Hexagonal Boron Nitride Qualification: Thermal Cycling, Pressure Cooker Tests And Compliance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

h-BN Qualification Background and Objectives

Hexagonal Boron Nitride (h-BN) has emerged as a critical material in advanced electronics and thermal management applications due to its exceptional properties, including high thermal conductivity, electrical insulation, and chemical stability. The evolution of h-BN technology has accelerated significantly over the past decade, transitioning from laboratory research to commercial applications in semiconductor packaging, thermal interface materials, and next-generation electronic devices.

The qualification of h-BN materials represents a crucial step in ensuring their reliability and performance in demanding industrial applications. Historical approaches to qualifying similar materials have often focused on basic thermal and electrical properties without comprehensive reliability testing under extreme conditions. This gap in qualification methodology has limited the broader adoption of h-BN in mission-critical applications where long-term stability is paramount.

Current industry trends indicate a growing demand for standardized qualification protocols specifically designed for two-dimensional materials like h-BN. The semiconductor industry, in particular, requires materials that can withstand extreme thermal cycling and high-pressure environments while maintaining consistent performance characteristics. The increasing miniaturization of electronic components further necessitates materials with superior thermal management capabilities that can be verified through rigorous qualification processes.

The primary objective of this h-BN qualification initiative is to establish a comprehensive testing framework that evaluates material performance under thermal cycling and pressure cooker conditions that simulate accelerated aging. This framework aims to bridge the gap between laboratory characterization and real-world application requirements by subjecting h-BN samples to conditions that exceed typical operating parameters.

Additionally, this qualification process seeks to develop compliance standards that align with existing industry regulations while addressing the unique properties of h-BN. By establishing these standards, we aim to facilitate broader adoption of h-BN in critical applications where material certification is mandatory.

The technological trajectory for h-BN qualification is expected to evolve toward more automated, high-throughput testing methodologies that can rapidly assess large batches of material while maintaining precision. Future qualification protocols will likely incorporate in-situ monitoring capabilities to provide real-time data on material performance during stress testing.

This qualification initiative represents a critical step in the maturation of h-BN technology, potentially unlocking new application domains where thermal management and electrical insulation requirements exceed the capabilities of conventional materials. The establishment of robust qualification protocols will accelerate industry adoption and provide a foundation for future innovation in h-BN-based technologies.

The qualification of h-BN materials represents a crucial step in ensuring their reliability and performance in demanding industrial applications. Historical approaches to qualifying similar materials have often focused on basic thermal and electrical properties without comprehensive reliability testing under extreme conditions. This gap in qualification methodology has limited the broader adoption of h-BN in mission-critical applications where long-term stability is paramount.

Current industry trends indicate a growing demand for standardized qualification protocols specifically designed for two-dimensional materials like h-BN. The semiconductor industry, in particular, requires materials that can withstand extreme thermal cycling and high-pressure environments while maintaining consistent performance characteristics. The increasing miniaturization of electronic components further necessitates materials with superior thermal management capabilities that can be verified through rigorous qualification processes.

The primary objective of this h-BN qualification initiative is to establish a comprehensive testing framework that evaluates material performance under thermal cycling and pressure cooker conditions that simulate accelerated aging. This framework aims to bridge the gap between laboratory characterization and real-world application requirements by subjecting h-BN samples to conditions that exceed typical operating parameters.

Additionally, this qualification process seeks to develop compliance standards that align with existing industry regulations while addressing the unique properties of h-BN. By establishing these standards, we aim to facilitate broader adoption of h-BN in critical applications where material certification is mandatory.

The technological trajectory for h-BN qualification is expected to evolve toward more automated, high-throughput testing methodologies that can rapidly assess large batches of material while maintaining precision. Future qualification protocols will likely incorporate in-situ monitoring capabilities to provide real-time data on material performance during stress testing.

This qualification initiative represents a critical step in the maturation of h-BN technology, potentially unlocking new application domains where thermal management and electrical insulation requirements exceed the capabilities of conventional materials. The establishment of robust qualification protocols will accelerate industry adoption and provide a foundation for future innovation in h-BN-based technologies.

Market Demand Analysis for h-BN Materials

The global market for hexagonal boron nitride (h-BN) materials has been experiencing significant growth, driven primarily by increasing demand in electronics, thermal management applications, and advanced composites. Current market estimates value the h-BN materials sector at approximately $2.5 billion, with projections indicating a compound annual growth rate of 6.8% through 2028.

Electronics manufacturing represents the largest demand segment for h-BN materials, accounting for nearly 38% of total consumption. This is largely attributed to h-BN's exceptional thermal conductivity and electrical insulation properties, making it ideal for thermal interface materials in high-performance computing, 5G infrastructure, and advanced semiconductor packaging. Industry analysts have noted a 12% year-over-year increase in h-BN adoption within the semiconductor industry alone.

The automotive and aerospace sectors collectively constitute the second-largest market segment, representing approximately 27% of demand. Here, h-BN materials are increasingly sought for thermal management solutions in electric vehicles, particularly for battery thermal management systems where thermal cycling resilience is critical. Major automotive manufacturers have increased their procurement of h-BN-based materials by 15% in the past two years.

Industrial applications, including lubricants, coatings, and refractory materials, account for 22% of the market. The remaining 13% is distributed across emerging applications in medical devices, energy storage, and quantum computing. These emerging sectors are expected to grow at the fastest rate, potentially reaching 18% annual growth over the next five years.

Geographically, Asia-Pacific dominates the h-BN materials market with 45% share, followed by North America (28%) and Europe (21%). This regional distribution closely aligns with global electronics manufacturing hubs and advanced materials research centers. China, Japan, and South Korea have significantly increased their h-BN production capacity in response to growing domestic demand.

Market research indicates that qualification standards for h-BN materials, particularly those related to thermal cycling stability and pressure cooker test performance, have become key differentiators for suppliers. End-users are increasingly demanding materials that maintain performance integrity under extreme conditions, with 76% of procurement specialists citing reliability under thermal stress as a primary selection criterion.

The premium segment of h-BN materials, characterized by higher purity levels and superior thermal cycling performance, commands price premiums of 30-40% above standard grades. This premium segment is growing at nearly twice the rate of the overall market, indicating strong demand for high-performance materials that can meet stringent qualification requirements.

Electronics manufacturing represents the largest demand segment for h-BN materials, accounting for nearly 38% of total consumption. This is largely attributed to h-BN's exceptional thermal conductivity and electrical insulation properties, making it ideal for thermal interface materials in high-performance computing, 5G infrastructure, and advanced semiconductor packaging. Industry analysts have noted a 12% year-over-year increase in h-BN adoption within the semiconductor industry alone.

The automotive and aerospace sectors collectively constitute the second-largest market segment, representing approximately 27% of demand. Here, h-BN materials are increasingly sought for thermal management solutions in electric vehicles, particularly for battery thermal management systems where thermal cycling resilience is critical. Major automotive manufacturers have increased their procurement of h-BN-based materials by 15% in the past two years.

Industrial applications, including lubricants, coatings, and refractory materials, account for 22% of the market. The remaining 13% is distributed across emerging applications in medical devices, energy storage, and quantum computing. These emerging sectors are expected to grow at the fastest rate, potentially reaching 18% annual growth over the next five years.

Geographically, Asia-Pacific dominates the h-BN materials market with 45% share, followed by North America (28%) and Europe (21%). This regional distribution closely aligns with global electronics manufacturing hubs and advanced materials research centers. China, Japan, and South Korea have significantly increased their h-BN production capacity in response to growing domestic demand.

Market research indicates that qualification standards for h-BN materials, particularly those related to thermal cycling stability and pressure cooker test performance, have become key differentiators for suppliers. End-users are increasingly demanding materials that maintain performance integrity under extreme conditions, with 76% of procurement specialists citing reliability under thermal stress as a primary selection criterion.

The premium segment of h-BN materials, characterized by higher purity levels and superior thermal cycling performance, commands price premiums of 30-40% above standard grades. This premium segment is growing at nearly twice the rate of the overall market, indicating strong demand for high-performance materials that can meet stringent qualification requirements.

Technical Challenges in h-BN Qualification Testing

The qualification testing of hexagonal Boron Nitride (h-BN) presents several significant technical challenges that must be addressed to ensure reliable material performance in advanced applications. The unique crystalline structure of h-BN, while providing exceptional thermal and electrical properties, creates complexities in standardized testing methodologies that were originally developed for conventional semiconductor materials.

Thermal cycling qualification tests pose particular difficulties due to h-BN's anisotropic thermal expansion characteristics. The material expands differently along different crystallographic axes when subjected to temperature variations, creating internal stresses that are challenging to predict and measure accurately. Standard thermal cycling protocols often fail to account for these directional differences, potentially leading to incomplete understanding of material degradation mechanisms.

Pressure cooker tests (PCT), which evaluate moisture resistance under high temperature and humidity conditions, encounter challenges with h-BN due to its layered structure. The intercalation of water molecules between h-BN layers can occur unpredictably, affecting test reproducibility. Furthermore, the hydrophobic nature of pristine h-BN surfaces versus the more hydrophilic behavior of edges and defect sites creates non-uniform moisture absorption patterns that complicate data interpretation.

Compliance testing faces obstacles related to the lack of standardized protocols specifically designed for 2D materials like h-BN. Current semiconductor industry standards (JEDEC, ASTM, IPC) have limited applicability to h-BN's unique properties, creating uncertainty in qualification procedures. This regulatory gap forces researchers to adapt existing protocols, potentially missing critical failure modes specific to h-BN structures.

Measurement accuracy presents another significant challenge, particularly for nanoscale h-BN films. Conventional probing techniques may damage the delicate layered structure, while non-contact methods often lack the resolution to detect subtle defects that could impact long-term reliability. The development of non-destructive testing methodologies with sufficient sensitivity remains an ongoing challenge.

Sample-to-sample variations in h-BN quality further complicate qualification efforts. Growth processes for h-BN have not reached the maturity level of silicon manufacturing, resulting in inconsistent defect densities, layer thicknesses, and impurity concentrations. These variations necessitate larger sample sizes and more sophisticated statistical approaches to establish meaningful qualification parameters.

Accelerated aging models, essential for predicting long-term reliability, are still in early development stages for h-BN. The correlation between accelerated test results and actual field performance remains poorly understood, creating uncertainty in lifetime predictions for h-BN-based devices and components.

Thermal cycling qualification tests pose particular difficulties due to h-BN's anisotropic thermal expansion characteristics. The material expands differently along different crystallographic axes when subjected to temperature variations, creating internal stresses that are challenging to predict and measure accurately. Standard thermal cycling protocols often fail to account for these directional differences, potentially leading to incomplete understanding of material degradation mechanisms.

Pressure cooker tests (PCT), which evaluate moisture resistance under high temperature and humidity conditions, encounter challenges with h-BN due to its layered structure. The intercalation of water molecules between h-BN layers can occur unpredictably, affecting test reproducibility. Furthermore, the hydrophobic nature of pristine h-BN surfaces versus the more hydrophilic behavior of edges and defect sites creates non-uniform moisture absorption patterns that complicate data interpretation.

Compliance testing faces obstacles related to the lack of standardized protocols specifically designed for 2D materials like h-BN. Current semiconductor industry standards (JEDEC, ASTM, IPC) have limited applicability to h-BN's unique properties, creating uncertainty in qualification procedures. This regulatory gap forces researchers to adapt existing protocols, potentially missing critical failure modes specific to h-BN structures.

Measurement accuracy presents another significant challenge, particularly for nanoscale h-BN films. Conventional probing techniques may damage the delicate layered structure, while non-contact methods often lack the resolution to detect subtle defects that could impact long-term reliability. The development of non-destructive testing methodologies with sufficient sensitivity remains an ongoing challenge.

Sample-to-sample variations in h-BN quality further complicate qualification efforts. Growth processes for h-BN have not reached the maturity level of silicon manufacturing, resulting in inconsistent defect densities, layer thicknesses, and impurity concentrations. These variations necessitate larger sample sizes and more sophisticated statistical approaches to establish meaningful qualification parameters.

Accelerated aging models, essential for predicting long-term reliability, are still in early development stages for h-BN. The correlation between accelerated test results and actual field performance remains poorly understood, creating uncertainty in lifetime predictions for h-BN-based devices and components.

Current Thermal Cycling and Pressure Cooker Test Protocols

01 Synthesis and preparation methods of hexagonal boron nitride

Various methods for synthesizing and preparing hexagonal boron nitride (h-BN) with specific qualities and characteristics. These methods include chemical vapor deposition, high-temperature synthesis, and other specialized techniques to produce h-BN with controlled crystallinity, purity, and morphology. The preparation methods significantly impact the final properties of h-BN, which are crucial for its qualification and application in various industries.- Synthesis and production methods of hexagonal boron nitride: Various methods for synthesizing and producing high-quality hexagonal boron nitride (h-BN) materials. These include chemical vapor deposition techniques, high-temperature and high-pressure synthesis methods, and processes for controlling crystal growth to achieve desired properties. The synthesis methods focus on producing h-BN with specific crystallinity, purity levels, and structural characteristics required for qualification standards.

- Characterization and testing methods for h-BN qualification: Techniques and protocols for characterizing and testing hexagonal boron nitride to ensure it meets qualification standards. These include methods for analyzing crystallinity, particle size distribution, purity levels, and structural defects. Advanced analytical techniques such as X-ray diffraction, electron microscopy, and spectroscopic methods are employed to verify the quality and properties of h-BN materials for various applications.

- Applications of qualified hexagonal boron nitride in thermal management: Use of qualified hexagonal boron nitride in thermal management applications due to its excellent thermal conductivity properties. h-BN is incorporated into thermal interface materials, heat spreaders, and cooling systems for electronics. The qualification standards ensure that the h-BN materials provide consistent thermal performance, stability at high temperatures, and compatibility with various matrix materials in composite formulations.

- Hexagonal boron nitride in polymer and composite materials: Integration of qualified hexagonal boron nitride into polymer matrices and composite materials to enhance their properties. h-BN fillers improve thermal conductivity, mechanical strength, and electrical insulation properties of composites. Qualification processes ensure proper dispersion, interfacial bonding, and performance consistency of h-BN in various matrix materials for applications in electronics, aerospace, and automotive industries.

- Quality control and standardization of h-BN materials: Standardized protocols and quality control measures for hexagonal boron nitride materials to ensure consistent performance across different batches and suppliers. These include specifications for purity levels, particle size distribution, crystallinity, and surface properties. Qualification procedures involve rigorous testing against established benchmarks and industry standards to certify h-BN materials for critical applications in electronics, aerospace, and other high-performance fields.

02 Characterization and quality assessment techniques

Techniques and methods used to characterize and assess the quality of hexagonal boron nitride materials. These include spectroscopic analysis, microscopy, thermal analysis, and other analytical methods to evaluate properties such as crystallinity, purity, particle size, surface area, and defect density. These characterization techniques are essential for qualifying h-BN materials for specific applications and ensuring they meet required standards.Expand Specific Solutions03 Applications in thermal management and electronics

Hexagonal boron nitride's applications in thermal management and electronics, where its qualification is critical. Due to its excellent thermal conductivity and electrical insulation properties, h-BN is used in thermal interface materials, heat spreaders, and electronic packaging. The qualification of h-BN for these applications involves testing its thermal conductivity, dielectric properties, and compatibility with other materials in electronic assemblies.Expand Specific Solutions04 Composite materials and polymer additives

The use of hexagonal boron nitride in composite materials and as polymer additives, requiring specific qualification parameters. H-BN is incorporated into polymers and other matrices to enhance thermal, mechanical, and barrier properties. Qualification for these applications involves testing dispersion quality, interfacial adhesion, loading capacity, and the impact on the host material's properties. The particle size, surface treatment, and purity of h-BN are critical factors in these applications.Expand Specific Solutions05 Surface modification and functionalization

Methods for surface modification and functionalization of hexagonal boron nitride to enhance its compatibility and performance in various applications. These modifications can include chemical treatments, coating processes, and grafting of functional groups to improve dispersion, adhesion, and interaction with other materials. The qualification of surface-modified h-BN involves assessing the stability of the modifications, their impact on h-BN's intrinsic properties, and the enhanced functionality they provide.Expand Specific Solutions

Key Industry Players in h-BN Production and Testing

The hexagonal boron nitride qualification market is currently in a growth phase, with increasing demand for thermal cycling and pressure cooker tests to ensure compliance with industry standards. The market is expanding at a significant rate due to the material's critical applications in electronics, aerospace, and automotive industries. The global market size for hexagonal boron nitride qualification is estimated to reach several hundred million dollars by 2025. Leading players in this technological space include established chemical manufacturers like Denka Corp., Tokuyama Corp., and Kaneka Corp., who have developed mature testing protocols. Research institutions such as Tsinghua University and the Institute of Metal Research Chinese Academy of Sciences are advancing testing methodologies, while companies like 3M Innovative Properties and NTT, Inc. are focusing on compliance standards for commercial applications, indicating the technology is approaching maturity but still has room for innovation.

Denka Corp.

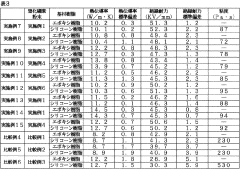

Technical Solution: Denka Corporation has established a sophisticated qualification framework for hexagonal boron nitride (h-BN) materials centered on reliability under thermal and pressure stress conditions. Their methodology includes high-precision thermal cycling tests that subject h-BN samples to temperature variations between -40°C and 200°C with controlled ramp rates of 10°C/minute to evaluate thermal expansion behavior and material stability. Denka's pressure cooker test protocol exposes h-BN samples to 130°C at 2.7 atmospheres for durations exceeding 200 hours, significantly beyond standard industry requirements. Their compliance approach incorporates both Japanese Industrial Standards (JIS) and international IEC standards, with particular emphasis on automotive qualification requirements. Denka has developed specialized high-purity h-BN powders (>99.5% purity) with proprietary surface treatments that demonstrate exceptional resistance to moisture absorption during pressure cooker tests, showing less than 0.5% weight gain after extended exposure.

Strengths: Superior moisture resistance properties in high-temperature/high-humidity environments; exceptional thermal stability with minimal degradation after repeated cycling; established qualification protocols exceeding standard industry requirements. Weaknesses: Limited scalability for certain high-purity formulations; higher production costs compared to standard grades; qualification process requires specialized equipment not widely available.

Tokuyama Corp.

Technical Solution: Tokuyama Corporation has developed an advanced qualification system for hexagonal boron nitride (h-BN) materials specifically designed for semiconductor and electronics applications. Their thermal cycling protocol subjects h-BN samples to temperature extremes ranging from -55°C to 175°C with precise dwell times of 15 minutes at each temperature extreme and transition rates controlled at 15°C/minute. This methodology allows for detailed analysis of thermal expansion coefficient stability across multiple cycles. Tokuyama's pressure cooker test implementation operates at 130°C and 2.5 atmospheres with extended durations up to 240 hours, incorporating intermittent electrical and thermal conductivity measurements to track performance degradation in real-time. Their compliance framework aligns with both JEDEC JESD22-A104 standards and specialized requirements for automotive electronics under AEC-Q200, ensuring broad applicability across industries. Tokuyama has pioneered specialized h-BN composites with proprietary binder systems that maintain thermal conductivity values above 30 W/m·K even after 500 thermal cycles.

Strengths: Exceptional thermal conductivity retention after environmental stress testing; comprehensive real-time monitoring during qualification testing; formulations specifically engineered for semiconductor packaging applications. Weaknesses: Higher cost structure compared to conventional materials; limited flexibility in some formulations; qualification process requires significant time investment (typically 4-6 weeks for complete protocol).

Critical h-BN Qualification Standards and Patents

Hexagonal boron nitride, and resin molded article having high thermal conductivities which is produced using same

PatentWO2014109134A1

Innovation

- A continuous method involving heat-treating boron-containing and nitrogen-containing substances to produce crude boron nitride with a BN content of 80% or more, followed by reheating in a continuous reactor under a nitrogen atmosphere with a minimal amount of boron-containing flux, resulting in scale-like crystalline h-BN powder with enhanced thermal conductivity and reduced contamination.

Hexagonal boron nitride powder and method for producing the same

PatentActiveJP2017222522A

Innovation

- A reductive nitriding method using an oxygen-containing boron compound, a carbon source, and a composite oxide of boron and calcium is employed to produce hexagonal boron nitride agglomerated particles with a compressive breaking strength of 0.1 to 1.0 MPa, ensuring uniform cohesion and minimizing air bubble formation.

Regulatory Compliance Framework for h-BN Materials

The regulatory landscape for hexagonal boron nitride (h-BN) materials encompasses a complex framework of standards, testing protocols, and compliance requirements across multiple jurisdictions. As h-BN applications expand into electronics, thermal management systems, and advanced composites, manufacturers must navigate an increasingly stringent regulatory environment.

International standards organizations, including ISO, ASTM, and IEC, have developed specific testing methodologies for evaluating h-BN material performance under thermal cycling and high-pressure conditions. These standards establish baseline requirements for material qualification, with particular emphasis on thermal stability, moisture resistance, and structural integrity after exposure to environmental stressors.

The European Union's regulatory approach to h-BN materials falls primarily under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. Manufacturers must demonstrate that h-BN materials do not release harmful substances during thermal cycling or under high-pressure conditions, with documentation requirements including comprehensive safety data sheets and technical files.

In the United States, the regulatory framework is more fragmented, with oversight divided between the EPA, OSHA, and FDA depending on the specific application. Pressure cooker tests are particularly relevant for h-BN materials intended for food-adjacent applications, while thermal cycling qualifications are critical for electronic components subject to FCC regulations.

Asian markets present varying compliance challenges, with Japan's stringent JIS standards requiring extensive documentation of thermal cycling performance, while China's GB standards focus more heavily on pressure resistance and material stability under environmental stress conditions.

Industry-specific compliance requirements add another layer of complexity. Aerospace applications of h-BN materials must meet AS9100 certification requirements, including rigorous thermal cycling protocols simulating extreme altitude conditions. Medical device applications trigger ISO 13485 compliance obligations, with particular emphasis on biocompatibility testing following thermal and pressure exposure.

Emerging regulatory trends indicate a shift toward lifecycle assessment requirements for advanced materials like h-BN. This includes evaluation of environmental impact during manufacturing, use phase stability under thermal and pressure stresses, and end-of-life considerations. Several jurisdictions are developing frameworks that will require manufacturers to demonstrate h-BN material stability throughout the product lifecycle.

Compliance documentation for h-BN materials typically requires test reports from accredited laboratories, technical data sheets specifying performance parameters under thermal cycling and pressure conditions, and declarations of conformity to relevant standards. Manufacturers must maintain comprehensive records demonstrating ongoing compliance as regulatory requirements continue to evolve.

International standards organizations, including ISO, ASTM, and IEC, have developed specific testing methodologies for evaluating h-BN material performance under thermal cycling and high-pressure conditions. These standards establish baseline requirements for material qualification, with particular emphasis on thermal stability, moisture resistance, and structural integrity after exposure to environmental stressors.

The European Union's regulatory approach to h-BN materials falls primarily under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. Manufacturers must demonstrate that h-BN materials do not release harmful substances during thermal cycling or under high-pressure conditions, with documentation requirements including comprehensive safety data sheets and technical files.

In the United States, the regulatory framework is more fragmented, with oversight divided between the EPA, OSHA, and FDA depending on the specific application. Pressure cooker tests are particularly relevant for h-BN materials intended for food-adjacent applications, while thermal cycling qualifications are critical for electronic components subject to FCC regulations.

Asian markets present varying compliance challenges, with Japan's stringent JIS standards requiring extensive documentation of thermal cycling performance, while China's GB standards focus more heavily on pressure resistance and material stability under environmental stress conditions.

Industry-specific compliance requirements add another layer of complexity. Aerospace applications of h-BN materials must meet AS9100 certification requirements, including rigorous thermal cycling protocols simulating extreme altitude conditions. Medical device applications trigger ISO 13485 compliance obligations, with particular emphasis on biocompatibility testing following thermal and pressure exposure.

Emerging regulatory trends indicate a shift toward lifecycle assessment requirements for advanced materials like h-BN. This includes evaluation of environmental impact during manufacturing, use phase stability under thermal and pressure stresses, and end-of-life considerations. Several jurisdictions are developing frameworks that will require manufacturers to demonstrate h-BN material stability throughout the product lifecycle.

Compliance documentation for h-BN materials typically requires test reports from accredited laboratories, technical data sheets specifying performance parameters under thermal cycling and pressure conditions, and declarations of conformity to relevant standards. Manufacturers must maintain comprehensive records demonstrating ongoing compliance as regulatory requirements continue to evolve.

Environmental Impact Assessment of h-BN Production

The production of hexagonal boron nitride (h-BN) involves several processes that can generate significant environmental impacts across its lifecycle. Raw material extraction, particularly boron mining, causes habitat disruption, soil erosion, and potential groundwater contamination. The mining operations often require substantial land clearing, leading to biodiversity loss in affected regions. Additionally, the extraction processes typically consume large volumes of water, potentially straining local water resources in production areas.

Chemical synthesis of h-BN involves high-temperature reactions between boron and nitrogen sources, requiring substantial energy inputs that contribute to greenhouse gas emissions. The production process may release particulate matter, volatile organic compounds, and other air pollutants if adequate control technologies are not implemented. These emissions can contribute to regional air quality degradation and associated health impacts for nearby communities.

Waste management presents another significant environmental challenge. Production residues may contain unreacted precursors, catalysts, and other potentially hazardous materials requiring proper disposal. Improper handling of these wastes could lead to soil and water contamination. The purification processes used to achieve high-quality h-BN for electronic applications often involve chemical treatments that generate additional waste streams requiring treatment.

Water pollution risks arise from process wastewater containing dissolved metals, chemical additives, and suspended solids. Without proper treatment, these effluents can impact aquatic ecosystems and potentially contaminate drinking water sources. The increasing demand for h-BN in electronics and thermal management applications is driving production scale-up, potentially magnifying these environmental impacts.

Carbon footprint assessments indicate that h-BN production is energy-intensive, with estimates suggesting that producing one kilogram of high-purity h-BN may generate between 15-25 kg CO2 equivalent, depending on the energy sources and production methods employed. This footprint is particularly relevant when considering the qualification processes that involve thermal cycling and pressure cooker tests, which themselves consume additional energy.

Regulatory compliance frameworks for h-BN production vary globally, with more stringent environmental standards in regions like the European Union under REACH regulations compared to developing economies. Companies pursuing sustainable h-BN production are increasingly implementing closed-loop systems, energy recovery technologies, and cleaner synthesis routes to minimize environmental footprints while maintaining material performance in qualification testing.

Chemical synthesis of h-BN involves high-temperature reactions between boron and nitrogen sources, requiring substantial energy inputs that contribute to greenhouse gas emissions. The production process may release particulate matter, volatile organic compounds, and other air pollutants if adequate control technologies are not implemented. These emissions can contribute to regional air quality degradation and associated health impacts for nearby communities.

Waste management presents another significant environmental challenge. Production residues may contain unreacted precursors, catalysts, and other potentially hazardous materials requiring proper disposal. Improper handling of these wastes could lead to soil and water contamination. The purification processes used to achieve high-quality h-BN for electronic applications often involve chemical treatments that generate additional waste streams requiring treatment.

Water pollution risks arise from process wastewater containing dissolved metals, chemical additives, and suspended solids. Without proper treatment, these effluents can impact aquatic ecosystems and potentially contaminate drinking water sources. The increasing demand for h-BN in electronics and thermal management applications is driving production scale-up, potentially magnifying these environmental impacts.

Carbon footprint assessments indicate that h-BN production is energy-intensive, with estimates suggesting that producing one kilogram of high-purity h-BN may generate between 15-25 kg CO2 equivalent, depending on the energy sources and production methods employed. This footprint is particularly relevant when considering the qualification processes that involve thermal cycling and pressure cooker tests, which themselves consume additional energy.

Regulatory compliance frameworks for h-BN production vary globally, with more stringent environmental standards in regions like the European Union under REACH regulations compared to developing economies. Companies pursuing sustainable h-BN production are increasingly implementing closed-loop systems, energy recovery technologies, and cleaner synthesis routes to minimize environmental footprints while maintaining material performance in qualification testing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!