Hexagonal Boron Nitride Composites: Filler Networks, Interfacial Adhesion And Thermal Cycling

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

hBN Composites Background and Development Goals

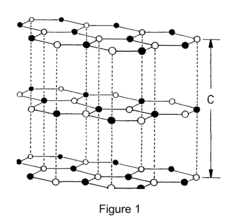

Hexagonal Boron Nitride (hBN) has emerged as a revolutionary material in the field of advanced composites over the past two decades. First discovered in the mid-20th century, hBN gained significant attention in the 2000s when researchers began exploring its potential as a thermal management material. The unique crystal structure of hBN, often referred to as "white graphite," provides exceptional thermal conductivity (up to 400 W/m·K in-plane) while maintaining electrical insulation properties, making it fundamentally different from other 2D materials like graphene.

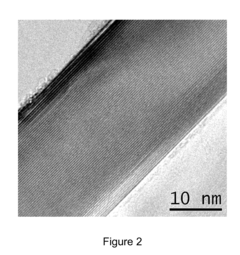

The evolution of hBN composites has progressed through several distinct phases. Initially, research focused on basic incorporation of hBN particles into polymer matrices, yielding modest improvements in thermal properties. The second phase, beginning around 2010, saw the development of exfoliation techniques to produce few-layer or single-layer hBN nanosheets, dramatically increasing the interfacial area between filler and matrix. The current phase emphasizes engineered filler networks and interface optimization to maximize thermal performance while addressing challenges in mechanical stability during thermal cycling.

Market drivers for hBN composite development include the exponential growth in power density of electronic devices, the miniaturization trend in electronics, and the increasing demand for efficient thermal management solutions in electric vehicles and 5G infrastructure. These applications require materials that can withstand repeated thermal cycling while maintaining structural integrity and thermal performance.

The primary technical goals for hBN composites development center around three interconnected challenges. First, creating optimized filler networks that maximize thermal conductivity while minimizing filler loading to preserve processability and mechanical properties. Second, enhancing interfacial adhesion between hBN and various matrix materials to prevent delamination during thermal cycling. Third, developing composites with thermal conductivity exceeding 10 W/m·K while maintaining flexibility and reliability through thousands of thermal cycles.

Long-term development goals include achieving anisotropic thermal conductivity for directional heat dissipation, developing manufacturing techniques suitable for mass production, and creating multi-functional composites that combine thermal management with additional properties such as EMI shielding or self-healing capabilities. The ultimate vision is to enable a new generation of thermal interface materials (TIMs) and thermally conductive adhesives that can meet the increasingly demanding requirements of next-generation electronics and power systems.

The evolution of hBN composites has progressed through several distinct phases. Initially, research focused on basic incorporation of hBN particles into polymer matrices, yielding modest improvements in thermal properties. The second phase, beginning around 2010, saw the development of exfoliation techniques to produce few-layer or single-layer hBN nanosheets, dramatically increasing the interfacial area between filler and matrix. The current phase emphasizes engineered filler networks and interface optimization to maximize thermal performance while addressing challenges in mechanical stability during thermal cycling.

Market drivers for hBN composite development include the exponential growth in power density of electronic devices, the miniaturization trend in electronics, and the increasing demand for efficient thermal management solutions in electric vehicles and 5G infrastructure. These applications require materials that can withstand repeated thermal cycling while maintaining structural integrity and thermal performance.

The primary technical goals for hBN composites development center around three interconnected challenges. First, creating optimized filler networks that maximize thermal conductivity while minimizing filler loading to preserve processability and mechanical properties. Second, enhancing interfacial adhesion between hBN and various matrix materials to prevent delamination during thermal cycling. Third, developing composites with thermal conductivity exceeding 10 W/m·K while maintaining flexibility and reliability through thousands of thermal cycles.

Long-term development goals include achieving anisotropic thermal conductivity for directional heat dissipation, developing manufacturing techniques suitable for mass production, and creating multi-functional composites that combine thermal management with additional properties such as EMI shielding or self-healing capabilities. The ultimate vision is to enable a new generation of thermal interface materials (TIMs) and thermally conductive adhesives that can meet the increasingly demanding requirements of next-generation electronics and power systems.

Market Analysis for Thermal Management Materials

The thermal management materials market has experienced significant growth in recent years, driven primarily by the increasing demand for efficient heat dissipation solutions across multiple industries. The global thermal management market was valued at approximately $11.7 billion in 2022 and is projected to reach $18.3 billion by 2027, growing at a CAGR of 9.4% during the forecast period. Within this broader market, hexagonal boron nitride (h-BN) composites represent a rapidly expanding segment due to their exceptional thermal conductivity properties.

Electronics and semiconductor industries currently dominate the demand for advanced thermal management materials, accounting for roughly 38% of the total market share. The miniaturization trend in electronic devices, coupled with increasing power densities, has created an urgent need for materials that can efficiently dissipate heat while maintaining electrical insulation properties—a combination where h-BN composites excel.

Automotive applications, particularly in electric vehicles (EVs), represent the fastest-growing segment for thermal management materials with a growth rate of 12.7% annually. The thermal cycling stability of h-BN composites makes them especially valuable in EV battery systems where temperature fluctuations can significantly impact performance and safety.

Regionally, Asia-Pacific leads the market with approximately 42% share, driven by the concentration of electronics manufacturing and rapid industrialization in countries like China, Japan, and South Korea. North America follows with 28% market share, with particular strength in aerospace and defense applications where thermal cycling resistance is critical.

Competition in the thermal management materials space has intensified, with major players including 3M, Henkel, Parker Chomerics, and Laird Technologies expanding their portfolios to include advanced composites. Specifically for h-BN composites, companies like Momentive Performance Materials, Saint-Gobain, and Denka Company have established strong market positions through proprietary filler network technologies and interface engineering solutions.

Price sensitivity varies significantly by application sector. While consumer electronics manufacturers remain highly cost-conscious, aerospace and defense sectors demonstrate willingness to pay premium prices for materials with superior thermal cycling resistance and reliability. The average price point for h-BN composite materials ranges from $80-150 per kilogram depending on purity levels and processing requirements.

Customer requirements are increasingly focused on multifunctional properties beyond thermal conductivity alone, including electrical insulation, mechanical strength, and environmental stability. This trend aligns well with h-BN composites' inherent property profile, particularly when engineered with optimized filler networks and interfacial adhesion.

Electronics and semiconductor industries currently dominate the demand for advanced thermal management materials, accounting for roughly 38% of the total market share. The miniaturization trend in electronic devices, coupled with increasing power densities, has created an urgent need for materials that can efficiently dissipate heat while maintaining electrical insulation properties—a combination where h-BN composites excel.

Automotive applications, particularly in electric vehicles (EVs), represent the fastest-growing segment for thermal management materials with a growth rate of 12.7% annually. The thermal cycling stability of h-BN composites makes them especially valuable in EV battery systems where temperature fluctuations can significantly impact performance and safety.

Regionally, Asia-Pacific leads the market with approximately 42% share, driven by the concentration of electronics manufacturing and rapid industrialization in countries like China, Japan, and South Korea. North America follows with 28% market share, with particular strength in aerospace and defense applications where thermal cycling resistance is critical.

Competition in the thermal management materials space has intensified, with major players including 3M, Henkel, Parker Chomerics, and Laird Technologies expanding their portfolios to include advanced composites. Specifically for h-BN composites, companies like Momentive Performance Materials, Saint-Gobain, and Denka Company have established strong market positions through proprietary filler network technologies and interface engineering solutions.

Price sensitivity varies significantly by application sector. While consumer electronics manufacturers remain highly cost-conscious, aerospace and defense sectors demonstrate willingness to pay premium prices for materials with superior thermal cycling resistance and reliability. The average price point for h-BN composite materials ranges from $80-150 per kilogram depending on purity levels and processing requirements.

Customer requirements are increasingly focused on multifunctional properties beyond thermal conductivity alone, including electrical insulation, mechanical strength, and environmental stability. This trend aligns well with h-BN composites' inherent property profile, particularly when engineered with optimized filler networks and interfacial adhesion.

Current Challenges in hBN Composite Technology

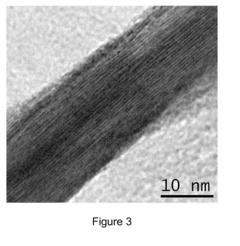

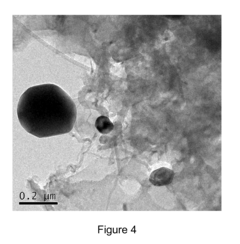

Despite significant advancements in hexagonal Boron Nitride (hBN) composite technology, several critical challenges continue to impede its widespread industrial application. One of the primary obstacles lies in achieving uniform dispersion of hBN particles within polymer matrices. The high surface energy and strong van der Waals interactions between hBN nanosheets lead to agglomeration, resulting in inconsistent thermal and mechanical properties across the composite material. This non-uniformity significantly compromises performance reliability in high-demand applications.

The interfacial adhesion between hBN fillers and polymer matrices presents another substantial challenge. The inherently inert surface of hBN limits chemical bonding with most polymer systems, creating weak interfaces that become failure points under mechanical stress. This weak adhesion reduces load transfer efficiency and diminishes the mechanical reinforcement potential of hBN fillers, particularly in applications requiring high structural integrity.

Thermal cycling stability remains a persistent issue for hBN composites. The coefficient of thermal expansion (CTE) mismatch between hBN fillers and polymer matrices generates internal stresses during temperature fluctuations. Over repeated thermal cycles, these stresses accumulate and eventually lead to microcrack formation, delamination, and degradation of thermal conductivity pathways. This phenomenon is particularly problematic in electronics cooling applications where thermal cycling is frequent.

Manufacturing scalability presents significant barriers to commercial adoption. Current methods for producing high-quality hBN-polymer composites often involve complex, multi-step processes that are difficult to scale economically. Techniques that work effectively at laboratory scale frequently encounter issues when transferred to industrial production environments, including increased defect rates, reduced property consistency, and elevated production costs.

The optimization of filler networks for specific property enhancements remains challenging. Creating percolation networks that maximize thermal conductivity while maintaining other desirable properties (electrical insulation, mechanical strength) requires precise control over filler orientation, concentration, and distribution. Current processing techniques provide limited control over these parameters, resulting in suboptimal performance trade-offs.

Environmental stability concerns also persist, particularly regarding moisture absorption and oxidation resistance in harsh operating environments. hBN composites intended for long-term deployment in aerospace, automotive, or industrial applications must maintain performance integrity under diverse environmental conditions, a requirement that current formulations struggle to consistently meet.

The interfacial adhesion between hBN fillers and polymer matrices presents another substantial challenge. The inherently inert surface of hBN limits chemical bonding with most polymer systems, creating weak interfaces that become failure points under mechanical stress. This weak adhesion reduces load transfer efficiency and diminishes the mechanical reinforcement potential of hBN fillers, particularly in applications requiring high structural integrity.

Thermal cycling stability remains a persistent issue for hBN composites. The coefficient of thermal expansion (CTE) mismatch between hBN fillers and polymer matrices generates internal stresses during temperature fluctuations. Over repeated thermal cycles, these stresses accumulate and eventually lead to microcrack formation, delamination, and degradation of thermal conductivity pathways. This phenomenon is particularly problematic in electronics cooling applications where thermal cycling is frequent.

Manufacturing scalability presents significant barriers to commercial adoption. Current methods for producing high-quality hBN-polymer composites often involve complex, multi-step processes that are difficult to scale economically. Techniques that work effectively at laboratory scale frequently encounter issues when transferred to industrial production environments, including increased defect rates, reduced property consistency, and elevated production costs.

The optimization of filler networks for specific property enhancements remains challenging. Creating percolation networks that maximize thermal conductivity while maintaining other desirable properties (electrical insulation, mechanical strength) requires precise control over filler orientation, concentration, and distribution. Current processing techniques provide limited control over these parameters, resulting in suboptimal performance trade-offs.

Environmental stability concerns also persist, particularly regarding moisture absorption and oxidation resistance in harsh operating environments. hBN composites intended for long-term deployment in aerospace, automotive, or industrial applications must maintain performance integrity under diverse environmental conditions, a requirement that current formulations struggle to consistently meet.

Current Filler Network Design Strategies

01 Hexagonal Boron Nitride as Thermal Interface Material

Hexagonal boron nitride (h-BN) is utilized as a thermal interface material in composite structures due to its excellent thermal conductivity properties. When incorporated into polymer matrices, h-BN forms networks that create efficient thermal pathways, enhancing heat dissipation in electronic components and other applications requiring thermal management. The orientation and distribution of h-BN particles within the composite significantly impact the thermal conductivity performance.- Hexagonal Boron Nitride as Thermal Interface Material: Hexagonal boron nitride (h-BN) is utilized as a thermal interface material in composite structures due to its excellent thermal conductivity properties. When incorporated into polymer matrices, h-BN forms networks that create efficient thermal pathways, enhancing heat dissipation in electronic devices and other applications. The orientation and dispersion of h-BN platelets within the composite significantly impact the thermal performance, with aligned networks providing superior directional heat transfer capabilities.

- Surface Modification of h-BN for Enhanced Interfacial Adhesion: Surface functionalization of hexagonal boron nitride particles improves their compatibility with polymer matrices, enhancing interfacial adhesion in composite materials. Various surface treatment methods, including silane coupling agents, polymer grafting, and chemical functionalization, are employed to modify the h-BN surface chemistry. These modifications reduce agglomeration, improve dispersion, and strengthen the interfacial bonding between h-BN fillers and the surrounding matrix, resulting in composites with superior mechanical properties and thermal stability.

- Three-Dimensional Filler Networks in h-BN Composites: Three-dimensional networks of hexagonal boron nitride fillers in polymer composites create continuous pathways for enhanced thermal and mechanical properties. These interconnected structures are formed through various processing techniques, including freeze-casting, template-assisted methods, and self-assembly processes. The 3D networks provide structural integrity while maintaining low filler content, resulting in lightweight composites with improved thermal conductivity, mechanical strength, and dimensional stability under thermal cycling conditions.

- h-BN Hybrid Fillers and Synergistic Effects: Hybrid filler systems combining hexagonal boron nitride with other materials such as graphene, carbon nanotubes, or metal particles create synergistic effects in composite materials. These hybrid systems form interconnected networks with enhanced thermal, electrical, and mechanical properties beyond what individual fillers can achieve alone. The complementary nature of different fillers allows for multifunctional composites with tailored properties, including improved thermal conductivity while maintaining electrical insulation, enhanced mechanical strength, and better interfacial adhesion to the polymer matrix.

- Processing Techniques for Optimized h-BN Filler Networks: Advanced processing techniques are employed to optimize the distribution and orientation of hexagonal boron nitride fillers within composite materials. Methods such as shear alignment, magnetic field orientation, extrusion, and hot pressing help create preferentially oriented h-BN networks with anisotropic properties. These processing approaches control the microstructure of the composite, enhancing thermal conductivity in specific directions while maintaining good interfacial adhesion between the h-BN fillers and the polymer matrix, resulting in composites with tailored performance characteristics for specific applications.

02 Surface Modification of h-BN for Enhanced Interfacial Adhesion

Surface functionalization of hexagonal boron nitride particles improves their compatibility with polymer matrices, enhancing interfacial adhesion. Various surface treatment methods, including silane coupling agents, plasma treatment, and chemical functionalization, are employed to modify the h-BN surface. These modifications reduce interfacial thermal resistance and prevent agglomeration, resulting in more uniform filler networks and improved mechanical properties of the composite.Expand Specific Solutions03 Three-Dimensional Filler Networks for Enhanced Mechanical Properties

Three-dimensional networks of hexagonal boron nitride fillers in composite materials provide enhanced mechanical strength, flexibility, and durability. These interconnected networks create structural reinforcement throughout the matrix while maintaining flexibility. The formation of such networks depends on processing techniques, filler concentration, and aspect ratio of the h-BN particles. Composites with well-developed 3D networks exhibit improved resistance to mechanical deformation and better load distribution.Expand Specific Solutions04 Hybrid Fillers with h-BN for Synergistic Effects

Combining hexagonal boron nitride with other fillers such as graphene, carbon nanotubes, or metal oxides creates hybrid filler systems with synergistic effects. These hybrid systems enhance multiple properties simultaneously, including thermal conductivity, electrical insulation, and mechanical strength. The interaction between different fillers creates unique network structures that can be tailored for specific applications, offering advantages over single-filler systems.Expand Specific Solutions05 Processing Techniques for Optimized h-BN Filler Distribution

Specialized processing techniques are employed to achieve optimal distribution and orientation of hexagonal boron nitride fillers within composite matrices. Methods such as solution mixing, melt blending, in-situ polymerization, and directional freezing help control the formation of filler networks. These techniques influence the interfacial adhesion between h-BN and the matrix, affecting the final properties of the composite. Proper processing prevents agglomeration and ensures uniform dispersion of the fillers.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Hexagonal Boron Nitride (h-BN) composites market is currently in a growth phase, with increasing applications in thermal management solutions across electronics, aerospace, and automotive industries. The global market size is expanding rapidly, projected to reach significant valuation due to growing demand for high-performance thermal interface materials. Technologically, the field is advancing from early commercial adoption toward maturity, with leading companies developing proprietary solutions. DuPont de Nemours, 3M Innovative Properties, and General Electric are pioneering advanced h-BN composite formulations with enhanced interfacial adhesion properties. Asian institutions and companies like Samsung Electronics, Tsinghua University, and Shenzhen Advanced Technology Research Institute are making significant contributions to filler network optimization. Meanwhile, Rogers Corp., Momentive Performance Materials, and Evonik Operations are focusing on thermal cycling stability improvements for next-generation applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced hexagonal boron nitride (h-BN) composite materials with optimized filler networks for thermal management applications. Their proprietary technology focuses on creating uniform h-BN particle dispersion within polymer matrices using surface functionalization techniques. DuPont's approach involves chemical modification of h-BN platelets with silane coupling agents to enhance interfacial adhesion with various polymer systems. Their research demonstrates that controlling the orientation of h-BN platelets through processing techniques like extrusion and lamination significantly improves through-plane thermal conductivity. DuPont has also developed specialized curing protocols that minimize thermal stresses during composite formation, resulting in materials with superior thermal cycling stability up to 1000 cycles between -40°C and 150°C without significant degradation in thermal performance.

Strengths: Superior interfacial adhesion between h-BN and polymer matrices through proprietary surface treatments; excellent thermal cycling stability; established manufacturing infrastructure for scale-up. Weaknesses: Higher production costs compared to conventional fillers; potential challenges in achieving consistent quality across large production volumes; limited transparency in high-filler content formulations.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a multi-scale approach to h-BN composite development, combining micro and nano-sized h-BN particles to create hierarchical filler networks. Their technology utilizes a combination of exfoliated h-BN nanosheets and larger h-BN platelets to form interconnected thermal pathways while minimizing filler loading. 3M's process involves a proprietary solvent-assisted dispersion technique that prevents agglomeration during composite formation. Their research has demonstrated thermal conductivity values exceeding 10 W/m·K in certain polymer systems while maintaining mechanical flexibility. 3M has also developed specialized adhesive formulations containing h-BN that maintain interfacial integrity during thermal cycling, with test data showing less than 5% degradation in thermal performance after 500 thermal cycles between -65°C and 175°C. Their technology enables the creation of thermally conductive yet electrically insulating interface materials critical for electronics applications.

Strengths: Excellent balance between thermal conductivity and mechanical flexibility; proprietary dispersion technology preventing agglomeration; strong intellectual property portfolio in h-BN composites. Weaknesses: Higher raw material costs due to specialized h-BN grades; processing complexity requiring precise control of multiple parameters; potential challenges in recycling composite materials at end-of-life.

Key Innovations in Interfacial Adhesion Mechanisms

Hexagonal boron nitride compositions characterized by interstitial ferromagnetic layers, process for preparing, and composites thereof with organic polymers

PatentInactiveUS8277936B2

Innovation

- Incorporating a ferromagnetic metal, such as nickel, cobalt, or iron, interstitially between the layers of hBN platelet particles, allowing for magnetic orientation without increasing electrical conductivity, achieved by forming an aqueous solution with a salt of the metal and NH4OH, combining with hBN, drying, and annealing in a reducing atmosphere, resulting in a composite that can be oriented in a magnetic field.

Composite of a polymer and surface modified hexagonal boron nitride particles

PatentInactiveEP2430091A2

Innovation

- Surface-modified hexagonal boron nitride particles with a substituted phenyl radical are dispersed in polymers, such as polyimides and epoxies, to improve compatibility and reduce viscosity, allowing for the production of tough and flexible substrates with enhanced thermal conductivity.

Environmental Impact and Sustainability Considerations

The environmental impact of hexagonal boron nitride (h-BN) composites represents a critical consideration in their development and application. The production of h-BN typically involves energy-intensive processes requiring high temperatures (1500-2000°C) and pressures, resulting in significant carbon emissions. However, compared to traditional ceramic fillers, h-BN's production footprint may be lower due to its relatively simple chemical composition and synthesis routes.

Life cycle assessment (LCA) studies indicate that h-BN composites offer environmental advantages through their extended service life in thermal management applications. The exceptional thermal stability and cycling resistance of these materials reduce replacement frequency, thereby decreasing waste generation and resource consumption over time. This longevity factor partially offsets the initial environmental costs of production.

The recyclability of h-BN composites presents both challenges and opportunities. While the thermoset matrices commonly used with h-BN fillers are difficult to recycle conventionally, emerging chemical recycling technologies show promise for recovering both the polymer matrix and the valuable h-BN fillers. Research into solvolysis and pyrolysis methods specifically tailored for these composites has demonstrated recovery rates of up to 85% for h-BN particles.

Water usage and potential aquatic toxicity require careful management in h-BN composite manufacturing. The dispersion processes often employ solvents and surfactants that, if improperly handled, could contaminate water systems. Implementation of closed-loop water systems and green chemistry principles in production facilities has shown potential to reduce water consumption by 40-60% compared to conventional manufacturing methods.

Biodegradability remains a significant concern, as h-BN particles persist in the environment indefinitely. However, recent innovations in biodegradable polymer matrices compatible with h-BN fillers offer promising alternatives for less demanding applications. These bio-based composites maintain adequate thermal performance while reducing end-of-life environmental impact.

The sustainability profile of h-BN composites is further enhanced through their contribution to energy efficiency in electronic devices and industrial systems. Thermal management improvements provided by these materials can reduce operational energy consumption by 15-30% in certain applications, creating a positive environmental offset throughout the product lifecycle.

Future research directions should focus on developing greener synthesis routes for h-BN, including lower temperature processes and renewable precursors. Additionally, designing for disassembly and material recovery will be crucial for establishing circular economy models for these advanced composite materials.

Life cycle assessment (LCA) studies indicate that h-BN composites offer environmental advantages through their extended service life in thermal management applications. The exceptional thermal stability and cycling resistance of these materials reduce replacement frequency, thereby decreasing waste generation and resource consumption over time. This longevity factor partially offsets the initial environmental costs of production.

The recyclability of h-BN composites presents both challenges and opportunities. While the thermoset matrices commonly used with h-BN fillers are difficult to recycle conventionally, emerging chemical recycling technologies show promise for recovering both the polymer matrix and the valuable h-BN fillers. Research into solvolysis and pyrolysis methods specifically tailored for these composites has demonstrated recovery rates of up to 85% for h-BN particles.

Water usage and potential aquatic toxicity require careful management in h-BN composite manufacturing. The dispersion processes often employ solvents and surfactants that, if improperly handled, could contaminate water systems. Implementation of closed-loop water systems and green chemistry principles in production facilities has shown potential to reduce water consumption by 40-60% compared to conventional manufacturing methods.

Biodegradability remains a significant concern, as h-BN particles persist in the environment indefinitely. However, recent innovations in biodegradable polymer matrices compatible with h-BN fillers offer promising alternatives for less demanding applications. These bio-based composites maintain adequate thermal performance while reducing end-of-life environmental impact.

The sustainability profile of h-BN composites is further enhanced through their contribution to energy efficiency in electronic devices and industrial systems. Thermal management improvements provided by these materials can reduce operational energy consumption by 15-30% in certain applications, creating a positive environmental offset throughout the product lifecycle.

Future research directions should focus on developing greener synthesis routes for h-BN, including lower temperature processes and renewable precursors. Additionally, designing for disassembly and material recovery will be crucial for establishing circular economy models for these advanced composite materials.

Applications in Electronics and Aerospace Industries

Hexagonal Boron Nitride (h-BN) composites have emerged as critical materials in modern electronics, offering exceptional thermal management solutions for increasingly miniaturized and high-performance devices. In the electronics industry, these composites address the persistent challenge of heat dissipation in densely packed semiconductor components, where traditional materials fail to meet thermal conductivity requirements while maintaining electrical insulation properties.

The integration of h-BN composites in printed circuit boards (PCBs) has revolutionized thermal management strategies, enabling the development of high-frequency electronic devices with significantly reduced thermal resistance. These materials demonstrate superior performance in applications requiring both high thermal conductivity and electrical insulation, such as LED packaging, power electronics, and 5G communication equipment.

Thermal interface materials (TIMs) incorporating h-BN have become essential components in electronic assemblies, providing efficient heat transfer between heat-generating components and heat sinks. The unique hexagonal structure of BN allows for the formation of effective thermal pathways while maintaining the mechanical flexibility needed to withstand thermal cycling conditions typical in electronic operations.

In aerospace applications, h-BN composites offer compelling advantages due to their lightweight nature, thermal stability at extreme temperatures, and resistance to harsh environmental conditions. These materials are increasingly utilized in satellite thermal control systems, where their ability to maintain dimensional stability during thermal cycling is particularly valuable for maintaining precise alignment of optical and communication systems.

Aircraft avionics systems benefit from h-BN composite encapsulants that protect sensitive electronics while efficiently dissipating heat generated during operation. The low coefficient of thermal expansion of these materials minimizes stress on electronic components during the rapid temperature fluctuations experienced in aerospace environments.

Advanced radar and communication systems in aerospace applications leverage h-BN composites for their transparency to radio frequency signals combined with excellent thermal management capabilities. This dual functionality allows for the design of more compact and reliable systems that can operate under extreme conditions without performance degradation.

The space industry has adopted h-BN composites for thermal protection systems in reentry vehicles and spacecraft components exposed to extreme temperature gradients. Their ability to maintain structural integrity and thermal properties during repeated thermal cycling makes them ideal for long-duration space missions where reliability is paramount.

Recent developments in manufacturing techniques have enabled the production of h-BN composites with tailored properties for specific aerospace and electronics applications, including 3D-printable formulations that allow for complex geometries and integrated thermal management solutions previously impossible with conventional materials.

The integration of h-BN composites in printed circuit boards (PCBs) has revolutionized thermal management strategies, enabling the development of high-frequency electronic devices with significantly reduced thermal resistance. These materials demonstrate superior performance in applications requiring both high thermal conductivity and electrical insulation, such as LED packaging, power electronics, and 5G communication equipment.

Thermal interface materials (TIMs) incorporating h-BN have become essential components in electronic assemblies, providing efficient heat transfer between heat-generating components and heat sinks. The unique hexagonal structure of BN allows for the formation of effective thermal pathways while maintaining the mechanical flexibility needed to withstand thermal cycling conditions typical in electronic operations.

In aerospace applications, h-BN composites offer compelling advantages due to their lightweight nature, thermal stability at extreme temperatures, and resistance to harsh environmental conditions. These materials are increasingly utilized in satellite thermal control systems, where their ability to maintain dimensional stability during thermal cycling is particularly valuable for maintaining precise alignment of optical and communication systems.

Aircraft avionics systems benefit from h-BN composite encapsulants that protect sensitive electronics while efficiently dissipating heat generated during operation. The low coefficient of thermal expansion of these materials minimizes stress on electronic components during the rapid temperature fluctuations experienced in aerospace environments.

Advanced radar and communication systems in aerospace applications leverage h-BN composites for their transparency to radio frequency signals combined with excellent thermal management capabilities. This dual functionality allows for the design of more compact and reliable systems that can operate under extreme conditions without performance degradation.

The space industry has adopted h-BN composites for thermal protection systems in reentry vehicles and spacecraft components exposed to extreme temperature gradients. Their ability to maintain structural integrity and thermal properties during repeated thermal cycling makes them ideal for long-duration space missions where reliability is paramount.

Recent developments in manufacturing techniques have enabled the production of h-BN composites with tailored properties for specific aerospace and electronics applications, including 3D-printable formulations that allow for complex geometries and integrated thermal management solutions previously impossible with conventional materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!