Exploring Polysilane's Versatility in Tech Developments

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Background

Polysilanes, a class of silicon-based polymers with a backbone consisting of silicon atoms, have emerged as versatile materials with significant potential in various technological applications. The exploration of polysilanes dates back to the early 20th century, with initial synthesis attempts by Kipping in 1921. However, it wasn't until the 1970s that significant progress was made in their synthesis and characterization, leading to a surge in research interest.

The unique electronic and optical properties of polysilanes stem from their σ-conjugated backbone, which allows for efficient electron delocalization along the silicon chain. This characteristic sets them apart from traditional carbon-based polymers and opens up a wide range of possibilities in optoelectronic applications. The ability to tune these properties through structural modifications has been a key driver in polysilane research and development.

One of the most notable features of polysilanes is their photosensitivity, which has led to their application in photoresists for microelectronics. When exposed to UV light, polysilanes undergo photodegradation, making them valuable in lithography processes for semiconductor manufacturing. This property has been extensively studied and optimized, contributing to advancements in high-resolution patterning techniques.

In addition to their photosensitive properties, polysilanes exhibit interesting electronic conductivity. While not as conductive as some organic polymers, their conductivity can be enhanced through doping or structural modifications. This has sparked interest in their potential use in organic electronics, including solar cells and light-emitting diodes (LEDs).

The thermal stability of polysilanes, particularly at high temperatures in inert atmospheres, has made them attractive precursors for silicon carbide (SiC) ceramics. This application has gained traction in the development of high-performance materials for extreme environments, such as aerospace components and high-temperature sensors.

Recent years have seen an expansion in the scope of polysilane applications. Their unique optical properties, including high refractive indices and nonlinear optical responses, have led to investigations into their use in photonic devices and optical waveguides. Furthermore, the biocompatibility of certain polysilane derivatives has opened up possibilities in biomedical applications, such as drug delivery systems and bioimaging.

The versatility of polysilanes extends to their potential in nanotechnology. Research has shown promise in using polysilanes as precursors for silicon nanoparticles and nanowires, which have applications in energy storage, catalysis, and nanoelectronics. This intersection with nanotechnology represents a frontier in polysilane research, offering new avenues for innovation and technological advancement.

The unique electronic and optical properties of polysilanes stem from their σ-conjugated backbone, which allows for efficient electron delocalization along the silicon chain. This characteristic sets them apart from traditional carbon-based polymers and opens up a wide range of possibilities in optoelectronic applications. The ability to tune these properties through structural modifications has been a key driver in polysilane research and development.

One of the most notable features of polysilanes is their photosensitivity, which has led to their application in photoresists for microelectronics. When exposed to UV light, polysilanes undergo photodegradation, making them valuable in lithography processes for semiconductor manufacturing. This property has been extensively studied and optimized, contributing to advancements in high-resolution patterning techniques.

In addition to their photosensitive properties, polysilanes exhibit interesting electronic conductivity. While not as conductive as some organic polymers, their conductivity can be enhanced through doping or structural modifications. This has sparked interest in their potential use in organic electronics, including solar cells and light-emitting diodes (LEDs).

The thermal stability of polysilanes, particularly at high temperatures in inert atmospheres, has made them attractive precursors for silicon carbide (SiC) ceramics. This application has gained traction in the development of high-performance materials for extreme environments, such as aerospace components and high-temperature sensors.

Recent years have seen an expansion in the scope of polysilane applications. Their unique optical properties, including high refractive indices and nonlinear optical responses, have led to investigations into their use in photonic devices and optical waveguides. Furthermore, the biocompatibility of certain polysilane derivatives has opened up possibilities in biomedical applications, such as drug delivery systems and bioimaging.

The versatility of polysilanes extends to their potential in nanotechnology. Research has shown promise in using polysilanes as precursors for silicon nanoparticles and nanowires, which have applications in energy storage, catalysis, and nanoelectronics. This intersection with nanotechnology represents a frontier in polysilane research, offering new avenues for innovation and technological advancement.

Market Demand Analysis

The market demand for polysilane-based technologies has been steadily growing across various industries due to its unique properties and versatile applications. In the semiconductor industry, polysilanes have shown promising potential as precursors for silicon-based materials, offering improved processability and control over material properties. This has led to increased interest from major semiconductor manufacturers looking to enhance their production processes and develop next-generation electronic devices.

The photonics sector has also witnessed a surge in demand for polysilane-based materials. Their photosensitive nature and ability to form well-defined nanostructures make them attractive for applications in optical waveguides, photoresists, and light-emitting devices. As the demand for high-performance optical components continues to rise in telecommunications and data centers, polysilanes are positioned to play a crucial role in meeting these market needs.

In the field of energy storage and conversion, polysilanes have garnered attention for their potential use in lithium-ion batteries and solar cells. The ability to tailor the electronic properties of polysilanes through structural modifications has opened up new possibilities for improving energy storage capacity and efficiency. This aligns well with the growing global demand for sustainable energy solutions and the push towards electrification in various industries.

The automotive sector has shown increasing interest in polysilane-based materials for lightweight components and advanced coatings. As the industry shifts towards electric vehicles and seeks to improve fuel efficiency, the demand for materials that can reduce vehicle weight while maintaining structural integrity has grown significantly. Polysilanes offer a promising avenue for developing such materials, potentially revolutionizing automotive design and manufacturing processes.

In the healthcare and biomedical fields, polysilanes have emerged as candidates for drug delivery systems and biocompatible materials. Their unique chemical structure allows for the development of biodegradable polymers with controlled release properties, addressing the need for more effective and targeted drug delivery methods. This aligns with the growing demand for personalized medicine and advanced therapeutic approaches in the pharmaceutical industry.

The construction industry has also begun exploring the potential of polysilane-based materials for improved insulation and weatherproofing solutions. As energy efficiency becomes increasingly important in building design, materials that can enhance thermal performance while offering durability and ease of application are in high demand. Polysilanes show promise in meeting these requirements, potentially leading to a new generation of high-performance construction materials.

Overall, the market demand for polysilane-based technologies spans multiple industries, driven by the need for advanced materials with tailored properties. As research and development in this field continue to progress, it is expected that new applications and market opportunities will emerge, further fueling the growth of the polysilane market in the coming years.

The photonics sector has also witnessed a surge in demand for polysilane-based materials. Their photosensitive nature and ability to form well-defined nanostructures make them attractive for applications in optical waveguides, photoresists, and light-emitting devices. As the demand for high-performance optical components continues to rise in telecommunications and data centers, polysilanes are positioned to play a crucial role in meeting these market needs.

In the field of energy storage and conversion, polysilanes have garnered attention for their potential use in lithium-ion batteries and solar cells. The ability to tailor the electronic properties of polysilanes through structural modifications has opened up new possibilities for improving energy storage capacity and efficiency. This aligns well with the growing global demand for sustainable energy solutions and the push towards electrification in various industries.

The automotive sector has shown increasing interest in polysilane-based materials for lightweight components and advanced coatings. As the industry shifts towards electric vehicles and seeks to improve fuel efficiency, the demand for materials that can reduce vehicle weight while maintaining structural integrity has grown significantly. Polysilanes offer a promising avenue for developing such materials, potentially revolutionizing automotive design and manufacturing processes.

In the healthcare and biomedical fields, polysilanes have emerged as candidates for drug delivery systems and biocompatible materials. Their unique chemical structure allows for the development of biodegradable polymers with controlled release properties, addressing the need for more effective and targeted drug delivery methods. This aligns with the growing demand for personalized medicine and advanced therapeutic approaches in the pharmaceutical industry.

The construction industry has also begun exploring the potential of polysilane-based materials for improved insulation and weatherproofing solutions. As energy efficiency becomes increasingly important in building design, materials that can enhance thermal performance while offering durability and ease of application are in high demand. Polysilanes show promise in meeting these requirements, potentially leading to a new generation of high-performance construction materials.

Overall, the market demand for polysilane-based technologies spans multiple industries, driven by the need for advanced materials with tailored properties. As research and development in this field continue to progress, it is expected that new applications and market opportunities will emerge, further fueling the growth of the polysilane market in the coming years.

Technical Challenges

Polysilanes, despite their promising potential in various technological applications, face several significant challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is their inherent instability when exposed to ultraviolet (UV) light. This photosensitivity can lead to rapid degradation of the polymer structure, limiting its use in outdoor applications or environments with high UV exposure.

The synthesis of high-molecular-weight polysilanes remains a complex and challenging process. Current methods often result in low yields or produce polymers with inconsistent molecular weights, which can significantly affect the material's properties and performance. This lack of control over the polymerization process makes it difficult to achieve reproducible results on an industrial scale.

Another critical challenge lies in the limited solubility of polysilanes in common organic solvents. This characteristic complicates processing and integration into existing manufacturing processes, particularly in the field of electronics and optoelectronics where solution-based fabrication methods are preferred.

The thermal stability of polysilanes is another area of concern. While they exhibit good thermal properties compared to some organic polymers, their decomposition at relatively low temperatures (typically below 300°C) restricts their use in high-temperature applications. This limitation is particularly problematic in the semiconductor industry, where high-temperature processes are often required.

The electrical conductivity of polysilanes, while promising for certain applications, is still not competitive with traditional semiconducting materials. Enhancing the conductivity without compromising other desirable properties remains a significant challenge for researchers in the field.

Furthermore, the environmental impact and potential toxicity of polysilanes and their degradation products are not yet fully understood. This lack of comprehensive safety data poses challenges for regulatory approval and widespread industrial adoption.

Lastly, the cost-effectiveness of polysilane production and processing is a major hurdle. Current synthesis methods are often expensive and not easily scalable, making polysilanes less economically viable compared to established materials in many applications.

Addressing these technical challenges requires a multidisciplinary approach, combining advances in polymer chemistry, materials science, and engineering. Overcoming these obstacles will be crucial for unlocking the full potential of polysilanes in various technological developments, from next-generation electronics to advanced optical materials.

The synthesis of high-molecular-weight polysilanes remains a complex and challenging process. Current methods often result in low yields or produce polymers with inconsistent molecular weights, which can significantly affect the material's properties and performance. This lack of control over the polymerization process makes it difficult to achieve reproducible results on an industrial scale.

Another critical challenge lies in the limited solubility of polysilanes in common organic solvents. This characteristic complicates processing and integration into existing manufacturing processes, particularly in the field of electronics and optoelectronics where solution-based fabrication methods are preferred.

The thermal stability of polysilanes is another area of concern. While they exhibit good thermal properties compared to some organic polymers, their decomposition at relatively low temperatures (typically below 300°C) restricts their use in high-temperature applications. This limitation is particularly problematic in the semiconductor industry, where high-temperature processes are often required.

The electrical conductivity of polysilanes, while promising for certain applications, is still not competitive with traditional semiconducting materials. Enhancing the conductivity without compromising other desirable properties remains a significant challenge for researchers in the field.

Furthermore, the environmental impact and potential toxicity of polysilanes and their degradation products are not yet fully understood. This lack of comprehensive safety data poses challenges for regulatory approval and widespread industrial adoption.

Lastly, the cost-effectiveness of polysilane production and processing is a major hurdle. Current synthesis methods are often expensive and not easily scalable, making polysilanes less economically viable compared to established materials in many applications.

Addressing these technical challenges requires a multidisciplinary approach, combining advances in polymer chemistry, materials science, and engineering. Overcoming these obstacles will be crucial for unlocking the full potential of polysilanes in various technological developments, from next-generation electronics to advanced optical materials.

Current Applications

01 Polysilane applications in electronic and optical devices

Polysilanes demonstrate versatility in electronic and optical applications due to their unique properties. They can be used in the fabrication of photoresists, semiconductors, and optical materials. Their ability to form thin films and their photosensitivity make them suitable for various electronic and optical device manufacturing processes.- Polysilane applications in electronic and optical devices: Polysilanes demonstrate versatility in electronic and optical applications due to their unique properties. They can be used in the fabrication of photoresists, semiconductors, and optical materials. Their ability to form stable films and their photosensitivity make them suitable for various electronic and optical device manufacturing processes.

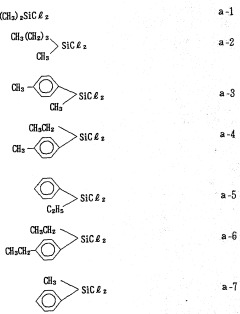

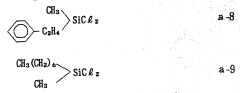

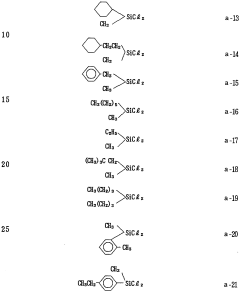

- Polysilane synthesis and modification methods: Various methods for synthesizing and modifying polysilanes have been developed, showcasing their versatility in chemical processes. These methods include catalytic dehydrogenative coupling, anionic polymerization, and post-polymerization modifications. The ability to control molecular weight, structure, and functional groups allows for tailoring polysilanes for specific applications.

- Polysilane-based composite materials: Polysilanes can be incorporated into composite materials, enhancing their properties and expanding their applications. These composites may include polysilane-polymer blends, polysilane-inorganic hybrids, or polysilane-reinforced materials. The resulting composites often exhibit improved mechanical, thermal, or optical properties compared to their individual components.

- Polysilane use in coating and film formation: Polysilanes demonstrate versatility in coating and film formation processes. They can be used to create protective coatings, thin films for electronic applications, and functional surface treatments. The ability to form stable, uniform films with controllable thickness and properties makes polysilanes valuable in various coating technologies.

- Polysilane applications in energy and environmental technologies: Polysilanes show potential in energy and environmental applications due to their unique properties. They can be used in the development of solar cells, energy storage devices, and environmental sensors. Their ability to interact with light and their chemical stability make them promising materials for sustainable technologies.

02 Polysilane synthesis and modification methods

Various methods for synthesizing and modifying polysilanes have been developed to enhance their properties and expand their applications. These include novel polymerization techniques, chemical modifications, and the incorporation of functional groups. Such methods allow for the tailoring of polysilanes for specific uses in different industries.Expand Specific Solutions03 Polysilane-based composite materials

Polysilanes can be combined with other materials to create composite materials with enhanced properties. These composites may exhibit improved mechanical strength, thermal stability, or specific functional characteristics. The versatility of polysilanes in forming composites expands their potential applications in various fields.Expand Specific Solutions04 Polysilane use in coating technologies

Polysilanes show versatility in coating applications due to their film-forming abilities and unique properties. They can be used to create protective coatings, functional surface treatments, and specialized coatings for various substrates. The adaptability of polysilanes in coating formulations allows for a wide range of industrial and consumer applications.Expand Specific Solutions05 Environmental and processing considerations of polysilanes

The versatility of polysilanes extends to their processing methods and environmental considerations. Research has focused on developing eco-friendly synthesis routes, improving processability, and enhancing the stability of polysilanes under various conditions. These advancements contribute to the broader adoption of polysilanes in sustainable technologies and manufacturing processes.Expand Specific Solutions

Key Industry Players

The polysilane technology market is in an early growth stage, characterized by increasing research and development activities across various industries. While the market size remains relatively small, it shows promising potential for expansion due to polysilane's versatile applications in electronics, photonics, and advanced materials. The technology's maturity is still evolving, with companies like JSR Corp., Wacker Chemie AG, and Momentive Performance Materials leading the way in developing innovative polysilane-based solutions. Academic institutions such as Shandong University and Shanghai University are also contributing to the advancement of polysilane research, indicating a collaborative ecosystem between industry and academia. As the technology progresses, we can expect to see increased commercialization efforts and potential market disruption in sectors leveraging polysilane's unique properties.

JSR Corp.

Technical Solution: JSR Corporation has made significant advancements in polysilane technology, particularly in the field of photoresists for semiconductor manufacturing. Their proprietary polysilane-based photoresist formulations offer enhanced sensitivity and resolution for next-generation lithography processes[1]. JSR's polysilane materials feature optimized molecular structures that provide excellent adhesion to substrate surfaces and improved etch resistance[2]. The company has also developed novel cross-linking mechanisms for polysilanes, resulting in photoresists with superior pattern fidelity and reduced line edge roughness[3]. Additionally, JSR has explored the use of polysilanes as precursors for silicon carbide ceramics, leveraging their unique thermal decomposition properties to create high-performance materials for extreme environments[4].

Strengths: Expertise in photoresist applications, advanced formulation techniques, strong presence in semiconductor industry. Weaknesses: Narrow focus on specific applications, potential challenges in diversifying polysilane product range.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has been at the forefront of polysilane research and development. Their innovative approach involves the synthesis of high-purity polysilanes through controlled polymerization of organosilicon monomers[1]. This process allows for precise control over molecular weight and structure, resulting in polysilanes with tailored properties for specific applications. Wacker has developed a range of polysilane products, including those with enhanced thermal stability and improved processability[2]. Their technology enables the production of polysilanes with varying side-chain structures, which can be fine-tuned for applications in optoelectronics, photoresists, and ceramic precursors[3]. The company has also made significant strides in developing water-soluble polysilanes, expanding the potential applications in biomedical and environmental fields[4].

Strengths: Advanced synthesis techniques, wide range of tailored polysilane products, expertise in optoelectronic applications. Weaknesses: High production costs, limited scalability for some specialized polysilanes.

Core Innovations

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Novel polysilane composition

PatentWO1991005018A1

Innovation

- A novel polysilane composition with a weight-average molecular weight of 6,000 to 2,000,000, where all substituents and terminal groups are substituted with specific organic groups without oxygen, combined with an acceptor or donor level former, enhancing solubility, film-forming ability, and structural integrity.

Environmental Impact

Polysilanes, as a class of silicon-based polymers, have garnered significant attention in recent years due to their unique properties and potential applications in various technological fields. However, as with any emerging technology, it is crucial to consider the environmental impact of polysilanes throughout their lifecycle, from production to disposal.

The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals. While efforts are being made to develop more environmentally friendly production methods, current manufacturing techniques may contribute to greenhouse gas emissions and generate chemical waste. Researchers are exploring greener alternatives, such as using renewable energy sources and developing catalysts that enable more efficient synthesis reactions, to mitigate these environmental concerns.

During their use phase, polysilanes demonstrate promising environmental benefits in certain applications. For instance, when employed in photovoltaic devices, they can contribute to the generation of clean, renewable energy. Their potential to enhance the efficiency of solar cells could lead to a reduction in overall energy consumption and associated carbon emissions. Additionally, polysilanes used in electronic components may lead to more energy-efficient devices, further contributing to sustainability efforts in the tech industry.

However, the end-of-life management of polysilane-based products presents challenges. The durability and stability of these materials, while advantageous for many applications, can make them resistant to natural degradation processes. This raises concerns about their persistence in the environment if not properly disposed of or recycled. Research is ongoing to develop effective recycling methods for polysilane-containing products, but current infrastructure may not be adequately equipped to handle these materials.

The potential for polysilanes to leach into soil or water systems is another environmental consideration. While initial studies suggest that polysilanes have relatively low toxicity compared to some other synthetic polymers, long-term ecological impacts are not yet fully understood. Ongoing research is focused on assessing the biodegradability of various polysilane formulations and their potential effects on ecosystems.

As the adoption of polysilane-based technologies increases, it becomes imperative to conduct comprehensive life cycle assessments. These studies will help quantify the environmental footprint of polysilanes across their entire lifecycle, from raw material extraction to disposal or recycling. Such assessments will inform policy decisions and guide the development of more sustainable practices in the production, use, and management of polysilane-based technologies.

The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals. While efforts are being made to develop more environmentally friendly production methods, current manufacturing techniques may contribute to greenhouse gas emissions and generate chemical waste. Researchers are exploring greener alternatives, such as using renewable energy sources and developing catalysts that enable more efficient synthesis reactions, to mitigate these environmental concerns.

During their use phase, polysilanes demonstrate promising environmental benefits in certain applications. For instance, when employed in photovoltaic devices, they can contribute to the generation of clean, renewable energy. Their potential to enhance the efficiency of solar cells could lead to a reduction in overall energy consumption and associated carbon emissions. Additionally, polysilanes used in electronic components may lead to more energy-efficient devices, further contributing to sustainability efforts in the tech industry.

However, the end-of-life management of polysilane-based products presents challenges. The durability and stability of these materials, while advantageous for many applications, can make them resistant to natural degradation processes. This raises concerns about their persistence in the environment if not properly disposed of or recycled. Research is ongoing to develop effective recycling methods for polysilane-containing products, but current infrastructure may not be adequately equipped to handle these materials.

The potential for polysilanes to leach into soil or water systems is another environmental consideration. While initial studies suggest that polysilanes have relatively low toxicity compared to some other synthetic polymers, long-term ecological impacts are not yet fully understood. Ongoing research is focused on assessing the biodegradability of various polysilane formulations and their potential effects on ecosystems.

As the adoption of polysilane-based technologies increases, it becomes imperative to conduct comprehensive life cycle assessments. These studies will help quantify the environmental footprint of polysilanes across their entire lifecycle, from raw material extraction to disposal or recycling. Such assessments will inform policy decisions and guide the development of more sustainable practices in the production, use, and management of polysilane-based technologies.

Regulatory Framework

The regulatory framework surrounding polysilane technology is a critical aspect of its development and application across various industries. As polysilanes continue to demonstrate their versatility in technological advancements, governments and regulatory bodies worldwide are adapting their policies to ensure safe and responsible use of these materials.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating polysilanes under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers and importers to submit premanufacture notices (PMNs) for new chemical substances, including novel polysilane compounds. This process allows the agency to assess potential risks and implement necessary restrictions or reporting requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to polysilanes and their derivatives. Under REACH, companies must register substances manufactured or imported in quantities of one tonne or more per year. This regulation ensures that comprehensive safety data is available for polysilane materials used in various applications.

In Japan, the Ministry of Economy, Trade and Industry (METI) oversees the regulation of chemical substances, including polysilanes, through the Chemical Substances Control Law. This law requires manufacturers and importers to notify the government of new chemical substances and provide safety data before commercialization.

As polysilanes find increasing applications in electronics and semiconductor industries, regulatory bodies are paying close attention to their use in these sectors. The International Electrotechnical Commission (IEC) has developed standards for the use of silicon-based materials in electronic components, which may be extended to include specific guidelines for polysilane applications in the future.

The growing interest in polysilanes for biomedical applications has prompted regulatory agencies to consider their potential use in medical devices and drug delivery systems. The U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) are likely to develop specific guidelines for the evaluation and approval of polysilane-based medical products as research in this area progresses.

Environmental regulations are also evolving to address the potential impacts of polysilane production and disposal. Many countries are implementing stricter waste management policies, requiring manufacturers to develop environmentally friendly processes for the synthesis and recycling of polysilane materials.

As the field of nanotechnology advances, regulatory frameworks are being updated to address the unique properties and potential risks associated with nanostructured polysilanes. The Organization for Economic Co-operation and Development (OECD) has been working on developing guidelines for the safety assessment of manufactured nanomaterials, which may impact future regulations on polysilane nanostructures.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating polysilanes under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers and importers to submit premanufacture notices (PMNs) for new chemical substances, including novel polysilane compounds. This process allows the agency to assess potential risks and implement necessary restrictions or reporting requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to polysilanes and their derivatives. Under REACH, companies must register substances manufactured or imported in quantities of one tonne or more per year. This regulation ensures that comprehensive safety data is available for polysilane materials used in various applications.

In Japan, the Ministry of Economy, Trade and Industry (METI) oversees the regulation of chemical substances, including polysilanes, through the Chemical Substances Control Law. This law requires manufacturers and importers to notify the government of new chemical substances and provide safety data before commercialization.

As polysilanes find increasing applications in electronics and semiconductor industries, regulatory bodies are paying close attention to their use in these sectors. The International Electrotechnical Commission (IEC) has developed standards for the use of silicon-based materials in electronic components, which may be extended to include specific guidelines for polysilane applications in the future.

The growing interest in polysilanes for biomedical applications has prompted regulatory agencies to consider their potential use in medical devices and drug delivery systems. The U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) are likely to develop specific guidelines for the evaluation and approval of polysilane-based medical products as research in this area progresses.

Environmental regulations are also evolving to address the potential impacts of polysilane production and disposal. Many countries are implementing stricter waste management policies, requiring manufacturers to develop environmentally friendly processes for the synthesis and recycling of polysilane materials.

As the field of nanotechnology advances, regulatory frameworks are being updated to address the unique properties and potential risks associated with nanostructured polysilanes. The Organization for Economic Co-operation and Development (OECD) has been working on developing guidelines for the safety assessment of manufactured nanomaterials, which may impact future regulations on polysilane nanostructures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!