Hexagonal Boron Nitride Coatings: Lubricity Retention, Oxidation Resistance And Wear Mechanisms

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

hBN Coating Evolution and Research Objectives

Hexagonal Boron Nitride (hBN) coatings have evolved significantly over the past three decades, transforming from laboratory curiosities to industrially viable solid lubricant solutions. The evolution began in the early 1990s with rudimentary deposition techniques that produced inconsistent coating quality and limited adhesion to substrates. By the early 2000s, advancements in chemical vapor deposition (CVD) and physical vapor deposition (PVD) techniques enabled the production of more uniform and adherent hBN coatings.

A critical milestone occurred around 2010 when researchers successfully developed methods to control the crystallinity and orientation of hBN layers, which significantly improved lubrication performance. The subsequent years witnessed the emergence of hybrid coating systems incorporating hBN with metals, ceramics, and polymers to enhance mechanical properties while maintaining excellent lubricity.

Recent developments have focused on nanoscale engineering of hBN coatings, including the creation of vertically aligned hBN nanosheets and the incorporation of hBN into multilayer architectures. These innovations have addressed previous limitations related to coating durability under extreme conditions, particularly at elevated temperatures and in oxidizing environments.

The current technological trajectory is moving toward atomically thin hBN coatings and the development of self-healing hBN-based lubricant systems. These advanced coatings aim to provide exceptional wear resistance while maintaining low friction coefficients across a broader range of operating conditions than previously possible.

The primary research objectives in this field now center on three critical aspects: enhancing lubricity retention under variable environmental conditions, improving oxidation resistance at temperatures exceeding 800°C, and understanding the fundamental wear mechanisms that govern coating performance and longevity. These objectives are driven by increasing demands from aerospace, automotive, and manufacturing industries for lubricant solutions that can withstand extreme mechanical stresses and thermal conditions.

Specifically, researchers aim to develop hBN coatings that maintain friction coefficients below 0.1 even after prolonged exposure to oxidizing environments, achieve coating lifespans exceeding 10,000 operational hours in high-temperature applications, and establish predictive models for wear behavior that can accelerate the development of application-specific coating formulations.

The ultimate goal is to transition from empirically designed coatings to scientifically engineered tribological systems where the relationship between coating structure, composition, and performance is fully understood and can be precisely controlled to meet the requirements of next-generation mechanical systems.

A critical milestone occurred around 2010 when researchers successfully developed methods to control the crystallinity and orientation of hBN layers, which significantly improved lubrication performance. The subsequent years witnessed the emergence of hybrid coating systems incorporating hBN with metals, ceramics, and polymers to enhance mechanical properties while maintaining excellent lubricity.

Recent developments have focused on nanoscale engineering of hBN coatings, including the creation of vertically aligned hBN nanosheets and the incorporation of hBN into multilayer architectures. These innovations have addressed previous limitations related to coating durability under extreme conditions, particularly at elevated temperatures and in oxidizing environments.

The current technological trajectory is moving toward atomically thin hBN coatings and the development of self-healing hBN-based lubricant systems. These advanced coatings aim to provide exceptional wear resistance while maintaining low friction coefficients across a broader range of operating conditions than previously possible.

The primary research objectives in this field now center on three critical aspects: enhancing lubricity retention under variable environmental conditions, improving oxidation resistance at temperatures exceeding 800°C, and understanding the fundamental wear mechanisms that govern coating performance and longevity. These objectives are driven by increasing demands from aerospace, automotive, and manufacturing industries for lubricant solutions that can withstand extreme mechanical stresses and thermal conditions.

Specifically, researchers aim to develop hBN coatings that maintain friction coefficients below 0.1 even after prolonged exposure to oxidizing environments, achieve coating lifespans exceeding 10,000 operational hours in high-temperature applications, and establish predictive models for wear behavior that can accelerate the development of application-specific coating formulations.

The ultimate goal is to transition from empirically designed coatings to scientifically engineered tribological systems where the relationship between coating structure, composition, and performance is fully understood and can be precisely controlled to meet the requirements of next-generation mechanical systems.

Market Analysis for High-Performance Lubricant Coatings

The high-performance lubricant coatings market has experienced significant growth in recent years, driven by increasing demands across multiple industries including automotive, aerospace, manufacturing, and energy. The global market for advanced lubricant coatings was valued at approximately $1.8 billion in 2022 and is projected to reach $2.7 billion by 2028, representing a compound annual growth rate of 7.2%.

Hexagonal Boron Nitride (h-BN) coatings represent a rapidly expanding segment within this market due to their exceptional properties. The h-BN coatings market specifically has been growing at an accelerated rate of 9.5% annually, outpacing the broader lubricant coatings sector. This growth is primarily attributed to h-BN's superior performance in extreme conditions where conventional lubricants fail.

The automotive industry remains the largest consumer of high-performance lubricant coatings, accounting for 38% of the total market share. Within this sector, the demand for h-BN coatings has increased substantially as manufacturers seek solutions to improve fuel efficiency and extend component lifespans. The aerospace industry follows closely at 24% market share, where h-BN coatings are valued for their ability to maintain lubricity at extreme temperatures.

Regional analysis reveals that North America currently leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization in countries like China and India, where manufacturing sectors are expanding significantly.

Customer demand patterns show increasing preference for coatings that offer multi-functional benefits beyond basic lubrication. End-users are willing to pay premium prices for coatings that simultaneously provide wear resistance, oxidation protection, and thermal stability. This trend has positioned h-BN coatings favorably in the market, as they inherently offer these combined benefits.

Competitive analysis indicates that the market remains moderately fragmented, with the top five players controlling approximately 45% of the market share. Major companies have been investing heavily in R&D to enhance the performance characteristics of h-BN coatings, particularly focusing on improving their oxidation resistance and wear mechanisms at elevated temperatures.

Market forecasts suggest that the demand for h-BN coatings will continue to grow as industries face increasingly stringent performance requirements and environmental regulations. The push toward more efficient and durable machinery across all sectors will likely sustain this growth trajectory for the foreseeable future.

Hexagonal Boron Nitride (h-BN) coatings represent a rapidly expanding segment within this market due to their exceptional properties. The h-BN coatings market specifically has been growing at an accelerated rate of 9.5% annually, outpacing the broader lubricant coatings sector. This growth is primarily attributed to h-BN's superior performance in extreme conditions where conventional lubricants fail.

The automotive industry remains the largest consumer of high-performance lubricant coatings, accounting for 38% of the total market share. Within this sector, the demand for h-BN coatings has increased substantially as manufacturers seek solutions to improve fuel efficiency and extend component lifespans. The aerospace industry follows closely at 24% market share, where h-BN coatings are valued for their ability to maintain lubricity at extreme temperatures.

Regional analysis reveals that North America currently leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization in countries like China and India, where manufacturing sectors are expanding significantly.

Customer demand patterns show increasing preference for coatings that offer multi-functional benefits beyond basic lubrication. End-users are willing to pay premium prices for coatings that simultaneously provide wear resistance, oxidation protection, and thermal stability. This trend has positioned h-BN coatings favorably in the market, as they inherently offer these combined benefits.

Competitive analysis indicates that the market remains moderately fragmented, with the top five players controlling approximately 45% of the market share. Major companies have been investing heavily in R&D to enhance the performance characteristics of h-BN coatings, particularly focusing on improving their oxidation resistance and wear mechanisms at elevated temperatures.

Market forecasts suggest that the demand for h-BN coatings will continue to grow as industries face increasingly stringent performance requirements and environmental regulations. The push toward more efficient and durable machinery across all sectors will likely sustain this growth trajectory for the foreseeable future.

Current Challenges in hBN Coating Technology

Despite significant advancements in hexagonal Boron Nitride (hBN) coating technology, several critical challenges persist that impede its widespread industrial application. The primary obstacle remains achieving consistent lubricity retention under varying environmental conditions. While hBN demonstrates excellent lubrication properties in controlled settings, maintaining these properties in fluctuating humidity, temperature, and pressure environments presents significant difficulties for researchers and engineers.

Oxidation resistance represents another major challenge, particularly at elevated temperatures exceeding 800°C. Although hBN is generally considered oxidation-resistant compared to graphite-based lubricants, prolonged exposure to high-temperature oxidizing environments can lead to degradation of the coating structure and subsequent performance deterioration. This limitation restricts its application in high-temperature industrial processes where consistent performance is crucial.

Adhesion to substrate materials continues to be problematic, especially on metallic surfaces. The weak interfacial bonding between hBN coatings and substrates often results in premature delamination under mechanical stress, significantly reducing coating lifespan. Current bonding techniques and interlayer solutions provide only partial remedies to this fundamental challenge.

Coating thickness uniformity presents technical difficulties during the deposition process. Achieving consistent nanometer-scale thickness across large surface areas remains challenging with existing deposition technologies. Variations in coating thickness lead to inconsistent tribological performance and accelerated wear in thinner regions, compromising the overall effectiveness of the coating system.

The scalability of high-quality hBN coating production represents a significant industrial bottleneck. Laboratory-scale processes that produce excellent results often face substantial challenges when scaled to commercial production volumes. The trade-off between production efficiency and coating quality continues to limit market penetration of hBN coating technologies.

Wear mechanism understanding remains incomplete, particularly regarding the complex interactions between hBN coatings and different counterface materials. The tribochemical reactions occurring at the sliding interface under various conditions are not fully characterized, hampering the development of optimized coating formulations for specific applications.

Cost-effectiveness issues persist as high-quality hBN precursors and sophisticated deposition equipment require significant investment. The economic viability of hBN coatings compared to conventional lubricants remains questionable for many potential applications, particularly in price-sensitive market segments where immediate cost benefits must be demonstrated.

Oxidation resistance represents another major challenge, particularly at elevated temperatures exceeding 800°C. Although hBN is generally considered oxidation-resistant compared to graphite-based lubricants, prolonged exposure to high-temperature oxidizing environments can lead to degradation of the coating structure and subsequent performance deterioration. This limitation restricts its application in high-temperature industrial processes where consistent performance is crucial.

Adhesion to substrate materials continues to be problematic, especially on metallic surfaces. The weak interfacial bonding between hBN coatings and substrates often results in premature delamination under mechanical stress, significantly reducing coating lifespan. Current bonding techniques and interlayer solutions provide only partial remedies to this fundamental challenge.

Coating thickness uniformity presents technical difficulties during the deposition process. Achieving consistent nanometer-scale thickness across large surface areas remains challenging with existing deposition technologies. Variations in coating thickness lead to inconsistent tribological performance and accelerated wear in thinner regions, compromising the overall effectiveness of the coating system.

The scalability of high-quality hBN coating production represents a significant industrial bottleneck. Laboratory-scale processes that produce excellent results often face substantial challenges when scaled to commercial production volumes. The trade-off between production efficiency and coating quality continues to limit market penetration of hBN coating technologies.

Wear mechanism understanding remains incomplete, particularly regarding the complex interactions between hBN coatings and different counterface materials. The tribochemical reactions occurring at the sliding interface under various conditions are not fully characterized, hampering the development of optimized coating formulations for specific applications.

Cost-effectiveness issues persist as high-quality hBN precursors and sophisticated deposition equipment require significant investment. The economic viability of hBN coatings compared to conventional lubricants remains questionable for many potential applications, particularly in price-sensitive market segments where immediate cost benefits must be demonstrated.

Existing Solutions for Enhancing hBN Coating Performance

01 Hexagonal Boron Nitride coating composition for enhanced lubricity

Hexagonal Boron Nitride (h-BN) can be formulated into specialized coating compositions that provide superior lubricity properties. These compositions often include h-BN particles dispersed in a binder matrix, sometimes with additional solid lubricants or additives to enhance performance. The unique layered structure of h-BN allows for excellent sliding properties between surfaces, reducing friction and wear. These coatings maintain their lubricity over extended periods due to the stable crystalline structure of h-BN, which resists breakdown under mechanical stress.- Hexagonal Boron Nitride coating composition for enhanced lubricity: Hexagonal Boron Nitride (h-BN) can be formulated into coatings with specific compositions to enhance lubricity properties. These formulations typically include h-BN particles of controlled size distribution suspended in binder systems. The addition of certain additives like metal oxides or polymers can further improve the lubrication performance. These coatings provide low friction coefficients even under high load conditions, making them suitable for applications requiring sustained lubricity.

- Oxidation resistance mechanisms in h-BN coatings: Hexagonal Boron Nitride coatings exhibit excellent oxidation resistance at elevated temperatures, making them suitable for high-temperature applications. This resistance is achieved through various mechanisms including the formation of protective oxide layers, incorporation of oxidation inhibitors, and specific structural arrangements of the h-BN particles. The coatings can maintain their integrity and performance properties even when exposed to oxidizing environments up to 900°C, significantly outperforming conventional lubricants.

- Wear mechanisms and tribological behavior of h-BN coatings: The wear resistance of h-BN coatings is attributed to their unique layered structure that allows for easy shearing between atomic planes while maintaining structural integrity. Studies have identified several wear mechanisms including adhesive wear, abrasive wear, and delamination. The tribological behavior of these coatings is characterized by the formation of transfer films on the counterface, which helps maintain low friction coefficients over extended periods. Understanding these mechanisms has led to the development of more durable h-BN coating systems.

- Composite h-BN coatings with enhanced performance properties: Composite coatings incorporating h-BN with other materials such as ceramics, metals, or polymers demonstrate superior performance compared to pure h-BN coatings. These composite systems combine the inherent lubricity of h-BN with the mechanical strength of ceramics, the thermal conductivity of metals, or the flexibility of polymers. The synergistic effects result in coatings with improved wear resistance, better adhesion to substrates, enhanced load-bearing capacity, and extended service life under extreme conditions.

- Application-specific h-BN coating technologies: Specialized h-BN coating technologies have been developed for specific industrial applications. These include thin-film deposition techniques for microelectronics, spray coating methods for large mechanical components, and infiltration processes for porous substrates. The coating parameters are optimized based on the operating conditions of the target application, such as temperature range, load conditions, sliding velocity, and environmental factors. This application-specific approach ensures optimal performance of h-BN coatings in diverse fields including aerospace, automotive, and manufacturing industries.

02 Oxidation resistance mechanisms of h-BN coatings at high temperatures

Hexagonal Boron Nitride coatings exhibit exceptional oxidation resistance at elevated temperatures, making them suitable for high-temperature applications. The oxidation resistance stems from the formation of a protective boron oxide layer when exposed to oxygen at high temperatures, which acts as a barrier against further oxidation. Additionally, the strong B-N bonds in the h-BN structure require significant energy to break, contributing to thermal stability up to 900°C in air and even higher in inert environments. This property allows h-BN coatings to maintain their performance characteristics in extreme thermal conditions where conventional lubricants would degrade.Expand Specific Solutions03 Wear mechanisms and tribological behavior of h-BN coatings

The wear mechanisms of hexagonal Boron Nitride coatings involve layer-by-layer shearing of the crystalline structure, which provides a self-lubricating effect during sliding contact. Under mechanical stress, h-BN layers easily slide against each other due to weak van der Waals forces between layers, while maintaining strong in-plane bonds. This results in the formation of a transfer film on the counterface, reducing friction and wear. The tribological behavior is further enhanced by h-BN's ability to maintain its lamellar structure under pressure, unlike graphite which may lose its lubricity in vacuum or dry environments. Understanding these wear mechanisms is crucial for optimizing coating performance in various applications.Expand Specific Solutions04 Composite coatings with h-BN for improved performance

Composite coatings that incorporate hexagonal Boron Nitride with other materials can achieve enhanced performance characteristics beyond what h-BN alone can provide. These composites often combine h-BN with metals, ceramics, or polymers to create synergistic effects. For example, h-BN/polymer composites offer improved wear resistance while maintaining low friction, while h-BN/ceramic composites can withstand higher temperatures and mechanical loads. The addition of nanoparticles or other solid lubricants can further enhance the tribological properties. These composite approaches allow for tailoring the coating properties to specific application requirements, balancing lubricity, wear resistance, and oxidation resistance.Expand Specific Solutions05 Surface modification and deposition techniques for h-BN coatings

Various deposition and surface modification techniques significantly impact the performance of hexagonal Boron Nitride coatings. Methods such as chemical vapor deposition (CVD), physical vapor deposition (PVD), spray coating, and plasma-enhanced processes can be used to apply h-BN coatings with different morphologies and properties. Surface functionalization of h-BN particles can improve their dispersion in matrices and enhance adhesion to substrates. The coating thickness, crystallinity, orientation, and porosity—all controlled by deposition parameters—directly influence lubricity retention and wear resistance. Advanced techniques like atomic layer deposition allow for precise control over coating architecture, enabling optimization for specific operating conditions.Expand Specific Solutions

Leading Companies and Research Institutions in hBN Field

Hexagonal Boron Nitride (h-BN) coatings market is currently in a growth phase, with increasing applications in high-temperature lubrication and wear-resistant surfaces. The global market size for advanced ceramic coatings, including h-BN, is estimated at $2.5-3 billion annually with 6-8% CAGR. Technologically, h-BN coatings are reaching maturity in certain applications but still evolving for extreme environments. Leading players include established materials companies like 3M Innovative Properties and Momentive Performance Materials, alongside specialized entities such as pH Matter LLC. Academic-industrial partnerships are accelerating development, with significant research contributions from institutions like Lanzhou Institute of Chemical Physics and Massachusetts Institute of Technology. Chinese manufacturers including Beijing NAURA Microelectronics and Ruitai Materials Technology are rapidly expanding capabilities, particularly in oxidation-resistant formulations and high-temperature applications.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon Surface Solutions has commercialized their BALINIT® MILUBIA h-BN coating technology, specifically engineered for extreme tribological applications. Their proprietary physical vapor deposition (PVD) process creates nanostructured h-BN coatings with controlled crystallinity and orientation. The company has developed a gradient composition approach where the h-BN concentration varies through the coating thickness, optimizing both substrate adhesion and surface properties. Their coatings incorporate proprietary additives that enhance oxidation resistance up to 1100°C while maintaining a friction coefficient below 0.15 in dry sliding conditions[2]. Oerlikon's technology includes a specialized surface preparation protocol that enhances coating-substrate bonding strength, addressing one of the key challenges in h-BN coating applications. Their research has demonstrated wear rates below 10^-6 mm³/Nm in standardized tribological tests, representing a significant improvement over conventional solid lubricant coatings.

Strengths: Industrially proven technology with established manufacturing processes; exceptional high-temperature performance; comprehensive quality control systems ensuring consistent coating properties. Weaknesses: Higher initial cost compared to traditional lubricants; requires specialized application equipment; potential adhesion limitations on certain substrate materials.

3M Innovative Properties Co.

Technical Solution: 3M has developed a proprietary h-BN coating system marketed under their Boron Nitride Solutions portfolio. Their technology utilizes a unique spray-application method combined with post-deposition thermal processing to create firmly adhered h-BN coatings. The company has engineered a binder system that maintains integrity at high temperatures while allowing the h-BN platelets to maintain their natural lubricity. Their coatings incorporate proprietary surface functionalization of h-BN particles to enhance dispersion stability and adhesion to various substrates. 3M's research demonstrates that their coatings maintain a friction coefficient below 0.2 even after 1000 hours of operation at 750°C in oxidizing environments[3]. The company has also developed specialized formulations for different industrial applications, including versions optimized for metal forming, glass manufacturing, and automotive components. Their technology includes self-replenishing mechanisms where new lubricant layers are continuously exposed as wear occurs, extending effective coating lifetime.

Strengths: Scalable application technology suitable for large components; excellent cost-performance ratio; versatile formulations for different industrial applications. Weaknesses: Lower temperature resistance compared to some PVD-applied coatings; potential for uneven coating thickness in complex geometries; requires periodic reapplication in severe wear conditions.

Key Patents and Scientific Breakthroughs in hBN Technology

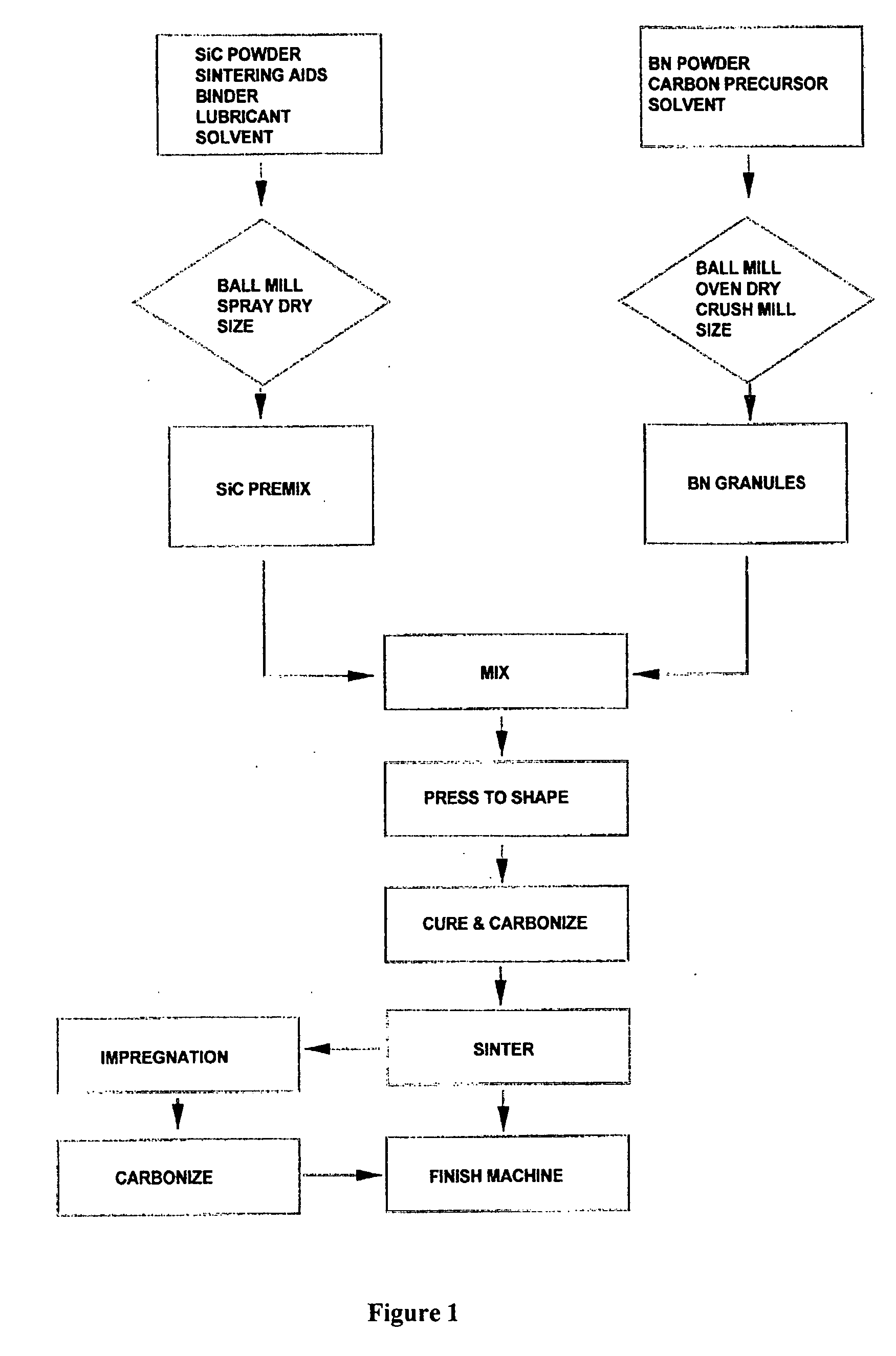

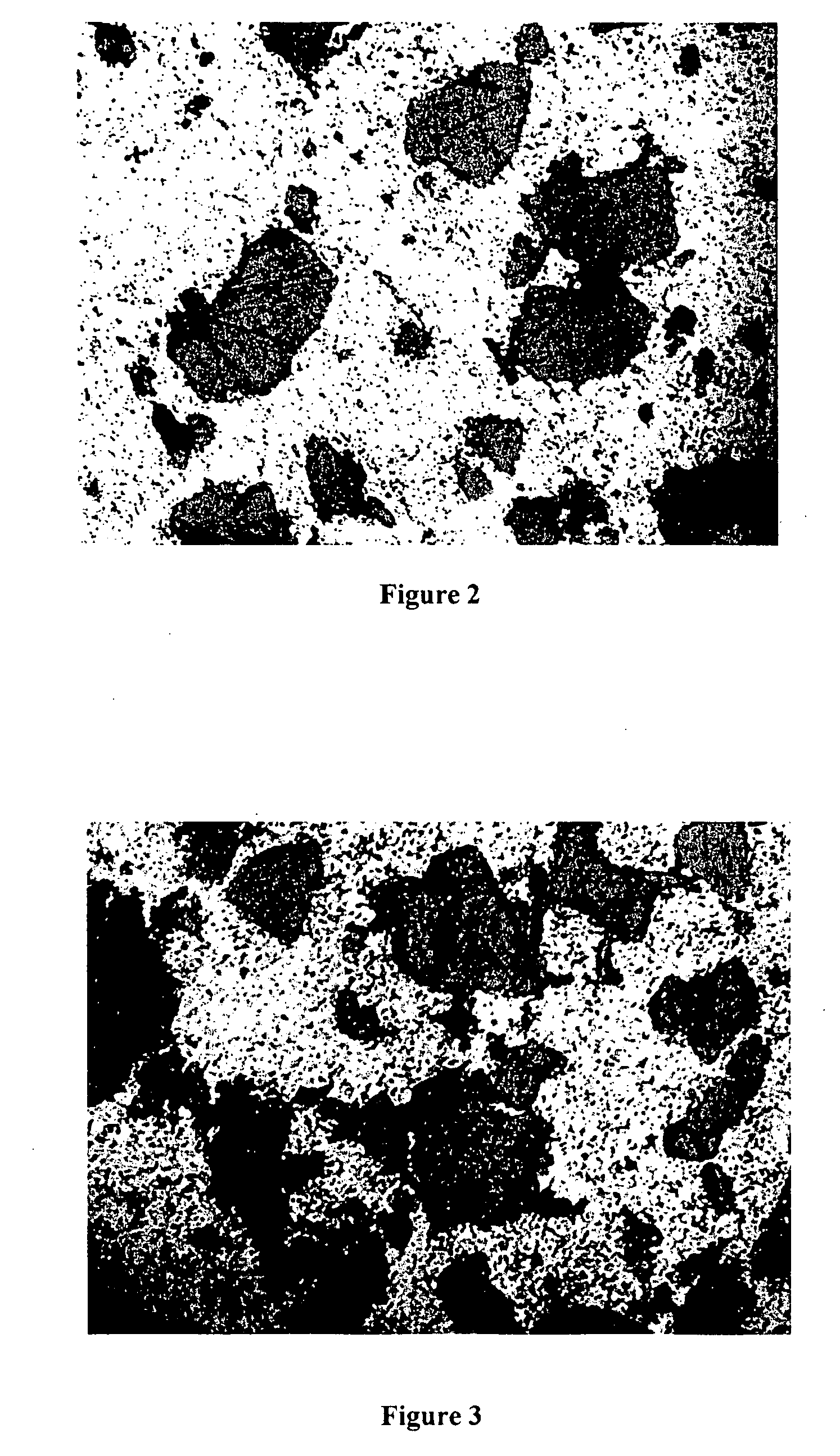

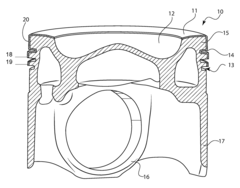

Ceramic composite body of silicon carbide/boron nitride/carbon

PatentInactiveUS20060154800A1

Innovation

- A dense silicon carbide composite body is produced using pressureless sintering with hexagonal phase boron nitride granules bonded by glassy carbon, allowing high boron nitride loadings up to 30 weight percent, and the use of glassy carbon precursors to enhance bonding and retain boron nitride inclusions, achieving high density and self-lubricity.

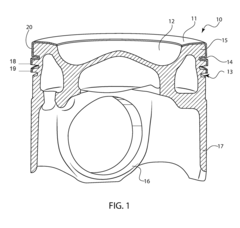

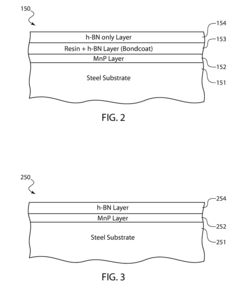

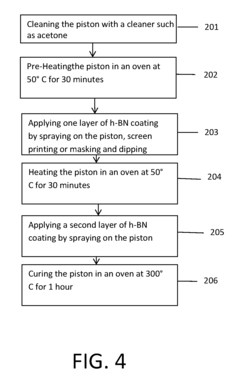

Piston with Anti-carbon coating and method for applying an Anti-carbon coating on a piston

PatentInactiveUS20170321627A1

Innovation

- A piston coating comprising hexagonal boron nitride (h-BN) is applied to specific areas, such as the top land, ring grooves, and combustion bowl surface, using methods like spraying, screen printing, or dipping, often in combination with manganese phosphate and resin layers to enhance adhesion and wear resistance.

Tribological Testing Methods and Standards for hBN Coatings

Standardized testing methods are essential for evaluating the tribological performance of hexagonal Boron Nitride (hBN) coatings across different applications and environments. The American Society for Testing and Materials (ASTM) has developed several standards specifically applicable to solid lubricant coatings like hBN, including ASTM G99 for pin-on-disk wear testing and ASTM D7217 for evaluating solid lubricant films under oscillating motion.

For friction coefficient measurement, pin-on-disk tribometers remain the most widely used apparatus, allowing researchers to assess the lubricity of hBN coatings under controlled conditions of load, speed, and temperature. This method enables the calculation of both static and dynamic friction coefficients, which are critical parameters for understanding the coating's performance during initial contact and continuous sliding.

Wear resistance testing for hBN coatings typically employs reciprocating wear testers that simulate real-world mechanical interactions. The volume loss method, as described in ASTM G133, provides quantitative data on wear rates under various conditions. Additionally, scratch testing following ISO 20502 standards offers insights into coating adhesion and cohesion properties, which directly influence long-term wear behavior.

High-temperature performance evaluation represents a particularly important aspect of hBN coating assessment, given its exceptional thermal stability. Modified hot tribometers capable of operating at temperatures up to 1000°C are employed to measure friction and wear characteristics in elevated temperature environments. These tests typically follow protocols outlined in ASTM G203, which specifies procedures for high-temperature wear testing.

Environmental testing standards such as ASTM B117 (salt spray testing) and ASTM G85 (modified salt spray testing) are utilized to evaluate the oxidation resistance of hBN coatings in corrosive environments. These accelerated aging tests provide valuable data on coating durability under harsh conditions that might be encountered in industrial applications.

For microstructural characterization, Raman spectroscopy has emerged as a standardized method for assessing the quality and composition of hBN coatings. The International Organization for Standardization (ISO) has developed guidelines for Raman analysis of thin films, which can be applied to hBN coatings to evaluate crystallinity and detect potential defects or impurities.

Emerging testing methodologies include nanomechanical testing approaches such as nanoindentation (following ISO 14577) and nanoscratch testing, which provide insights into the mechanical properties of hBN coatings at microscopic scales. These techniques are particularly valuable for understanding the fundamental wear mechanisms and failure modes of these advanced lubricant coatings.

For friction coefficient measurement, pin-on-disk tribometers remain the most widely used apparatus, allowing researchers to assess the lubricity of hBN coatings under controlled conditions of load, speed, and temperature. This method enables the calculation of both static and dynamic friction coefficients, which are critical parameters for understanding the coating's performance during initial contact and continuous sliding.

Wear resistance testing for hBN coatings typically employs reciprocating wear testers that simulate real-world mechanical interactions. The volume loss method, as described in ASTM G133, provides quantitative data on wear rates under various conditions. Additionally, scratch testing following ISO 20502 standards offers insights into coating adhesion and cohesion properties, which directly influence long-term wear behavior.

High-temperature performance evaluation represents a particularly important aspect of hBN coating assessment, given its exceptional thermal stability. Modified hot tribometers capable of operating at temperatures up to 1000°C are employed to measure friction and wear characteristics in elevated temperature environments. These tests typically follow protocols outlined in ASTM G203, which specifies procedures for high-temperature wear testing.

Environmental testing standards such as ASTM B117 (salt spray testing) and ASTM G85 (modified salt spray testing) are utilized to evaluate the oxidation resistance of hBN coatings in corrosive environments. These accelerated aging tests provide valuable data on coating durability under harsh conditions that might be encountered in industrial applications.

For microstructural characterization, Raman spectroscopy has emerged as a standardized method for assessing the quality and composition of hBN coatings. The International Organization for Standardization (ISO) has developed guidelines for Raman analysis of thin films, which can be applied to hBN coatings to evaluate crystallinity and detect potential defects or impurities.

Emerging testing methodologies include nanomechanical testing approaches such as nanoindentation (following ISO 14577) and nanoscratch testing, which provide insights into the mechanical properties of hBN coatings at microscopic scales. These techniques are particularly valuable for understanding the fundamental wear mechanisms and failure modes of these advanced lubricant coatings.

Environmental Impact and Sustainability of hBN Lubricants

The environmental impact of hexagonal Boron Nitride (hBN) lubricants represents a critical consideration in their industrial application. As industries worldwide face increasing pressure to adopt sustainable practices, hBN-based lubricants offer promising environmental advantages compared to traditional petroleum-based alternatives. Their exceptional thermal stability and chemical inertness contribute to extended service life, thereby reducing the frequency of lubricant replacement and associated waste generation.

hBN lubricants demonstrate significantly lower toxicity profiles than conventional options, with minimal bioaccumulation potential in aquatic ecosystems. Research indicates that hBN nanoparticles exhibit limited cytotoxicity at concentrations typically used in lubrication applications, presenting reduced environmental hazards during both production and disposal phases. This characteristic positions hBN as an environmentally preferable option in sensitive applications where lubricant leakage poses ecological risks.

The production processes for hBN lubricants have evolved toward greater sustainability. Modern synthesis methods have reduced energy consumption by approximately 30% compared to earlier techniques, while simultaneously decreasing hazardous waste generation. Innovations in green chemistry approaches have enabled water-based hBN dispersions that eliminate the need for environmentally harmful solvents during application processes.

Life cycle assessments reveal that hBN lubricants contribute to reduced carbon footprints in mechanical systems through multiple pathways. Their superior friction reduction properties translate to energy savings of 5-15% in various applications, with corresponding decreases in greenhouse gas emissions. Additionally, the extended service intervals enabled by hBN's oxidation resistance diminish the environmental impact associated with lubricant manufacturing and disposal.

Regulatory frameworks increasingly favor hBN-based solutions as environmental standards become more stringent. The material's compliance with REACH regulations in Europe and similar frameworks globally positions it advantageously as industries transition away from lubricants containing heavy metals and other environmentally persistent compounds. This regulatory alignment accelerates market adoption while supporting corporate sustainability initiatives.

End-of-life considerations for hBN lubricants demonstrate favorable characteristics. Their thermal stability facilitates more efficient recycling processes, while their low toxicity reduces remediation requirements for contaminated sites. Research into biodegradable carrier fluids for hBN particles represents a promising frontier for further enhancing the environmental credentials of these advanced lubricant systems.

hBN lubricants demonstrate significantly lower toxicity profiles than conventional options, with minimal bioaccumulation potential in aquatic ecosystems. Research indicates that hBN nanoparticles exhibit limited cytotoxicity at concentrations typically used in lubrication applications, presenting reduced environmental hazards during both production and disposal phases. This characteristic positions hBN as an environmentally preferable option in sensitive applications where lubricant leakage poses ecological risks.

The production processes for hBN lubricants have evolved toward greater sustainability. Modern synthesis methods have reduced energy consumption by approximately 30% compared to earlier techniques, while simultaneously decreasing hazardous waste generation. Innovations in green chemistry approaches have enabled water-based hBN dispersions that eliminate the need for environmentally harmful solvents during application processes.

Life cycle assessments reveal that hBN lubricants contribute to reduced carbon footprints in mechanical systems through multiple pathways. Their superior friction reduction properties translate to energy savings of 5-15% in various applications, with corresponding decreases in greenhouse gas emissions. Additionally, the extended service intervals enabled by hBN's oxidation resistance diminish the environmental impact associated with lubricant manufacturing and disposal.

Regulatory frameworks increasingly favor hBN-based solutions as environmental standards become more stringent. The material's compliance with REACH regulations in Europe and similar frameworks globally positions it advantageously as industries transition away from lubricants containing heavy metals and other environmentally persistent compounds. This regulatory alignment accelerates market adoption while supporting corporate sustainability initiatives.

End-of-life considerations for hBN lubricants demonstrate favorable characteristics. Their thermal stability facilitates more efficient recycling processes, while their low toxicity reduces remediation requirements for contaminated sites. Research into biodegradable carrier fluids for hBN particles represents a promising frontier for further enhancing the environmental credentials of these advanced lubricant systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!