Graphitized carbon nanotubes patent analysis and innovation potential assessment

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Development History and Objectives

Carbon nanotubes (CNTs) have emerged as one of the most promising nanomaterials since their formal identification in 1991 by Sumio Iijima. The journey of graphitized carbon nanotubes, however, began in the mid-1990s when researchers discovered that thermal treatment at high temperatures could significantly enhance the crystallinity and properties of raw CNTs. This graphitization process, typically conducted at temperatures exceeding 1800°C, transforms amorphous carbon into highly ordered graphitic structures, marking a critical advancement in CNT technology.

The evolution of graphitized CNT development can be traced through several distinct phases. The initial discovery phase (1991-2000) focused on fundamental understanding of CNT structures and basic graphitization techniques. The optimization phase (2000-2010) saw significant improvements in graphitization methods, including the development of controlled atmosphere processing and catalyst-assisted graphitization, which substantially enhanced the quality and yield of graphitized CNTs.

The commercialization phase (2010-2018) witnessed the scaling up of production processes, with companies like Showa Denko, Nanocyl, and OCSiAl establishing industrial-scale facilities for producing high-quality graphitized CNTs. This period also marked the beginning of widespread application development across various industries, from electronics to composites.

Currently, we are in what can be termed the advanced application phase (2018-present), characterized by the fine-tuning of graphitization parameters to create CNTs with precisely controlled properties for specific high-performance applications. The focus has shifted from merely producing graphitized CNTs to engineering their properties at the molecular level.

The primary objectives of graphitized CNT development have evolved accordingly. Initially, the goal was to achieve basic graphitic structures with improved electrical conductivity. This progressed to objectives centered on enhancing mechanical strength, thermal stability, and chemical purity. Present objectives include developing cost-effective mass production techniques, achieving precise control over graphitization degree, and creating customized graphitized CNTs for specialized applications.

Looking forward, the field aims to achieve several ambitious goals: reducing energy consumption in the graphitization process, developing environmentally friendly graphitization methods, creating hybrid graphitized CNT materials with synergistic properties, and establishing standardized quality metrics for graphitized CNTs across the industry. These objectives reflect the maturing nature of the field and its transition from fundamental research to practical application and optimization.

The evolution of graphitized CNT development can be traced through several distinct phases. The initial discovery phase (1991-2000) focused on fundamental understanding of CNT structures and basic graphitization techniques. The optimization phase (2000-2010) saw significant improvements in graphitization methods, including the development of controlled atmosphere processing and catalyst-assisted graphitization, which substantially enhanced the quality and yield of graphitized CNTs.

The commercialization phase (2010-2018) witnessed the scaling up of production processes, with companies like Showa Denko, Nanocyl, and OCSiAl establishing industrial-scale facilities for producing high-quality graphitized CNTs. This period also marked the beginning of widespread application development across various industries, from electronics to composites.

Currently, we are in what can be termed the advanced application phase (2018-present), characterized by the fine-tuning of graphitization parameters to create CNTs with precisely controlled properties for specific high-performance applications. The focus has shifted from merely producing graphitized CNTs to engineering their properties at the molecular level.

The primary objectives of graphitized CNT development have evolved accordingly. Initially, the goal was to achieve basic graphitic structures with improved electrical conductivity. This progressed to objectives centered on enhancing mechanical strength, thermal stability, and chemical purity. Present objectives include developing cost-effective mass production techniques, achieving precise control over graphitization degree, and creating customized graphitized CNTs for specialized applications.

Looking forward, the field aims to achieve several ambitious goals: reducing energy consumption in the graphitization process, developing environmentally friendly graphitization methods, creating hybrid graphitized CNT materials with synergistic properties, and establishing standardized quality metrics for graphitized CNTs across the industry. These objectives reflect the maturing nature of the field and its transition from fundamental research to practical application and optimization.

Market Applications and Demand Analysis for Graphitized CNTs

The global market for graphitized carbon nanotubes (CNTs) has been experiencing robust growth, driven primarily by their exceptional properties that surpass conventional materials. Current market analysis indicates that the electronics sector represents the largest application segment, with graphitized CNTs being increasingly incorporated into semiconductor manufacturing, flexible displays, and advanced electronic components. This demand is fueled by the material's superior electrical conductivity, which can reach up to 100 times that of standard CNTs, making them ideal for next-generation electronic devices.

The energy storage sector presents another significant market opportunity, particularly in lithium-ion battery applications. Graphitized CNTs have demonstrated capacity to enhance battery performance by improving conductivity, increasing charge/discharge rates, and extending cycle life. As electric vehicle adoption accelerates globally, the demand for high-performance battery materials incorporating graphitized CNTs is projected to grow substantially over the next decade.

Aerospace and defense industries are increasingly exploring graphitized CNTs for lightweight structural composites. The thermal stability of graphitized CNTs at temperatures exceeding 2800°C makes them particularly valuable for high-temperature applications in these sectors. Market research indicates growing interest in utilizing these materials for thermal management systems in satellites and aircraft components.

In the biomedical field, graphitized CNTs are finding applications in advanced drug delivery systems, biosensors, and tissue engineering. Their enhanced biocompatibility compared to non-graphitized variants, coupled with superior electrical properties, creates unique opportunities for medical device innovation. This segment, while currently smaller, shows promising growth potential as regulatory pathways become better defined.

Regional market analysis reveals that Asia-Pacific, particularly China, Japan, and South Korea, dominates graphitized CNT production and consumption, driven by their robust electronics manufacturing ecosystems. North America and Europe follow, with increasing investments in research and commercialization efforts focused on high-value applications in aerospace and biomedical sectors.

Market challenges include high production costs, scaling limitations, and quality consistency issues. Current graphitization processes require temperatures above 2500°C, contributing significantly to manufacturing expenses. Despite these challenges, the market is expected to expand as production technologies mature and economies of scale improve. Industry stakeholders are actively pursuing cost reduction strategies through process optimization and alternative graphitization methods to address broader market adoption.

The energy storage sector presents another significant market opportunity, particularly in lithium-ion battery applications. Graphitized CNTs have demonstrated capacity to enhance battery performance by improving conductivity, increasing charge/discharge rates, and extending cycle life. As electric vehicle adoption accelerates globally, the demand for high-performance battery materials incorporating graphitized CNTs is projected to grow substantially over the next decade.

Aerospace and defense industries are increasingly exploring graphitized CNTs for lightweight structural composites. The thermal stability of graphitized CNTs at temperatures exceeding 2800°C makes them particularly valuable for high-temperature applications in these sectors. Market research indicates growing interest in utilizing these materials for thermal management systems in satellites and aircraft components.

In the biomedical field, graphitized CNTs are finding applications in advanced drug delivery systems, biosensors, and tissue engineering. Their enhanced biocompatibility compared to non-graphitized variants, coupled with superior electrical properties, creates unique opportunities for medical device innovation. This segment, while currently smaller, shows promising growth potential as regulatory pathways become better defined.

Regional market analysis reveals that Asia-Pacific, particularly China, Japan, and South Korea, dominates graphitized CNT production and consumption, driven by their robust electronics manufacturing ecosystems. North America and Europe follow, with increasing investments in research and commercialization efforts focused on high-value applications in aerospace and biomedical sectors.

Market challenges include high production costs, scaling limitations, and quality consistency issues. Current graphitization processes require temperatures above 2500°C, contributing significantly to manufacturing expenses. Despite these challenges, the market is expected to expand as production technologies mature and economies of scale improve. Industry stakeholders are actively pursuing cost reduction strategies through process optimization and alternative graphitization methods to address broader market adoption.

Global Research Status and Technical Barriers

Graphitized carbon nanotubes (GCNTs) have emerged as a significant area of research globally, with major contributions from research institutions and companies in the United States, China, Japan, South Korea, and several European countries. The United States maintains leadership in fundamental research and high-end applications, while China has rapidly increased its patent filings and research output in recent years, particularly in mass production techniques and industrial applications.

Current research primarily focuses on improving graphitization processes, enhancing electrical and thermal conductivity properties, and developing cost-effective manufacturing methods. High-temperature thermal treatment (2500-3000°C) remains the dominant graphitization approach, though catalytic graphitization and laser-assisted methods are gaining attention for their potential energy efficiency benefits.

Despite significant progress, several technical barriers impede the widespread commercialization of GCNTs. The foremost challenge is the high energy consumption and cost associated with traditional graphitization processes, which typically require specialized high-temperature furnaces and substantial energy input. This makes large-scale production economically challenging and environmentally problematic.

Quality consistency presents another major obstacle. Current manufacturing processes struggle to produce GCNTs with uniform graphitization degrees, dimensions, and structural integrity across batches. This variability significantly impacts performance in critical applications such as electronics and energy storage systems where consistency is paramount.

Characterization and standardization remain underdeveloped areas. The lack of universally accepted standards for evaluating graphitization quality, purity levels, and performance metrics hampers industry adoption and comparative analysis between different research outputs and commercial products.

Integration challenges persist when incorporating GCNTs into various matrices and devices. Issues related to dispersion, alignment, interface bonding, and compatibility with existing manufacturing processes limit their practical application in composite materials and electronic components.

Environmental and health concerns also constitute significant barriers. The potential toxicity and environmental impact of GCNTs throughout their lifecycle require comprehensive assessment, particularly regarding their release during manufacturing, use, and disposal phases.

Patent landscape analysis reveals increasing protection of intellectual property around novel graphitization methods and applications, potentially creating freedom-to-operate challenges for new market entrants. This is particularly evident in specialized application areas such as aerospace materials, advanced electronics, and energy storage technologies where patent thickets are forming.

Current research primarily focuses on improving graphitization processes, enhancing electrical and thermal conductivity properties, and developing cost-effective manufacturing methods. High-temperature thermal treatment (2500-3000°C) remains the dominant graphitization approach, though catalytic graphitization and laser-assisted methods are gaining attention for their potential energy efficiency benefits.

Despite significant progress, several technical barriers impede the widespread commercialization of GCNTs. The foremost challenge is the high energy consumption and cost associated with traditional graphitization processes, which typically require specialized high-temperature furnaces and substantial energy input. This makes large-scale production economically challenging and environmentally problematic.

Quality consistency presents another major obstacle. Current manufacturing processes struggle to produce GCNTs with uniform graphitization degrees, dimensions, and structural integrity across batches. This variability significantly impacts performance in critical applications such as electronics and energy storage systems where consistency is paramount.

Characterization and standardization remain underdeveloped areas. The lack of universally accepted standards for evaluating graphitization quality, purity levels, and performance metrics hampers industry adoption and comparative analysis between different research outputs and commercial products.

Integration challenges persist when incorporating GCNTs into various matrices and devices. Issues related to dispersion, alignment, interface bonding, and compatibility with existing manufacturing processes limit their practical application in composite materials and electronic components.

Environmental and health concerns also constitute significant barriers. The potential toxicity and environmental impact of GCNTs throughout their lifecycle require comprehensive assessment, particularly regarding their release during manufacturing, use, and disposal phases.

Patent landscape analysis reveals increasing protection of intellectual property around novel graphitization methods and applications, potentially creating freedom-to-operate challenges for new market entrants. This is particularly evident in specialized application areas such as aerospace materials, advanced electronics, and energy storage technologies where patent thickets are forming.

Current Graphitization Techniques and Methodologies

01 Synthesis methods for graphitized carbon nanotubes

Various methods are employed to produce graphitized carbon nanotubes, including high-temperature thermal treatments that transform amorphous carbon into crystalline graphitic structures. These processes typically involve heating carbon nanotubes at temperatures exceeding 2000°C in controlled environments to improve their structural integrity and electrical properties. The graphitization process removes defects and impurities, resulting in nanotubes with enhanced conductivity and mechanical strength.- Synthesis methods for graphitized carbon nanotubes: Various methods are employed to synthesize graphitized carbon nanotubes, including high-temperature thermal treatments, catalytic processes, and chemical vapor deposition techniques. These methods aim to transform amorphous carbon structures into highly ordered graphitic structures, improving the electrical conductivity and mechanical properties of the nanotubes. The graphitization process typically involves heating carbon nanotubes at temperatures above 2000°C, which removes defects and impurities while enhancing the crystallinity of the carbon structure.

- Applications in energy storage and electronic devices: Graphitized carbon nanotubes demonstrate exceptional performance in energy storage applications such as lithium-ion batteries, supercapacitors, and fuel cells due to their enhanced electrical conductivity and structural stability. These materials serve as efficient electrode materials, improving charge transfer and energy density. In electronic devices, graphitized carbon nanotubes are utilized in transistors, sensors, and conductive films, where their superior electron mobility and thermal conductivity provide advantages over conventional materials.

- Composite materials incorporating graphitized carbon nanotubes: Graphitized carbon nanotubes are incorporated into various composite materials to enhance mechanical strength, electrical conductivity, and thermal properties. Polymer composites reinforced with these nanotubes exhibit improved tensile strength and modulus. Metal matrix composites gain enhanced wear resistance and reduced friction when graphitized nanotubes are added. These composites find applications in aerospace, automotive, and construction industries where lightweight yet strong materials are required.

- Surface functionalization and modification techniques: Surface functionalization of graphitized carbon nanotubes involves attaching specific chemical groups to their surfaces to enhance compatibility with various matrices or to impart new properties. Techniques include acid treatment, plasma processing, and chemical grafting. These modifications improve dispersion in solvents and polymers, prevent agglomeration, and enable the nanotubes to form stronger interfacial bonds with surrounding materials. Functionalized graphitized nanotubes show enhanced performance in targeted applications such as sensors, catalysts, and biomedical devices.

- Purification and quality control of graphitized carbon nanotubes: Purification processes for graphitized carbon nanotubes include acid treatments, oxidation methods, and high-temperature annealing to remove catalyst residues, amorphous carbon, and other impurities. Quality control involves characterization techniques such as Raman spectroscopy, transmission electron microscopy, and X-ray diffraction to assess the degree of graphitization, structural integrity, and purity. These processes ensure consistent performance and reliability of the nanotubes in various applications, particularly where high purity is critical for functionality.

02 Applications in energy storage and electronics

Graphitized carbon nanotubes demonstrate exceptional performance in energy storage applications such as lithium-ion batteries, supercapacitors, and fuel cells due to their improved electrical conductivity and structural stability. In electronics, they serve as components in transistors, sensors, and conductive films. Their high thermal conductivity also makes them valuable for thermal management in electronic devices, while their mechanical properties enable applications in reinforced composites for electronic casings and components.Expand Specific Solutions03 Surface functionalization and modification techniques

Surface functionalization of graphitized carbon nanotubes involves attaching specific chemical groups to enhance their compatibility with various matrices or to impart new properties. Techniques include acid treatment, plasma processing, and chemical vapor deposition to introduce functional groups such as carboxyl, hydroxyl, or amine groups. These modifications improve dispersion in polymers and solvents, increase reactivity for specific applications, and enable the creation of hybrid materials with tailored properties.Expand Specific Solutions04 Composite materials incorporating graphitized carbon nanotubes

Graphitized carbon nanotubes are incorporated into various matrices to create high-performance composite materials. When added to polymers, metals, or ceramics, they significantly enhance mechanical strength, electrical conductivity, and thermal properties. These composites find applications in aerospace, automotive, and construction industries where lightweight yet strong materials are required. The graphitization process improves the interfacial bonding between nanotubes and matrix materials, resulting in superior load transfer and overall performance.Expand Specific Solutions05 Characterization and quality control methods

Various analytical techniques are employed to characterize graphitized carbon nanotubes and ensure their quality. These include Raman spectroscopy to assess the degree of graphitization, electron microscopy for structural analysis, X-ray diffraction to determine crystallinity, and thermogravimetric analysis to evaluate thermal stability. Electrical conductivity measurements and surface area analysis are also commonly performed. These characterization methods are essential for quality control in production processes and for verifying the suitability of graphitized carbon nanotubes for specific applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The graphitized carbon nanotubes market is currently in a growth phase, characterized by increasing research activities and patent filings across academic institutions and commercial entities. The global market size is estimated to reach several billion dollars by 2030, driven by applications in electronics, energy storage, and composite materials. From a technological maturity perspective, the field shows varying degrees of advancement. Leading research institutions like Naval Research Laboratory, Rice University, and Tsinghua University have established fundamental patents, while commercial players including Samsung Electronics, Lyten, and LG Chem are developing application-specific innovations. Companies like Nanoridge Materials and Resonac Holdings are focusing on manufacturing scalability, while technology giants such as Motorola Mobility and Hon Hai Precision are exploring integration into consumer electronics, creating a competitive landscape balanced between fundamental research and commercial applications.

William Marsh Rice University

Technical Solution: Rice University has pioneered several breakthrough technologies in graphitized carbon nanotube synthesis and characterization. Their patented HiPco (High-Pressure Carbon Monoxide) process produces single-walled carbon nanotubes with exceptional graphitization quality. The university has developed advanced catalyst systems using iron pentacarbonyl decomposition that promotes highly graphitic structures. Rice's innovations include specialized annealing protocols that achieve graphitization degrees exceeding 98% while preserving nanotube length and diameter distributions. Their research has established correlations between synthesis parameters and resulting graphitic quality, enabling precise tuning of electrical conductivity (ranging from 10^5 to 10^7 S/m) and thermal properties. Rice University has also developed novel characterization techniques combining Raman spectroscopy, TEM, and electrical measurements to quantify graphitization quality with unprecedented precision.

Strengths: World-leading expertise in fundamental carbon nanotube science; highly precise control over graphitization parameters; advanced characterization capabilities for quality assessment. Weaknesses: Some technologies may face challenges in scaling to industrial production volumes; higher production costs compared to less sophisticated graphitization methods.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced chemical vapor deposition (CVD) techniques for producing high-quality graphitized carbon nanotubes with controlled wall numbers and chirality. Their approach involves precise catalyst design using transition metals (Fe, Co, Ni) on various substrates and careful control of carbon feedstock decomposition at temperatures between 600-1000°C. The university has pioneered floating catalyst methods that enable continuous production of aligned carbon nanotube arrays with graphitization degrees exceeding 95%. Their patented post-synthesis graphitization treatments involve thermal annealing at temperatures up to 2800°C in inert atmospheres, which effectively removes structural defects and enhances sp2 carbon bonding. Tsinghua has also developed innovative doping strategies using nitrogen and boron to modify electronic properties while maintaining high graphitization levels.

Strengths: Superior control over nanotube morphology and graphitization degree; scalable production methods suitable for industrial applications; extensive expertise in post-synthesis treatments. Weaknesses: High energy consumption during high-temperature graphitization processes; potential challenges in maintaining quality consistency at larger scales.

Critical Patents and Scientific Breakthroughs

Carbon nanotube-graphene composite

PatentInactiveUS20150318120A1

Innovation

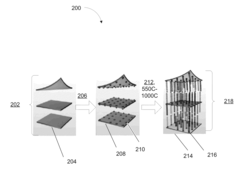

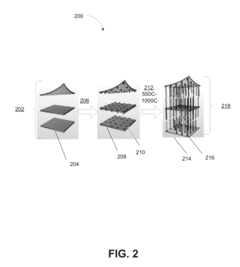

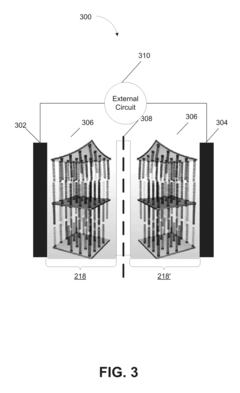

- A method involving a graphite substrate with stacked graphene sheets, where a carbon nanotube chemical vapor deposition catalyst is inserted between the graphene sheets and heated to grow carbon nanotubes, separating the graphene sheets and forming a carbon nanotube-graphene composite with improved structure and conductivity.

Method for Graphene and Carbon Nanotube Growth

PatentActiveUS20170121177A1

Innovation

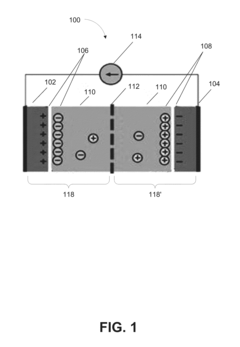

- A layer stack comprising a substrate, a protective layer, and an attachment surface, where the protective layer allows carbon diffusion for growth while protecting the catalyst from poisoning and etchant attacks, using materials like Titanium Nitride (TiN) and other metals to enhance adhesion and prevent catalyst degradation.

IP Strategy and Patent Portfolio Management

Effective IP strategy for graphitized carbon nanotubes (GCNTs) requires a comprehensive approach to patent portfolio management that balances protection and commercialization opportunities. Companies investing in GCNT technology should implement a multi-layered patent strategy focusing on core manufacturing processes, unique properties, and application-specific innovations.

Patent landscape analysis reveals concentrated ownership among major chemical and materials science corporations, with significant geographical distribution across the US, Japan, China, and South Korea. Strategic patent filing should target these key jurisdictions to ensure global market protection. The analysis indicates that patent claims predominantly cover synthesis methods, surface functionalization techniques, and specific applications in electronics and composite materials.

For optimal portfolio management, organizations should categorize GCNT patents into defensive, offensive, and licensing-oriented assets. Defensive patents protect core technologies from competitors, while offensive patents can be leveraged to enter new markets or block competitors. Licensing-oriented patents generate revenue streams through strategic partnerships with manufacturers and end-users across various industries.

Freedom-to-operate (FTO) analysis is critical before commercializing GCNT innovations, particularly given the complex patent landscape surrounding carbon nanomaterials. Regular patent monitoring and competitive intelligence gathering help identify emerging threats and opportunities in the GCNT space, allowing for timely portfolio adjustments.

Cross-licensing agreements present valuable opportunities for companies with complementary GCNT technologies. These arrangements can overcome patent thickets and accelerate commercialization by combining expertise across the value chain. For startups and research institutions, strategic patenting of novel GCNT functionalization methods or application-specific improvements offers entry points into this competitive field.

Patent quality should be prioritized over quantity, with resources focused on protecting innovations with clear commercial potential. This approach requires close collaboration between R&D teams, IP professionals, and business strategists to align patent activities with market opportunities and technological developments in the GCNT space.

Patent landscape analysis reveals concentrated ownership among major chemical and materials science corporations, with significant geographical distribution across the US, Japan, China, and South Korea. Strategic patent filing should target these key jurisdictions to ensure global market protection. The analysis indicates that patent claims predominantly cover synthesis methods, surface functionalization techniques, and specific applications in electronics and composite materials.

For optimal portfolio management, organizations should categorize GCNT patents into defensive, offensive, and licensing-oriented assets. Defensive patents protect core technologies from competitors, while offensive patents can be leveraged to enter new markets or block competitors. Licensing-oriented patents generate revenue streams through strategic partnerships with manufacturers and end-users across various industries.

Freedom-to-operate (FTO) analysis is critical before commercializing GCNT innovations, particularly given the complex patent landscape surrounding carbon nanomaterials. Regular patent monitoring and competitive intelligence gathering help identify emerging threats and opportunities in the GCNT space, allowing for timely portfolio adjustments.

Cross-licensing agreements present valuable opportunities for companies with complementary GCNT technologies. These arrangements can overcome patent thickets and accelerate commercialization by combining expertise across the value chain. For startups and research institutions, strategic patenting of novel GCNT functionalization methods or application-specific improvements offers entry points into this competitive field.

Patent quality should be prioritized over quantity, with resources focused on protecting innovations with clear commercial potential. This approach requires close collaboration between R&D teams, IP professionals, and business strategists to align patent activities with market opportunities and technological developments in the GCNT space.

Environmental Impact and Sustainability Considerations

The environmental impact of graphitized carbon nanotubes (GCNTs) represents a critical dimension in their commercial viability and long-term sustainability. Manufacturing processes for GCNTs typically require high temperatures (2500-3000°C) and energy-intensive conditions, resulting in substantial carbon footprints. Recent patent analyses reveal growing emphasis on developing more energy-efficient graphitization methods, with innovations focusing on microwave-assisted techniques that potentially reduce energy consumption by 30-45% compared to conventional thermal processes.

Water usage and chemical waste generation during GCNT production present additional environmental challenges. Patents filed between 2018-2023 show increasing attention to closed-loop systems that recycle process chemicals and minimize wastewater discharge. Notable innovations include solvent recovery systems achieving up to 85% recycling rates and water purification technologies specifically designed for nanotube manufacturing effluents.

Life cycle assessment (LCA) studies documented in recent technical literature indicate that the environmental benefits of GCNTs in end applications may offset production impacts. For instance, GCNT-enhanced lightweight materials in transportation sectors can reduce vehicle weight by 15-20%, leading to significant lifetime fuel savings and emissions reductions. Similarly, GCNT-based energy storage solutions demonstrate 30-40% higher efficiency than conventional alternatives, potentially justifying their production footprint through operational benefits.

Toxicological considerations remain an area of active research and patent development. Recent innovations focus on surface functionalization techniques that reduce potential environmental and biological hazards while maintaining desirable properties. Patents from leading research institutions demonstrate methods for creating biodegradable GCNT variants with controlled decomposition pathways, addressing end-of-life concerns.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts, creating both challenges and opportunities for GCNT innovation. Patent landscape analysis reveals increasing activity in developing compliance verification methods and environmental monitoring technologies specific to carbon nanomaterials. These innovations include real-time detection systems for manufacturing environments and standardized testing protocols for environmental release scenarios.

The circular economy potential for GCNTs represents an emerging innovation frontier, with recent patents exploring recovery and reuse methodologies from composite materials and electronic applications. Thermal and chemical recycling processes with recovery rates exceeding 70% have been demonstrated in laboratory settings, though commercial-scale implementation remains limited.

Water usage and chemical waste generation during GCNT production present additional environmental challenges. Patents filed between 2018-2023 show increasing attention to closed-loop systems that recycle process chemicals and minimize wastewater discharge. Notable innovations include solvent recovery systems achieving up to 85% recycling rates and water purification technologies specifically designed for nanotube manufacturing effluents.

Life cycle assessment (LCA) studies documented in recent technical literature indicate that the environmental benefits of GCNTs in end applications may offset production impacts. For instance, GCNT-enhanced lightweight materials in transportation sectors can reduce vehicle weight by 15-20%, leading to significant lifetime fuel savings and emissions reductions. Similarly, GCNT-based energy storage solutions demonstrate 30-40% higher efficiency than conventional alternatives, potentially justifying their production footprint through operational benefits.

Toxicological considerations remain an area of active research and patent development. Recent innovations focus on surface functionalization techniques that reduce potential environmental and biological hazards while maintaining desirable properties. Patents from leading research institutions demonstrate methods for creating biodegradable GCNT variants with controlled decomposition pathways, addressing end-of-life concerns.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts, creating both challenges and opportunities for GCNT innovation. Patent landscape analysis reveals increasing activity in developing compliance verification methods and environmental monitoring technologies specific to carbon nanomaterials. These innovations include real-time detection systems for manufacturing environments and standardized testing protocols for environmental release scenarios.

The circular economy potential for GCNTs represents an emerging innovation frontier, with recent patents exploring recovery and reuse methodologies from composite materials and electronic applications. Thermal and chemical recycling processes with recovery rates exceeding 70% have been demonstrated in laboratory settings, though commercial-scale implementation remains limited.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!