy Group has pioneered the use of hydrochloric acid in the oil and gas industry, particularly for well stimulation and enhanced oil recovery. Their proprietary HCl-based formulations are designed to improve reservoir permeability and increase hydrocarbon production[1]. They have developed environmentally friendly HCl alternatives that reduce corrosion and environmental impact while maintaining effectiveness[2]. Additionally, Fluid Energy Group has created innovative delivery systems for HCl-based fluids, allowing for more precise and controlled application in challenging downhole environments[3].

Strengths: Specialized expertise in oilfield chemistry, environmentally conscious formulations, and innovative delivery systems. Weaknesses: Heavy reliance on the oil and gas industry, which can be subject to market volatility.

Covestro Deutschland AG

Technical Solution: Covestro has developed advanced applications for hydrochloric acid in the production of polyurethanes and polycarbonates. Their innovative approach involves using HCl as a key reagent in the synthesis of isocyanates, which are essential components in polyurethane production[1]. They have also implemented a closed-loop system for HCl recycling in their manufacturing processes, significantly reducing waste and improving efficiency[2]. Furthermore, Covestro has developed novel catalysts that enable more efficient use of HCl in various chemical reactions, leading to improved product quality and reduced environmental impact[3].

Strengths: Strong focus on sustainability, innovative recycling technologies, and expertise in polymer chemistry. Weaknesses: Dependence on petrochemical feedstocks and potential market fluctuations in the plastics industry.

HCl Innovation Breakthroughs

Synthetic acid compositions and uses thereof

PatentWO2016049737A1

Innovation

- A synthetic acid composition comprising urea and hydrogen chloride in a specific molar ratio, combined with amino acids and phosphonic acids, which reduces corrosion and toxicity, is developed, offering a safer, non-fuming, and biodegradable alternative for industrial applications.

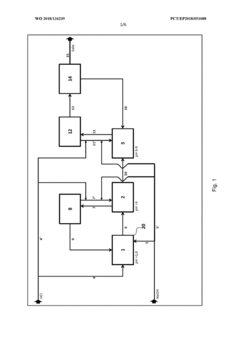

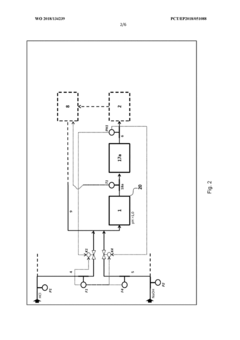

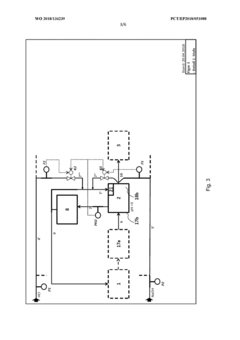

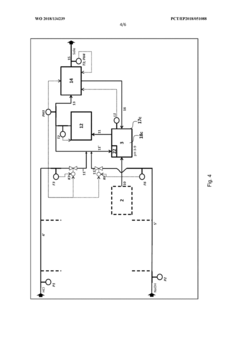

Method for flexibly controlling the use of hydrochloric acid from chemical production

PatentWO2018134239A1

Innovation

- A flexible control process for hydrochloric acid management involves neutralizing hydrochloric acid with concentrated alkali, specifically sodium hydroxide, in a multi-stage continuous process that adjusts pH values and compensates for flow and concentration variations, allowing for efficient handling and recycling of hydrochloric acid even when traditional acceptance points are unavailable.

Environmental Impact of HCl

The environmental impact of hydrochloric acid (HCl) is a critical consideration in its widespread industrial use. HCl, while essential for many processes, can have significant effects on ecosystems and human health if not properly managed.

One of the primary environmental concerns associated with HCl is its potential to contribute to acid rain. When released into the atmosphere, HCl can react with water vapor to form hydrochloric acid droplets. These droplets can fall as acid rain, leading to the acidification of soil and water bodies. This acidification can have detrimental effects on plant life, aquatic ecosystems, and infrastructure.

In aquatic environments, the release of HCl can cause a rapid decrease in pH levels. This sudden change can be lethal to fish and other aquatic organisms, disrupting entire ecosystems. Even small, chronic releases can lead to long-term changes in water chemistry, affecting the survival and reproduction of various species.

Soil contamination is another significant issue. HCl spills or improper disposal can lead to soil acidification, altering its chemical composition and affecting plant growth. This can have cascading effects on local flora and fauna, potentially leading to habitat degradation and loss of biodiversity.

The production and transportation of HCl also contribute to its environmental footprint. Manufacturing processes often involve energy-intensive steps and may result in emissions of greenhouse gases and other pollutants. Transportation risks include accidental spills during handling or transit, which can have immediate and severe local environmental impacts.

However, it's important to note that many industries have implemented stringent safety measures and environmental controls to mitigate these risks. Advanced containment systems, neutralization techniques, and proper disposal methods have significantly reduced the environmental impact of HCl in industrial settings.

Recycling and reuse strategies have also been developed to minimize waste and environmental exposure. Some industries have implemented closed-loop systems where HCl is continuously recycled within the production process, reducing the need for fresh acid and minimizing waste.

Regulatory frameworks play a crucial role in managing HCl's environmental impact. Many countries have strict regulations governing the production, use, and disposal of HCl, including emissions standards and handling protocols. These regulations aim to balance the industrial necessity of HCl with environmental protection.

Research into alternative technologies and greener chemistry approaches is ongoing, seeking to reduce reliance on HCl or develop less environmentally impactful substitutes for certain applications. This includes exploring bio-based alternatives and developing more efficient processes that require less acid or produce less waste.

One of the primary environmental concerns associated with HCl is its potential to contribute to acid rain. When released into the atmosphere, HCl can react with water vapor to form hydrochloric acid droplets. These droplets can fall as acid rain, leading to the acidification of soil and water bodies. This acidification can have detrimental effects on plant life, aquatic ecosystems, and infrastructure.

In aquatic environments, the release of HCl can cause a rapid decrease in pH levels. This sudden change can be lethal to fish and other aquatic organisms, disrupting entire ecosystems. Even small, chronic releases can lead to long-term changes in water chemistry, affecting the survival and reproduction of various species.

Soil contamination is another significant issue. HCl spills or improper disposal can lead to soil acidification, altering its chemical composition and affecting plant growth. This can have cascading effects on local flora and fauna, potentially leading to habitat degradation and loss of biodiversity.

The production and transportation of HCl also contribute to its environmental footprint. Manufacturing processes often involve energy-intensive steps and may result in emissions of greenhouse gases and other pollutants. Transportation risks include accidental spills during handling or transit, which can have immediate and severe local environmental impacts.

However, it's important to note that many industries have implemented stringent safety measures and environmental controls to mitigate these risks. Advanced containment systems, neutralization techniques, and proper disposal methods have significantly reduced the environmental impact of HCl in industrial settings.

Recycling and reuse strategies have also been developed to minimize waste and environmental exposure. Some industries have implemented closed-loop systems where HCl is continuously recycled within the production process, reducing the need for fresh acid and minimizing waste.

Regulatory frameworks play a crucial role in managing HCl's environmental impact. Many countries have strict regulations governing the production, use, and disposal of HCl, including emissions standards and handling protocols. These regulations aim to balance the industrial necessity of HCl with environmental protection.

Research into alternative technologies and greener chemistry approaches is ongoing, seeking to reduce reliance on HCl or develop less environmentally impactful substitutes for certain applications. This includes exploring bio-based alternatives and developing more efficient processes that require less acid or produce less waste.

Safety Regulations for HCl

The safety regulations for hydrochloric acid (HCl) are extensive and stringent due to its corrosive and hazardous nature. These regulations are designed to protect workers, the environment, and the general public from potential harm associated with HCl handling, storage, and use.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for HCl exposure in the workplace. The permissible exposure limit (PEL) for HCl is set at 5 parts per million (ppm) as a ceiling limit, meaning that this concentration should never be exceeded during any part of the workday. OSHA also requires employers to provide appropriate personal protective equipment (PPE) to workers handling HCl, including chemical-resistant gloves, goggles, face shields, and respiratory protection when necessary.

The Environmental Protection Agency (EPA) regulates HCl under the Clean Air Act as a hazardous air pollutant. Facilities that emit HCl must comply with emission standards and implement control technologies to minimize releases. The EPA also classifies HCl as a hazardous substance under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), which mandates reporting of spills and proper cleanup procedures.

Transportation of HCl is regulated by the Department of Transportation (DOT) in the United States. HCl is classified as a corrosive material, and specific packaging, labeling, and shipping requirements must be followed. These include using UN-approved containers, proper hazard labels, and shipping papers that accurately describe the material and its hazards.

Internationally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Under GHS, HCl is classified as a corrosive substance, and specific labeling elements, including pictograms, signal words, and hazard statements, must be used on containers and safety data sheets.

Many countries have adopted similar regulations to those in the United States, often with additional local requirements. For example, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers of HCl to register the substance and provide detailed safety information.

Storage regulations for HCl typically require corrosion-resistant containers, secondary containment systems, and proper ventilation in storage areas. Facilities must also have emergency response plans in place, including procedures for spill containment and neutralization.

In industrial settings, process safety management (PSM) regulations may apply to HCl use, particularly in large quantities or high concentrations. These regulations require comprehensive safety programs, including hazard analysis, operating procedures, training, and incident investigation protocols.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for HCl exposure in the workplace. The permissible exposure limit (PEL) for HCl is set at 5 parts per million (ppm) as a ceiling limit, meaning that this concentration should never be exceeded during any part of the workday. OSHA also requires employers to provide appropriate personal protective equipment (PPE) to workers handling HCl, including chemical-resistant gloves, goggles, face shields, and respiratory protection when necessary.

The Environmental Protection Agency (EPA) regulates HCl under the Clean Air Act as a hazardous air pollutant. Facilities that emit HCl must comply with emission standards and implement control technologies to minimize releases. The EPA also classifies HCl as a hazardous substance under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), which mandates reporting of spills and proper cleanup procedures.

Transportation of HCl is regulated by the Department of Transportation (DOT) in the United States. HCl is classified as a corrosive material, and specific packaging, labeling, and shipping requirements must be followed. These include using UN-approved containers, proper hazard labels, and shipping papers that accurately describe the material and its hazards.

Internationally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Under GHS, HCl is classified as a corrosive substance, and specific labeling elements, including pictograms, signal words, and hazard statements, must be used on containers and safety data sheets.

Many countries have adopted similar regulations to those in the United States, often with additional local requirements. For example, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers of HCl to register the substance and provide detailed safety information.

Storage regulations for HCl typically require corrosion-resistant containers, secondary containment systems, and proper ventilation in storage areas. Facilities must also have emergency response plans in place, including procedures for spill containment and neutralization.

In industrial settings, process safety management (PSM) regulations may apply to HCl use, particularly in large quantities or high concentrations. These regulations require comprehensive safety programs, including hazard analysis, operating procedures, training, and incident investigation protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!