Functionalization Techniques for 2D Semiconductor Heterostructures

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2D Semiconductor Heterostructure Evolution and Objectives

Two-dimensional (2D) semiconductor materials have emerged as a revolutionary class of materials since the isolation of graphene in 2004. The evolution of 2D semiconductor heterostructures represents one of the most significant advancements in materials science over the past decade. Initially, research focused primarily on graphene, but quickly expanded to include transition metal dichalcogenides (TMDs), hexagonal boron nitride (h-BN), and other 2D materials, creating a diverse portfolio of building blocks for next-generation electronics.

The development trajectory of 2D semiconductor heterostructures has been characterized by several distinct phases. The discovery phase (2004-2010) centered on material isolation and basic characterization. This was followed by the exploration phase (2010-2015), where researchers began stacking different 2D materials to create van der Waals heterostructures with unique properties. Since 2015, we have entered the functionalization phase, where the focus has shifted toward tailoring these heterostructures for specific applications through chemical and physical modifications.

Functionalization techniques have evolved from simple surface modifications to sophisticated approaches involving covalent and non-covalent bonding strategies. Early methods primarily utilized physical adsorption of molecules, while current techniques employ precision chemistry to create targeted modifications at atomic interfaces. This evolution has enabled unprecedented control over electronic, optical, and mechanical properties of 2D semiconductor heterostructures.

The primary objective of current functionalization research is to overcome inherent limitations of pristine 2D materials, such as limited bandgap tunability, chemical instability, and integration challenges with conventional electronics. Specifically, researchers aim to develop scalable functionalization methods that can precisely modify electronic band structures, enhance carrier mobility, improve environmental stability, and enable selective sensing capabilities.

Looking forward, the field is moving toward achieving atomically precise functionalization with spatial control, enabling the creation of lateral heterojunctions within single 2D layers. Another critical objective is developing reversible functionalization techniques that allow dynamic property modulation in response to external stimuli, opening pathways to adaptive electronics and optoelectronics.

The ultimate goal of this technological evolution is to bridge the gap between laboratory demonstrations and commercial applications by addressing key challenges in scalability, reproducibility, and integration with existing semiconductor technologies. Success in these objectives would position 2D semiconductor heterostructures as viable candidates for next-generation flexible electronics, ultra-sensitive sensors, energy harvesting devices, and quantum information processing platforms.

The development trajectory of 2D semiconductor heterostructures has been characterized by several distinct phases. The discovery phase (2004-2010) centered on material isolation and basic characterization. This was followed by the exploration phase (2010-2015), where researchers began stacking different 2D materials to create van der Waals heterostructures with unique properties. Since 2015, we have entered the functionalization phase, where the focus has shifted toward tailoring these heterostructures for specific applications through chemical and physical modifications.

Functionalization techniques have evolved from simple surface modifications to sophisticated approaches involving covalent and non-covalent bonding strategies. Early methods primarily utilized physical adsorption of molecules, while current techniques employ precision chemistry to create targeted modifications at atomic interfaces. This evolution has enabled unprecedented control over electronic, optical, and mechanical properties of 2D semiconductor heterostructures.

The primary objective of current functionalization research is to overcome inherent limitations of pristine 2D materials, such as limited bandgap tunability, chemical instability, and integration challenges with conventional electronics. Specifically, researchers aim to develop scalable functionalization methods that can precisely modify electronic band structures, enhance carrier mobility, improve environmental stability, and enable selective sensing capabilities.

Looking forward, the field is moving toward achieving atomically precise functionalization with spatial control, enabling the creation of lateral heterojunctions within single 2D layers. Another critical objective is developing reversible functionalization techniques that allow dynamic property modulation in response to external stimuli, opening pathways to adaptive electronics and optoelectronics.

The ultimate goal of this technological evolution is to bridge the gap between laboratory demonstrations and commercial applications by addressing key challenges in scalability, reproducibility, and integration with existing semiconductor technologies. Success in these objectives would position 2D semiconductor heterostructures as viable candidates for next-generation flexible electronics, ultra-sensitive sensors, energy harvesting devices, and quantum information processing platforms.

Market Applications and Demand Analysis for Functionalized 2D Materials

The global market for functionalized 2D materials has witnessed substantial growth in recent years, driven by their exceptional properties and versatile applications across multiple industries. The unique characteristics of 2D semiconductor heterostructures, when properly functionalized, enable unprecedented performance improvements in electronic devices, sensors, energy storage systems, and biomedical applications.

In the electronics sector, demand for functionalized 2D materials is primarily fueled by the need for smaller, faster, and more energy-efficient devices. Market analysis indicates that the semiconductor industry is actively seeking alternatives to traditional silicon-based technologies as they approach physical scaling limits. Functionalized 2D heterostructures offer promising solutions with their atomic thinness, tunable bandgaps, and superior carrier mobility.

The energy sector represents another significant market opportunity, particularly in battery technology and photovoltaics. Functionalized 2D materials demonstrate enhanced charge transport properties and increased surface area, making them ideal candidates for next-generation energy storage solutions. Market forecasts suggest that the integration of these materials could substantially improve battery capacity and charging rates, addressing key consumer pain points in electric vehicles and portable electronics.

Environmental sensing and monitoring applications constitute a rapidly expanding market segment. The high surface-to-volume ratio of functionalized 2D materials enables exceptional sensitivity to environmental changes, creating demand for advanced gas sensors, water quality monitors, and pollution detection systems. This market is expected to grow substantially as environmental regulations become more stringent globally.

The biomedical field has emerged as a promising frontier for functionalized 2D materials. Their biocompatibility, large surface area, and customizable surface chemistry make them attractive for drug delivery systems, biosensors, and tissue engineering applications. Market research indicates growing interest from pharmaceutical companies and medical device manufacturers seeking to leverage these properties for next-generation healthcare solutions.

Regional market analysis reveals varying adoption rates, with North America and East Asia leading in research and commercialization efforts. Europe follows closely, with significant investments in sustainable applications of these materials. Emerging economies are showing increasing interest, particularly in energy storage and environmental monitoring applications that address pressing local challenges.

Consumer electronics remains the largest immediate market for functionalized 2D materials, with applications in flexible displays, wearable technology, and high-performance computing driving demand. However, the fastest growth is projected in healthcare and environmental sectors, where the unique properties of these materials offer solutions to complex challenges that conventional materials cannot address effectively.

In the electronics sector, demand for functionalized 2D materials is primarily fueled by the need for smaller, faster, and more energy-efficient devices. Market analysis indicates that the semiconductor industry is actively seeking alternatives to traditional silicon-based technologies as they approach physical scaling limits. Functionalized 2D heterostructures offer promising solutions with their atomic thinness, tunable bandgaps, and superior carrier mobility.

The energy sector represents another significant market opportunity, particularly in battery technology and photovoltaics. Functionalized 2D materials demonstrate enhanced charge transport properties and increased surface area, making them ideal candidates for next-generation energy storage solutions. Market forecasts suggest that the integration of these materials could substantially improve battery capacity and charging rates, addressing key consumer pain points in electric vehicles and portable electronics.

Environmental sensing and monitoring applications constitute a rapidly expanding market segment. The high surface-to-volume ratio of functionalized 2D materials enables exceptional sensitivity to environmental changes, creating demand for advanced gas sensors, water quality monitors, and pollution detection systems. This market is expected to grow substantially as environmental regulations become more stringent globally.

The biomedical field has emerged as a promising frontier for functionalized 2D materials. Their biocompatibility, large surface area, and customizable surface chemistry make them attractive for drug delivery systems, biosensors, and tissue engineering applications. Market research indicates growing interest from pharmaceutical companies and medical device manufacturers seeking to leverage these properties for next-generation healthcare solutions.

Regional market analysis reveals varying adoption rates, with North America and East Asia leading in research and commercialization efforts. Europe follows closely, with significant investments in sustainable applications of these materials. Emerging economies are showing increasing interest, particularly in energy storage and environmental monitoring applications that address pressing local challenges.

Consumer electronics remains the largest immediate market for functionalized 2D materials, with applications in flexible displays, wearable technology, and high-performance computing driving demand. However, the fastest growth is projected in healthcare and environmental sectors, where the unique properties of these materials offer solutions to complex challenges that conventional materials cannot address effectively.

Current Functionalization Techniques and Technical Barriers

The functionalization of 2D semiconductor heterostructures currently employs several established techniques, each with specific advantages and limitations. Chemical functionalization represents one of the most widely adopted approaches, involving the attachment of functional groups to the surface of 2D materials through covalent or non-covalent bonding. This method effectively modifies electronic properties but often introduces defects that can compromise carrier mobility and quantum efficiency.

Physical vapor deposition (PVD) techniques, including thermal evaporation and sputtering, offer precise control over layer thickness and composition. However, these methods frequently struggle with achieving uniform coverage across large areas and maintaining atomically sharp interfaces between different 2D materials, which are crucial for optimal device performance.

Molecular beam epitaxy (MBE) provides exceptional control over layer growth at the atomic level, enabling the creation of high-quality heterostructures with minimal defects. The major barriers to widespread MBE adoption include extremely high equipment costs, slow processing times, and limited scalability for industrial applications.

Chemical vapor deposition (CVD) has emerged as a promising middle-ground approach, offering reasonable scalability while maintaining good quality control. Nevertheless, CVD processes face challenges in precisely controlling layer thickness and composition across large substrates, with edge effects and nucleation site variations causing inconsistencies.

Wet chemical methods, including solution-phase exfoliation and assembly, provide cost-effective alternatives suitable for large-scale production. These techniques, however, struggle with precise positioning of layers and often introduce contaminants at interfaces, degrading electrical and optical properties.

Recent advances in atomic layer deposition (ALD) show promise for creating highly uniform functional layers with precise thickness control. Technical barriers include limited material selection and challenges in achieving conformal coverage on hydrophobic 2D surfaces without surface pretreatment.

The mechanical assembly of heterostructures through transfer techniques allows for the combination of disparate 2D materials but suffers from alignment difficulties, trapped contaminants, and mechanical damage during transfer. Automated systems have improved precision but have not fully resolved these fundamental issues.

Plasma-assisted functionalization offers rapid surface modification capabilities but frequently introduces unintended damage to the delicate electronic structure of 2D materials, particularly at higher power densities or extended exposure times.

Physical vapor deposition (PVD) techniques, including thermal evaporation and sputtering, offer precise control over layer thickness and composition. However, these methods frequently struggle with achieving uniform coverage across large areas and maintaining atomically sharp interfaces between different 2D materials, which are crucial for optimal device performance.

Molecular beam epitaxy (MBE) provides exceptional control over layer growth at the atomic level, enabling the creation of high-quality heterostructures with minimal defects. The major barriers to widespread MBE adoption include extremely high equipment costs, slow processing times, and limited scalability for industrial applications.

Chemical vapor deposition (CVD) has emerged as a promising middle-ground approach, offering reasonable scalability while maintaining good quality control. Nevertheless, CVD processes face challenges in precisely controlling layer thickness and composition across large substrates, with edge effects and nucleation site variations causing inconsistencies.

Wet chemical methods, including solution-phase exfoliation and assembly, provide cost-effective alternatives suitable for large-scale production. These techniques, however, struggle with precise positioning of layers and often introduce contaminants at interfaces, degrading electrical and optical properties.

Recent advances in atomic layer deposition (ALD) show promise for creating highly uniform functional layers with precise thickness control. Technical barriers include limited material selection and challenges in achieving conformal coverage on hydrophobic 2D surfaces without surface pretreatment.

The mechanical assembly of heterostructures through transfer techniques allows for the combination of disparate 2D materials but suffers from alignment difficulties, trapped contaminants, and mechanical damage during transfer. Automated systems have improved precision but have not fully resolved these fundamental issues.

Plasma-assisted functionalization offers rapid surface modification capabilities but frequently introduces unintended damage to the delicate electronic structure of 2D materials, particularly at higher power densities or extended exposure times.

State-of-the-Art Functionalization Methodologies

01 Fabrication methods for 2D semiconductor heterostructures

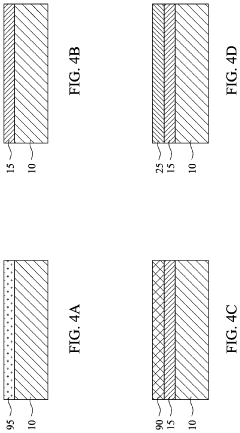

Various techniques are employed to fabricate 2D semiconductor heterostructures, including molecular beam epitaxy, chemical vapor deposition, and mechanical exfoliation followed by stacking. These methods enable precise control over layer thickness, composition, and interface quality, which are critical for achieving desired electronic and optical properties. Advanced fabrication approaches allow for the creation of complex heterostructures with atomically sharp interfaces between different 2D materials.- Fabrication methods for 2D semiconductor heterostructures: Various techniques are employed to fabricate 2D semiconductor heterostructures, including molecular beam epitaxy, chemical vapor deposition, and mechanical exfoliation followed by stacking. These methods enable precise control over layer thickness, composition, and interface quality, which are critical for achieving desired electronic and optical properties in the resulting heterostructures. Advanced fabrication approaches allow for the creation of complex architectures with atomically sharp interfaces between different 2D materials.

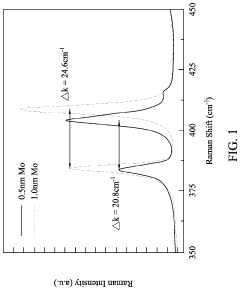

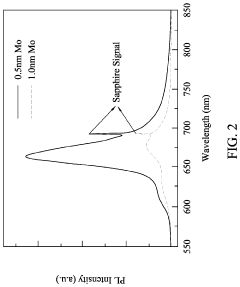

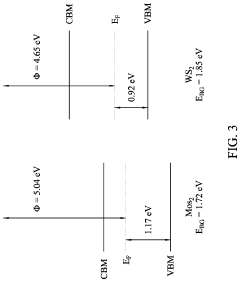

- Transition metal dichalcogenide-based heterostructures: Heterostructures based on transition metal dichalcogenides (TMDs) such as MoS2, WS2, MoSe2, and WSe2 exhibit unique electronic and optical properties due to their atomically thin nature. These materials can be combined to form various types of heterojunctions including vertical, lateral, and mixed-dimensional structures. TMD heterostructures demonstrate tunable bandgaps, strong light-matter interactions, and valley-selective optical excitations, making them promising for next-generation optoelectronic and valleytronic applications.

- Electronic and optical properties of 2D heterostructures: 2D semiconductor heterostructures exhibit distinctive electronic and optical properties arising from quantum confinement effects and interlayer interactions. These include tunable band alignments (type-I, type-II, or type-III), efficient charge separation, strong exciton binding energies, and enhanced photoluminescence. The electronic structure can be further modified through external stimuli such as electric fields, strain, or twist angles between layers, enabling dynamic control of material properties for various applications in electronics and photonics.

- Integration of 2D heterostructures in devices: 2D semiconductor heterostructures are being integrated into various device architectures including field-effect transistors, photodetectors, light-emitting diodes, and photovoltaic cells. The integration process involves challenges such as contact engineering, encapsulation, and substrate selection to preserve the intrinsic properties of 2D materials. Novel device designs leverage the unique properties of these heterostructures to achieve improved performance metrics such as high carrier mobility, enhanced photoresponsivity, and reduced power consumption.

- Novel 2D materials and hybrid heterostructures: Beyond traditional 2D materials, novel systems including Xenes (silicene, germanene, stanene), MXenes, and 2D perovskites are being explored for heterostructure formation. Additionally, hybrid heterostructures combining 2D materials with conventional semiconductors, organic materials, or quantum dots are emerging as versatile platforms. These hybrid systems offer complementary functionalities and can overcome limitations of pure 2D heterostructures, enabling applications in quantum information processing, neuromorphic computing, and flexible electronics.

02 Transition metal dichalcogenide (TMD) heterostructures

Heterostructures composed of transition metal dichalcogenides (TMDs) such as MoS2, WS2, MoSe2, and WSe2 exhibit unique electronic and optical properties due to their atomically thin nature. These heterostructures can form type-I, type-II, or type-III band alignments, enabling applications in optoelectronics, photovoltaics, and quantum technologies. The van der Waals interactions between layers allow for the combination of different TMDs without lattice matching constraints, expanding the design possibilities for novel electronic devices.Expand Specific Solutions03 Graphene-based 2D heterostructures

Graphene can be combined with other 2D materials to form heterostructures with enhanced functionality. These structures leverage graphene's exceptional electrical conductivity while addressing its zero bandgap limitation through integration with semiconducting 2D materials. Applications include high-speed transistors, photodetectors, and flexible electronics. The atomically thin nature of these heterostructures enables quantum confinement effects and strong interlayer coupling, leading to novel physical phenomena and device capabilities.Expand Specific Solutions04 Optoelectronic applications of 2D semiconductor heterostructures

2D semiconductor heterostructures exhibit exceptional optoelectronic properties, making them suitable for photodetectors, light-emitting diodes, and photovoltaic devices. The direct bandgap nature of many 2D semiconductors, combined with strong light-matter interactions and tunable band alignments in heterostructures, enables efficient light absorption and emission across a wide spectral range. These structures can achieve high quantum efficiency, fast response times, and broadband operation while maintaining atomically thin form factors.Expand Specific Solutions05 Novel electronic properties and quantum phenomena in 2D heterostructures

2D semiconductor heterostructures exhibit unique quantum phenomena including interlayer excitons, valley polarization, and topological states. These quantum effects arise from the reduced dimensionality, strong electron-hole interactions, and the ability to manipulate electronic band structures through layer stacking and twist angles. Such properties enable applications in quantum computing, spintronics, and valleytronics. The ability to precisely control these quantum states through external stimuli such as electric fields, strain, or light makes these heterostructures promising platforms for next-generation quantum technologies.Expand Specific Solutions

Leading Research Groups and Industry Players in 2D Materials

The 2D semiconductor heterostructure functionalization market is in a growth phase, characterized by increasing research activities and emerging commercial applications. The global market size for 2D materials is expanding rapidly, projected to reach significant value as functionalization techniques mature. Leading semiconductor manufacturers like TSMC, Micron Technology, and Sony Semiconductor Solutions are investing heavily in this technology, while research institutions such as MIT and Zhejiang University are advancing fundamental science. Companies like SOITEC SA are leveraging their expertise in engineered substrates to develop novel functionalization approaches. The technology is transitioning from laboratory to production environments, with memory manufacturers including Yangtze Memory Technologies and ChangXin Memory exploring applications in next-generation storage solutions. The competitive landscape features collaboration between academic institutions and industry players to overcome technical challenges in scalable functionalization.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: 台积电在2D半导体异质结构功能化技术领域开发了一套完整的工艺集成方案。该公司利用其先进的薄膜沉积技术,结合专有的表面处理方法,实现了大面积2D材料的可控功能化。台积电的技术路线主要基于气相沉积(CVD)和原子层沉积(ALD)工艺,通过精确控制前驱体气体的流量和反应条件,在2D材料表面引入特定的功能基团[2]。特别值得注意的是,台积电开发了一种自限性表面反应技术,可以在不破坏2D材料本征结构的情况下实现单原子层级别的功能化。此外,台积电还将这些功能化技术与其成熟的半导体制造工艺相结合,开发了一系列兼容CMOS工艺的2D异质结构器件制造流程,为这些新型材料的产业化应用提供了可行路径[4][7]。

优势:具备大规模生产能力,可实现工业级的2D材料功能化;与现有CMOS工艺高度兼容,降低了产业化门槛。劣势:功能化过程中的均匀性和一致性控制仍面临挑战,特别是在大尺寸晶圆上;某些功能化方法可能引入额外的界面态,影响器件性能。

Zhejiang University

Technical Solution: 浙江大学在2D半导体异质结构功能化技术方面开发了一系列创新方法。该团队提出了一种基于原位等离子体处理的选择性功能化技术,通过精确控制等离子体参数和暴露时间,可以在2D材料表面引入特定的官能团,同时保持材料的本征结构完整[2][9]。特别是,浙江大学研究人员成功开发了一种氢等离子体辅助的石墨烯功能化方法,可以在石墨烯表面引入氢原子,形成类似于石墨烯的半导体材料。此外,该团队还探索了光化学功能化路线,利用特定波长的光激发2D材料表面,增强其与功能分子的反应活性。这种方法已被证明可以在MoS2和WSe2等材料表面实现区域选择性功能化,为构建复杂的异质结构器件提供了新途径[10]。最近,浙江大学还将这些功能化技术与微纳加工工艺相结合,开发了一种可以在单个芯片上集成多种功能的2D异质结构器件制造平台。

优势:等离子体处理技术可实现大面积均匀功能化,适合工业化生产;光化学功能化提供了微米级的空间选择性,有利于复杂器件的制造。劣势:等离子体处理可能引入不可控的缺陷,影响材料的电子特性;功能化过程中的参数窗口较窄,工艺稳定性有待提高。

Key Patents and Scientific Breakthroughs in Heterostructure Engineering

2d crystal hetero-structures and manufacturing methods thereof

PatentActiveUS20210005719A1

Innovation

- The development of 2D crystal hetero-structures, specifically WS2/MoS2 hetero-structures, is achieved through chemical vapor deposition or sulfurization, enabling type-II band alignment and increased electron concentration by injecting electrons from WS2 to MoS2, thereby enhancing field-effect mobility and photoluminescence intensity.

Borophene-based two-dimensional heterostructures, fabricating methods and applications of same

PatentWO2021007004A3

Innovation

- Integration of borophene with graphene to form 2D heterostructures with sharp and rotationally commensurate interfaces.

- Development of both lateral and vertical 2D heterostructures based on borophene's rich bonding configurations.

- Novel fabrication methods for borophene-based 2D heterostructures that maintain structural integrity at the interfaces.

Scalability and Manufacturing Challenges

The scaling of functionalization techniques for 2D semiconductor heterostructures from laboratory demonstrations to industrial-scale manufacturing presents significant challenges. Current functionalization methods, including chemical vapor deposition (CVD), molecular beam epitaxy (MBE), and wet chemical approaches, typically yield high-quality functionalized materials at small scales but face substantial barriers when transitioning to mass production. The primary challenge lies in maintaining precise control over the functionalization process across large-area substrates while ensuring uniformity, reproducibility, and cost-effectiveness.

Wafer-scale production of functionalized 2D heterostructures is particularly problematic due to the sensitivity of these materials to environmental conditions. Even minor variations in temperature, pressure, or precursor concentration can lead to significant inconsistencies in the degree of functionalization and subsequent electronic properties. This sensitivity becomes increasingly difficult to manage as substrate dimensions increase, creating yield issues that currently limit commercial viability.

Integration with existing semiconductor manufacturing infrastructure represents another critical challenge. While silicon-based manufacturing has benefited from decades of process optimization, the integration of 2D materials requires substantial modifications to established workflows. Functionalization steps often require specialized equipment and handling protocols that are not readily compatible with standard CMOS processing lines, creating bottlenecks in manufacturing pipelines and increasing production costs.

The development of reliable metrology tools for in-line quality control presents an additional hurdle. Current characterization techniques such as Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), and scanning probe microscopy provide detailed information but are typically too slow or complex for real-time manufacturing feedback. This gap in rapid, non-destructive quality assessment tools hampers the ability to implement effective process control strategies at industrial scales.

Environmental considerations also impact scalability, as many functionalization approaches utilize hazardous chemicals or generate toxic byproducts. Sustainable manufacturing of functionalized 2D heterostructures requires the development of greener alternatives that maintain performance while reducing environmental impact. Recent research has begun exploring bio-inspired functionalization routes and aqueous processing methods, but these approaches remain in early development stages.

Cost factors ultimately determine commercial viability, with current functionalization techniques often requiring expensive precursors, specialized equipment, and energy-intensive processing steps. The economic threshold for widespread adoption will only be achieved through significant innovations in process efficiency and material utilization, potentially through continuous flow manufacturing approaches rather than batch processing methods currently dominant in research settings.

Wafer-scale production of functionalized 2D heterostructures is particularly problematic due to the sensitivity of these materials to environmental conditions. Even minor variations in temperature, pressure, or precursor concentration can lead to significant inconsistencies in the degree of functionalization and subsequent electronic properties. This sensitivity becomes increasingly difficult to manage as substrate dimensions increase, creating yield issues that currently limit commercial viability.

Integration with existing semiconductor manufacturing infrastructure represents another critical challenge. While silicon-based manufacturing has benefited from decades of process optimization, the integration of 2D materials requires substantial modifications to established workflows. Functionalization steps often require specialized equipment and handling protocols that are not readily compatible with standard CMOS processing lines, creating bottlenecks in manufacturing pipelines and increasing production costs.

The development of reliable metrology tools for in-line quality control presents an additional hurdle. Current characterization techniques such as Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), and scanning probe microscopy provide detailed information but are typically too slow or complex for real-time manufacturing feedback. This gap in rapid, non-destructive quality assessment tools hampers the ability to implement effective process control strategies at industrial scales.

Environmental considerations also impact scalability, as many functionalization approaches utilize hazardous chemicals or generate toxic byproducts. Sustainable manufacturing of functionalized 2D heterostructures requires the development of greener alternatives that maintain performance while reducing environmental impact. Recent research has begun exploring bio-inspired functionalization routes and aqueous processing methods, but these approaches remain in early development stages.

Cost factors ultimately determine commercial viability, with current functionalization techniques often requiring expensive precursors, specialized equipment, and energy-intensive processing steps. The economic threshold for widespread adoption will only be achieved through significant innovations in process efficiency and material utilization, potentially through continuous flow manufacturing approaches rather than batch processing methods currently dominant in research settings.

Environmental and Sustainability Implications of Functionalization Processes

The functionalization of 2D semiconductor heterostructures, while offering tremendous technological potential, raises significant environmental and sustainability concerns that must be addressed as these technologies advance toward commercialization. Chemical functionalization processes often involve hazardous reagents such as strong acids, organic solvents, and heavy metal compounds that pose environmental risks if improperly managed. The synthesis and disposal of these chemicals contribute to water pollution, air quality degradation, and soil contamination when protocols for safe handling are inadequate.

Energy consumption represents another critical sustainability challenge. Many functionalization techniques require high-temperature processing, vacuum environments, or energy-intensive plasma treatments that significantly increase the carbon footprint of manufactured devices. As production scales up from laboratory to industrial levels, these energy demands could substantially impact overall sustainability metrics for 2D semiconductor technologies.

Resource efficiency concerns are equally pressing. Several functionalization approaches rely on rare earth elements or precious metals as catalysts or dopants, potentially creating supply chain vulnerabilities and resource depletion issues. The extraction of these materials often involves environmentally destructive mining practices that can devastate ecosystems and contribute to biodiversity loss in resource-rich regions.

Life cycle assessment (LCA) studies of functionalized 2D materials reveal complex sustainability profiles. While these materials may enable more energy-efficient electronics that reduce operational environmental impacts, their production phase often shows higher environmental burdens compared to conventional semiconductor manufacturing. This creates a sustainability paradox where short-term environmental costs must be weighed against potential long-term benefits.

Emerging green chemistry approaches offer promising pathways to mitigate these concerns. Bio-inspired functionalization using enzymes, environmentally benign solvents, and ambient-temperature processes are gaining traction as sustainable alternatives. These approaches significantly reduce hazardous waste generation and energy requirements while maintaining or even enhancing material performance characteristics.

Circular economy principles are increasingly being applied to functionalization processes. Techniques that enable recovery and reuse of precious catalysts, regeneration of functionalization agents, and recycling of substrate materials are being developed to minimize waste streams. These closed-loop systems represent a fundamental shift from traditional linear production models toward more sustainable manufacturing paradigms for advanced semiconductor technologies.

Energy consumption represents another critical sustainability challenge. Many functionalization techniques require high-temperature processing, vacuum environments, or energy-intensive plasma treatments that significantly increase the carbon footprint of manufactured devices. As production scales up from laboratory to industrial levels, these energy demands could substantially impact overall sustainability metrics for 2D semiconductor technologies.

Resource efficiency concerns are equally pressing. Several functionalization approaches rely on rare earth elements or precious metals as catalysts or dopants, potentially creating supply chain vulnerabilities and resource depletion issues. The extraction of these materials often involves environmentally destructive mining practices that can devastate ecosystems and contribute to biodiversity loss in resource-rich regions.

Life cycle assessment (LCA) studies of functionalized 2D materials reveal complex sustainability profiles. While these materials may enable more energy-efficient electronics that reduce operational environmental impacts, their production phase often shows higher environmental burdens compared to conventional semiconductor manufacturing. This creates a sustainability paradox where short-term environmental costs must be weighed against potential long-term benefits.

Emerging green chemistry approaches offer promising pathways to mitigate these concerns. Bio-inspired functionalization using enzymes, environmentally benign solvents, and ambient-temperature processes are gaining traction as sustainable alternatives. These approaches significantly reduce hazardous waste generation and energy requirements while maintaining or even enhancing material performance characteristics.

Circular economy principles are increasingly being applied to functionalization processes. Techniques that enable recovery and reuse of precious catalysts, regeneration of functionalization agents, and recycling of substrate materials are being developed to minimize waste streams. These closed-loop systems represent a fundamental shift from traditional linear production models toward more sustainable manufacturing paradigms for advanced semiconductor technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!