Field weakening strategies in PMSM operations

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Field Weakening Background and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have gained significant traction in various industrial applications due to their high efficiency, power density, and excellent dynamic performance. The concept of field weakening in PMSM operations has emerged as a crucial strategy to extend the motor's operating range beyond its base speed.

Field weakening in PMSMs involves reducing the magnetic field strength in the air gap to achieve higher speeds while maintaining constant power output. This technique has its roots in the early development of electric motors and has evolved significantly over the past few decades. The primary objective of field weakening is to overcome the limitations imposed by the motor's voltage constraints, allowing it to operate at speeds higher than the base speed.

The evolution of field weakening strategies in PMSMs can be traced back to the 1980s when researchers began exploring ways to improve the speed range of these motors. Initially, simple methods such as reducing the field current were employed. However, as the demand for more efficient and versatile motor drives increased, more sophisticated field weakening techniques were developed.

One of the key drivers behind the advancement of field weakening strategies has been the automotive industry's push towards electrification. Electric and hybrid vehicles require motors that can operate efficiently over a wide speed range, making field weakening an essential feature in modern PMSM designs.

The objectives of field weakening in PMSM operations are multifaceted. Primarily, it aims to extend the constant power region of the motor, enabling it to operate at higher speeds without exceeding voltage limits. This is particularly important in applications where a wide speed range is required, such as in electric vehicles or industrial machinery.

Another critical objective is to optimize the motor's efficiency across its entire operating range. By implementing effective field weakening strategies, engineers can ensure that the motor maintains high efficiency even at speeds well above the base speed. This contributes to overall system efficiency and helps reduce energy consumption in various applications.

Furthermore, field weakening techniques seek to improve the dynamic performance of PMSMs. This includes enhancing the motor's response to sudden load changes and improving its ability to maintain stable operation under varying conditions. As a result, field weakening strategies play a crucial role in expanding the applicability of PMSMs in diverse industrial settings.

As technology continues to advance, the goals of field weakening strategies in PMSM operations are evolving. Current research focuses on developing more sophisticated control algorithms, improving the accuracy of flux estimation, and integrating advanced materials to enhance motor performance. These ongoing efforts aim to push the boundaries of PMSM capabilities, making them even more versatile and efficient in future applications.

Field weakening in PMSMs involves reducing the magnetic field strength in the air gap to achieve higher speeds while maintaining constant power output. This technique has its roots in the early development of electric motors and has evolved significantly over the past few decades. The primary objective of field weakening is to overcome the limitations imposed by the motor's voltage constraints, allowing it to operate at speeds higher than the base speed.

The evolution of field weakening strategies in PMSMs can be traced back to the 1980s when researchers began exploring ways to improve the speed range of these motors. Initially, simple methods such as reducing the field current were employed. However, as the demand for more efficient and versatile motor drives increased, more sophisticated field weakening techniques were developed.

One of the key drivers behind the advancement of field weakening strategies has been the automotive industry's push towards electrification. Electric and hybrid vehicles require motors that can operate efficiently over a wide speed range, making field weakening an essential feature in modern PMSM designs.

The objectives of field weakening in PMSM operations are multifaceted. Primarily, it aims to extend the constant power region of the motor, enabling it to operate at higher speeds without exceeding voltage limits. This is particularly important in applications where a wide speed range is required, such as in electric vehicles or industrial machinery.

Another critical objective is to optimize the motor's efficiency across its entire operating range. By implementing effective field weakening strategies, engineers can ensure that the motor maintains high efficiency even at speeds well above the base speed. This contributes to overall system efficiency and helps reduce energy consumption in various applications.

Furthermore, field weakening techniques seek to improve the dynamic performance of PMSMs. This includes enhancing the motor's response to sudden load changes and improving its ability to maintain stable operation under varying conditions. As a result, field weakening strategies play a crucial role in expanding the applicability of PMSMs in diverse industrial settings.

As technology continues to advance, the goals of field weakening strategies in PMSM operations are evolving. Current research focuses on developing more sophisticated control algorithms, improving the accuracy of flux estimation, and integrating advanced materials to enhance motor performance. These ongoing efforts aim to push the boundaries of PMSM capabilities, making them even more versatile and efficient in future applications.

Market Demand for Extended Speed Range PMSMs

The market demand for extended speed range Permanent Magnet Synchronous Motors (PMSMs) has been steadily increasing across various industries. This growth is primarily driven by the need for more efficient and versatile motor systems in applications such as electric vehicles, industrial automation, and renewable energy systems.

In the automotive sector, the push for extended speed range PMSMs is particularly strong. As electric vehicles (EVs) become more mainstream, manufacturers are seeking motors that can provide high torque at low speeds for quick acceleration and maintain efficiency at high speeds for highway driving. This dual requirement has led to a significant market demand for PMSMs with field weakening capabilities, allowing for a wider operational speed range without compromising overall system efficiency.

The industrial automation sector is another key driver for extended speed range PMSMs. In manufacturing processes, motors that can operate efficiently across a broad speed range offer greater flexibility and productivity. This is especially valuable in applications such as machine tools, conveyor systems, and robotic arms, where varying speed requirements are common throughout different operational phases.

Renewable energy systems, particularly wind turbines, have also contributed to the growing demand for extended speed range PMSMs. Wind turbine generators need to operate efficiently at both low and high wind speeds, making field weakening strategies crucial for maximizing energy capture across diverse wind conditions.

The market for extended speed range PMSMs is further bolstered by the global push for energy efficiency. As governments worldwide implement stricter energy regulations, industries are increasingly adopting motor systems that can maintain high efficiency across a wide operational range. This trend is expected to continue, driving further innovation in field weakening strategies for PMSMs.

Moreover, the advent of Industry 4.0 and the Internet of Things (IoT) has created new opportunities for smart motor systems. Extended speed range PMSMs, when coupled with advanced control systems and sensors, can provide valuable data for predictive maintenance and process optimization, further enhancing their appeal in the market.

As the demand for more versatile and efficient motor systems continues to grow, the market for extended speed range PMSMs is projected to expand significantly in the coming years. This trend is likely to spur further research and development in field weakening strategies, aiming to push the boundaries of PMSM performance and efficiency across an even wider operational range.

In the automotive sector, the push for extended speed range PMSMs is particularly strong. As electric vehicles (EVs) become more mainstream, manufacturers are seeking motors that can provide high torque at low speeds for quick acceleration and maintain efficiency at high speeds for highway driving. This dual requirement has led to a significant market demand for PMSMs with field weakening capabilities, allowing for a wider operational speed range without compromising overall system efficiency.

The industrial automation sector is another key driver for extended speed range PMSMs. In manufacturing processes, motors that can operate efficiently across a broad speed range offer greater flexibility and productivity. This is especially valuable in applications such as machine tools, conveyor systems, and robotic arms, where varying speed requirements are common throughout different operational phases.

Renewable energy systems, particularly wind turbines, have also contributed to the growing demand for extended speed range PMSMs. Wind turbine generators need to operate efficiently at both low and high wind speeds, making field weakening strategies crucial for maximizing energy capture across diverse wind conditions.

The market for extended speed range PMSMs is further bolstered by the global push for energy efficiency. As governments worldwide implement stricter energy regulations, industries are increasingly adopting motor systems that can maintain high efficiency across a wide operational range. This trend is expected to continue, driving further innovation in field weakening strategies for PMSMs.

Moreover, the advent of Industry 4.0 and the Internet of Things (IoT) has created new opportunities for smart motor systems. Extended speed range PMSMs, when coupled with advanced control systems and sensors, can provide valuable data for predictive maintenance and process optimization, further enhancing their appeal in the market.

As the demand for more versatile and efficient motor systems continues to grow, the market for extended speed range PMSMs is projected to expand significantly in the coming years. This trend is likely to spur further research and development in field weakening strategies, aiming to push the boundaries of PMSM performance and efficiency across an even wider operational range.

Current Field Weakening Techniques and Challenges

Field weakening techniques in Permanent Magnet Synchronous Motors (PMSMs) have evolved significantly over the years, addressing the challenges of extending the speed range beyond the base speed while maintaining optimal performance. The current state-of-the-art techniques primarily focus on manipulating the d-axis current to reduce the air-gap flux and achieve higher speeds.

One of the most widely adopted methods is the Maximum Torque Per Ampere (MTPA) control strategy, which optimizes the torque production while minimizing copper losses. However, as the motor speed increases, this technique transitions into the flux-weakening region, where the d-axis current is adjusted to counteract the permanent magnet flux. This method effectively extends the speed range but faces challenges in maintaining efficiency at very high speeds.

Another prominent technique is the Direct Flux Vector Control (DFVC), which directly controls the stator flux amplitude and angle. This method offers improved dynamic performance and better utilization of the inverter voltage limit. However, it requires accurate flux estimation, which can be challenging in practice, especially at high speeds and under varying load conditions.

The use of online parameter estimation techniques has gained traction in recent years. These adaptive methods continuously update motor parameters such as stator resistance and inductances, allowing for more precise field weakening control. While effective, these techniques often struggle with computational complexity and may require specialized hardware for real-time implementation.

A significant challenge in current field weakening techniques is the trade-off between extended speed range and efficiency. As the field is weakened, the motor's power factor decreases, leading to higher current requirements and increased losses. This issue is particularly pronounced in motors with high saliency ratios.

Moreover, the stability of field weakening control at very high speeds remains a concern. The reduced flux levels can lead to loss of controllability, especially under sudden load changes. Researchers are actively working on robust control algorithms to address this issue, but a universally effective solution is yet to be developed.

The integration of field weakening strategies with advanced power electronics is another area of ongoing development. Wide bandgap semiconductors, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), offer potential for higher switching frequencies and improved efficiency in the field weakening region. However, the full exploitation of these technologies in PMSM drives is still in its early stages.

One of the most widely adopted methods is the Maximum Torque Per Ampere (MTPA) control strategy, which optimizes the torque production while minimizing copper losses. However, as the motor speed increases, this technique transitions into the flux-weakening region, where the d-axis current is adjusted to counteract the permanent magnet flux. This method effectively extends the speed range but faces challenges in maintaining efficiency at very high speeds.

Another prominent technique is the Direct Flux Vector Control (DFVC), which directly controls the stator flux amplitude and angle. This method offers improved dynamic performance and better utilization of the inverter voltage limit. However, it requires accurate flux estimation, which can be challenging in practice, especially at high speeds and under varying load conditions.

The use of online parameter estimation techniques has gained traction in recent years. These adaptive methods continuously update motor parameters such as stator resistance and inductances, allowing for more precise field weakening control. While effective, these techniques often struggle with computational complexity and may require specialized hardware for real-time implementation.

A significant challenge in current field weakening techniques is the trade-off between extended speed range and efficiency. As the field is weakened, the motor's power factor decreases, leading to higher current requirements and increased losses. This issue is particularly pronounced in motors with high saliency ratios.

Moreover, the stability of field weakening control at very high speeds remains a concern. The reduced flux levels can lead to loss of controllability, especially under sudden load changes. Researchers are actively working on robust control algorithms to address this issue, but a universally effective solution is yet to be developed.

The integration of field weakening strategies with advanced power electronics is another area of ongoing development. Wide bandgap semiconductors, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), offer potential for higher switching frequencies and improved efficiency in the field weakening region. However, the full exploitation of these technologies in PMSM drives is still in its early stages.

Existing Field Weakening Control Methods

01 Field weakening control methods

Various control methods are employed for field weakening in PMSM, including advanced algorithms and control strategies to extend the speed range beyond the base speed. These methods often involve manipulating the d-axis current to reduce the magnetic field strength, allowing for higher speed operation while maintaining efficiency.- Field weakening control methods: Various control methods are employed for field weakening in PMSM, including advanced algorithms and control strategies to extend the speed range beyond the base speed. These methods often involve manipulating the d-axis current to reduce the magnetic field strength, allowing for higher speed operation while maintaining efficiency.

- Flux estimation techniques: Accurate flux estimation is crucial for effective field weakening control in PMSM. Advanced techniques are developed to estimate the magnetic flux in real-time, considering factors such as temperature variations and saturation effects. These estimation methods improve the overall performance and reliability of the field weakening operation.

- Optimization of PMSM design for field weakening: PMSM designs are optimized to enhance field weakening capabilities. This includes modifications to rotor and stator configurations, magnet arrangements, and material selections. The goal is to achieve a wider constant power speed range and improved efficiency during field weakening operation.

- Sensorless control in field weakening region: Sensorless control techniques are developed for PMSM operation in the field weakening region. These methods eliminate the need for position sensors, reducing cost and improving reliability. Advanced algorithms are used to estimate rotor position and speed accurately, even at high speeds and under varying load conditions.

- Efficiency improvement in field weakening operation: Strategies are implemented to improve the efficiency of PMSM during field weakening operation. This includes optimizing the current vector control, minimizing losses, and adapting the control parameters based on operating conditions. Advanced power electronics and control algorithms are utilized to maximize energy efficiency across the entire speed range.

02 Flux estimation techniques

Accurate flux estimation is crucial for effective field weakening control in PMSM. Advanced techniques are developed to estimate the magnetic flux in real-time, considering factors such as temperature variations and saturation effects. These estimation methods improve the overall performance and reliability of the field weakening operation.Expand Specific Solutions03 Optimization of PMSM design for field weakening

PMSM designs are optimized to enhance field weakening capabilities. This includes modifications to the rotor structure, magnet arrangement, and winding configurations. Such optimizations aim to improve the motor's performance in the field weakening region while maintaining high efficiency and torque output.Expand Specific Solutions04 Sensorless control in field weakening region

Sensorless control techniques are developed for PMSM operation in the field weakening region. These methods eliminate the need for position sensors, reducing cost and improving reliability. Advanced algorithms are used to estimate rotor position and speed accurately, even at high speeds and under varying load conditions.Expand Specific Solutions05 Efficiency improvement in field weakening operation

Strategies are implemented to improve the efficiency of PMSM during field weakening operation. This includes optimizing the current vector control, minimizing losses, and enhancing the power factor. Advanced control algorithms and hardware designs are employed to maximize energy efficiency across a wide speed range.Expand Specific Solutions

Key Players in PMSM Drive System Industry

The field weakening strategies in PMSM operations market is in a growth phase, driven by increasing demand for electric vehicles and industrial applications. The global market size for PMSM control systems is projected to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with companies like LG Electronics, Ericsson, and Huawei leading innovation in motor control algorithms and power electronics. Academic institutions such as Huazhong University of Science & Technology and Dalian University of Technology are contributing to fundamental research. While the technology is mature for many applications, ongoing research focuses on improving efficiency, extending operating range, and integrating advanced control techniques.

LG Electronics, Inc.

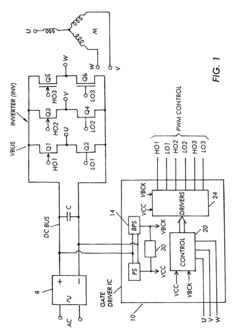

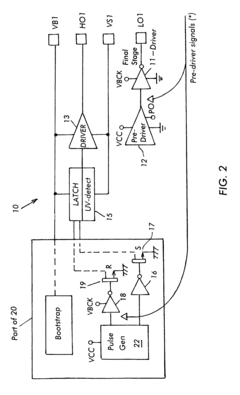

Technical Solution: LG Electronics has implemented a sophisticated field weakening strategy for PMSM operations in their home appliance and electric vehicle motor systems. Their approach utilizes a hybrid control scheme that combines conventional field-oriented control (FOC) with a novel flux-weakening algorithm. This strategy employs a look-up table-based method for rapid transition between constant torque and constant power regions[2]. LG's system features an adaptive maximum torque per ampere (MTPA) control in the constant torque region, seamlessly transitioning to a field weakening mode in the constant power region. The company has also developed a unique online parameter estimation technique to account for motor parameter variations, ensuring optimal field weakening performance across various operating conditions[4]. Additionally, LG's strategy incorporates a voltage feedback loop to prevent over-modulation and maintain stability at high speeds[6].

Strengths: Efficient operation across a wide speed range, improved dynamic response, and adaptability to parameter variations. Weaknesses: May require significant computational resources and precise sensor calibration for optimal performance.

Zhejiang Leapmotor Technology Co., Ltd.

Technical Solution: Leapmotor has developed an advanced field weakening strategy for PMSM operations in electric vehicles. Their approach utilizes a combination of vector control and flux-weakening techniques to extend the speed range of the motor beyond its base speed. The company employs a dynamic d-axis current injection method, which adjusts the stator current vector to reduce the air-gap flux at high speeds[1]. This strategy is complemented by a real-time adaptive algorithm that optimizes the field weakening current based on motor parameters and operating conditions[3]. Leapmotor's system also incorporates a novel thermal management solution to mitigate the increased losses associated with field weakening, ensuring sustained high-speed operation without compromising motor efficiency or lifespan[5].

Strengths: Extends motor speed range, improves high-speed efficiency, and enhances overall vehicle performance. Weaknesses: May require more complex control algorithms and additional sensors, potentially increasing system cost and complexity.

Core Innovations in PMSM Flux-Weakening Control

Field weakening control method for PMSM drive and permanent magnet synchronous motor system

PatentActiveKR1020200049165A

Innovation

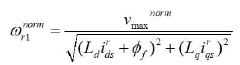

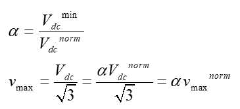

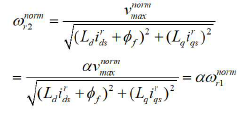

- A method involving the generation of a speed-torque lookup table that considers DC link voltage changes, allowing for the omission of DSP calculations by normalizing current speed information and converting lookup tables to accommodate voltage variations.

Protection circuit for permanent magnet synchronous motor in field weakening operation

PatentActiveUS7554276B2

Innovation

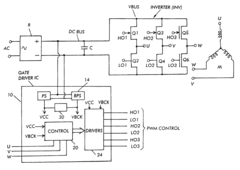

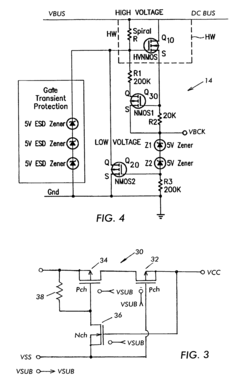

- A safety circuit with a main and backup power supply is implemented in the gate driver IC to manage high back EMF by turning on low side switches and turning off high side switches, effectively short-circuiting the motor terminals and controlling back EMF to safe levels, even during power supply failures.

Efficiency and Performance Trade-offs

Field weakening strategies in Permanent Magnet Synchronous Motors (PMSMs) involve a delicate balance between efficiency and performance. These strategies are essential for extending the operating range of PMSMs beyond their base speed, but they come with inherent trade-offs that must be carefully considered.

At lower speeds, PMSMs operate with high efficiency due to the strong magnetic field provided by the permanent magnets. However, as the motor speed increases, the back-EMF generated by the rotor magnets also rises, potentially exceeding the voltage limit of the inverter. Field weakening techniques are employed to counteract this effect, allowing the motor to operate at higher speeds.

The primary method of field weakening involves injecting a negative d-axis current, which opposes the magnetic field of the permanent magnets. This reduces the overall magnetic flux in the air gap, effectively lowering the back-EMF and enabling higher speed operation. However, this approach introduces several efficiency and performance trade-offs.

One significant trade-off is the reduction in torque production capability. As the magnetic field is weakened, the motor's ability to generate torque diminishes, particularly at high speeds. This can limit the motor's acceleration and load-carrying capacity in the extended speed range, potentially impacting overall system performance.

Additionally, the injection of field weakening current increases copper losses in the motor windings. These losses manifest as heat generation, which can reduce overall system efficiency and potentially lead to thermal management challenges. The increased current also places higher demands on the inverter, potentially necessitating more robust and costly power electronics.

Another consideration is the impact on power factor. Field weakening typically results in a lower power factor, which can affect the overall efficiency of the motor drive system. This may require oversizing of power electronic components to handle the apparent power, leading to increased system cost and complexity.

The relationship between efficiency and performance in field weakening operations is not linear. As the speed increases and field weakening becomes more pronounced, the efficiency tends to decrease more rapidly. This creates a challenge in optimizing the motor's performance across its entire operating range, often requiring compromises between low-speed efficiency and high-speed capability.

Advanced control strategies, such as Maximum Torque Per Ampere (MTPA) and Maximum Torque Per Volt (MTPV), aim to optimize the balance between efficiency and performance in field weakening regions. These techniques dynamically adjust the d-axis and q-axis currents to achieve the best possible combination of torque production and efficiency under varying operating conditions.

At lower speeds, PMSMs operate with high efficiency due to the strong magnetic field provided by the permanent magnets. However, as the motor speed increases, the back-EMF generated by the rotor magnets also rises, potentially exceeding the voltage limit of the inverter. Field weakening techniques are employed to counteract this effect, allowing the motor to operate at higher speeds.

The primary method of field weakening involves injecting a negative d-axis current, which opposes the magnetic field of the permanent magnets. This reduces the overall magnetic flux in the air gap, effectively lowering the back-EMF and enabling higher speed operation. However, this approach introduces several efficiency and performance trade-offs.

One significant trade-off is the reduction in torque production capability. As the magnetic field is weakened, the motor's ability to generate torque diminishes, particularly at high speeds. This can limit the motor's acceleration and load-carrying capacity in the extended speed range, potentially impacting overall system performance.

Additionally, the injection of field weakening current increases copper losses in the motor windings. These losses manifest as heat generation, which can reduce overall system efficiency and potentially lead to thermal management challenges. The increased current also places higher demands on the inverter, potentially necessitating more robust and costly power electronics.

Another consideration is the impact on power factor. Field weakening typically results in a lower power factor, which can affect the overall efficiency of the motor drive system. This may require oversizing of power electronic components to handle the apparent power, leading to increased system cost and complexity.

The relationship between efficiency and performance in field weakening operations is not linear. As the speed increases and field weakening becomes more pronounced, the efficiency tends to decrease more rapidly. This creates a challenge in optimizing the motor's performance across its entire operating range, often requiring compromises between low-speed efficiency and high-speed capability.

Advanced control strategies, such as Maximum Torque Per Ampere (MTPA) and Maximum Torque Per Volt (MTPV), aim to optimize the balance between efficiency and performance in field weakening regions. These techniques dynamically adjust the d-axis and q-axis currents to achieve the best possible combination of torque production and efficiency under varying operating conditions.

Thermal Management in Extended Speed Operation

Thermal management plays a crucial role in the extended speed operation of Permanent Magnet Synchronous Motors (PMSMs) utilizing field weakening strategies. As the motor operates at higher speeds, the increased electrical frequency and current density lead to elevated heat generation, potentially compromising the motor's performance and longevity.

One of the primary challenges in thermal management during extended speed operation is the efficient dissipation of heat from the stator windings and rotor magnets. The field weakening technique, while enabling higher speed operation, introduces additional heat sources due to increased current in the d-axis. This heat must be effectively removed to prevent thermal degradation of the motor components.

Advanced cooling techniques are essential for maintaining optimal thermal conditions. Liquid cooling systems, such as oil or water jackets surrounding the stator, have proven effective in dissipating heat from the windings. These systems can be further enhanced by incorporating microchannels or spray cooling methods to improve heat transfer efficiency.

For the rotor, which experiences significant heat generation due to eddy currents and hysteresis losses, innovative cooling solutions are required. Axial cooling channels within the rotor structure can facilitate the flow of coolant, effectively removing heat from the permanent magnets. Additionally, the use of high-thermal-conductivity materials for rotor construction can aid in heat dissipation.

Thermal modeling and simulation play a vital role in optimizing the thermal management strategy. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations enable engineers to predict temperature distributions and identify potential hotspots within the motor structure. These tools are invaluable for designing effective cooling systems and selecting appropriate materials with optimal thermal properties.

The integration of temperature sensors and real-time monitoring systems is crucial for maintaining safe operating conditions during extended speed operation. Advanced control algorithms can utilize this thermal feedback to adjust the field weakening strategy dynamically, balancing performance requirements with thermal constraints.

Emerging technologies, such as phase-change materials and thermoelectric cooling devices, show promise for future thermal management solutions in high-speed PMSMs. These innovations could potentially provide more efficient and compact cooling options, further extending the operational range of field-weakened PMSMs.

One of the primary challenges in thermal management during extended speed operation is the efficient dissipation of heat from the stator windings and rotor magnets. The field weakening technique, while enabling higher speed operation, introduces additional heat sources due to increased current in the d-axis. This heat must be effectively removed to prevent thermal degradation of the motor components.

Advanced cooling techniques are essential for maintaining optimal thermal conditions. Liquid cooling systems, such as oil or water jackets surrounding the stator, have proven effective in dissipating heat from the windings. These systems can be further enhanced by incorporating microchannels or spray cooling methods to improve heat transfer efficiency.

For the rotor, which experiences significant heat generation due to eddy currents and hysteresis losses, innovative cooling solutions are required. Axial cooling channels within the rotor structure can facilitate the flow of coolant, effectively removing heat from the permanent magnets. Additionally, the use of high-thermal-conductivity materials for rotor construction can aid in heat dissipation.

Thermal modeling and simulation play a vital role in optimizing the thermal management strategy. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations enable engineers to predict temperature distributions and identify potential hotspots within the motor structure. These tools are invaluable for designing effective cooling systems and selecting appropriate materials with optimal thermal properties.

The integration of temperature sensors and real-time monitoring systems is crucial for maintaining safe operating conditions during extended speed operation. Advanced control algorithms can utilize this thermal feedback to adjust the field weakening strategy dynamically, balancing performance requirements with thermal constraints.

Emerging technologies, such as phase-change materials and thermoelectric cooling devices, show promise for future thermal management solutions in high-speed PMSMs. These innovations could potentially provide more efficient and compact cooling options, further extending the operational range of field-weakened PMSMs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!