Hexagonal Boron Nitride Tribology: Transfer Films, Counterface Effects And Long-Term Wear

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

hBN Tribology Background and Research Objectives

Hexagonal Boron Nitride (hBN) has emerged as a significant solid lubricant material in tribological applications due to its unique layered structure similar to graphite. The history of hBN in tribology dates back to the 1950s when researchers began exploring alternatives to graphite for applications where electrical conductivity was undesirable. Over subsequent decades, hBN has gained prominence for its exceptional thermal stability, chemical inertness, and lubrication properties in extreme environments.

The evolution of hBN tribology research has progressed through several distinct phases. Initially, studies focused on basic friction and wear characteristics, followed by investigations into its performance under various environmental conditions. Recent advancements have shifted toward understanding the fundamental mechanisms of hBN's tribological behavior, particularly the formation and function of transfer films on counterface materials and their long-term wear implications.

Current technological trends in hBN tribology include the development of nanostructured hBN materials, hBN-based composites, and hybrid lubricant systems that combine hBN with other solid lubricants or liquid media. These innovations aim to enhance performance across a broader range of operating conditions and extend component lifespans in critical applications.

The primary technical objectives of this research are multifaceted. First, to comprehensively characterize the mechanisms governing transfer film formation when hBN interfaces with various counterface materials, including metals, ceramics, and polymers. Second, to quantify how counterface properties—such as surface roughness, hardness, and chemical composition—influence the tribological performance of hBN. Third, to establish predictive models for long-term wear behavior in hBN-lubricated systems under continuous operation.

Additionally, this research aims to address several knowledge gaps in the field, including the molecular-level interactions at the sliding interface, the role of crystallographic orientation in friction reduction, and the impact of environmental factors such as humidity, temperature, and atmospheric composition on transfer film stability and wear progression.

The technological significance of advancing hBN tribology extends across multiple industries. In aerospace, hBN lubricants enable reliable operation of mechanical components in the extreme temperatures and vacuum conditions of space. In manufacturing, hBN-based lubrication systems can enhance tool life and machining precision. In energy production, particularly nuclear and renewable sectors, hBN's radiation resistance and thermal stability make it valuable for components operating in harsh environments.

By establishing a deeper understanding of hBN transfer films, counterface effects, and long-term wear behavior, this research seeks to enable the development of next-generation tribological systems with enhanced reliability, efficiency, and durability across diverse industrial applications.

The evolution of hBN tribology research has progressed through several distinct phases. Initially, studies focused on basic friction and wear characteristics, followed by investigations into its performance under various environmental conditions. Recent advancements have shifted toward understanding the fundamental mechanisms of hBN's tribological behavior, particularly the formation and function of transfer films on counterface materials and their long-term wear implications.

Current technological trends in hBN tribology include the development of nanostructured hBN materials, hBN-based composites, and hybrid lubricant systems that combine hBN with other solid lubricants or liquid media. These innovations aim to enhance performance across a broader range of operating conditions and extend component lifespans in critical applications.

The primary technical objectives of this research are multifaceted. First, to comprehensively characterize the mechanisms governing transfer film formation when hBN interfaces with various counterface materials, including metals, ceramics, and polymers. Second, to quantify how counterface properties—such as surface roughness, hardness, and chemical composition—influence the tribological performance of hBN. Third, to establish predictive models for long-term wear behavior in hBN-lubricated systems under continuous operation.

Additionally, this research aims to address several knowledge gaps in the field, including the molecular-level interactions at the sliding interface, the role of crystallographic orientation in friction reduction, and the impact of environmental factors such as humidity, temperature, and atmospheric composition on transfer film stability and wear progression.

The technological significance of advancing hBN tribology extends across multiple industries. In aerospace, hBN lubricants enable reliable operation of mechanical components in the extreme temperatures and vacuum conditions of space. In manufacturing, hBN-based lubrication systems can enhance tool life and machining precision. In energy production, particularly nuclear and renewable sectors, hBN's radiation resistance and thermal stability make it valuable for components operating in harsh environments.

By establishing a deeper understanding of hBN transfer films, counterface effects, and long-term wear behavior, this research seeks to enable the development of next-generation tribological systems with enhanced reliability, efficiency, and durability across diverse industrial applications.

Market Applications and Demand for hBN Lubricants

The global market for hexagonal boron nitride (hBN) lubricants has witnessed significant growth in recent years, driven by increasing demand for high-performance lubricants in extreme operating conditions. The unique tribological properties of hBN, particularly its ability to form effective transfer films and demonstrate long-term wear resistance, have positioned it as a premium solution for specialized industrial applications.

The aerospace industry represents one of the largest market segments for hBN lubricants, where components must operate reliably under extreme temperatures, vacuum conditions, and high loads. The ability of hBN to maintain lubricity in temperatures exceeding 900°C makes it invaluable for aircraft engines, space mechanisms, and satellite components where conventional lubricants would degrade rapidly.

Automotive manufacturing constitutes another significant market, with hBN lubricants finding applications in high-temperature engine components, metal forming processes, and specialized bearings. The growing trend toward electric vehicles has created new demand for hBN lubricants in battery systems and electric motor components where traditional petroleum-based lubricants may be unsuitable.

The semiconductor and electronics manufacturing sector has emerged as a rapidly expanding market for hBN lubricants. The clean, non-contaminating nature of hBN makes it ideal for precision equipment where particulate contamination must be minimized. Additionally, its electrical insulating properties provide added value in electronic assembly processes.

Heavy industry applications, including metal forming, die casting, and high-temperature processing equipment, represent substantial market volume. In these environments, the ability of hBN to form persistent transfer films on counterface materials translates to extended equipment life and reduced maintenance costs.

Market analysis indicates regional variations in hBN lubricant adoption, with North America and Asia-Pacific leading in consumption volume. The Asia-Pacific region, particularly China, Japan, and South Korea, shows the highest growth rate, driven by expanding manufacturing sectors and increasing technological sophistication in industrial processes.

Consumer demand increasingly emphasizes environmentally sustainable solutions, creating market opportunities for water-based hBN lubricant formulations as alternatives to traditional oil-based products. This trend aligns with stricter environmental regulations in Europe and North America regarding industrial chemicals and emissions.

The market structure features a mix of specialized lubricant manufacturers and larger chemical companies that have incorporated hBN formulations into their product portfolios. Premium pricing remains standard due to processing complexities and the specialized nature of applications, though economies of scale are gradually improving cost-effectiveness for broader industrial adoption.

The aerospace industry represents one of the largest market segments for hBN lubricants, where components must operate reliably under extreme temperatures, vacuum conditions, and high loads. The ability of hBN to maintain lubricity in temperatures exceeding 900°C makes it invaluable for aircraft engines, space mechanisms, and satellite components where conventional lubricants would degrade rapidly.

Automotive manufacturing constitutes another significant market, with hBN lubricants finding applications in high-temperature engine components, metal forming processes, and specialized bearings. The growing trend toward electric vehicles has created new demand for hBN lubricants in battery systems and electric motor components where traditional petroleum-based lubricants may be unsuitable.

The semiconductor and electronics manufacturing sector has emerged as a rapidly expanding market for hBN lubricants. The clean, non-contaminating nature of hBN makes it ideal for precision equipment where particulate contamination must be minimized. Additionally, its electrical insulating properties provide added value in electronic assembly processes.

Heavy industry applications, including metal forming, die casting, and high-temperature processing equipment, represent substantial market volume. In these environments, the ability of hBN to form persistent transfer films on counterface materials translates to extended equipment life and reduced maintenance costs.

Market analysis indicates regional variations in hBN lubricant adoption, with North America and Asia-Pacific leading in consumption volume. The Asia-Pacific region, particularly China, Japan, and South Korea, shows the highest growth rate, driven by expanding manufacturing sectors and increasing technological sophistication in industrial processes.

Consumer demand increasingly emphasizes environmentally sustainable solutions, creating market opportunities for water-based hBN lubricant formulations as alternatives to traditional oil-based products. This trend aligns with stricter environmental regulations in Europe and North America regarding industrial chemicals and emissions.

The market structure features a mix of specialized lubricant manufacturers and larger chemical companies that have incorporated hBN formulations into their product portfolios. Premium pricing remains standard due to processing complexities and the specialized nature of applications, though economies of scale are gradually improving cost-effectiveness for broader industrial adoption.

Current Challenges in hBN Transfer Film Formation

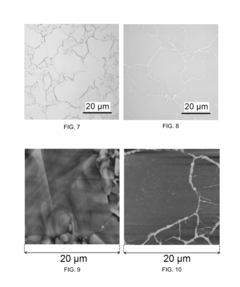

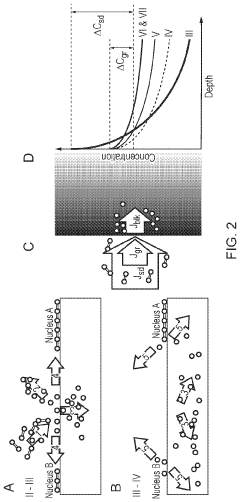

The formation of hexagonal Boron Nitride (hBN) transfer films represents a critical mechanism in solid lubrication applications, yet several significant challenges impede optimal performance and widespread industrial adoption. One primary obstacle is the inconsistent transfer film formation across varying operational conditions. Unlike graphite, hBN requires specific environmental parameters to form stable transfer films, with humidity levels and temperature significantly affecting film development and adherence properties.

Surface chemistry compatibility presents another substantial challenge, as hBN transfer films exhibit selective adhesion behaviors depending on counterface material composition. Studies indicate that while hBN readily forms coherent films on certain metal surfaces, it demonstrates poor adhesion to ceramic and some polymer surfaces, limiting its universal application across diverse tribological systems.

The mechanical stability of formed transfer films remains problematic, particularly under high-load or high-speed conditions where film delamination frequently occurs. This instability creates unpredictable friction coefficients and accelerated wear rates, compromising the reliability of lubrication performance in demanding industrial applications.

Film thickness control represents a persistent technical hurdle, as optimal tribological performance requires precise film thickness that balances coverage with minimal friction. Current application methods struggle to achieve this balance consistently, resulting in either insufficient coverage or excessive material buildup that paradoxically increases friction and wear.

Contamination sensitivity further complicates hBN transfer film formation, with even minor surface contaminants potentially disrupting the molecular orientation and packing density necessary for effective lubrication. This sensitivity necessitates stringent surface preparation protocols that may be impractical in many industrial settings.

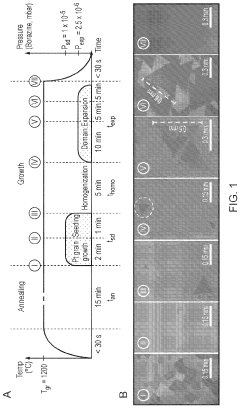

The time-dependent nature of film formation introduces additional complexity, as the establishment of effective transfer films often requires an extended "break-in" period during which wear rates may be elevated. This temporal dependency creates challenges for applications requiring immediate lubrication effectiveness upon startup.

Environmental degradation of formed films, particularly in oxidizing or high-humidity environments, limits long-term stability and necessitates frequent reapplication. Research indicates that chemical modifications to enhance environmental resistance often compromise the intrinsic lubrication properties of hBN, creating a technological trade-off that remains unresolved.

These challenges collectively highlight the need for advanced engineering approaches to hBN transfer film formation, potentially including surface functionalization techniques, composite formulations, and novel application methodologies to overcome current limitations.

Surface chemistry compatibility presents another substantial challenge, as hBN transfer films exhibit selective adhesion behaviors depending on counterface material composition. Studies indicate that while hBN readily forms coherent films on certain metal surfaces, it demonstrates poor adhesion to ceramic and some polymer surfaces, limiting its universal application across diverse tribological systems.

The mechanical stability of formed transfer films remains problematic, particularly under high-load or high-speed conditions where film delamination frequently occurs. This instability creates unpredictable friction coefficients and accelerated wear rates, compromising the reliability of lubrication performance in demanding industrial applications.

Film thickness control represents a persistent technical hurdle, as optimal tribological performance requires precise film thickness that balances coverage with minimal friction. Current application methods struggle to achieve this balance consistently, resulting in either insufficient coverage or excessive material buildup that paradoxically increases friction and wear.

Contamination sensitivity further complicates hBN transfer film formation, with even minor surface contaminants potentially disrupting the molecular orientation and packing density necessary for effective lubrication. This sensitivity necessitates stringent surface preparation protocols that may be impractical in many industrial settings.

The time-dependent nature of film formation introduces additional complexity, as the establishment of effective transfer films often requires an extended "break-in" period during which wear rates may be elevated. This temporal dependency creates challenges for applications requiring immediate lubrication effectiveness upon startup.

Environmental degradation of formed films, particularly in oxidizing or high-humidity environments, limits long-term stability and necessitates frequent reapplication. Research indicates that chemical modifications to enhance environmental resistance often compromise the intrinsic lubrication properties of hBN, creating a technological trade-off that remains unresolved.

These challenges collectively highlight the need for advanced engineering approaches to hBN transfer film formation, potentially including surface functionalization techniques, composite formulations, and novel application methodologies to overcome current limitations.

Existing Methodologies for Enhancing hBN Tribological Performance

01 h-BN film fabrication and transfer techniques

Various methods for fabricating and transferring hexagonal boron nitride films onto different substrates. These techniques include chemical vapor deposition (CVD), mechanical exfoliation, and specialized transfer processes that maintain the structural integrity of the h-BN films. The transfer methods are critical for ensuring proper adhesion and performance of the h-BN films in various applications, particularly for tribological purposes.- h-BN film fabrication and transfer techniques: Various methods for fabricating and transferring hexagonal boron nitride films onto different substrates. These techniques include chemical vapor deposition (CVD), mechanical exfoliation, and specialized transfer processes that maintain the structural integrity of the h-BN films. The transfer methods are critical for ensuring proper adhesion and functionality of the h-BN films in various applications, particularly for tribological purposes.

- Tribological properties and wear resistance of h-BN coatings: Hexagonal boron nitride exhibits excellent tribological properties including low friction coefficient and high wear resistance. When used as a coating or film, h-BN provides self-lubricating properties that significantly reduce friction between contacting surfaces. The layered structure of h-BN allows for easy shearing between atomic planes, contributing to its effectiveness as a solid lubricant for long-term wear applications under various operating conditions.

- Counterface material interactions with h-BN films: The performance of h-BN films is significantly affected by the counterface materials they interact with. Different counterface materials (such as steel, ceramics, or other composites) show varying tribological behaviors when sliding against h-BN films. These interactions influence the formation of transfer films, friction coefficients, and wear mechanisms. Understanding these counterface effects is crucial for optimizing h-BN-based tribological systems for specific applications.

- h-BN composite materials for enhanced performance: Incorporating h-BN into composite materials with polymers, metals, or ceramics enhances tribological performance. These composites combine the lubricating properties of h-BN with the mechanical strength of the matrix material, resulting in improved wear resistance and reduced friction. The composition, concentration, and dispersion of h-BN within these composites significantly affect their long-term wear behavior and overall performance in demanding applications.

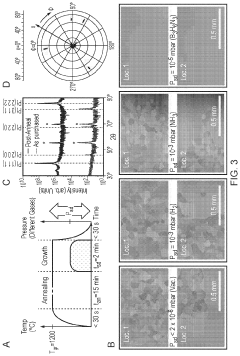

- Environmental and operational factors affecting h-BN film durability: The long-term wear performance of h-BN films is influenced by environmental and operational factors such as temperature, humidity, load, and sliding speed. Under high temperatures, h-BN maintains its lubricating properties while many conventional lubricants fail. However, humidity can affect the interlayer bonding of h-BN, potentially altering its tribological behavior. Understanding these factors is essential for predicting the durability and reliability of h-BN films in various application environments.

02 Tribological properties and wear resistance of h-BN coatings

Hexagonal boron nitride exhibits excellent tribological properties including low friction coefficient and high wear resistance. When used as a coating or film, h-BN provides self-lubricating properties that significantly reduce friction between contacting surfaces. The layered structure of h-BN allows for easy shearing between atomic planes, contributing to its effectiveness as a solid lubricant for long-term wear applications under various operating conditions.Expand Specific Solutions03 Counterface material interactions with h-BN films

The interaction between h-BN films and counterface materials significantly affects the tribological performance of the system. Different counterface materials (such as steel, ceramics, or polymers) exhibit varying degrees of compatibility with h-BN films. These interactions influence the formation of transfer films, friction coefficient stability, and overall wear behavior. Optimizing the counterface material selection can enhance the longevity and performance of h-BN-based tribological systems.Expand Specific Solutions04 h-BN composite materials for enhanced wear performance

Incorporating h-BN into composite materials with polymers, metals, or ceramics creates advanced materials with superior wear resistance and tribological properties. These composites combine the self-lubricating properties of h-BN with the mechanical strength of the matrix material. The resulting materials demonstrate improved long-term wear performance, thermal stability, and load-bearing capacity, making them suitable for demanding applications in various industries.Expand Specific Solutions05 Long-term wear behavior and stability of h-BN transfer films

The long-term wear behavior of h-BN transfer films depends on various factors including operating conditions, environment, and substrate properties. These films demonstrate remarkable stability under prolonged use, maintaining their lubricating properties even after extended wear cycles. The formation and maintenance of stable transfer films on counterface surfaces contribute significantly to the sustained low friction and wear resistance. Environmental factors such as humidity, temperature, and oxidation can influence the long-term performance of h-BN transfer films.Expand Specific Solutions

Leading Manufacturers and Research Institutions in hBN Technology

Hexagonal Boron Nitride (h-BN) tribology is currently in a growth phase, with the market expanding as industries seek advanced lubricants for extreme conditions. The global h-BN market is projected to reach significant scale due to its exceptional tribological properties, particularly transfer film formation and long-term wear resistance. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include DuPont de Nemours developing specialized formulations, Tokyo Electron and Applied Materials focusing on semiconductor applications, and research institutions like MIT and Chinese Academy of Sciences advancing fundamental understanding. Samsung Electronics and 3M are integrating h-BN into commercial products, while Sumitomo Chemical and Mitsubishi are enhancing manufacturing processes. The competitive landscape features both established chemical corporations and specialized research entities collaborating to overcome counterface effect challenges.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered composite materials incorporating hexagonal boron nitride for tribological applications, focusing on transfer film optimization. Their technology utilizes a proprietary matrix of fluoropolymers (typically PTFE or PFA) with precisely controlled h-BN concentrations (5-15% by weight) to create self-lubricating surfaces. The company's research has demonstrated that these composites form stable transfer films on counterface materials with thicknesses of 50-200 nm, providing consistent lubrication across extended wear cycles. DuPont's approach includes surface treatment processes that enhance h-BN exfoliation during sliding, promoting nanoscale sheet formation that reduces friction coefficients by up to 40% compared to untreated h-BN. Their long-term wear studies show that optimized h-BN composites maintain performance for over 500,000 cycles under loads up to 5 MPa, with wear rates below 10^-6 mm³/Nm.

Strengths: Exceptional transfer film formation and stability; excellent compatibility with polymer matrices; consistent performance over extended wear cycles. Weaknesses: Limited effectiveness at temperatures above 350°C; requires careful control of counterface roughness for optimal transfer film formation; higher cost compared to conventional solid lubricants.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced h-BN tribological coatings for semiconductor manufacturing equipment where ultra-clean, high-performance lubrication is critical. Their technology utilizes plasma-enhanced chemical vapor deposition (PECVD) to create highly crystalline h-BN films with precisely controlled thicknesses (typically 50-500 nm) and exceptional uniformity (±5%). The company's research demonstrates that these coatings exhibit remarkable wear resistance in semiconductor processing environments, with wear rates below 10^-8 mm³/Nm under loads up to 2 GPa. Applied Materials has engineered specialized surface preparation techniques that enhance h-BN adhesion to various substrates while maintaining its intrinsic lubricity. Their studies on counterface effects show that h-BN transfer films form differently on various semiconductor materials, with optimal performance on silicon and silicon carbide surfaces. The company's long-term wear testing demonstrates that their h-BN coatings maintain stable friction coefficients (0.05-0.15) for over 1 million cycles in both vacuum and controlled atmospheric conditions.

Strengths: Ultra-high purity h-BN films suitable for semiconductor applications; exceptional uniformity and thickness control; excellent performance in vacuum environments. Weaknesses: Highly specialized application methods limit broader industrial adoption; higher production costs compared to conventional lubricants; requires sophisticated deposition equipment.

Critical Analysis of hBN Transfer Film Mechanisms

Fabrication of large-area hexagonal boron nitride thin films

PatentInactiveUS8592291B2

Innovation

- The method involves using borazine as a precursor for h-BN thin film production via ambient-pressure chemical vapor deposition (APCVD) on a polycrystalline Ni(111) surface, followed by high-temperature annealing, and applying a protective support layer to facilitate the release and transfer of the h-BN film onto arbitrary substrates, allowing for large-area, high-quality film production at reduced temperatures.

Synthesis of hexagonal boron nitride films and transfer method

PatentInactiveUS20210222295A1

Innovation

- A method involving chemical vapour deposition (CVD) with a four-step process: annealing, recrystallization/seeding, homogenization, and domain expansion, using a platinum substrate for growth and a carrier material for non-destructive transfer, which allows for the production of large-area h-BN with minimal nucleation and preservation of quality.

Environmental Impact and Sustainability of hBN Lubricants

The environmental impact of hexagonal boron nitride (hBN) lubricants represents a critical consideration in their industrial application and future development. As a solid lubricant, hBN offers significant sustainability advantages over traditional petroleum-based lubricants, primarily due to its non-toxic nature and chemical stability. Unlike conventional lubricants that release volatile organic compounds (VOCs) and contribute to air pollution, hBN-based lubricants demonstrate minimal environmental emissions during operation.

The extraction and processing of boron nitride, however, does present certain environmental challenges. Mining operations for boron compounds can lead to habitat disruption and potential water contamination if not properly managed. The synthesis of high-quality hBN typically requires high temperatures (around 1500°C), resulting in considerable energy consumption and associated carbon emissions. Recent advancements in production techniques have focused on reducing these energy requirements through catalytic methods and optimized reaction pathways.

Lifecycle assessment studies indicate that hBN lubricants offer reduced environmental impact during their use phase compared to conventional options. The exceptional wear resistance and long-term stability of hBN transfer films contribute to extended component lifespans, thereby reducing material consumption and waste generation. This longevity factor significantly enhances the sustainability profile of hBN tribological applications.

Water contamination risks from hBN are substantially lower than those posed by petroleum lubricants. The material's chemical inertness prevents leaching of harmful compounds into groundwater systems. Additionally, hBN particles demonstrate limited bioaccumulation potential in aquatic ecosystems, though comprehensive long-term studies on environmental fate remain somewhat limited.

Recycling and end-of-life management present both challenges and opportunities for hBN lubricant systems. While recovery of hBN from composite materials can be technically challenging, the material's thermal stability allows for potential reclamation through thermal processing methods. Several research initiatives are currently exploring efficient separation techniques to facilitate closed-loop recycling of hBN from spent lubricant systems.

Regulatory frameworks worldwide are increasingly recognizing hBN as an environmentally preferable alternative in tribological applications. The European Union's REACH regulations classify hBN as a low-concern substance, while the US EPA has acknowledged its potential as a green chemistry alternative in certain lubrication scenarios. These regulatory advantages may accelerate industrial adoption as environmental compliance requirements continue to strengthen globally.

The extraction and processing of boron nitride, however, does present certain environmental challenges. Mining operations for boron compounds can lead to habitat disruption and potential water contamination if not properly managed. The synthesis of high-quality hBN typically requires high temperatures (around 1500°C), resulting in considerable energy consumption and associated carbon emissions. Recent advancements in production techniques have focused on reducing these energy requirements through catalytic methods and optimized reaction pathways.

Lifecycle assessment studies indicate that hBN lubricants offer reduced environmental impact during their use phase compared to conventional options. The exceptional wear resistance and long-term stability of hBN transfer films contribute to extended component lifespans, thereby reducing material consumption and waste generation. This longevity factor significantly enhances the sustainability profile of hBN tribological applications.

Water contamination risks from hBN are substantially lower than those posed by petroleum lubricants. The material's chemical inertness prevents leaching of harmful compounds into groundwater systems. Additionally, hBN particles demonstrate limited bioaccumulation potential in aquatic ecosystems, though comprehensive long-term studies on environmental fate remain somewhat limited.

Recycling and end-of-life management present both challenges and opportunities for hBN lubricant systems. While recovery of hBN from composite materials can be technically challenging, the material's thermal stability allows for potential reclamation through thermal processing methods. Several research initiatives are currently exploring efficient separation techniques to facilitate closed-loop recycling of hBN from spent lubricant systems.

Regulatory frameworks worldwide are increasingly recognizing hBN as an environmentally preferable alternative in tribological applications. The European Union's REACH regulations classify hBN as a low-concern substance, while the US EPA has acknowledged its potential as a green chemistry alternative in certain lubrication scenarios. These regulatory advantages may accelerate industrial adoption as environmental compliance requirements continue to strengthen globally.

Standardization and Testing Protocols for hBN Tribological Systems

The development of standardized testing protocols for hexagonal Boron Nitride (hBN) tribological systems represents a critical need in the field. Current research on hBN tribology suffers from significant inconsistencies in testing methodologies, making cross-study comparisons challenging and limiting industrial implementation. Establishing uniform protocols would enable reliable benchmarking of hBN's performance across different applications and environments.

A comprehensive standardization framework should address multiple testing parameters including load conditions, sliding speeds, temperature ranges, humidity controls, and substrate preparation methods. These parameters significantly influence hBN's tribological behavior, particularly its transfer film formation mechanisms and long-term wear characteristics. The lack of standardized reporting of these conditions has contributed to contradictory findings in literature regarding hBN's coefficient of friction and wear resistance.

Testing protocols must specifically account for counterface material interactions, as hBN exhibits distinct tribological behaviors when paired with different materials. Steel, aluminum, ceramic, and polymer counterfaces each produce unique transfer film characteristics that affect overall system performance. Standardized protocols should include detailed specifications for counterface preparation, roughness measurements, and chemical characterization before and after testing.

Environmental testing standards are particularly important for hBN tribological systems due to their sensitivity to humidity and temperature. Protocols should mandate controlled environmental chambers with precise monitoring capabilities, as hBN's layered structure and tribological performance can be significantly altered by moisture intercalation and temperature-induced structural changes. This is especially relevant for applications in extreme environments where hBN's advantages over traditional lubricants are most pronounced.

Long-term wear testing standardization presents unique challenges that must be addressed. Accelerated testing methodologies need validation against real-world performance data to ensure relevance. Protocols should define standard intervals for wear measurement, surface characterization, and transfer film analysis throughout extended testing periods. This would provide valuable insights into hBN's progressive wear mechanisms and transfer film evolution over time.

International collaboration between research institutions, industry stakeholders, and standards organizations is essential for developing widely accepted protocols. Organizations such as ASTM International, ISO, and DIN have established frameworks that could be adapted specifically for hBN tribological testing. The development of reference materials and calibration standards would further enhance testing reliability and facilitate interlaboratory comparisons.

A comprehensive standardization framework should address multiple testing parameters including load conditions, sliding speeds, temperature ranges, humidity controls, and substrate preparation methods. These parameters significantly influence hBN's tribological behavior, particularly its transfer film formation mechanisms and long-term wear characteristics. The lack of standardized reporting of these conditions has contributed to contradictory findings in literature regarding hBN's coefficient of friction and wear resistance.

Testing protocols must specifically account for counterface material interactions, as hBN exhibits distinct tribological behaviors when paired with different materials. Steel, aluminum, ceramic, and polymer counterfaces each produce unique transfer film characteristics that affect overall system performance. Standardized protocols should include detailed specifications for counterface preparation, roughness measurements, and chemical characterization before and after testing.

Environmental testing standards are particularly important for hBN tribological systems due to their sensitivity to humidity and temperature. Protocols should mandate controlled environmental chambers with precise monitoring capabilities, as hBN's layered structure and tribological performance can be significantly altered by moisture intercalation and temperature-induced structural changes. This is especially relevant for applications in extreme environments where hBN's advantages over traditional lubricants are most pronounced.

Long-term wear testing standardization presents unique challenges that must be addressed. Accelerated testing methodologies need validation against real-world performance data to ensure relevance. Protocols should define standard intervals for wear measurement, surface characterization, and transfer film analysis throughout extended testing periods. This would provide valuable insights into hBN's progressive wear mechanisms and transfer film evolution over time.

International collaboration between research institutions, industry stakeholders, and standards organizations is essential for developing widely accepted protocols. Organizations such as ASTM International, ISO, and DIN have established frameworks that could be adapted specifically for hBN tribological testing. The development of reference materials and calibration standards would further enhance testing reliability and facilitate interlaboratory comparisons.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!