Hexagonal Boron Nitride Additive Manufacturing Inks: Rheology Windows, Print Fidelity And Sintering

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

hBN Additive Manufacturing Background and Objectives

Hexagonal Boron Nitride (hBN) has emerged as a critical advanced ceramic material in the landscape of additive manufacturing due to its exceptional thermal conductivity, electrical insulation properties, and chemical stability. The evolution of hBN-based additive manufacturing technologies can be traced back to the early 2010s when researchers began exploring its potential beyond traditional manufacturing methods. This technological progression has been driven by increasing demands for high-performance materials in extreme environments where conventional materials fail to deliver optimal performance.

The development trajectory of hBN additive manufacturing has been characterized by significant advancements in material formulation, particularly in creating printable inks with appropriate rheological properties. Early attempts faced challenges in achieving proper dispersion of hBN particles and maintaining stable suspensions with suitable flow characteristics for various printing techniques. The field has since witnessed substantial improvements in ink formulations, enabling more precise control over print parameters and final material properties.

Current technological trends indicate a growing focus on multi-material printing systems incorporating hBN, tailored sintering protocols, and post-processing techniques to enhance the mechanical and thermal properties of printed components. The integration of computational modeling with experimental approaches has accelerated the optimization of printing parameters and material formulations, reducing the traditional trial-and-error approach that dominated early research efforts.

The primary technical objectives in hBN additive manufacturing research center on establishing comprehensive rheology windows that enable consistent print fidelity across various printing platforms. These windows represent the optimal range of rheological parameters—including viscosity, yield stress, and viscoelastic properties—that ensure successful printing outcomes. Researchers aim to develop standardized methodologies for characterizing these properties and correlating them with print quality metrics.

Another critical objective involves optimizing sintering protocols specifically designed for additively manufactured hBN structures. Unlike conventionally processed ceramics, printed hBN components present unique challenges during densification due to their complex geometries and potential compositional gradients. Developing sintering approaches that preserve geometric accuracy while achieving desired microstructural characteristics remains a significant research focus.

The ultimate goal of current research efforts is to establish hBN-based additive manufacturing as a viable production method for high-performance components in aerospace, electronics, and energy applications. This includes developing design guidelines that leverage the anisotropic properties of hBN, creating multi-functional composites with tailored property gradients, and scaling production processes for industrial implementation while maintaining consistent quality and performance.

The development trajectory of hBN additive manufacturing has been characterized by significant advancements in material formulation, particularly in creating printable inks with appropriate rheological properties. Early attempts faced challenges in achieving proper dispersion of hBN particles and maintaining stable suspensions with suitable flow characteristics for various printing techniques. The field has since witnessed substantial improvements in ink formulations, enabling more precise control over print parameters and final material properties.

Current technological trends indicate a growing focus on multi-material printing systems incorporating hBN, tailored sintering protocols, and post-processing techniques to enhance the mechanical and thermal properties of printed components. The integration of computational modeling with experimental approaches has accelerated the optimization of printing parameters and material formulations, reducing the traditional trial-and-error approach that dominated early research efforts.

The primary technical objectives in hBN additive manufacturing research center on establishing comprehensive rheology windows that enable consistent print fidelity across various printing platforms. These windows represent the optimal range of rheological parameters—including viscosity, yield stress, and viscoelastic properties—that ensure successful printing outcomes. Researchers aim to develop standardized methodologies for characterizing these properties and correlating them with print quality metrics.

Another critical objective involves optimizing sintering protocols specifically designed for additively manufactured hBN structures. Unlike conventionally processed ceramics, printed hBN components present unique challenges during densification due to their complex geometries and potential compositional gradients. Developing sintering approaches that preserve geometric accuracy while achieving desired microstructural characteristics remains a significant research focus.

The ultimate goal of current research efforts is to establish hBN-based additive manufacturing as a viable production method for high-performance components in aerospace, electronics, and energy applications. This includes developing design guidelines that leverage the anisotropic properties of hBN, creating multi-functional composites with tailored property gradients, and scaling production processes for industrial implementation while maintaining consistent quality and performance.

Market Analysis for hBN AM Inks

The global market for hexagonal boron nitride (hBN) additive manufacturing inks is experiencing significant growth, driven by increasing demand for advanced materials in electronics, aerospace, and thermal management applications. Current market estimates value the hBN AM inks sector at approximately $320 million in 2023, with projections indicating a compound annual growth rate of 18.7% through 2030.

The electronics industry represents the largest market segment for hBN AM inks, accounting for roughly 42% of total demand. This is primarily due to hBN's exceptional thermal conductivity and electrical insulation properties, making it ideal for thermal interface materials and electronic packaging applications. The miniaturization trend in electronics continues to drive demand for materials that can efficiently dissipate heat while maintaining electrical isolation.

Aerospace and defense applications constitute the second-largest market segment at 27%, where hBN's high-temperature stability, chemical inertness, and lightweight characteristics are particularly valuable. The remaining market share is distributed across automotive (15%), industrial equipment (10%), and emerging applications (6%).

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows at 30%, with Europe accounting for 20% of the global market. The remaining 5% is distributed across other regions.

Market analysis reveals several key drivers fueling growth in the hBN AM inks sector. First, the rapid expansion of 5G infrastructure and electric vehicle production has intensified demand for advanced thermal management materials. Second, increasing adoption of additive manufacturing across industries has created new application opportunities for specialized materials like hBN inks.

Customer requirements are evolving toward inks with precisely controlled rheological properties that enable higher print resolution and fidelity. End-users are increasingly demanding materials that can be sintered at lower temperatures while maintaining excellent thermal and electrical properties in the final printed components.

Market challenges include high production costs, limited standardization of material properties, and competition from alternative thermal management solutions. The relatively high price point of hBN AM inks compared to conventional materials remains a barrier to wider adoption in cost-sensitive applications.

Future market growth will likely be driven by innovations in ink formulation that expand the rheology windows, enabling more precise control over print parameters and final part properties. Additionally, developments in sintering technologies that reduce energy requirements while improving material performance will be critical for market expansion.

The electronics industry represents the largest market segment for hBN AM inks, accounting for roughly 42% of total demand. This is primarily due to hBN's exceptional thermal conductivity and electrical insulation properties, making it ideal for thermal interface materials and electronic packaging applications. The miniaturization trend in electronics continues to drive demand for materials that can efficiently dissipate heat while maintaining electrical isolation.

Aerospace and defense applications constitute the second-largest market segment at 27%, where hBN's high-temperature stability, chemical inertness, and lightweight characteristics are particularly valuable. The remaining market share is distributed across automotive (15%), industrial equipment (10%), and emerging applications (6%).

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows at 30%, with Europe accounting for 20% of the global market. The remaining 5% is distributed across other regions.

Market analysis reveals several key drivers fueling growth in the hBN AM inks sector. First, the rapid expansion of 5G infrastructure and electric vehicle production has intensified demand for advanced thermal management materials. Second, increasing adoption of additive manufacturing across industries has created new application opportunities for specialized materials like hBN inks.

Customer requirements are evolving toward inks with precisely controlled rheological properties that enable higher print resolution and fidelity. End-users are increasingly demanding materials that can be sintered at lower temperatures while maintaining excellent thermal and electrical properties in the final printed components.

Market challenges include high production costs, limited standardization of material properties, and competition from alternative thermal management solutions. The relatively high price point of hBN AM inks compared to conventional materials remains a barrier to wider adoption in cost-sensitive applications.

Future market growth will likely be driven by innovations in ink formulation that expand the rheology windows, enabling more precise control over print parameters and final part properties. Additionally, developments in sintering technologies that reduce energy requirements while improving material performance will be critical for market expansion.

Technical Challenges in hBN Ink Development

The development of hexagonal boron nitride (hBN) inks for additive manufacturing faces several significant technical challenges that must be overcome to achieve optimal performance. One of the primary obstacles is controlling the rheological properties of hBN-based inks. These inks must exhibit shear-thinning behavior to flow through printing nozzles while maintaining sufficient viscosity at rest to retain their printed shape. Achieving this delicate balance requires precise formulation of binders, solvents, and dispersants tailored specifically for hBN's unique surface chemistry.

Particle size distribution presents another critical challenge. hBN's natural tendency to form large, anisotropic flakes complicates the creation of homogeneous inks with consistent flow properties. Excessive particle size variation leads to nozzle clogging during printing and structural inconsistencies in the final product. Current milling and exfoliation techniques often produce wide particle size distributions that compromise print quality and reproducibility.

Dispersion stability remains problematic due to hBN's hydrophobic nature and tendency to agglomerate. Unlike graphene-based materials, hBN particles exhibit different surface energies and interaction mechanisms with dispersants. This necessitates the development of specialized surfactants and functionalization approaches to achieve stable suspensions with adequate shelf life for industrial applications.

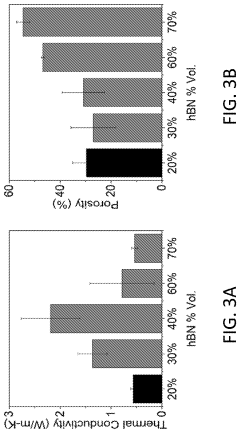

The sintering behavior of hBN presents unique challenges compared to other ceramic materials. Its high thermal stability (melting point >3000°C) and strong covalent bonds require extreme processing conditions to achieve densification. Conventional sintering approaches often result in porous structures with compromised thermal and mechanical properties. Alternative sintering methods such as spark plasma sintering or pressure-assisted techniques add complexity and cost to the manufacturing process.

Adhesion between printed layers and to various substrates represents another significant hurdle. The chemical inertness of hBN, while beneficial for many applications, complicates the formation of strong interfacial bonds during multi-layer printing. This challenge is particularly pronounced when creating composite structures that combine hBN with other materials, requiring innovative approaches to surface modification or the introduction of coupling agents.

Finally, achieving dimensional accuracy and surface finish comparable to traditional manufacturing methods remains difficult. The combination of ink shrinkage during drying, sintering-induced densification, and the anisotropic properties of hBN particles contributes to warping, cracking, and surface roughness in printed components. These defects compromise both the aesthetic quality and functional performance of additively manufactured hBN parts.

Particle size distribution presents another critical challenge. hBN's natural tendency to form large, anisotropic flakes complicates the creation of homogeneous inks with consistent flow properties. Excessive particle size variation leads to nozzle clogging during printing and structural inconsistencies in the final product. Current milling and exfoliation techniques often produce wide particle size distributions that compromise print quality and reproducibility.

Dispersion stability remains problematic due to hBN's hydrophobic nature and tendency to agglomerate. Unlike graphene-based materials, hBN particles exhibit different surface energies and interaction mechanisms with dispersants. This necessitates the development of specialized surfactants and functionalization approaches to achieve stable suspensions with adequate shelf life for industrial applications.

The sintering behavior of hBN presents unique challenges compared to other ceramic materials. Its high thermal stability (melting point >3000°C) and strong covalent bonds require extreme processing conditions to achieve densification. Conventional sintering approaches often result in porous structures with compromised thermal and mechanical properties. Alternative sintering methods such as spark plasma sintering or pressure-assisted techniques add complexity and cost to the manufacturing process.

Adhesion between printed layers and to various substrates represents another significant hurdle. The chemical inertness of hBN, while beneficial for many applications, complicates the formation of strong interfacial bonds during multi-layer printing. This challenge is particularly pronounced when creating composite structures that combine hBN with other materials, requiring innovative approaches to surface modification or the introduction of coupling agents.

Finally, achieving dimensional accuracy and surface finish comparable to traditional manufacturing methods remains difficult. The combination of ink shrinkage during drying, sintering-induced densification, and the anisotropic properties of hBN particles contributes to warping, cracking, and surface roughness in printed components. These defects compromise both the aesthetic quality and functional performance of additively manufactured hBN parts.

Current hBN Ink Formulation Approaches

01 Rheological properties of h-BN inks for additive manufacturing

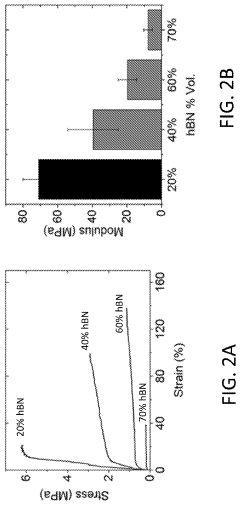

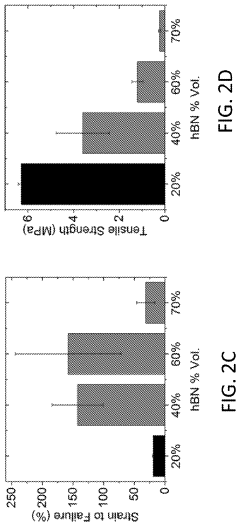

The rheological properties of hexagonal boron nitride (h-BN) inks are crucial for successful additive manufacturing processes. These properties determine the flow behavior during printing and affect print fidelity. Adjusting viscosity modifiers, shear-thinning characteristics, and yield stress parameters creates optimal rheology windows that enable precise extrusion and shape retention. Proper formulation ensures consistent flow through nozzles while maintaining structural integrity after deposition.- Rheological properties of h-BN inks for additive manufacturing: The rheological properties of hexagonal boron nitride (h-BN) inks are crucial for successful additive manufacturing processes. These properties determine the flow behavior during printing and affect print fidelity. By controlling parameters such as viscosity, shear thinning behavior, and yield stress, manufacturers can achieve optimal printing conditions. Additives and dispersants can be incorporated to modify the rheological window, ensuring proper extrusion and shape retention after deposition.

- Sintering techniques for h-BN printed structures: Various sintering techniques can be applied to hexagonal boron nitride structures produced through additive manufacturing to enhance their mechanical and thermal properties. These include conventional thermal sintering, spark plasma sintering, and microwave sintering. The sintering process helps to densify the printed parts, reduce porosity, and improve the bonding between h-BN particles. Controlling sintering parameters such as temperature, time, and atmosphere is essential for achieving desired material properties while maintaining dimensional accuracy.

- Formulation of h-BN composite inks: Hexagonal boron nitride can be combined with various materials to create composite inks with enhanced properties for additive manufacturing. These formulations may include polymeric binders, ceramic precursors, or other functional materials that improve printability and final part performance. The composition of these inks affects their rheological behavior, print fidelity, and sintering characteristics. By carefully selecting the components and their ratios, manufacturers can tailor the properties of the printed structures for specific applications such as thermal management, electrical insulation, or structural components.

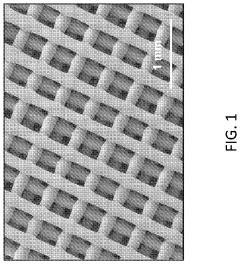

- Print fidelity optimization for h-BN structures: Achieving high print fidelity with hexagonal boron nitride inks requires optimization of multiple parameters including printing speed, nozzle diameter, layer height, and extrusion pressure. The relationship between ink rheology and printing parameters directly impacts the resolution and accuracy of printed structures. Advanced printing strategies such as support structures, infill patterns, and path planning can be employed to improve the quality of complex geometries. Post-processing techniques may also be used to enhance the surface finish and dimensional accuracy of the printed parts.

- Surface modification of h-BN particles for improved ink performance: Surface modification of hexagonal boron nitride particles can significantly improve their dispersion in printing inks and enhance overall performance. Various functionalization methods, including chemical treatments and coating with coupling agents, can be used to modify the surface properties of h-BN particles. These modifications help prevent agglomeration, improve compatibility with the ink matrix, and enhance the rheological properties of the formulation. Better dispersion leads to more consistent printing behavior, improved mechanical properties, and more uniform sintering of the final parts.

02 Sintering processes for h-BN printed structures

Sintering is a critical post-processing step for hexagonal boron nitride printed structures that enhances mechanical properties and functional performance. Various sintering techniques including conventional thermal, microwave, and spark plasma sintering can be employed to achieve densification while preserving the unique crystalline structure of h-BN. The sintering parameters such as temperature profiles, holding times, and atmospheric conditions significantly influence the final microstructure, porosity, and thermal conductivity of the printed components.Expand Specific Solutions03 h-BN composite ink formulations

Composite ink formulations incorporating hexagonal boron nitride with polymers, ceramics, or other nanomaterials enhance printability and final part performance. These formulations typically combine h-BN with binders, dispersants, and plasticizers to achieve desired rheological properties. The addition of secondary materials like silica, alumina, or carbon nanotubes can modify thermal, electrical, and mechanical properties of the printed structures. Proper dispersion techniques ensure homogeneous distribution of h-BN particles throughout the ink matrix.Expand Specific Solutions04 Print fidelity optimization for h-BN structures

Achieving high print fidelity with hexagonal boron nitride inks requires careful optimization of printing parameters and ink formulations. Factors such as nozzle diameter, printing speed, layer height, and extrusion pressure significantly impact dimensional accuracy and surface quality. Advanced printing strategies including support structures, infill patterns, and multi-material approaches can be employed to create complex geometries while maintaining structural integrity. Real-time monitoring and feedback control systems help maintain consistent print quality throughout the manufacturing process.Expand Specific Solutions05 Functional applications of 3D printed h-BN structures

3D printed hexagonal boron nitride structures find applications in various high-performance domains due to their excellent thermal conductivity, electrical insulation, and chemical stability. These printed components can be used in thermal management systems, electronic packaging, high-temperature insulators, and specialized industrial equipment. The ability to create complex geometries with controlled porosity enables the development of customized filters, catalytic supports, and biomedical devices. Post-processing treatments can further enhance functionality by modifying surface properties or introducing additional active components.Expand Specific Solutions

Leading Companies in hBN AM Industry

Hexagonal Boron Nitride (h-BN) additive manufacturing inks market is in an early growth phase, characterized by increasing research activity but limited commercial applications. The global market is estimated at approximately $50-70 million, with projected annual growth of 15-20% driven by electronics and thermal management applications. Technologically, the field remains in development with challenges in rheology control and sintering optimization. Leading players include established materials companies like Denka Corp., Tokuyama Corp., and Mitsubishi Gas Chemical developing commercial formulations, while research institutions such as Northwestern University and Chinese Academy of Sciences focus on fundamental properties. Companies like pH Matter LLC and Samsung Electronics are advancing specialized applications, indicating a competitive landscape divided between materials suppliers and application developers.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered advanced hexagonal boron nitride (hBN) additive manufacturing ink systems designed specifically for high-performance thermal management applications. Their technology centers on tailored rheological modifiers that create precise printing windows for various deposition techniques including direct ink writing and robocasting. Honeywell's formulations incorporate nano-engineered hBN particles with controlled aspect ratios and surface functionalization to enhance dispersion stability and prevent agglomeration during printing processes. Their inks demonstrate exceptional thixotropic behavior with yield stress values optimized for layer-by-layer deposition while maintaining structural integrity. The company has developed specialized sintering protocols that achieve densification above 95% while preserving the crystalline structure of hBN, resulting in components with thermal conductivity values reaching 33 W/m·K. Honeywell's manufacturing approach includes proprietary binder burnout cycles that minimize defect formation during thermal processing, enabling the production of complex geometries with feature resolution down to 100 microns.

Strengths: Comprehensive expertise in both materials formulation and thermal processing techniques enables production of high-performance components with excellent thermal properties. Their established quality control systems ensure consistent performance across production batches. Weaknesses: Their solutions may require specialized printing equipment and processing conditions, potentially limiting accessibility for smaller manufacturers or research institutions.

Northwestern University

Technical Solution: Northwestern University has developed innovative hexagonal boron nitride (hBN) additive manufacturing ink formulations through pioneering research in colloidal science and materials processing. Their approach centers on controlling the rheological behavior of hBN suspensions through precise manipulation of interparticle forces and solvent interactions. Northwestern's technology incorporates specially functionalized hBN nanosheets with controlled aspect ratios to create inks with exceptional shear-thinning characteristics and high shape fidelity during printing. Their formulations utilize environmentally friendly solvent systems and biodegradable binders that facilitate green manufacturing while maintaining excellent printability. The university has pioneered novel sintering approaches including flash sintering and microwave-assisted sintering that significantly reduce processing times and energy consumption compared to conventional methods. Their research demonstrates the ability to produce complex hBN structures with hierarchical porosity control, enabling tailored thermal and mechanical properties for specific applications. Northwestern's printed hBN components exhibit thermal conductivity values of 25-35 W/m·K depending on processing conditions, with electrical resistivity exceeding 10^12 Ω·cm.

Strengths: Cutting-edge research in colloidal science enables precise control over rheological properties and printing behavior. Their environmentally friendly formulations address growing sustainability concerns in advanced manufacturing. Weaknesses: As an academic institution, their technologies may require further development for industrial implementation, and their formulations might prioritize scientific novelty over commercial practicality in some cases.

Critical Rheology and Sintering Technologies

Flexible hexagonal boron nitride composites for additive manufacturing applications

PatentActiveUS11850327B2

Innovation

- Development of composite materials with hexagonal boron nitride particles dispersed in a biocompatible elastomeric polymer binder, enabling 3D extrusion printing of thermally conductive, electrically insulating, and cytocompatible scaffolds for thermal management in implantable medical devices, while maintaining high mechanical flexibility and stretchability.

Method for applying a high-temperature lubricant

PatentActiveEP2435544A1

Innovation

- A sintered hBN solid, preferably in the shape of a cylindrical pin, is rubbed over the surface with pressure to form conglomerates that interlock with the rough surface, ensuring adhesion and preventing easy removal.

Material Characterization Methods

The comprehensive characterization of hexagonal boron nitride (hBN) materials is essential for developing effective additive manufacturing inks. X-ray diffraction (XRD) serves as a primary technique for analyzing the crystalline structure of hBN, providing critical information about phase purity, crystallite size, and orientation. Complementary to XRD, Raman spectroscopy offers insights into the vibrational modes of hBN, particularly the characteristic E2g mode at approximately 1366 cm-1, which can indicate layer thickness and structural integrity.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) enable detailed morphological examination of hBN particles within the ink formulations. These techniques reveal particle size distribution, shape characteristics, and agglomeration tendencies—factors that significantly influence rheological properties and printing behavior. High-resolution TEM further allows for visualization of the layered structure of hBN and assessment of exfoliation quality when nanosheets are utilized.

Rheological characterization represents a cornerstone of ink development, employing rotational and oscillatory rheometry to quantify viscosity profiles across varying shear rates. The identification of shear-thinning behavior is particularly crucial for extrusion-based printing processes. Yield stress measurements help predict ink stability during and after deposition, while viscoelastic properties (storage and loss moduli) inform printability assessments and shape retention capabilities.

Thermal analysis techniques, including thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC), provide essential data regarding the thermal stability of ink components during sintering processes. These methods help establish appropriate sintering protocols by identifying decomposition temperatures of organic binders and revealing phase transitions or oxidation events.

Surface characterization techniques such as atomic force microscopy (AFM) and Brunauer-Emmett-Teller (BET) analysis offer valuable information about surface roughness, specific surface area, and porosity—properties that influence both printing behavior and final material performance. Contact angle measurements assess wettability characteristics, which affect adhesion to substrates and layer-to-layer bonding.

Spectroscopic methods including Fourier-transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS) enable identification of surface functional groups and chemical bonding states, providing insights into potential ink-substrate interactions and helping optimize formulations for specific applications. These techniques are particularly valuable when surface modifications are employed to enhance dispersion stability or introduce specific functionalities.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) enable detailed morphological examination of hBN particles within the ink formulations. These techniques reveal particle size distribution, shape characteristics, and agglomeration tendencies—factors that significantly influence rheological properties and printing behavior. High-resolution TEM further allows for visualization of the layered structure of hBN and assessment of exfoliation quality when nanosheets are utilized.

Rheological characterization represents a cornerstone of ink development, employing rotational and oscillatory rheometry to quantify viscosity profiles across varying shear rates. The identification of shear-thinning behavior is particularly crucial for extrusion-based printing processes. Yield stress measurements help predict ink stability during and after deposition, while viscoelastic properties (storage and loss moduli) inform printability assessments and shape retention capabilities.

Thermal analysis techniques, including thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC), provide essential data regarding the thermal stability of ink components during sintering processes. These methods help establish appropriate sintering protocols by identifying decomposition temperatures of organic binders and revealing phase transitions or oxidation events.

Surface characterization techniques such as atomic force microscopy (AFM) and Brunauer-Emmett-Teller (BET) analysis offer valuable information about surface roughness, specific surface area, and porosity—properties that influence both printing behavior and final material performance. Contact angle measurements assess wettability characteristics, which affect adhesion to substrates and layer-to-layer bonding.

Spectroscopic methods including Fourier-transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS) enable identification of surface functional groups and chemical bonding states, providing insights into potential ink-substrate interactions and helping optimize formulations for specific applications. These techniques are particularly valuable when surface modifications are employed to enhance dispersion stability or introduce specific functionalities.

Sustainability Aspects of hBN AM Processes

The sustainability aspects of hexagonal boron nitride (hBN) additive manufacturing processes represent a critical dimension in evaluating their industrial viability and environmental impact. The production and utilization of hBN-based inks involve multiple sustainability considerations that must be systematically assessed to ensure responsible implementation.

Energy consumption during the sintering phase constitutes a significant sustainability challenge in hBN additive manufacturing. Traditional sintering methods require temperatures exceeding 1500°C, resulting in substantial energy expenditure and associated carbon emissions. Recent research has focused on developing lower-temperature sintering protocols and alternative energy sources, including microwave-assisted and spark plasma sintering, which can reduce energy requirements by up to 40%.

Material efficiency in hBN ink formulation presents another sustainability dimension. Current formulations typically achieve 30-45% hBN loading, with the remainder comprising binders, solvents, and rheological modifiers. Optimizing these formulations to increase hBN content while maintaining printability could significantly reduce material waste and processing steps. Additionally, the development of water-based hBN inks represents a promising direction for eliminating toxic organic solvents commonly used in conventional formulations.

Lifecycle assessment (LCA) studies indicate that the environmental footprint of hBN additive manufacturing is heavily influenced by raw material sourcing. The mining and processing of boron compounds generate substantial environmental impacts, including habitat disruption and water pollution. Emerging research into synthetic production routes from agricultural waste and recycled boron-containing materials shows potential for reducing these impacts by up to 60% compared to conventional mining operations.

Waste management strategies for hBN manufacturing processes are increasingly focusing on circular economy principles. Failed prints and support structures can be reprocessed into new ink formulations, though current recycling efficiencies remain below 70% due to contamination and degradation challenges. Innovative approaches using selective dissolution techniques have demonstrated promising results in laboratory settings, potentially enabling near-complete recovery of hBN from printed components.

The long-term environmental persistence of hBN particles presents both advantages and concerns. While hBN's chemical stability ensures durable performance in applications, it also raises questions about end-of-life management. Current research into biodegradable binder systems that facilitate controlled decomposition of hBN composites may offer pathways to more environmentally responsible product lifecycles without compromising the exceptional thermal and electrical properties that make hBN valuable in advanced manufacturing contexts.

Energy consumption during the sintering phase constitutes a significant sustainability challenge in hBN additive manufacturing. Traditional sintering methods require temperatures exceeding 1500°C, resulting in substantial energy expenditure and associated carbon emissions. Recent research has focused on developing lower-temperature sintering protocols and alternative energy sources, including microwave-assisted and spark plasma sintering, which can reduce energy requirements by up to 40%.

Material efficiency in hBN ink formulation presents another sustainability dimension. Current formulations typically achieve 30-45% hBN loading, with the remainder comprising binders, solvents, and rheological modifiers. Optimizing these formulations to increase hBN content while maintaining printability could significantly reduce material waste and processing steps. Additionally, the development of water-based hBN inks represents a promising direction for eliminating toxic organic solvents commonly used in conventional formulations.

Lifecycle assessment (LCA) studies indicate that the environmental footprint of hBN additive manufacturing is heavily influenced by raw material sourcing. The mining and processing of boron compounds generate substantial environmental impacts, including habitat disruption and water pollution. Emerging research into synthetic production routes from agricultural waste and recycled boron-containing materials shows potential for reducing these impacts by up to 60% compared to conventional mining operations.

Waste management strategies for hBN manufacturing processes are increasingly focusing on circular economy principles. Failed prints and support structures can be reprocessed into new ink formulations, though current recycling efficiencies remain below 70% due to contamination and degradation challenges. Innovative approaches using selective dissolution techniques have demonstrated promising results in laboratory settings, potentially enabling near-complete recovery of hBN from printed components.

The long-term environmental persistence of hBN particles presents both advantages and concerns. While hBN's chemical stability ensures durable performance in applications, it also raises questions about end-of-life management. Current research into biodegradable binder systems that facilitate controlled decomposition of hBN composites may offer pathways to more environmentally responsible product lifecycles without compromising the exceptional thermal and electrical properties that make hBN valuable in advanced manufacturing contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!