Hexagonal Boron Nitride Sintered Bodies: Densification Routes, Grain Architecture And Strength

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

hBN Sintering Background and Objectives

Hexagonal Boron Nitride (hBN) has emerged as a critical advanced ceramic material with exceptional thermal stability, electrical insulation properties, and chemical inertness. The development of hBN sintered bodies can be traced back to the 1950s, when researchers first began exploring methods to densify this material for industrial applications. Over subsequent decades, significant advancements have been made in understanding the fundamental mechanisms governing hBN sintering behavior and microstructural development.

The evolution of hBN sintering technology has progressed through several distinct phases. Initially, hot-pressing techniques dominated the field, offering moderate densification but limited control over microstructure. The 1980s and 1990s saw the introduction of pressure-assisted sintering methods, including hot isostatic pressing (HIP), which enabled higher densities but often at considerable cost. Recent technological trends have focused on developing more efficient sintering routes that can achieve near-theoretical densities while maintaining control over grain architecture.

Current research objectives in hBN sintering technology center on addressing several persistent challenges. Primary among these is the inherent difficulty in achieving full densification due to hBN's strong covalent bonding and highly anisotropic crystal structure. This anisotropy results in preferential grain growth along basal planes, creating microstructural complexities that significantly impact mechanical properties, particularly strength and fracture toughness.

The relationship between densification routes, resulting grain architecture, and mechanical strength represents a critical knowledge gap that must be addressed to advance hBN applications. Various sintering additives, including metal oxides, borates, and rare earth compounds, have been investigated to enhance densification kinetics and control grain growth. However, systematic understanding of how these additives influence the final microstructure-property relationships remains incomplete.

The technical objectives of current research efforts include developing optimized sintering protocols that can achieve densities exceeding 98% of theoretical while maintaining controlled grain size and orientation. Additionally, researchers aim to establish clear correlations between processing parameters, resultant microstructures, and mechanical properties to enable tailored hBN components for specific applications.

Emerging trends in this field include the exploration of novel sintering techniques such as spark plasma sintering (SPS), microwave sintering, and two-step sintering approaches. These methods offer potential advantages in terms of reduced processing temperatures, shorter cycle times, and improved control over grain architecture. Furthermore, there is growing interest in developing gradient or composite hBN structures that combine the material's inherent thermal and electrical properties with enhanced mechanical performance.

The evolution of hBN sintering technology has progressed through several distinct phases. Initially, hot-pressing techniques dominated the field, offering moderate densification but limited control over microstructure. The 1980s and 1990s saw the introduction of pressure-assisted sintering methods, including hot isostatic pressing (HIP), which enabled higher densities but often at considerable cost. Recent technological trends have focused on developing more efficient sintering routes that can achieve near-theoretical densities while maintaining control over grain architecture.

Current research objectives in hBN sintering technology center on addressing several persistent challenges. Primary among these is the inherent difficulty in achieving full densification due to hBN's strong covalent bonding and highly anisotropic crystal structure. This anisotropy results in preferential grain growth along basal planes, creating microstructural complexities that significantly impact mechanical properties, particularly strength and fracture toughness.

The relationship between densification routes, resulting grain architecture, and mechanical strength represents a critical knowledge gap that must be addressed to advance hBN applications. Various sintering additives, including metal oxides, borates, and rare earth compounds, have been investigated to enhance densification kinetics and control grain growth. However, systematic understanding of how these additives influence the final microstructure-property relationships remains incomplete.

The technical objectives of current research efforts include developing optimized sintering protocols that can achieve densities exceeding 98% of theoretical while maintaining controlled grain size and orientation. Additionally, researchers aim to establish clear correlations between processing parameters, resultant microstructures, and mechanical properties to enable tailored hBN components for specific applications.

Emerging trends in this field include the exploration of novel sintering techniques such as spark plasma sintering (SPS), microwave sintering, and two-step sintering approaches. These methods offer potential advantages in terms of reduced processing temperatures, shorter cycle times, and improved control over grain architecture. Furthermore, there is growing interest in developing gradient or composite hBN structures that combine the material's inherent thermal and electrical properties with enhanced mechanical performance.

Market Applications and Demand Analysis

The global market for hexagonal boron nitride (h-BN) sintered bodies has been experiencing significant growth, driven primarily by increasing demand in high-temperature applications across multiple industries. The current market size for h-BN sintered products is estimated at over $500 million annually, with projections indicating a compound annual growth rate of 6-7% through 2028.

The electronics industry represents the largest application segment, accounting for approximately 30% of total demand. H-BN sintered bodies are increasingly utilized as substrates for high-power electronic devices, particularly in 5G infrastructure and electric vehicle components, due to their excellent thermal conductivity and electrical insulation properties. The thermal management capabilities of h-BN are becoming critical as power densities in electronic devices continue to increase.

Metallurgical applications constitute the second-largest market segment at roughly 25%. H-BN sintered components are extensively used in molten metal handling, crucibles, and nozzles for non-ferrous metals processing. The material's non-wettability by most molten metals and exceptional thermal shock resistance make it indispensable in these high-temperature environments.

The aerospace and defense sectors have shown the fastest growth rate in h-BN sintered body adoption, increasing by approximately 9% annually. Applications include thermal protection systems, radar components, and specialized parts for hypersonic vehicles where the material's strength retention at extreme temperatures provides significant advantages over competing materials.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 45% of global consumption, with China, Japan, and South Korea leading in both production and consumption. North America and Europe follow with approximately 25% and 20% market share respectively, primarily driven by aerospace, defense, and advanced electronics applications.

Customer requirements are increasingly focused on improved mechanical strength without sacrificing thermal conductivity. Market research indicates that end-users are willing to pay premium prices (typically 15-20% higher) for h-BN sintered bodies that demonstrate superior strength-to-weight ratios while maintaining thermal performance. This trend is particularly pronounced in aerospace and semiconductor manufacturing equipment applications.

Emerging applications in nuclear energy, particularly for next-generation small modular reactors, represent a potentially significant growth area. The neutron absorption characteristics and stability under radiation make h-BN sintered bodies attractive for specific components in these systems, potentially adding $50-70 million to the market by 2030.

The electronics industry represents the largest application segment, accounting for approximately 30% of total demand. H-BN sintered bodies are increasingly utilized as substrates for high-power electronic devices, particularly in 5G infrastructure and electric vehicle components, due to their excellent thermal conductivity and electrical insulation properties. The thermal management capabilities of h-BN are becoming critical as power densities in electronic devices continue to increase.

Metallurgical applications constitute the second-largest market segment at roughly 25%. H-BN sintered components are extensively used in molten metal handling, crucibles, and nozzles for non-ferrous metals processing. The material's non-wettability by most molten metals and exceptional thermal shock resistance make it indispensable in these high-temperature environments.

The aerospace and defense sectors have shown the fastest growth rate in h-BN sintered body adoption, increasing by approximately 9% annually. Applications include thermal protection systems, radar components, and specialized parts for hypersonic vehicles where the material's strength retention at extreme temperatures provides significant advantages over competing materials.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 45% of global consumption, with China, Japan, and South Korea leading in both production and consumption. North America and Europe follow with approximately 25% and 20% market share respectively, primarily driven by aerospace, defense, and advanced electronics applications.

Customer requirements are increasingly focused on improved mechanical strength without sacrificing thermal conductivity. Market research indicates that end-users are willing to pay premium prices (typically 15-20% higher) for h-BN sintered bodies that demonstrate superior strength-to-weight ratios while maintaining thermal performance. This trend is particularly pronounced in aerospace and semiconductor manufacturing equipment applications.

Emerging applications in nuclear energy, particularly for next-generation small modular reactors, represent a potentially significant growth area. The neutron absorption characteristics and stability under radiation make h-BN sintered bodies attractive for specific components in these systems, potentially adding $50-70 million to the market by 2030.

Current Densification Challenges and Limitations

Despite significant advancements in hexagonal boron nitride (h-BN) sintering technology, several critical challenges persist in achieving optimal densification of h-BN sintered bodies. The inherent anisotropic crystal structure of h-BN, characterized by strong covalent bonds within the basal planes and weak van der Waals forces between layers, creates fundamental difficulties in the densification process. This anisotropy results in preferential grain alignment during sintering, leading to inconsistent mechanical properties throughout the material.

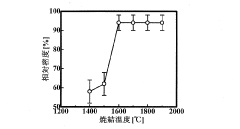

Conventional pressureless sintering methods struggle to achieve densities exceeding 70-80% of theoretical density without additives, primarily due to the low surface energy and poor atomic diffusion characteristics of h-BN. The high covalency of B-N bonds further inhibits mass transport mechanisms necessary for effective densification, requiring extremely high temperatures (>1800°C) that approach the decomposition point of h-BN.

The presence of oxygen impurities represents another significant limitation, as they form B2O3 during sintering, which can volatilize at high temperatures, creating undesirable porosity. This effect becomes particularly problematic when attempting to produce high-purity h-BN components for electronic or nuclear applications where impurities must be minimized.

Current pressure-assisted techniques such as hot pressing and spark plasma sintering (SPS) improve densification but introduce their own limitations. Hot pressing typically induces strong texture with basal planes oriented perpendicular to the pressing direction, resulting in anisotropic properties that may be undesirable for certain applications. SPS, while enabling rapid densification at lower temperatures, often produces microstructural inhomogeneities due to non-uniform current distribution and thermal gradients.

The use of sintering aids, while effective for enhancing densification, introduces phase boundary issues and often compromises the high-temperature performance and chemical inertness that make h-BN valuable. Common additives like B2O3, CaO, and rare earth oxides create liquid phases that facilitate densification but remain at grain boundaries, potentially limiting high-temperature applications above 1000°C.

Scale-up challenges also persist, as laboratory-scale densification processes often prove difficult to translate to industrial production. Maintaining uniform temperature distribution and pressure application becomes increasingly problematic with larger sample sizes, leading to density gradients and inconsistent microstructures in commercially-sized components.

The control of grain architecture during densification represents perhaps the most sophisticated challenge, as the final grain size, aspect ratio, and orientation dramatically influence mechanical strength. Current techniques provide limited control over these parameters, making it difficult to engineer h-BN microstructures with predictable and optimized mechanical properties.

Conventional pressureless sintering methods struggle to achieve densities exceeding 70-80% of theoretical density without additives, primarily due to the low surface energy and poor atomic diffusion characteristics of h-BN. The high covalency of B-N bonds further inhibits mass transport mechanisms necessary for effective densification, requiring extremely high temperatures (>1800°C) that approach the decomposition point of h-BN.

The presence of oxygen impurities represents another significant limitation, as they form B2O3 during sintering, which can volatilize at high temperatures, creating undesirable porosity. This effect becomes particularly problematic when attempting to produce high-purity h-BN components for electronic or nuclear applications where impurities must be minimized.

Current pressure-assisted techniques such as hot pressing and spark plasma sintering (SPS) improve densification but introduce their own limitations. Hot pressing typically induces strong texture with basal planes oriented perpendicular to the pressing direction, resulting in anisotropic properties that may be undesirable for certain applications. SPS, while enabling rapid densification at lower temperatures, often produces microstructural inhomogeneities due to non-uniform current distribution and thermal gradients.

The use of sintering aids, while effective for enhancing densification, introduces phase boundary issues and often compromises the high-temperature performance and chemical inertness that make h-BN valuable. Common additives like B2O3, CaO, and rare earth oxides create liquid phases that facilitate densification but remain at grain boundaries, potentially limiting high-temperature applications above 1000°C.

Scale-up challenges also persist, as laboratory-scale densification processes often prove difficult to translate to industrial production. Maintaining uniform temperature distribution and pressure application becomes increasingly problematic with larger sample sizes, leading to density gradients and inconsistent microstructures in commercially-sized components.

The control of grain architecture during densification represents perhaps the most sophisticated challenge, as the final grain size, aspect ratio, and orientation dramatically influence mechanical strength. Current techniques provide limited control over these parameters, making it difficult to engineer h-BN microstructures with predictable and optimized mechanical properties.

Contemporary Densification Methodologies

01 Sintering methods for h-BN densification

Various sintering methods can be employed to achieve high-density hexagonal boron nitride bodies. These include hot pressing, spark plasma sintering, and pressureless sintering techniques. The selection of appropriate sintering parameters such as temperature, pressure, and duration significantly impacts the final density of the h-BN bodies. Higher densification leads to improved mechanical properties and reduced porosity in the final sintered product.- Sintering methods for h-BN densification: Various sintering methods can be employed to achieve high-density hexagonal boron nitride bodies. These include hot pressing, hot isostatic pressing, and pressureless sintering techniques. The selection of appropriate sintering parameters such as temperature, pressure, and duration significantly affects the final density of the h-BN bodies. Higher densification leads to improved mechanical properties and reduced porosity in the final sintered product.

- Grain architecture control and orientation: The microstructural development and grain architecture of h-BN sintered bodies can be controlled through processing parameters. Techniques to manipulate grain size, shape, and orientation include the use of specific sintering additives, controlled cooling rates, and application of directional pressure during sintering. Textured microstructures with aligned h-BN platelets can be achieved, resulting in anisotropic properties that can be advantageous for specific applications requiring directional strength or thermal conductivity.

- Sintering additives and their effects: Various additives can be incorporated into h-BN powder mixtures to enhance densification and control grain growth during sintering. Common additives include boron oxide, calcium oxide, aluminum compounds, and rare earth oxides. These additives form liquid phases during sintering that facilitate mass transport and promote densification. The type and amount of sintering aids significantly influence the final microstructure, density, and mechanical properties of the sintered h-BN bodies.

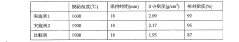

- Mechanical strength enhancement techniques: The mechanical strength of h-BN sintered bodies can be enhanced through various approaches. These include increasing the density through optimized sintering processes, controlling grain size and orientation, incorporating reinforcing phases such as silicon carbide or silicon nitride, and creating composite structures. Post-sintering treatments like heat treatments or surface modifications can also improve the mechanical properties of h-BN sintered bodies for applications requiring high strength and durability.

- Advanced processing techniques for specialized h-BN structures: Novel processing techniques have been developed to create specialized h-BN structures with unique properties. These include spark plasma sintering for rapid densification, chemical vapor deposition for thin films, template growth methods for controlled grain architecture, and additive manufacturing approaches. These advanced techniques allow for the fabrication of h-BN bodies with tailored microstructures, complex shapes, and gradient properties that cannot be achieved through conventional sintering methods.

02 Grain architecture control and orientation

The microstructural development and grain architecture of h-BN sintered bodies can be controlled through processing parameters. Techniques to manipulate grain size, shape, and orientation include the use of specific sintering additives, application of directional pressure during sintering, and post-sintering treatments. Aligned grain structures can be achieved to enhance anisotropic properties, while equiaxed grain structures may provide more isotropic performance. The grain boundary characteristics significantly influence the overall mechanical and thermal properties of the sintered body.Expand Specific Solutions03 Sintering additives and binders for enhanced properties

Various additives and binders can be incorporated into h-BN powder mixtures to enhance densification and mechanical properties. Common additives include boron oxide, calcium oxide, aluminum compounds, and rare earth oxides. These additives promote liquid phase sintering, reduce sintering temperature, and improve grain boundary strength. The type and amount of additives significantly affect the final microstructure, density, and mechanical properties of the sintered h-BN bodies.Expand Specific Solutions04 Mechanical strength enhancement techniques

The mechanical strength of h-BN sintered bodies can be enhanced through various techniques. These include optimizing particle size distribution of starting powders, incorporating reinforcing phases such as silicon carbide or silicon nitride, controlling porosity, and implementing specific heat treatment regimes. Post-sintering treatments like hot isostatic pressing can eliminate residual porosity and further improve mechanical properties. The balance between density, grain size, and phase composition is critical for achieving optimal strength in h-BN sintered bodies.Expand Specific Solutions05 Advanced characterization and property evaluation

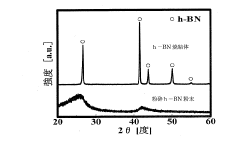

Advanced characterization techniques are essential for evaluating the microstructure and properties of h-BN sintered bodies. Methods such as scanning electron microscopy, X-ray diffraction, and transmission electron microscopy provide insights into grain morphology, crystallographic orientation, and phase composition. Mechanical testing techniques including flexural strength, hardness, and fracture toughness measurements help quantify the mechanical performance. Thermal conductivity and electrical resistivity measurements assess the functional properties of the sintered bodies. These characterization approaches guide the optimization of processing parameters for tailored h-BN properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Hexagonal Boron Nitride (h-BN) sintered bodies market is currently in a growth phase, with increasing applications in high-temperature electronics, thermal management, and advanced ceramics. The global market size for h-BN materials is expanding at approximately 5-7% annually, driven by demand in aerospace, semiconductor, and automotive industries. Technologically, the field is moderately mature but still evolving, with significant innovations in densification techniques and microstructural control. Key players include Sumitomo Electric Industries and Tokuyama Corp., who lead in commercial production, while Denka Corp. and Mitsubishi Gas Chemical focus on specialized formulations. Research institutions like MIT and Rice University are advancing fundamental understanding of grain architecture-strength relationships. Companies such as 3M and Kennametal are developing application-specific h-BN composites, while AIST and Samsung Electronics are exploring next-generation electronic applications.

Tokuyama Corp.

Technical Solution: Tokuyama Corporation has developed advanced sintering techniques for hexagonal boron nitride (h-BN) that focus on controlling grain architecture through hot isostatic pressing (HIP). Their approach involves a two-stage densification process where initial cold pressing is followed by high-temperature sintering at 1800-2000°C under nitrogen atmosphere with specific pressure profiles[1]. This method achieves densification rates exceeding 95% while maintaining the hexagonal crystal structure. Tokuyama's proprietary process incorporates sintering aids such as calcium borate and aluminum oxide in precise quantities (typically 2-5 wt%) to promote liquid phase sintering without compromising the thermal and electrical insulation properties of the final product[3]. Their technology enables the production of h-BN bodies with controlled grain size distribution (1-10 μm) and preferred orientation, resulting in anisotropic mechanical properties that can be tailored for specific applications.

Strengths: Achieves high densification rates while preserving h-BN's beneficial properties; produces components with excellent thermal shock resistance and machinability. Weaknesses: Requires expensive high-temperature equipment; sintering aids may introduce impurities that affect electrical properties in some applications; process is energy-intensive and has relatively long production cycles.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric Industries has pioneered a spark plasma sintering (SPS) approach for h-BN densification that significantly reduces processing time while achieving near-theoretical density values. Their technology applies pulsed direct current through graphite dies containing h-BN powder, generating localized heating at particle contact points[2]. This process operates at temperatures between 1600-1900°C with applied pressures of 30-50 MPa and typical holding times of only 5-15 minutes, dramatically shorter than conventional sintering methods. Sumitomo's technique incorporates precise control of heating rates (50-200°C/min) and cooling profiles to minimize thermal stresses and optimize grain boundary formation. The company has developed proprietary surface treatments for h-BN powders that enhance sinterability without compromising purity, resulting in bodies with uniform microstructure and superior mechanical properties[4]. Their process enables the production of complex-shaped components with densities exceeding 98% of theoretical values while maintaining the crystallographic orientation that provides anisotropic thermal conductivity.

Strengths: Rapid processing times reduce manufacturing costs; achieves exceptionally high densification with minimal additives; produces components with excellent thermal conductivity and electrical insulation. Weaknesses: Equipment costs are high; limited to relatively small component sizes due to power supply constraints; some challenges in scaling up for mass production.

Critical Patents and Research on Grain Architecture

Method for producing high density hexagonal boron nitride sintered article

PatentInactiveUS5064589A

Innovation

- A method involving the mixing of hexagonal boron nitride powder with boron carbide and an alkaline earth metal compound, followed by firing in a nitrogen atmosphere, which allows for pressureless sintering and eliminates the need for hot pressing, resulting in a high-density, high-purity boron nitride sintered body.

Hexagonal boron nitride sintered compact and its manufacturing method

PatentInactiveJP2007191339A

Innovation

- A method involving pressure sintering h-BN powder under specific conditions, including a nitrogen or inert gas atmosphere, controlled temperature rise, and pulse current sintering to produce h-BN sintered bodies with a disordered structure, without the use of sintering aids, ensuring high relative density and mechanical strength.

Thermal and Electrical Properties Evaluation

Hexagonal Boron Nitride (h-BN) sintered bodies exhibit remarkable thermal and electrical properties that make them valuable for various high-performance applications. The thermal conductivity of h-BN sintered bodies typically ranges from 30 to 300 W/m·K, depending on densification methods, grain orientation, and purity levels. This thermal performance positions h-BN as an excellent material for thermal management solutions in electronics and high-temperature applications.

The thermal properties of h-BN sintered bodies demonstrate strong anisotropy, with heat conduction occurring primarily along the basal planes rather than perpendicular to them. This characteristic can be advantageously manipulated through controlled grain architecture during the sintering process. Hot-pressed h-BN bodies with aligned grains show significantly higher in-plane thermal conductivity compared to randomly oriented structures, with differences of up to 10 times observed in some studies.

Densification routes significantly impact thermal performance. Spark plasma sintering (SPS) techniques have demonstrated the ability to produce h-BN bodies with thermal conductivities approaching theoretical limits due to reduced grain boundary scattering. Conversely, pressureless sintering methods typically yield lower thermal conductivity values but offer more economical production routes for less demanding applications.

Electrically, h-BN sintered bodies function as excellent insulators with dielectric strengths ranging from 3-10 kV/mm and electrical resistivities exceeding 10^15 Ω·cm at room temperature. These properties remain remarkably stable even at elevated temperatures up to 900°C, where many competing ceramic insulators experience significant degradation in performance.

The relationship between grain architecture and electrical properties reveals that larger grain sizes tend to improve dielectric strength, while higher densities reduce electrical breakdown susceptibility. Impurity content, particularly metallic contaminants introduced during processing, can dramatically reduce the insulating properties and must be carefully controlled during production.

Temperature-dependent evaluations show that thermal conductivity of h-BN sintered bodies typically decreases with increasing temperature, following a T^-1 relationship characteristic of phonon-dominated thermal transport. This behavior contrasts with the electrical resistivity, which exhibits a negative temperature coefficient at elevated temperatures due to thermally activated charge carriers.

Recent advancements in characterization techniques, including laser flash analysis and impedance spectroscopy, have enabled more precise evaluation of these properties across different temperature ranges and environmental conditions, providing valuable data for engineering applications requiring precise thermal management and electrical isolation.

The thermal properties of h-BN sintered bodies demonstrate strong anisotropy, with heat conduction occurring primarily along the basal planes rather than perpendicular to them. This characteristic can be advantageously manipulated through controlled grain architecture during the sintering process. Hot-pressed h-BN bodies with aligned grains show significantly higher in-plane thermal conductivity compared to randomly oriented structures, with differences of up to 10 times observed in some studies.

Densification routes significantly impact thermal performance. Spark plasma sintering (SPS) techniques have demonstrated the ability to produce h-BN bodies with thermal conductivities approaching theoretical limits due to reduced grain boundary scattering. Conversely, pressureless sintering methods typically yield lower thermal conductivity values but offer more economical production routes for less demanding applications.

Electrically, h-BN sintered bodies function as excellent insulators with dielectric strengths ranging from 3-10 kV/mm and electrical resistivities exceeding 10^15 Ω·cm at room temperature. These properties remain remarkably stable even at elevated temperatures up to 900°C, where many competing ceramic insulators experience significant degradation in performance.

The relationship between grain architecture and electrical properties reveals that larger grain sizes tend to improve dielectric strength, while higher densities reduce electrical breakdown susceptibility. Impurity content, particularly metallic contaminants introduced during processing, can dramatically reduce the insulating properties and must be carefully controlled during production.

Temperature-dependent evaluations show that thermal conductivity of h-BN sintered bodies typically decreases with increasing temperature, following a T^-1 relationship characteristic of phonon-dominated thermal transport. This behavior contrasts with the electrical resistivity, which exhibits a negative temperature coefficient at elevated temperatures due to thermally activated charge carriers.

Recent advancements in characterization techniques, including laser flash analysis and impedance spectroscopy, have enabled more precise evaluation of these properties across different temperature ranges and environmental conditions, providing valuable data for engineering applications requiring precise thermal management and electrical isolation.

Environmental Impact and Sustainability Considerations

The environmental footprint of hexagonal boron nitride (h-BN) sintered bodies extends throughout their lifecycle, from raw material extraction to end-of-life disposal. Mining operations for boron and nitrogen compounds generate significant land disturbances, water pollution, and energy consumption. The sintering process itself, particularly hot pressing and spark plasma sintering methods, requires substantial energy inputs at temperatures exceeding 1800°C, contributing to greenhouse gas emissions when powered by fossil fuels.

Water usage represents another critical environmental concern, as both mining and processing operations consume substantial quantities of freshwater resources. Chemical treatments employed during purification stages may introduce harmful substances into wastewater streams if not properly managed. Additionally, the production of sintering aids and binders often involves environmentally problematic chemicals that require careful handling and disposal protocols.

Recent sustainability initiatives in h-BN manufacturing have focused on developing lower-temperature sintering routes to reduce energy consumption. Research into alternative pressure-assisted sintering techniques has demonstrated potential energy savings of 15-30% compared to conventional methods while maintaining comparable mechanical properties. Several manufacturers have implemented closed-loop water systems that reduce freshwater requirements by up to 60% through advanced filtration and recycling processes.

The durability and chemical stability of h-BN sintered bodies offer sustainability advantages through extended service lifespans, particularly in high-temperature applications where frequent replacement of less durable materials would otherwise be necessary. End-of-life considerations remain challenging, however, as h-BN materials are not biodegradable and recycling options are currently limited by technological and economic constraints.

Life cycle assessment (LCA) studies indicate that optimizing grain architecture during manufacturing can significantly impact environmental performance. Fine-grained structures typically require more intensive processing but deliver superior strength properties that extend product lifespans. Conversely, coarse-grained structures may offer reduced processing energy requirements but potentially shorter service lives, creating complex sustainability trade-offs that must be evaluated on an application-specific basis.

Emerging research directions include the development of bio-inspired densification routes utilizing lower environmental impact additives derived from renewable resources. Additionally, hybrid manufacturing approaches combining additive manufacturing with minimal post-processing have shown promise for reducing material waste by up to 40% compared to traditional subtractive manufacturing methods for complex h-BN components.

Water usage represents another critical environmental concern, as both mining and processing operations consume substantial quantities of freshwater resources. Chemical treatments employed during purification stages may introduce harmful substances into wastewater streams if not properly managed. Additionally, the production of sintering aids and binders often involves environmentally problematic chemicals that require careful handling and disposal protocols.

Recent sustainability initiatives in h-BN manufacturing have focused on developing lower-temperature sintering routes to reduce energy consumption. Research into alternative pressure-assisted sintering techniques has demonstrated potential energy savings of 15-30% compared to conventional methods while maintaining comparable mechanical properties. Several manufacturers have implemented closed-loop water systems that reduce freshwater requirements by up to 60% through advanced filtration and recycling processes.

The durability and chemical stability of h-BN sintered bodies offer sustainability advantages through extended service lifespans, particularly in high-temperature applications where frequent replacement of less durable materials would otherwise be necessary. End-of-life considerations remain challenging, however, as h-BN materials are not biodegradable and recycling options are currently limited by technological and economic constraints.

Life cycle assessment (LCA) studies indicate that optimizing grain architecture during manufacturing can significantly impact environmental performance. Fine-grained structures typically require more intensive processing but deliver superior strength properties that extend product lifespans. Conversely, coarse-grained structures may offer reduced processing energy requirements but potentially shorter service lives, creating complex sustainability trade-offs that must be evaluated on an application-specific basis.

Emerging research directions include the development of bio-inspired densification routes utilizing lower environmental impact additives derived from renewable resources. Additionally, hybrid manufacturing approaches combining additive manufacturing with minimal post-processing have shown promise for reducing material waste by up to 40% compared to traditional subtractive manufacturing methods for complex h-BN components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!