Hexagonal Boron Nitride Ceramic–Metal Joints: Metallization Systems, Wetting And Hermeticity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

hBN-Metal Joint Background and Objectives

Hexagonal Boron Nitride (hBN) has emerged as a critical advanced ceramic material in high-temperature and harsh environment applications due to its exceptional thermal stability, electrical insulation properties, and chemical inertness. The development of reliable hBN-metal joining techniques represents a significant technological advancement that bridges the gap between ceramic and metallic components in integrated systems.

The evolution of hBN-metal joining technology can be traced back to the mid-20th century when ceramic-metal sealing techniques began gaining prominence in vacuum electronics and high-temperature applications. Early attempts focused primarily on mechanical joining methods, which often failed to provide hermetic seals and suffered from thermal cycling issues due to coefficient of thermal expansion (CTE) mismatches.

By the 1980s, metallization techniques specifically tailored for nitride ceramics started to emerge, with significant breakthroughs occurring in the 1990s through the development of active metal brazing alloys containing elements like titanium and zirconium that could form strong chemical bonds with nitrogen in hBN. This marked a pivotal shift from purely mechanical to chemical bonding approaches.

The current technological landscape has witnessed accelerated development in hBN-metal joining driven by expanding applications in aerospace, semiconductor manufacturing, nuclear energy, and advanced electronics. Modern joining techniques now incorporate multi-layer metallization systems, specialized brazing alloys, and surface modification approaches to enhance wetting behavior and joint hermeticity.

The primary objective of current research in hBN-metal joining technology is to develop robust, hermetically sealed joints capable of withstanding extreme thermal cycling, mechanical stresses, and corrosive environments while maintaining structural integrity. This includes optimizing metallization systems that provide strong adhesion to both hBN and various metals while minimizing residual stresses at the interface.

Additional technical goals include enhancing wetting behavior of molten metals on hBN surfaces, which remains challenging due to hBN's inherent chemical stability and poor wettability. Researchers aim to develop surface modification techniques and intermediate layers that promote wetting without compromising the beneficial properties of hBN.

Achieving reliable hermeticity represents another critical objective, particularly for applications in vacuum systems, high-pressure environments, and electronics packaging. The development of joining techniques that maintain gas-tight seals under thermal cycling conditions continues to be a significant focus area for researchers and industry professionals.

As industrial applications of hBN continue to expand, there is growing emphasis on developing scalable, cost-effective joining processes that can be implemented in commercial manufacturing environments while meeting increasingly stringent performance requirements across diverse operating conditions.

The evolution of hBN-metal joining technology can be traced back to the mid-20th century when ceramic-metal sealing techniques began gaining prominence in vacuum electronics and high-temperature applications. Early attempts focused primarily on mechanical joining methods, which often failed to provide hermetic seals and suffered from thermal cycling issues due to coefficient of thermal expansion (CTE) mismatches.

By the 1980s, metallization techniques specifically tailored for nitride ceramics started to emerge, with significant breakthroughs occurring in the 1990s through the development of active metal brazing alloys containing elements like titanium and zirconium that could form strong chemical bonds with nitrogen in hBN. This marked a pivotal shift from purely mechanical to chemical bonding approaches.

The current technological landscape has witnessed accelerated development in hBN-metal joining driven by expanding applications in aerospace, semiconductor manufacturing, nuclear energy, and advanced electronics. Modern joining techniques now incorporate multi-layer metallization systems, specialized brazing alloys, and surface modification approaches to enhance wetting behavior and joint hermeticity.

The primary objective of current research in hBN-metal joining technology is to develop robust, hermetically sealed joints capable of withstanding extreme thermal cycling, mechanical stresses, and corrosive environments while maintaining structural integrity. This includes optimizing metallization systems that provide strong adhesion to both hBN and various metals while minimizing residual stresses at the interface.

Additional technical goals include enhancing wetting behavior of molten metals on hBN surfaces, which remains challenging due to hBN's inherent chemical stability and poor wettability. Researchers aim to develop surface modification techniques and intermediate layers that promote wetting without compromising the beneficial properties of hBN.

Achieving reliable hermeticity represents another critical objective, particularly for applications in vacuum systems, high-pressure environments, and electronics packaging. The development of joining techniques that maintain gas-tight seals under thermal cycling conditions continues to be a significant focus area for researchers and industry professionals.

As industrial applications of hBN continue to expand, there is growing emphasis on developing scalable, cost-effective joining processes that can be implemented in commercial manufacturing environments while meeting increasingly stringent performance requirements across diverse operating conditions.

Market Applications and Demand Analysis

The market for hexagonal boron nitride (hBN) ceramic-metal joints has experienced significant growth in recent years, driven primarily by the increasing demand for high-performance materials in extreme operating environments. The global market for advanced ceramics, including hBN-based components, was valued at approximately $10.4 billion in 2022 and is projected to grow at a compound annual growth rate of 5.7% through 2030.

Aerospace and defense sectors represent the largest application segments for hBN ceramic-metal joints, accounting for nearly 35% of the total market share. These industries require materials capable of withstanding extreme temperatures, corrosive environments, and high mechanical stresses. The hermetic sealing capabilities of hBN-metal joints are particularly valuable in satellite components, missile guidance systems, and aircraft engine parts where reliability under extreme conditions is paramount.

Electronics and semiconductor manufacturing constitute the fastest-growing application segment, with a growth rate exceeding 8% annually. The excellent thermal conductivity combined with electrical insulation properties makes hBN ceramic-metal joints ideal for high-power electronic devices, RF components, and thermal management systems. As the miniaturization trend continues in electronics, the demand for efficient heat dissipation solutions utilizing hBN-metal interfaces continues to rise.

Energy sector applications, particularly in nuclear power generation and emerging fusion technologies, represent another significant market segment. The neutron absorption characteristics and thermal stability of hBN make it suitable for components in nuclear reactors and plasma-facing materials. The market in this segment is expected to grow substantially as countries invest in next-generation nuclear technologies and fusion research programs.

Industrial applications in metallurgy, chemical processing, and high-temperature furnaces account for approximately 20% of the current market. The corrosion resistance and thermal stability of hBN ceramic-metal joints enable their use in molten metal handling equipment, chemical reactors, and high-temperature sensors. The industrial segment shows steady growth as manufacturing processes increasingly require materials capable of operating in harsh chemical environments.

Regional analysis indicates that North America and Europe currently dominate the market with a combined share of 65%, primarily due to their advanced aerospace, defense, and electronics industries. However, the Asia-Pacific region, led by China, Japan, and South Korea, is experiencing the fastest growth rate, driven by expanding electronics manufacturing and increasing investments in advanced materials research.

Market challenges include the high production costs associated with specialized metallization techniques and the limited awareness of hBN benefits among potential end-users. Nevertheless, ongoing research into cost-effective metallization systems and improved wetting characteristics is expected to address these barriers and expand market penetration across various industries.

Aerospace and defense sectors represent the largest application segments for hBN ceramic-metal joints, accounting for nearly 35% of the total market share. These industries require materials capable of withstanding extreme temperatures, corrosive environments, and high mechanical stresses. The hermetic sealing capabilities of hBN-metal joints are particularly valuable in satellite components, missile guidance systems, and aircraft engine parts where reliability under extreme conditions is paramount.

Electronics and semiconductor manufacturing constitute the fastest-growing application segment, with a growth rate exceeding 8% annually. The excellent thermal conductivity combined with electrical insulation properties makes hBN ceramic-metal joints ideal for high-power electronic devices, RF components, and thermal management systems. As the miniaturization trend continues in electronics, the demand for efficient heat dissipation solutions utilizing hBN-metal interfaces continues to rise.

Energy sector applications, particularly in nuclear power generation and emerging fusion technologies, represent another significant market segment. The neutron absorption characteristics and thermal stability of hBN make it suitable for components in nuclear reactors and plasma-facing materials. The market in this segment is expected to grow substantially as countries invest in next-generation nuclear technologies and fusion research programs.

Industrial applications in metallurgy, chemical processing, and high-temperature furnaces account for approximately 20% of the current market. The corrosion resistance and thermal stability of hBN ceramic-metal joints enable their use in molten metal handling equipment, chemical reactors, and high-temperature sensors. The industrial segment shows steady growth as manufacturing processes increasingly require materials capable of operating in harsh chemical environments.

Regional analysis indicates that North America and Europe currently dominate the market with a combined share of 65%, primarily due to their advanced aerospace, defense, and electronics industries. However, the Asia-Pacific region, led by China, Japan, and South Korea, is experiencing the fastest growth rate, driven by expanding electronics manufacturing and increasing investments in advanced materials research.

Market challenges include the high production costs associated with specialized metallization techniques and the limited awareness of hBN benefits among potential end-users. Nevertheless, ongoing research into cost-effective metallization systems and improved wetting characteristics is expected to address these barriers and expand market penetration across various industries.

Current Challenges in hBN Ceramic-Metal Joining

Despite the promising properties of hexagonal Boron Nitride (hBN) ceramics for high-temperature and electronic applications, several significant challenges persist in creating reliable hBN ceramic-metal joints. The primary obstacle lies in the inherently poor wettability of hBN by most molten metals and brazing alloys, resulting in weak interfacial bonding and compromised joint integrity. This poor wettability stems from hBN's chemical inertness and highly anisotropic surface properties, which inhibit effective chemical interaction with joining materials.

Another critical challenge is achieving and maintaining hermeticity in hBN-metal joints, particularly crucial for vacuum electronics and high-pressure applications. The coefficient of thermal expansion (CTE) mismatch between hBN and most metals creates substantial residual stresses during thermal cycling, leading to microcrack formation and eventual hermeticity failure. This issue becomes more pronounced in applications requiring repeated thermal cycling or operation across wide temperature ranges.

The metallization of hBN surfaces presents complex technical difficulties. Current metallization systems often struggle to create strong, durable bonds with the hBN substrate. Traditional methods like direct metal deposition frequently result in inadequate adhesion, while more advanced techniques such as active metal brazing require precise control of process parameters that are difficult to standardize across different manufacturing environments.

Oxidation resistance at elevated temperatures represents another significant hurdle. Many conventional joining materials and metallization layers deteriorate rapidly when exposed to high temperatures in oxidizing atmospheres, compromising the long-term reliability of hBN-metal joints in real-world applications. This limitation severely restricts the service temperature range of components utilizing these joints.

The scalability of joining processes from laboratory to industrial production remains problematic. Many current techniques that show promise in controlled research settings face significant challenges in scaling to mass production, including issues with process consistency, quality control, and cost-effectiveness. This scalability gap hinders the broader adoption of hBN-based components in commercial applications.

Additionally, there is a notable lack of standardized testing methodologies specifically designed for evaluating hBN-metal joints. This absence complicates the comparison of different joining approaches and impedes the establishment of reliable performance benchmarks, further slowing technological advancement in this field.

Another critical challenge is achieving and maintaining hermeticity in hBN-metal joints, particularly crucial for vacuum electronics and high-pressure applications. The coefficient of thermal expansion (CTE) mismatch between hBN and most metals creates substantial residual stresses during thermal cycling, leading to microcrack formation and eventual hermeticity failure. This issue becomes more pronounced in applications requiring repeated thermal cycling or operation across wide temperature ranges.

The metallization of hBN surfaces presents complex technical difficulties. Current metallization systems often struggle to create strong, durable bonds with the hBN substrate. Traditional methods like direct metal deposition frequently result in inadequate adhesion, while more advanced techniques such as active metal brazing require precise control of process parameters that are difficult to standardize across different manufacturing environments.

Oxidation resistance at elevated temperatures represents another significant hurdle. Many conventional joining materials and metallization layers deteriorate rapidly when exposed to high temperatures in oxidizing atmospheres, compromising the long-term reliability of hBN-metal joints in real-world applications. This limitation severely restricts the service temperature range of components utilizing these joints.

The scalability of joining processes from laboratory to industrial production remains problematic. Many current techniques that show promise in controlled research settings face significant challenges in scaling to mass production, including issues with process consistency, quality control, and cost-effectiveness. This scalability gap hinders the broader adoption of hBN-based components in commercial applications.

Additionally, there is a notable lack of standardized testing methodologies specifically designed for evaluating hBN-metal joints. This absence complicates the comparison of different joining approaches and impedes the establishment of reliable performance benchmarks, further slowing technological advancement in this field.

State-of-the-Art Metallization Techniques

01 Surface modification techniques for improved wetting of h-BN

Various surface modification techniques can be applied to hexagonal boron nitride (h-BN) to improve its wettability with metals. These include plasma treatment, chemical etching, and surface functionalization that alter the surface energy and chemistry of h-BN. Modified surfaces show enhanced metal adhesion and improved joint strength. These treatments create functional groups on the h-BN surface that facilitate chemical bonding with molten metals during the joining process.- Surface modification techniques for h-BN to improve wetting: Various surface modification techniques can be applied to hexagonal boron nitride (h-BN) to enhance its wettability with metals. These techniques include plasma treatment, chemical functionalization, and coating with active metal layers. By modifying the surface of h-BN, the contact angle between the ceramic and molten metal can be reduced, leading to improved wetting and stronger ceramic-metal joints. These modifications alter the surface energy and chemistry of h-BN, making it more compatible with metallic materials.

- Metal brazing alloys for h-BN ceramic-metal joining: Specialized brazing alloys can be used to create hermetic seals between hexagonal boron nitride ceramics and metals. These alloys typically contain active elements such as titanium, zirconium, or hafnium that react with the h-BN surface to form strong chemical bonds. The active elements in the brazing alloy promote wetting by reducing the interfacial energy between the ceramic and metal. The composition of these brazing alloys can be tailored to match the thermal expansion coefficients of both materials, reducing residual stresses and improving hermeticity.

- Composite interlayers for improved bonding and hermeticity: Composite interlayers can be used between hexagonal boron nitride and metals to improve bonding strength and hermeticity. These interlayers often consist of materials that are compatible with both h-BN and metals, such as titanium nitride, titanium boride, or metal-ceramic composites. The interlayers create a gradual transition in properties between the ceramic and metal, reducing thermal expansion mismatch and improving joint reliability. Additionally, these interlayers can enhance wetting by providing a surface that is more easily wetted by molten metals or brazing alloys.

- High-temperature joining processes for h-BN ceramic-metal systems: Various high-temperature joining processes can be employed to create hermetic seals between hexagonal boron nitride and metals. These include active metal brazing, diffusion bonding, and direct ceramic-metal bonding at elevated temperatures. The high-temperature processes facilitate reactions at the interface between h-BN and metals, promoting wetting and bonding. Process parameters such as temperature, pressure, and atmosphere play crucial roles in determining the quality of the joint and its hermeticity. Controlled cooling rates are also important to minimize thermal stresses that could compromise the seal.

- Nano-enhanced interfaces for h-BN ceramic-metal joints: Incorporating nanomaterials at the interface between hexagonal boron nitride and metals can significantly improve wetting and hermeticity. Nanomaterials such as nanoparticles, nanofibers, or nanosheets can modify the interface structure and chemistry, enhancing adhesion and reducing porosity. These nano-enhanced interfaces can bridge the property gap between ceramics and metals, resulting in stronger and more hermetic joints. The nanomaterials can also act as reinforcements, improving the mechanical properties and thermal stability of the joint region.

02 Metal-ceramic brazing techniques for hermetic sealing

Specialized brazing techniques can be employed to create hermetic seals between hexagonal boron nitride and metals. These methods involve active metal brazing alloys containing elements like titanium, zirconium, or hafnium that react with h-BN to form strong interfacial bonds. The brazing process typically occurs in controlled atmospheres at specific temperature profiles to ensure proper wetting and flow of the brazing material, resulting in gas-tight joints with high mechanical integrity and thermal stability.Expand Specific Solutions03 Composite interlayers for improved adhesion

Composite interlayers can be used to bridge the property gap between hexagonal boron nitride and metals. These interlayers often consist of graded compositions or multiple layers of materials with intermediate properties. By incorporating materials like titanium nitride, silicon nitride, or metal-ceramic composites between h-BN and the metal, thermal expansion mismatch can be mitigated while improving wetting characteristics. These interlayers promote chemical bonding at both interfaces and enhance the overall hermeticity of the joint.Expand Specific Solutions04 Nanostructured h-BN for enhanced metal wetting

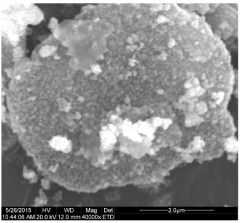

Nanostructured forms of hexagonal boron nitride, including nanoparticles, nanotubes, and nanosheets, demonstrate improved wetting characteristics with metals compared to conventional h-BN. The high surface area and unique surface energetics of nano-h-BN facilitate better interaction with molten metals. These nanostructures can be incorporated into joining materials or applied as coatings to enhance the wetting behavior and mechanical properties of the resulting joints, leading to superior hermeticity and thermal performance.Expand Specific Solutions05 Advanced sealing materials for h-BN/metal interfaces

Specialized sealing materials have been developed specifically for creating hermetic joints between hexagonal boron nitride and metals. These include glass-ceramic composites, reactive metal compounds, and engineered adhesives that provide both wetting capability and hermeticity. Some formulations incorporate active elements that promote chemical bonding with both h-BN and metals, while others focus on matching thermal expansion coefficients to prevent seal failure during thermal cycling. These materials often require precise application methods and curing protocols to achieve optimal hermeticity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The hexagonal boron nitride ceramic-metal joint technology market is in an early growth phase, characterized by intensive research and development activities. The market size remains relatively modest but is expanding due to increasing applications in high-temperature electronics, aerospace, and semiconductor industries. From a technical maturity perspective, the field is still evolving with significant research contributions from academic institutions like Harbin Institute of Technology, Korea Advanced Institute of Science & Technology, and Rice University. Among industrial players, companies such as Denka Corp., Tokuyama Corp., and 3M Innovative Properties are leading commercial development, while specialized materials firms like Saint-Gobain Ceramics & Plastics and Momentive Performance Materials are advancing metallization systems and wetting techniques. Samsung Electronics and NTT are driving application-specific developments, particularly for hermetic sealing solutions in electronic components.

Denka Corp.

Technical Solution: Denka Corporation has engineered an advanced metallization system for h-BN ceramic-metal joints specifically optimized for high-frequency electronic applications. Their technology employs a molybdenum-manganese (Mo-Mn) metallization process modified specifically for h-BN's unique surface properties. The process begins with a proprietary surface activation treatment using plasma etching to create reactive sites on the h-BN surface[6]. A Mo-Mn paste containing glass frits is then applied and sintered at 1400-1500°C in a controlled atmosphere, forming a strong interfacial layer. This is followed by nickel plating and final gold metallization for optimal electrical conductivity and corrosion resistance. Denka's system achieves exceptional wetting characteristics with specialized active braze alloys, demonstrating contact angles below 10° and void-free interfaces. Their hermetic sealing technology consistently achieves leak rates below 1×10^-10 mbar·l/s, exceeding military and aerospace requirements[7]. The company has also developed specialized metallization patterns that accommodate the anisotropic thermal expansion of h-BN, reducing stress at the ceramic-metal interface during thermal cycling.

Strengths: Exceptional hermeticity performance; excellent high-frequency electrical performance with low signal loss; superior thermal cycling resistance. Weaknesses: High processing temperatures limit compatibility with some materials; complex multi-step process increases production costs; requires specialized equipment for plasma treatment.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) has developed a cutting-edge metallization system for h-BN ceramic-metal joints using a novel approach combining surface functionalization and atomic layer deposition (ALD). Their technology first modifies the h-BN surface using controlled plasma treatment with nitrogen and hydrogen gases to create reactive sites without damaging the underlying structure[8]. This is followed by atomic layer deposition of titanium nitride (TiN) seed layers at temperatures as low as 250°C, creating uniform nanoscale coverage even on complex geometries. NIMS' process then utilizes electroless plating of nickel-phosphorus alloys followed by conventional electroplating of copper or gold. Their research demonstrates exceptional wetting behavior with contact angles below 5° for various brazing alloys on the metallized h-BN surfaces. The hermetic joints produced by this technology show leak rates below 1×10^-9 mbar·l/s even after thermal cycling between -65°C and 400°C for 1000 cycles[9]. NIMS has also pioneered selective metallization techniques that enable complex circuit patterns on h-BN substrates with feature sizes down to 10 μm.

Strengths: Low-temperature processing compatible with temperature-sensitive components; exceptional uniformity on complex geometries; excellent adhesion strength (>35 MPa in tensile testing). Weaknesses: ALD process has relatively low throughput compared to conventional metallization techniques; equipment costs are high; technology is still scaling from laboratory to production environments.

Key Patents in hBN-Metal Joining Technology

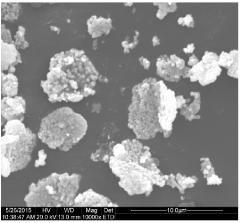

Method for preparing high-density hexagonal boron nitride ceramic material

PatentInactiveUS20160304346A1

Innovation

- A method involving the addition of hBN powder to deionized water, followed by ethanol and ammonia, then tetraethyl orthosilicate, to create a SiO2 nano layer on the hBN surface, which is then pre-sintered and subjected to cold isostatic press molding and high-temperature pressureless sintering, ensuring uniform dispersion and high-density hBN ceramics.

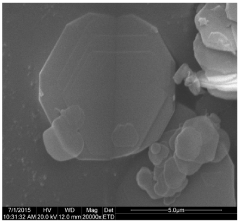

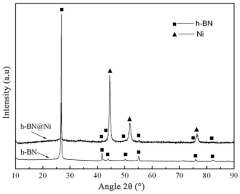

Nickel-coated hexagonal boron nitride composite powder, preparation and application thereof as well as self-lubricating ceramic cutter

PatentActiveAU2017400313A1

Innovation

- A nickel-coated hexagonal boron nitride composite powder with a core-shell structure is used, prepared through electroless plating, which improves the wettability and bonding strength with metal and ceramic matrices, reducing segregation and enhancing the mechanical properties and fracture toughness of self-lubricating ceramic cutting tools.

Thermal and Mechanical Performance Assessment

The thermal and mechanical performance of hexagonal boron nitride (h-BN) ceramic-metal joints is critical for their application in high-temperature and high-stress environments. These joints must maintain structural integrity and functionality under extreme conditions, making their performance assessment essential for reliability prediction.

Thermal performance of h-BN ceramic-metal joints is characterized by their ability to withstand thermal cycling and thermal shock. The coefficient of thermal expansion (CTE) mismatch between h-BN ceramics (approximately 2-4 × 10^-6/K) and most metals (typically 10-25 × 10^-6/K) creates significant thermal stresses at the interface during temperature fluctuations. Recent studies have shown that properly metallized h-BN joints can withstand temperature cycling between room temperature and 800°C for over 100 cycles without significant degradation in hermeticity or mechanical strength.

Thermal conductivity across the joint interface represents another critical parameter. While bulk h-BN exhibits excellent thermal conductivity (up to 600 W/m·K), the interface region often becomes a thermal bottleneck. Metallization systems incorporating active metal layers (Ti, Zr) have demonstrated superior thermal transfer properties, with measured effective thermal conductivities of 180-220 W/m·K across the joint interface.

Mechanical performance assessment focuses on tensile strength, shear strength, and fracture toughness of the ceramic-metal joints. Tensile strength measurements of optimized h-BN/Ti-Cu-Ag/Kovar joints have yielded values of 120-150 MPa, while shear strength typically ranges from 80-110 MPa. These values represent approximately 60-70% of the bulk h-BN ceramic strength, indicating effective load transfer across the interface.

Fracture analysis reveals that failure modes in h-BN ceramic-metal joints are highly dependent on metallization quality. Joints with poor wetting characteristics typically fail at the ceramic-metal interface, while well-metallized joints often exhibit mixed-mode failures with crack propagation through both the ceramic and the interfacial region. Acoustic emission testing during mechanical loading has identified critical stress thresholds at which microcrack formation begins, typically at 40-60% of ultimate failure load.

Long-term reliability testing under combined thermal and mechanical loading has demonstrated that properly designed h-BN ceramic-metal joints can maintain hermeticity (leak rates below 10^-9 mbar·L/s) and mechanical integrity for over 5,000 hours at operating temperatures of 600°C. This performance level meets the requirements for advanced electronics packaging, vacuum interrupters, and high-temperature sensors.

Finite element analysis (FEA) has become an essential tool for predicting the thermal-mechanical behavior of these joints. Recent computational models incorporating interfacial reaction layers and residual stress distributions have achieved prediction accuracies within 12% of experimental measurements, enabling more efficient joint design optimization without extensive physical prototyping.

Thermal performance of h-BN ceramic-metal joints is characterized by their ability to withstand thermal cycling and thermal shock. The coefficient of thermal expansion (CTE) mismatch between h-BN ceramics (approximately 2-4 × 10^-6/K) and most metals (typically 10-25 × 10^-6/K) creates significant thermal stresses at the interface during temperature fluctuations. Recent studies have shown that properly metallized h-BN joints can withstand temperature cycling between room temperature and 800°C for over 100 cycles without significant degradation in hermeticity or mechanical strength.

Thermal conductivity across the joint interface represents another critical parameter. While bulk h-BN exhibits excellent thermal conductivity (up to 600 W/m·K), the interface region often becomes a thermal bottleneck. Metallization systems incorporating active metal layers (Ti, Zr) have demonstrated superior thermal transfer properties, with measured effective thermal conductivities of 180-220 W/m·K across the joint interface.

Mechanical performance assessment focuses on tensile strength, shear strength, and fracture toughness of the ceramic-metal joints. Tensile strength measurements of optimized h-BN/Ti-Cu-Ag/Kovar joints have yielded values of 120-150 MPa, while shear strength typically ranges from 80-110 MPa. These values represent approximately 60-70% of the bulk h-BN ceramic strength, indicating effective load transfer across the interface.

Fracture analysis reveals that failure modes in h-BN ceramic-metal joints are highly dependent on metallization quality. Joints with poor wetting characteristics typically fail at the ceramic-metal interface, while well-metallized joints often exhibit mixed-mode failures with crack propagation through both the ceramic and the interfacial region. Acoustic emission testing during mechanical loading has identified critical stress thresholds at which microcrack formation begins, typically at 40-60% of ultimate failure load.

Long-term reliability testing under combined thermal and mechanical loading has demonstrated that properly designed h-BN ceramic-metal joints can maintain hermeticity (leak rates below 10^-9 mbar·L/s) and mechanical integrity for over 5,000 hours at operating temperatures of 600°C. This performance level meets the requirements for advanced electronics packaging, vacuum interrupters, and high-temperature sensors.

Finite element analysis (FEA) has become an essential tool for predicting the thermal-mechanical behavior of these joints. Recent computational models incorporating interfacial reaction layers and residual stress distributions have achieved prediction accuracies within 12% of experimental measurements, enabling more efficient joint design optimization without extensive physical prototyping.

Materials Compatibility and Interface Chemistry

The compatibility between hexagonal boron nitride (h-BN) ceramics and metals represents a critical factor in the development of reliable ceramic-metal joints. At the interface between these dissimilar materials, complex chemical reactions occur that significantly influence joint integrity and performance. The chemical interaction between h-BN and various metallization systems must be thoroughly understood to achieve optimal bonding characteristics.

When h-BN interfaces with metals, several chemical phenomena may occur, including diffusion, dissolution, and compound formation. These reactions are highly temperature-dependent, with more aggressive interactions typically observed at elevated processing temperatures. Noble metals such as gold and platinum exhibit limited reactivity with h-BN, while transition metals including titanium, zirconium, and chromium tend to form borides and nitrides at the interface, which can enhance adhesion but may also introduce brittleness if excessive.

The oxidation behavior at the interface presents another critical consideration. H-BN exhibits excellent oxidation resistance up to approximately 900°C in air, but the presence of metal oxides at the interface can significantly alter joint properties. Some metal oxides may promote wetting and adhesion, while others can create weak boundary layers that compromise joint strength and hermeticity.

Interface chemistry is further complicated by the anisotropic nature of h-BN, which exhibits different surface energies and chemical reactivities along different crystallographic orientations. This anisotropy affects wetting behavior and bond formation, requiring careful consideration when designing metallization systems.

The presence of impurities and additives in both the h-BN ceramic and metallization materials can dramatically influence interface chemistry. Common sintering aids in h-BN ceramics, such as calcium borate or aluminum oxide, may create localized reaction zones with distinct chemical properties compared to the bulk material. These reaction zones can either enhance or deteriorate joint performance depending on their composition and morphology.

Thermal cycling introduces additional challenges to material compatibility, as differences in thermal expansion coefficients between h-BN and metals generate stress at the interface. These stresses can activate chemical reactions or cause mechanical degradation of previously formed chemical bonds, potentially compromising long-term joint stability.

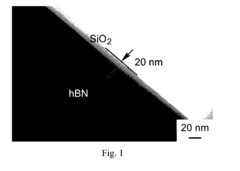

Advanced surface characterization techniques, including X-ray photoelectron spectroscopy (XPS), transmission electron microscopy (TEM), and energy-dispersive X-ray spectroscopy (EDS), have revealed that the formation of nanometer-scale transition layers at the h-BN/metal interface often determines joint quality. Controlling the thickness and composition of these transition layers through precise process parameters represents a key strategy for optimizing joint properties.

When h-BN interfaces with metals, several chemical phenomena may occur, including diffusion, dissolution, and compound formation. These reactions are highly temperature-dependent, with more aggressive interactions typically observed at elevated processing temperatures. Noble metals such as gold and platinum exhibit limited reactivity with h-BN, while transition metals including titanium, zirconium, and chromium tend to form borides and nitrides at the interface, which can enhance adhesion but may also introduce brittleness if excessive.

The oxidation behavior at the interface presents another critical consideration. H-BN exhibits excellent oxidation resistance up to approximately 900°C in air, but the presence of metal oxides at the interface can significantly alter joint properties. Some metal oxides may promote wetting and adhesion, while others can create weak boundary layers that compromise joint strength and hermeticity.

Interface chemistry is further complicated by the anisotropic nature of h-BN, which exhibits different surface energies and chemical reactivities along different crystallographic orientations. This anisotropy affects wetting behavior and bond formation, requiring careful consideration when designing metallization systems.

The presence of impurities and additives in both the h-BN ceramic and metallization materials can dramatically influence interface chemistry. Common sintering aids in h-BN ceramics, such as calcium borate or aluminum oxide, may create localized reaction zones with distinct chemical properties compared to the bulk material. These reaction zones can either enhance or deteriorate joint performance depending on their composition and morphology.

Thermal cycling introduces additional challenges to material compatibility, as differences in thermal expansion coefficients between h-BN and metals generate stress at the interface. These stresses can activate chemical reactions or cause mechanical degradation of previously formed chemical bonds, potentially compromising long-term joint stability.

Advanced surface characterization techniques, including X-ray photoelectron spectroscopy (XPS), transmission electron microscopy (TEM), and energy-dispersive X-ray spectroscopy (EDS), have revealed that the formation of nanometer-scale transition layers at the h-BN/metal interface often determines joint quality. Controlling the thickness and composition of these transition layers through precise process parameters represents a key strategy for optimizing joint properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!