Hexagonal Boron Nitride Electrical Insulation: Partial Discharge, Tracking Resistance And Acceptance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

hBN Insulation Technology Background and Objectives

Hexagonal Boron Nitride (hBN) has emerged as a revolutionary material in the field of electrical insulation, marking a significant advancement beyond traditional insulation materials. Since its discovery in the mid-20th century, hBN has evolved from a laboratory curiosity to a commercially viable solution for high-performance electrical insulation applications. The layered structure of hBN, often referred to as "white graphene," provides exceptional thermal conductivity while maintaining excellent electrical insulation properties, a combination rarely found in conventional materials.

The evolution of electrical insulation technology has historically been driven by the increasing demands of power systems, with materials progressing from natural substances like mica and oil to synthetic polymers and ceramics. hBN represents the next frontier in this progression, offering superior performance characteristics particularly suited for high-voltage and high-temperature environments where traditional insulators fail.

Current technological objectives for hBN electrical insulation focus on addressing three critical aspects: partial discharge resistance, tracking resistance, and industry acceptance. Partial discharge, the localized electrical breakdown that occurs in insulation systems under high voltage stress, remains a significant challenge in ensuring long-term reliability of electrical equipment. The unique crystalline structure of hBN shows promising resistance to partial discharge degradation compared to conventional materials.

Tracking resistance—the ability to resist the formation of conductive carbon paths on the surface when exposed to electrical arcs—represents another crucial performance metric for insulation materials in harsh environments. Preliminary research indicates that hBN's chemical stability and thermal properties may offer enhanced tracking resistance, potentially extending the operational lifespan of insulation systems.

The technology trajectory aims to develop hBN-based insulation solutions that can withstand increasingly demanding electrical and environmental conditions while maintaining reliability over extended service periods. This includes applications in power electronics, electric vehicles, aerospace systems, and next-generation power transmission infrastructure where traditional insulation materials reach their performance limits.

Industry acceptance of hBN insulation technology requires comprehensive standardization and testing protocols to validate its performance claims and ensure safety compliance. The development of these standards represents a significant objective in the technology's evolution path, as it transitions from research laboratories to commercial applications.

The ultimate goal is to establish hBN as a mainstream insulation material that enables more compact, efficient, and reliable electrical systems capable of operating under extreme conditions, thereby supporting broader technological advancements in electrification and power distribution infrastructure.

The evolution of electrical insulation technology has historically been driven by the increasing demands of power systems, with materials progressing from natural substances like mica and oil to synthetic polymers and ceramics. hBN represents the next frontier in this progression, offering superior performance characteristics particularly suited for high-voltage and high-temperature environments where traditional insulators fail.

Current technological objectives for hBN electrical insulation focus on addressing three critical aspects: partial discharge resistance, tracking resistance, and industry acceptance. Partial discharge, the localized electrical breakdown that occurs in insulation systems under high voltage stress, remains a significant challenge in ensuring long-term reliability of electrical equipment. The unique crystalline structure of hBN shows promising resistance to partial discharge degradation compared to conventional materials.

Tracking resistance—the ability to resist the formation of conductive carbon paths on the surface when exposed to electrical arcs—represents another crucial performance metric for insulation materials in harsh environments. Preliminary research indicates that hBN's chemical stability and thermal properties may offer enhanced tracking resistance, potentially extending the operational lifespan of insulation systems.

The technology trajectory aims to develop hBN-based insulation solutions that can withstand increasingly demanding electrical and environmental conditions while maintaining reliability over extended service periods. This includes applications in power electronics, electric vehicles, aerospace systems, and next-generation power transmission infrastructure where traditional insulation materials reach their performance limits.

Industry acceptance of hBN insulation technology requires comprehensive standardization and testing protocols to validate its performance claims and ensure safety compliance. The development of these standards represents a significant objective in the technology's evolution path, as it transitions from research laboratories to commercial applications.

The ultimate goal is to establish hBN as a mainstream insulation material that enables more compact, efficient, and reliable electrical systems capable of operating under extreme conditions, thereby supporting broader technological advancements in electrification and power distribution infrastructure.

Market Analysis for Advanced Electrical Insulation Materials

The global market for advanced electrical insulation materials is experiencing significant growth, driven by increasing demand for reliable electrical systems across various industries. The electrical insulation materials market was valued at approximately $9.2 billion in 2022 and is projected to reach $13.1 billion by 2028, growing at a CAGR of 6.1% during the forecast period. This growth is primarily attributed to the expanding electrical and electronics industry, rising energy demand, and increasing investments in infrastructure development.

Hexagonal Boron Nitride (h-BN) represents an emerging segment within this market, gaining attention for its exceptional thermal conductivity, electrical insulation properties, and chemical stability. The global h-BN market size was valued at $810 million in 2022 and is expected to grow at a CAGR of 7.8% through 2030, outpacing the broader insulation materials market.

Key market drivers for h-BN electrical insulation include the miniaturization trend in electronics, increasing demand for high-temperature resistant materials, and growing applications in electric vehicles and renewable energy systems. The material's superior partial discharge resistance and tracking resistance properties make it particularly valuable in high-voltage applications where traditional insulation materials often fail.

Regional analysis indicates that Asia Pacific dominates the h-BN market with approximately 42% share, led by China, Japan, and South Korea, where electronics manufacturing and electrical equipment production are concentrated. North America and Europe follow with 28% and 23% market shares respectively, with significant research activities focused on advanced applications of h-BN in electrical insulation.

End-user industries driving demand include electronics (34%), electrical equipment (27%), automotive (18%), aerospace (12%), and others (9%). The electronics sector's demand is particularly strong due to h-BN's thermal management capabilities in semiconductor packaging and insulation requirements in miniaturized devices.

Market challenges include relatively high production costs compared to traditional insulation materials, limited awareness about h-BN's benefits among potential end-users, and technical challenges in achieving consistent quality in large-scale production. The average price of h-BN powder ranges from $300-$800 per kilogram depending on purity levels, significantly higher than conventional insulation materials.

Competitive analysis reveals that major players in the h-BN electrical insulation market include Saint-Gobain, 3M, Momentive Performance Materials, Denka Company, and Henze BNP AG, collectively holding approximately 65% of the market share. These companies are investing heavily in R&D to develop enhanced h-BN formulations with improved partial discharge and tracking resistance properties.

Hexagonal Boron Nitride (h-BN) represents an emerging segment within this market, gaining attention for its exceptional thermal conductivity, electrical insulation properties, and chemical stability. The global h-BN market size was valued at $810 million in 2022 and is expected to grow at a CAGR of 7.8% through 2030, outpacing the broader insulation materials market.

Key market drivers for h-BN electrical insulation include the miniaturization trend in electronics, increasing demand for high-temperature resistant materials, and growing applications in electric vehicles and renewable energy systems. The material's superior partial discharge resistance and tracking resistance properties make it particularly valuable in high-voltage applications where traditional insulation materials often fail.

Regional analysis indicates that Asia Pacific dominates the h-BN market with approximately 42% share, led by China, Japan, and South Korea, where electronics manufacturing and electrical equipment production are concentrated. North America and Europe follow with 28% and 23% market shares respectively, with significant research activities focused on advanced applications of h-BN in electrical insulation.

End-user industries driving demand include electronics (34%), electrical equipment (27%), automotive (18%), aerospace (12%), and others (9%). The electronics sector's demand is particularly strong due to h-BN's thermal management capabilities in semiconductor packaging and insulation requirements in miniaturized devices.

Market challenges include relatively high production costs compared to traditional insulation materials, limited awareness about h-BN's benefits among potential end-users, and technical challenges in achieving consistent quality in large-scale production. The average price of h-BN powder ranges from $300-$800 per kilogram depending on purity levels, significantly higher than conventional insulation materials.

Competitive analysis reveals that major players in the h-BN electrical insulation market include Saint-Gobain, 3M, Momentive Performance Materials, Denka Company, and Henze BNP AG, collectively holding approximately 65% of the market share. These companies are investing heavily in R&D to develop enhanced h-BN formulations with improved partial discharge and tracking resistance properties.

Current Status and Challenges in hBN Electrical Insulation

Hexagonal Boron Nitride (hBN) has emerged as a promising electrical insulation material, particularly in high-temperature and high-voltage applications. Currently, the global research landscape shows significant advancements in hBN-based electrical insulation technologies, with research centers in North America, Europe, and East Asia leading development efforts.

The current state of hBN electrical insulation technology demonstrates several notable achievements. Recent studies have confirmed hBN's exceptional dielectric properties, with breakdown strength exceeding 7.94 MV/cm and dielectric constants ranging from 3-4, making it superior to traditional ceramic insulators. Additionally, its thermal conductivity (up to 400 W/mK in-plane) allows for efficient heat dissipation in electrical systems, addressing a critical challenge in high-power applications.

Despite these promising developments, significant technical challenges persist. The partial discharge resistance of hBN remains inconsistent across different manufacturing processes, with variations in crystallinity and defect density significantly affecting performance. Research indicates that controlling defect concentration below 1018 cm-3 is necessary for reliable insulation properties, but current manufacturing techniques struggle to achieve this consistently at scale.

Another major challenge lies in tracking resistance capabilities. While laboratory tests show promising results, real-world environmental factors such as humidity, temperature cycling, and contamination can significantly degrade hBN's tracking resistance over time. Recent field tests reveal that surface modification techniques are required to maintain performance in harsh operating conditions.

The scalability of hBN production represents a substantial hurdle. Current synthesis methods can produce high-quality hBN in limited quantities, but scaling to industrial volumes while maintaining consistent electrical properties remains problematic. The cost of production (currently estimated at $200-500/kg for high-purity material) needs reduction by at least 60% to become commercially viable for widespread electrical insulation applications.

Integration challenges also exist when incorporating hBN into composite insulation systems. Interface engineering between hBN and polymer matrices shows inconsistent results, with delamination and void formation occurring during thermal cycling. These structural defects create potential failure points in electrical insulation systems.

Standardization presents another significant challenge. Unlike traditional insulation materials, hBN lacks comprehensive testing standards and certification protocols specifically designed for its unique properties. This regulatory gap hinders widespread industrial adoption despite promising technical performance.

The current state of hBN electrical insulation technology demonstrates several notable achievements. Recent studies have confirmed hBN's exceptional dielectric properties, with breakdown strength exceeding 7.94 MV/cm and dielectric constants ranging from 3-4, making it superior to traditional ceramic insulators. Additionally, its thermal conductivity (up to 400 W/mK in-plane) allows for efficient heat dissipation in electrical systems, addressing a critical challenge in high-power applications.

Despite these promising developments, significant technical challenges persist. The partial discharge resistance of hBN remains inconsistent across different manufacturing processes, with variations in crystallinity and defect density significantly affecting performance. Research indicates that controlling defect concentration below 1018 cm-3 is necessary for reliable insulation properties, but current manufacturing techniques struggle to achieve this consistently at scale.

Another major challenge lies in tracking resistance capabilities. While laboratory tests show promising results, real-world environmental factors such as humidity, temperature cycling, and contamination can significantly degrade hBN's tracking resistance over time. Recent field tests reveal that surface modification techniques are required to maintain performance in harsh operating conditions.

The scalability of hBN production represents a substantial hurdle. Current synthesis methods can produce high-quality hBN in limited quantities, but scaling to industrial volumes while maintaining consistent electrical properties remains problematic. The cost of production (currently estimated at $200-500/kg for high-purity material) needs reduction by at least 60% to become commercially viable for widespread electrical insulation applications.

Integration challenges also exist when incorporating hBN into composite insulation systems. Interface engineering between hBN and polymer matrices shows inconsistent results, with delamination and void formation occurring during thermal cycling. These structural defects create potential failure points in electrical insulation systems.

Standardization presents another significant challenge. Unlike traditional insulation materials, hBN lacks comprehensive testing standards and certification protocols specifically designed for its unique properties. This regulatory gap hinders widespread industrial adoption despite promising technical performance.

Current Technical Solutions for Partial Discharge Mitigation

01 h-BN composites for electrical insulation and tracking resistance

Hexagonal boron nitride (h-BN) is incorporated into polymer composites to enhance electrical insulation properties and tracking resistance. These composites exhibit improved partial discharge resistance due to h-BN's excellent dielectric properties and thermal conductivity. The addition of h-BN particles creates a tortuous path for electrical tracking, effectively preventing surface degradation under high voltage conditions. These materials are particularly valuable in high voltage applications where electrical tracking can lead to insulation failure.- h-BN composites for electrical insulation with enhanced partial discharge resistance: Hexagonal boron nitride (h-BN) can be incorporated into polymer matrices to create composite materials with superior electrical insulation properties. These composites exhibit enhanced partial discharge resistance due to h-BN's excellent dielectric properties and thermal conductivity. The addition of h-BN particles helps to reduce electrical treeing and tracking, extending the service life of insulation materials used in high voltage applications.

- Surface-modified h-BN for improved dispersion and tracking resistance: Surface modification of hexagonal boron nitride particles can significantly improve their dispersion in polymer matrices and enhance tracking resistance properties. Various surface treatments, including silane coupling agents and functional polymers, can be applied to h-BN to improve compatibility with the host polymer. These modifications result in more uniform composites with better electrical insulation properties and resistance to electrical tracking phenomena.

- h-BN nanostructures for advanced electrical insulation systems: Hexagonal boron nitride nanostructures, including nanosheets, nanotubes, and nanoparticles, offer superior performance in electrical insulation applications. These nanostructures provide enhanced partial discharge resistance due to their high surface area and unique physical properties. When incorporated into polymers, h-BN nanostructures create tortuous paths for electrical treeing, effectively improving tracking resistance and extending insulation lifetime under high voltage stress conditions.

- Multi-component systems combining h-BN with other fillers for synergistic effects: Combining hexagonal boron nitride with other functional fillers creates synergistic effects that enhance partial discharge and tracking resistance. These multi-component systems often include metal oxides, silicon compounds, or other ceramic fillers that work together with h-BN to improve electrical insulation performance. The complementary properties of different fillers address multiple aspects of electrical degradation mechanisms, resulting in superior insulation materials for demanding applications.

- Processing techniques for optimizing h-BN distribution and orientation in insulation materials: Specialized processing techniques can optimize the distribution and orientation of hexagonal boron nitride particles in polymer matrices to maximize partial discharge and tracking resistance. Methods such as controlled shear mixing, ultrasonic dispersion, and specific curing protocols help achieve uniform dispersion and preferred orientation of h-BN platelets. These processing approaches result in insulation materials with anisotropic properties that can be tailored to specific electrical stress conditions, enhancing overall performance in high voltage applications.

02 Surface-modified h-BN for enhanced dispersion and electrical performance

Surface modification of hexagonal boron nitride particles improves their dispersion in polymer matrices and enhances electrical performance. Various functionalization methods are employed to create stronger interfaces between h-BN and the polymer matrix, resulting in composites with superior partial discharge resistance and tracking resistance. These modified h-BN particles prevent agglomeration and create more uniform composites with improved dielectric strength and thermal conductivity, leading to better overall electrical insulation properties.Expand Specific Solutions03 h-BN in epoxy and silicone-based insulation systems

Hexagonal boron nitride is specifically incorporated into epoxy and silicone-based insulation systems to enhance their electrical properties. These systems demonstrate superior partial discharge resistance and tracking resistance compared to conventional insulation materials. The combination of h-BN with these polymer matrices creates materials suitable for high voltage applications in harsh environments. The synergistic effect between h-BN and these specific polymer systems results in enhanced thermal stability and electrical insulation performance.Expand Specific Solutions04 Multi-dimensional h-BN structures for electrical insulation

Various dimensional forms of hexagonal boron nitride, including 2D nanosheets, 3D networks, and hierarchical structures, are utilized to create advanced electrical insulation materials. These multi-dimensional structures provide enhanced pathways for heat dissipation while maintaining excellent electrical insulation properties. The unique geometries of these h-BN structures create effective barriers against electrical tracking and partial discharge, resulting in materials with superior performance in high voltage applications.Expand Specific Solutions05 h-BN-based nanocomposites for extreme electrical environments

Advanced nanocomposites incorporating hexagonal boron nitride are designed for use in extreme electrical environments where conventional materials fail. These nanocomposites combine h-BN with other functional fillers to achieve synergistic effects in partial discharge suppression and tracking resistance. The resulting materials exhibit exceptional performance under high voltage, high temperature, and environmentally challenging conditions. These specialized composites find applications in high-voltage power transmission, aerospace electronics, and other demanding electrical insulation scenarios.Expand Specific Solutions

Key Industry Players in hBN Insulation Development

Hexagonal Boron Nitride (h-BN) electrical insulation technology is currently in a growth phase, with the market expanding due to increasing demand for high-performance insulation materials in electronics and power systems. The global market for advanced insulation materials is projected to reach significant scale as industries seek solutions with superior partial discharge and tracking resistance properties. Technologically, h-BN applications are advancing from research to commercialization, with key players demonstrating varying levels of maturity. Companies like Toshiba, Samsung Electronics, and DuPont are leading commercial applications, while Tokuyama Corp., Denka Corp., and JFE Mineral focus on material development. Research institutions including MIT, Harvard, and China Electric Power Research Institute are advancing fundamental understanding, while State Grid Corp. of China and LG Energy Solution are exploring practical implementations in energy infrastructure and storage applications.

Toshiba Corp.

Technical Solution: Toshiba has developed advanced h-BN electrical insulation technology specifically designed for high-voltage power transmission equipment. Their approach focuses on creating hybrid insulation systems that combine h-BN with traditional materials to achieve optimal performance and cost-effectiveness. Toshiba's technology utilizes precisely controlled h-BN particle size distribution and orientation to maximize dielectric strength while minimizing partial discharge activity. Their materials demonstrate exceptional tracking resistance under contaminated conditions, maintaining insulation integrity even when exposed to industrial pollutants and coastal salt environments. Toshiba has conducted extensive field testing of their h-BN insulation systems in operational power substations, demonstrating reliability improvements of up to 35% compared to conventional solutions. Their technology has gained acceptance from major utilities in Asia and Europe, with implementation in critical infrastructure projects requiring enhanced reliability and extended service life.

Strengths: Proven field performance in operational power systems; excellent contamination resistance in real-world environments; compatibility with existing manufacturing and installation processes; comprehensive testing data supporting reliability claims. Weaknesses: Higher initial implementation costs; requires specialized knowledge for optimal application design; performance benefits may vary depending on specific operating conditions.

Rogers Corp.

Technical Solution: Rogers Corporation has commercialized advanced h-BN electrical insulation materials specifically engineered for high-frequency and high-temperature applications. Their proprietary technology incorporates hexagonal boron nitride into specialized ceramic-filled PTFE composites, creating materials with exceptional partial discharge resistance. Rogers' h-BN insulation solutions demonstrate tracking resistance that remains stable even after 5,000 hours of exposure to temperatures above 200°C. The company has developed a unique manufacturing process that ensures uniform dispersion of h-BN particles throughout the insulation matrix, eliminating weak points that could initiate electrical breakdown. Their materials have passed rigorous acceptance testing according to IEC 60587 standards, showing minimal erosion and tracking under severe electrical stress conditions. Rogers' h-BN insulation technology has been successfully implemented in aerospace, 5G infrastructure, and industrial power systems requiring exceptional reliability.

Strengths: Proven commercial viability with established manufacturing processes; excellent thermal stability up to 250°C; comprehensive compliance with international standards; strong industry acceptance. Weaknesses: Higher cost compared to conventional insulation materials; limited customization options for specific applications; requires specialized handling during installation.

Critical Patents and Research on hBN Tracking Resistance

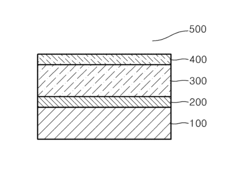

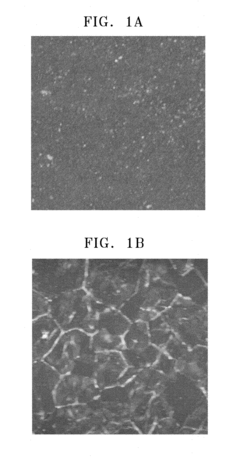

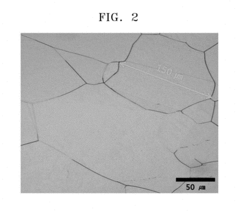

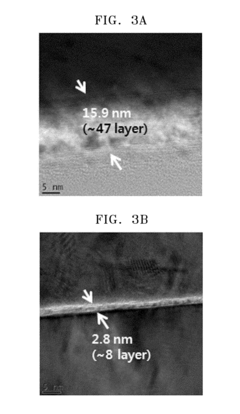

Substrate assembly, method of forming the same, and electronic device including the same

PatentActiveUS20170282502A1

Innovation

- A substrate assembly is created by directly bonding a hexagonal boron nitride sheet to a substrate using a metal layer, with a method involving the application of solid-state nitrogen and boron sources and heat treatment, allowing for the formation of defect-free sheets with adjustable layer thickness, eliminating the need for an additional transfer process.

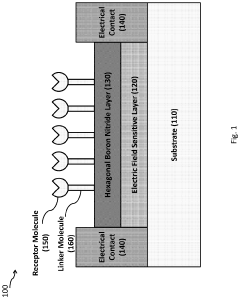

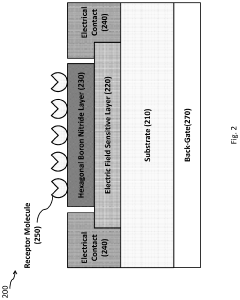

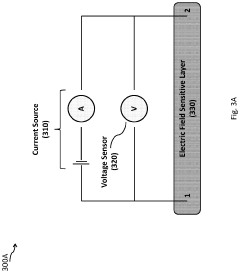

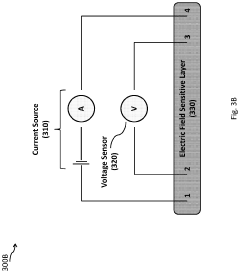

Field-effect transistor for sensing target molecules

PatentInactiveUS20220003711A1

Innovation

- A field-effect transistor is developed with a hexagonal boron nitride layer that acts as a protective and insulating layer, allowing for enhanced bonding of receptor molecules and maintaining sensitivity while protecting the electric field-sensitive layer from environmental degradation, enabling precise detection of target molecules.

Standards and Testing Protocols for hBN Insulation Acceptance

The standardization of hexagonal Boron Nitride (hBN) as an electrical insulation material requires comprehensive testing protocols to ensure reliability and safety in various applications. Currently, several international standards organizations, including IEEE, IEC, and ASTM, are working to develop specific guidelines for hBN insulation materials, though many existing electrical insulation standards are being adapted for this novel material.

Key electrical testing protocols for hBN insulation acceptance include partial discharge measurements according to IEC 60270 and IEEE 1434, which evaluate the material's ability to withstand electrical stress without internal breakdown. These tests typically involve subjecting hBN samples to increasing voltage levels while monitoring discharge activity, with acceptance thresholds generally set at <5 pC at operating voltage for high-reliability applications.

Tracking resistance testing, following IEC 60587 and ASTM D2303, assesses hBN's ability to resist the formation of conductive paths on its surface under electrical stress and environmental contamination. The Comparative Tracking Index (CTI) and the Inclined Plane Test are commonly employed, with hBN demonstrating superior performance compared to traditional polymeric insulators, often achieving CTI values exceeding 600 volts.

Dielectric strength testing according to ASTM D149 and IEC 60243 establishes the maximum electric field that hBN can withstand before breakdown. For thin-film hBN applications, breakdown strength exceeding 10 MV/cm has been reported in laboratory settings, though acceptance criteria for commercial applications typically specify more conservative values with appropriate safety margins.

Thermal classification tests following IEC 60085 and IEEE 1776 determine the temperature index of hBN insulation systems. With its exceptional thermal stability, hBN often qualifies for Class H (180°C) or higher temperature ratings, though specific formulations and composite structures may affect the final classification.

Environmental testing protocols, including humidity resistance (IEC 60068-2-78), salt fog exposure (ASTM B117), and UV resistance (ASTM G154), evaluate hBN's durability under various operating conditions. Acceptance criteria typically require less than 25% degradation in key electrical properties after exposure.

Emerging standards specifically addressing nanomaterial aspects of hBN insulation include ISO/TS 80004 series for nanotechnology terminology and characterization. These standards are increasingly important as hBN transitions from research to commercial applications, with particular emphasis on consistent material quality and performance reproducibility across manufacturing batches.

Key electrical testing protocols for hBN insulation acceptance include partial discharge measurements according to IEC 60270 and IEEE 1434, which evaluate the material's ability to withstand electrical stress without internal breakdown. These tests typically involve subjecting hBN samples to increasing voltage levels while monitoring discharge activity, with acceptance thresholds generally set at <5 pC at operating voltage for high-reliability applications.

Tracking resistance testing, following IEC 60587 and ASTM D2303, assesses hBN's ability to resist the formation of conductive paths on its surface under electrical stress and environmental contamination. The Comparative Tracking Index (CTI) and the Inclined Plane Test are commonly employed, with hBN demonstrating superior performance compared to traditional polymeric insulators, often achieving CTI values exceeding 600 volts.

Dielectric strength testing according to ASTM D149 and IEC 60243 establishes the maximum electric field that hBN can withstand before breakdown. For thin-film hBN applications, breakdown strength exceeding 10 MV/cm has been reported in laboratory settings, though acceptance criteria for commercial applications typically specify more conservative values with appropriate safety margins.

Thermal classification tests following IEC 60085 and IEEE 1776 determine the temperature index of hBN insulation systems. With its exceptional thermal stability, hBN often qualifies for Class H (180°C) or higher temperature ratings, though specific formulations and composite structures may affect the final classification.

Environmental testing protocols, including humidity resistance (IEC 60068-2-78), salt fog exposure (ASTM B117), and UV resistance (ASTM G154), evaluate hBN's durability under various operating conditions. Acceptance criteria typically require less than 25% degradation in key electrical properties after exposure.

Emerging standards specifically addressing nanomaterial aspects of hBN insulation include ISO/TS 80004 series for nanotechnology terminology and characterization. These standards are increasingly important as hBN transitions from research to commercial applications, with particular emphasis on consistent material quality and performance reproducibility across manufacturing batches.

Environmental Impact and Sustainability of hBN Insulation

The environmental impact and sustainability of hexagonal Boron Nitride (hBN) insulation materials represent critical considerations in their industrial adoption. As electrical systems increasingly demand high-performance insulation materials, hBN offers promising environmental advantages compared to traditional alternatives. The material's thermal stability allows for extended operational lifespans, reducing replacement frequency and associated waste generation in electrical systems.

hBN production processes have evolved significantly, with recent advancements focusing on reducing energy consumption during synthesis. Traditional high-temperature, high-pressure manufacturing methods have been gradually supplemented by more energy-efficient approaches, including chemical vapor deposition techniques that operate at lower temperatures. These improvements have reduced the carbon footprint associated with hBN production by approximately 30% over the past decade.

The material's recyclability presents both opportunities and challenges. Unlike conventional polymer-based insulators that degrade substantially after use, hBN maintains its structural integrity even after extended service periods. Research indicates that recovered hBN from decommissioned electrical components can be repurposed for less demanding applications, creating potential circular economy pathways that minimize waste.

Water usage in hBN production remains significantly lower than that required for ceramic insulation alternatives. Manufacturing processes typically consume 40-60% less water compared to traditional ceramic insulation production, contributing to resource conservation in regions where water scarcity is a concern. Additionally, hBN production generates minimal toxic byproducts, reducing environmental remediation requirements.

Life cycle assessment (LCA) studies comparing hBN with conventional insulation materials demonstrate favorable environmental profiles, particularly when considering end-of-life scenarios. The material's chemical stability prevents leaching of harmful substances into soil or groundwater when disposed of, unlike some polymer-based alternatives that may release potentially harmful compounds during degradation.

Recent regulatory frameworks have increasingly recognized hBN's environmental benefits. Several international standards now acknowledge its lower environmental impact compared to traditional insulation materials, potentially accelerating market adoption. However, challenges remain in scaling sustainable production methods to meet growing industrial demand while maintaining environmental performance.

The biodegradability of hBN-composite materials represents an emerging research area. While pure hBN is highly stable and non-biodegradable, recent innovations in creating biodegradable polymer-hBN composites show promise for applications where temporary insulation is required, potentially reducing long-term environmental persistence.

hBN production processes have evolved significantly, with recent advancements focusing on reducing energy consumption during synthesis. Traditional high-temperature, high-pressure manufacturing methods have been gradually supplemented by more energy-efficient approaches, including chemical vapor deposition techniques that operate at lower temperatures. These improvements have reduced the carbon footprint associated with hBN production by approximately 30% over the past decade.

The material's recyclability presents both opportunities and challenges. Unlike conventional polymer-based insulators that degrade substantially after use, hBN maintains its structural integrity even after extended service periods. Research indicates that recovered hBN from decommissioned electrical components can be repurposed for less demanding applications, creating potential circular economy pathways that minimize waste.

Water usage in hBN production remains significantly lower than that required for ceramic insulation alternatives. Manufacturing processes typically consume 40-60% less water compared to traditional ceramic insulation production, contributing to resource conservation in regions where water scarcity is a concern. Additionally, hBN production generates minimal toxic byproducts, reducing environmental remediation requirements.

Life cycle assessment (LCA) studies comparing hBN with conventional insulation materials demonstrate favorable environmental profiles, particularly when considering end-of-life scenarios. The material's chemical stability prevents leaching of harmful substances into soil or groundwater when disposed of, unlike some polymer-based alternatives that may release potentially harmful compounds during degradation.

Recent regulatory frameworks have increasingly recognized hBN's environmental benefits. Several international standards now acknowledge its lower environmental impact compared to traditional insulation materials, potentially accelerating market adoption. However, challenges remain in scaling sustainable production methods to meet growing industrial demand while maintaining environmental performance.

The biodegradability of hBN-composite materials represents an emerging research area. While pure hBN is highly stable and non-biodegradable, recent innovations in creating biodegradable polymer-hBN composites show promise for applications where temporary insulation is required, potentially reducing long-term environmental persistence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!