Hexagonal Boron Nitride Thermal Interface Materials: Orientation Control, Contact Resistance And Lifetime

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

h-BN TIM Background and Objectives

Hexagonal Boron Nitride (h-BN) has emerged as a promising material for thermal interface applications due to its exceptional thermal conductivity, electrical insulation properties, and chemical stability. The evolution of thermal management solutions has become increasingly critical as electronic devices continue to miniaturize while simultaneously increasing in power density. Traditional thermal interface materials (TIMs) such as silicone-based compounds and metal-based solutions are reaching their performance limits, creating an urgent need for next-generation materials.

The historical development of h-BN as a TIM began in the early 2000s when researchers first recognized its potential for heat dissipation applications. Initial studies focused primarily on its fundamental thermal properties, with subsequent research expanding to explore various forms including powders, films, and composites. The last decade has witnessed significant advancements in synthesis methods, enabling better control over h-BN's structure and properties.

Current technological trends indicate a growing interest in two-dimensional (2D) materials for thermal management, with h-BN standing out due to its hexagonal lattice structure that facilitates efficient in-plane heat conduction. The anisotropic thermal conductivity of h-BN presents both challenges and opportunities, as proper orientation control can dramatically enhance thermal performance in specific directions.

The primary technical objectives for h-BN TIMs focus on three critical aspects: orientation control, minimization of contact resistance, and lifetime stability. Orientation control aims to align h-BN flakes to maximize heat transfer across interfaces, which requires innovative processing techniques and composite formulations. Contact resistance reduction involves optimizing the interface between h-BN and adjacent materials to minimize thermal boundary resistance, a significant bottleneck in overall thermal performance.

Lifetime stability represents perhaps the most challenging objective, as TIMs must maintain their thermal performance under various environmental conditions, thermal cycling, and mechanical stresses over extended periods. This is particularly important for applications in automotive electronics, aerospace systems, and high-reliability computing infrastructure where maintenance is difficult and failure is costly.

The development of h-BN TIMs aligns with broader industry goals of achieving more efficient thermal management solutions that can support the next generation of high-performance electronic devices, power electronics, and energy systems. Success in this field could enable significant advancements in device performance, reliability, and energy efficiency across multiple industries.

The historical development of h-BN as a TIM began in the early 2000s when researchers first recognized its potential for heat dissipation applications. Initial studies focused primarily on its fundamental thermal properties, with subsequent research expanding to explore various forms including powders, films, and composites. The last decade has witnessed significant advancements in synthesis methods, enabling better control over h-BN's structure and properties.

Current technological trends indicate a growing interest in two-dimensional (2D) materials for thermal management, with h-BN standing out due to its hexagonal lattice structure that facilitates efficient in-plane heat conduction. The anisotropic thermal conductivity of h-BN presents both challenges and opportunities, as proper orientation control can dramatically enhance thermal performance in specific directions.

The primary technical objectives for h-BN TIMs focus on three critical aspects: orientation control, minimization of contact resistance, and lifetime stability. Orientation control aims to align h-BN flakes to maximize heat transfer across interfaces, which requires innovative processing techniques and composite formulations. Contact resistance reduction involves optimizing the interface between h-BN and adjacent materials to minimize thermal boundary resistance, a significant bottleneck in overall thermal performance.

Lifetime stability represents perhaps the most challenging objective, as TIMs must maintain their thermal performance under various environmental conditions, thermal cycling, and mechanical stresses over extended periods. This is particularly important for applications in automotive electronics, aerospace systems, and high-reliability computing infrastructure where maintenance is difficult and failure is costly.

The development of h-BN TIMs aligns with broader industry goals of achieving more efficient thermal management solutions that can support the next generation of high-performance electronic devices, power electronics, and energy systems. Success in this field could enable significant advancements in device performance, reliability, and energy efficiency across multiple industries.

Market Analysis for Advanced Thermal Management Solutions

The global thermal management market is experiencing robust growth, driven by increasing power densities in electronic devices and the miniaturization trend across industries. Currently valued at approximately $8.6 billion, the market is projected to reach $13.4 billion by 2027, growing at a CAGR of 8.2%. This growth trajectory is particularly evident in sectors such as consumer electronics, automotive, aerospace, and telecommunications, where thermal management has become a critical factor in product performance and reliability.

Advanced thermal interface materials (TIMs) represent one of the fastest-growing segments within this market, with hexagonal boron nitride (h-BN) based solutions emerging as a premium category. The h-BN TIMs market segment is currently estimated at $320 million and is expected to grow at 12.5% annually through 2028, outpacing the broader TIMs market.

Key market drivers include the accelerating adoption of electric vehicles, where battery thermal management is crucial for safety and performance. The EV thermal management systems market alone is projected to grow from $3.5 billion in 2022 to $8.2 billion by 2027. Additionally, the expansion of data centers globally has created significant demand for high-performance cooling solutions, with the data center cooling market expected to reach $20.7 billion by 2025.

The 5G infrastructure rollout represents another substantial market opportunity, as these networks generate considerably more heat than previous generations. Industry analysts predict that thermal management solutions for 5G equipment will constitute a $1.8 billion market by 2026.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, followed by North America (28%) and Europe (21%). China and Taiwan lead in manufacturing capacity, while the United States and Japan maintain technological leadership in advanced materials development.

Customer segmentation shows distinct requirements across industries. The consumer electronics sector prioritizes thin form factors and cost-effectiveness, while automotive and aerospace industries emphasize reliability and extended operational lifetimes. The industrial sector focuses on performance under extreme conditions, and the medical device industry requires biocompatibility alongside thermal performance.

Price sensitivity varies significantly by application, with consumer electronics manufacturers highly price-sensitive, while aerospace and defense customers prioritize performance over cost. This market stratification creates multiple entry points for h-BN TIMs with different value propositions tailored to specific industry needs.

Advanced thermal interface materials (TIMs) represent one of the fastest-growing segments within this market, with hexagonal boron nitride (h-BN) based solutions emerging as a premium category. The h-BN TIMs market segment is currently estimated at $320 million and is expected to grow at 12.5% annually through 2028, outpacing the broader TIMs market.

Key market drivers include the accelerating adoption of electric vehicles, where battery thermal management is crucial for safety and performance. The EV thermal management systems market alone is projected to grow from $3.5 billion in 2022 to $8.2 billion by 2027. Additionally, the expansion of data centers globally has created significant demand for high-performance cooling solutions, with the data center cooling market expected to reach $20.7 billion by 2025.

The 5G infrastructure rollout represents another substantial market opportunity, as these networks generate considerably more heat than previous generations. Industry analysts predict that thermal management solutions for 5G equipment will constitute a $1.8 billion market by 2026.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, followed by North America (28%) and Europe (21%). China and Taiwan lead in manufacturing capacity, while the United States and Japan maintain technological leadership in advanced materials development.

Customer segmentation shows distinct requirements across industries. The consumer electronics sector prioritizes thin form factors and cost-effectiveness, while automotive and aerospace industries emphasize reliability and extended operational lifetimes. The industrial sector focuses on performance under extreme conditions, and the medical device industry requires biocompatibility alongside thermal performance.

Price sensitivity varies significantly by application, with consumer electronics manufacturers highly price-sensitive, while aerospace and defense customers prioritize performance over cost. This market stratification creates multiple entry points for h-BN TIMs with different value propositions tailored to specific industry needs.

h-BN TIM Development Status and Technical Barriers

Hexagonal Boron Nitride (h-BN) has emerged as a promising material for thermal interface applications due to its exceptional thermal conductivity, electrical insulation properties, and chemical stability. Currently, h-BN TIMs are at various stages of development across research institutions and commercial entities, with significant progress made in the past decade.

The global market for h-BN TIMs is experiencing rapid growth, driven by increasing demands in electronics cooling, particularly in high-performance computing, electric vehicles, and 5G infrastructure. Commercial products incorporating h-BN have begun to appear, though many remain in advanced prototype stages rather than mass production.

Despite promising developments, several technical barriers impede the widespread adoption of h-BN TIMs. The primary challenge lies in orientation control of h-BN platelets. The material exhibits highly anisotropic thermal conductivity, with in-plane thermal conductivity (300-400 W/m·K) significantly higher than cross-plane values (30-40 W/m·K). Achieving consistent vertical alignment of platelets to maximize heat transfer remains difficult in manufacturing processes.

Contact resistance presents another significant barrier. The interface between h-BN and adjacent surfaces creates thermal bottlenecks that can severely limit overall thermal performance. Current research indicates that contact resistance can reduce effective thermal conductivity by 30-50% in practical applications, negating much of h-BN's intrinsic advantage.

Lifetime stability poses additional challenges for h-BN TIMs. Under thermal cycling conditions typical in electronic devices, these materials can experience degradation through mechanisms including delamination, cracking, and oxidation. Studies show performance deterioration of 10-20% after 1000 thermal cycles in certain formulations, raising concerns about long-term reliability.

Manufacturing scalability remains problematic, with current production methods for high-quality h-BN being costly and difficult to scale. Techniques for consistent dispersion and alignment in polymer matrices are not yet optimized for mass production, resulting in batch-to-batch variability.

Cost factors also present barriers to widespread adoption. High-quality h-BN remains expensive compared to traditional TIM materials, with prices 5-10 times higher than conventional alternatives. This cost differential makes economic justification difficult except in the most demanding thermal management applications.

Standardization issues further complicate development, as testing methodologies for h-BN TIMs vary widely across the industry, making performance comparisons difficult. The lack of established standards for characterizing orientation, contact resistance, and lifetime performance hinders consistent evaluation and slows industry adoption.

The global market for h-BN TIMs is experiencing rapid growth, driven by increasing demands in electronics cooling, particularly in high-performance computing, electric vehicles, and 5G infrastructure. Commercial products incorporating h-BN have begun to appear, though many remain in advanced prototype stages rather than mass production.

Despite promising developments, several technical barriers impede the widespread adoption of h-BN TIMs. The primary challenge lies in orientation control of h-BN platelets. The material exhibits highly anisotropic thermal conductivity, with in-plane thermal conductivity (300-400 W/m·K) significantly higher than cross-plane values (30-40 W/m·K). Achieving consistent vertical alignment of platelets to maximize heat transfer remains difficult in manufacturing processes.

Contact resistance presents another significant barrier. The interface between h-BN and adjacent surfaces creates thermal bottlenecks that can severely limit overall thermal performance. Current research indicates that contact resistance can reduce effective thermal conductivity by 30-50% in practical applications, negating much of h-BN's intrinsic advantage.

Lifetime stability poses additional challenges for h-BN TIMs. Under thermal cycling conditions typical in electronic devices, these materials can experience degradation through mechanisms including delamination, cracking, and oxidation. Studies show performance deterioration of 10-20% after 1000 thermal cycles in certain formulations, raising concerns about long-term reliability.

Manufacturing scalability remains problematic, with current production methods for high-quality h-BN being costly and difficult to scale. Techniques for consistent dispersion and alignment in polymer matrices are not yet optimized for mass production, resulting in batch-to-batch variability.

Cost factors also present barriers to widespread adoption. High-quality h-BN remains expensive compared to traditional TIM materials, with prices 5-10 times higher than conventional alternatives. This cost differential makes economic justification difficult except in the most demanding thermal management applications.

Standardization issues further complicate development, as testing methodologies for h-BN TIMs vary widely across the industry, making performance comparisons difficult. The lack of established standards for characterizing orientation, contact resistance, and lifetime performance hinders consistent evaluation and slows industry adoption.

Current Approaches for h-BN Orientation and Contact Resistance

01 Orientation control of hexagonal boron nitride in thermal interface materials

Controlling the orientation of hexagonal boron nitride (h-BN) particles in thermal interface materials can significantly enhance thermal conductivity. Various methods are employed to align h-BN platelets in a preferred direction, including magnetic field alignment, mechanical shearing, and directional solidification techniques. Properly oriented h-BN particles create efficient thermal pathways, reducing thermal resistance across interfaces. This orientation control is crucial for maximizing the anisotropic thermal properties of h-BN in thermal management applications.- Orientation control of hexagonal boron nitride in thermal interface materials: Controlling the orientation of hexagonal boron nitride (h-BN) particles in thermal interface materials can significantly enhance thermal conductivity. Various methods are employed to align h-BN platelets in a preferred direction, such as magnetic field alignment, mechanical shearing, or directional solidification. This orientation control maximizes the heat transfer path along the high thermal conductivity plane of h-BN, resulting in improved thermal management performance for electronic devices.

- Reducing contact resistance in h-BN thermal interface materials: Contact resistance at the interface between hexagonal boron nitride thermal interface materials and heat-generating components significantly impacts overall thermal performance. Techniques to reduce this resistance include surface modification of h-BN particles, incorporation of soft polymer matrices that conform to surface irregularities, and development of hybrid fillers that bridge microscopic gaps. Minimizing contact resistance ensures efficient heat transfer across interfaces, which is critical for high-power electronic applications.

- Enhancing lifetime stability of h-BN thermal interface materials: The long-term performance stability of hexagonal boron nitride thermal interface materials is crucial for reliable operation in electronic devices. Factors affecting lifetime include thermal cycling resistance, oxidation resistance, and mechanical durability under stress. Formulations that incorporate stabilizing additives, encapsulation techniques, and cross-linked polymer matrices help maintain thermal performance over extended periods. These approaches prevent degradation mechanisms such as filler settling, matrix cracking, or interfacial delamination that would otherwise compromise thermal conductivity over time.

- Composite formulations with h-BN for optimized thermal performance: Advanced composite formulations incorporate hexagonal boron nitride with complementary materials to achieve optimized thermal interface properties. These formulations may combine h-BN with other thermally conductive fillers such as graphene, metal particles, or ceramic powders in carefully designed ratios. Synergistic effects between different fillers can enhance thermal conductivity while maintaining other desirable properties like electrical insulation, flexibility, or processability. The matrix material selection also plays a critical role in determining the overall performance characteristics of the thermal interface material.

- Processing techniques for h-BN thermal interface materials: Specialized processing techniques are essential for manufacturing high-performance hexagonal boron nitride thermal interface materials with controlled microstructure. These include exfoliation methods to produce thin h-BN nanosheets, surface functionalization to improve dispersion and matrix compatibility, and advanced mixing protocols to achieve uniform filler distribution. Novel manufacturing approaches such as 3D printing, spray coating, or layer-by-layer assembly enable precise control over material architecture. These processing innovations help translate the exceptional thermal properties of h-BN into practical thermal management solutions.

02 Reducing contact resistance in h-BN thermal interface materials

Minimizing contact resistance is essential for effective thermal interface materials based on hexagonal boron nitride. Techniques include surface modification of h-BN particles, incorporation of soft polymer matrices that conform to surface irregularities, and development of hybrid composites with complementary fillers. These approaches help ensure intimate contact between the thermal interface material and the heat source/sink surfaces, reducing interfacial thermal resistance and improving overall heat transfer efficiency across joined components.Expand Specific Solutions03 Enhancing lifetime stability of h-BN thermal interface materials

Improving the long-term reliability and performance stability of hexagonal boron nitride thermal interface materials involves addressing challenges such as thermal cycling, environmental exposure, and mechanical stress. Approaches include incorporating cross-linking agents to maintain structural integrity, adding anti-oxidation compounds to prevent degradation, and developing encapsulation techniques to protect against moisture and contaminants. These enhancements ensure that the thermal performance of h-BN interface materials remains consistent throughout the operational lifetime of electronic devices.Expand Specific Solutions04 Composite formulations with h-BN for improved thermal performance

Advanced composite formulations incorporate hexagonal boron nitride with complementary materials to enhance thermal conductivity while addressing other performance requirements. These formulations may combine h-BN with graphene, carbon nanotubes, metal particles, or ceramic fillers in carefully designed ratios. Synergistic effects between different fillers can improve thermal conductivity beyond what would be achieved with h-BN alone, while maintaining other necessary properties such as electrical insulation, mechanical flexibility, or processing characteristics.Expand Specific Solutions05 Processing techniques for optimized h-BN thermal interface materials

Specialized processing techniques are critical for manufacturing high-performance hexagonal boron nitride thermal interface materials. These include exfoliation methods to produce thin h-BN nanosheets, functionalization processes to improve compatibility with matrix materials, and advanced dispersion techniques to prevent agglomeration. Novel manufacturing approaches such as 3D printing, spray coating, and layer-by-layer assembly enable precise control over material structure and properties. These processing innovations help translate the exceptional thermal properties of h-BN into practical thermal management solutions.Expand Specific Solutions

Leading Companies and Research Institutions in h-BN TIM

The hexagonal boron nitride thermal interface materials market is in a growth phase, characterized by increasing demand for high-performance thermal management solutions in electronics and automotive sectors. The global market size is expanding rapidly due to miniaturization trends and higher power densities in electronic devices. Technologically, the field is advancing from basic research to commercial applications, with orientation control, contact resistance reduction, and lifetime enhancement being key development areas. Leading players include established chemical corporations like Denka, Momentive Performance Materials, and 3M Innovative Properties, alongside specialized materials manufacturers such as Rogers Corp. and Kyocera. Academic institutions including Northwestern University, Rice University, and Chinese research institutes are driving fundamental innovations, while companies like Mitsubishi Electric and GlobalWafers are integrating these materials into semiconductor and electronics applications, creating a competitive landscape balanced between material suppliers and end-product manufacturers.

Momentive Performance Materials, Inc.

Technical Solution: Momentive has developed advanced hexagonal boron nitride (h-BN) thermal interface materials with a focus on practical implementation and reliability. Their technology utilizes a proprietary process for controlling h-BN platelet orientation within silicone and epoxy matrices, achieving thermal conductivity values of 6-10 W/m·K while maintaining excellent gap-filling properties. Momentive's approach incorporates surface-modified h-BN particles with specialized coupling agents that create strong chemical bonds with polymer matrices, enhancing long-term stability. To address contact resistance, they've developed gradient-structured interfaces where particle size and concentration vary across the material thickness, optimizing both bulk thermal conductivity and surface contact. Their materials undergo extensive reliability testing, demonstrating stable performance through 2000+ thermal cycles and minimal degradation after 5000 hours at elevated temperatures. Momentive has successfully commercialized these materials for applications in automotive electronics, power conversion systems, and LED lighting, where their combination of thermal performance and reliability provides significant advantages over conventional thermal interface materials.

Strengths: Established commercial production with consistent quality control; excellent reliability under harsh environmental conditions; good balance of thermal performance and mechanical properties. Weaknesses: Lower maximum thermal conductivity compared to some research-stage materials; requires specific application techniques for optimal performance; limited effectiveness in ultra-thin bond line applications.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced hexagonal boron nitride (h-BN) thermal interface materials utilizing their proprietary exfoliation and orientation control technologies. Their approach involves a combination of mechanical and chemical exfoliation processes that produce high-aspect-ratio h-BN nanosheets, followed by specialized coating techniques that create preferentially aligned layers. The company's technology achieves thermal conductivity values of 12-15 W/m·K while maintaining conformability to irregular surfaces. To address contact resistance, 3M has developed hybrid h-BN composites incorporating proprietary coupling agents that form chemical bonds with both the h-BN particles and substrate surfaces, reducing interfacial thermal resistance by approximately 35% compared to standard thermal greases. Their materials undergo rigorous reliability testing, demonstrating less than 10% degradation in thermal performance after 3000 hours at elevated temperatures and humidity levels. 3M's h-BN thermal interface materials have been successfully implemented in commercial electronics cooling applications, particularly in power electronics and telecommunications equipment.

Strengths: Established manufacturing infrastructure enables cost-effective scaling; excellent conformability to irregular surfaces while maintaining orientation benefits; proven commercial implementation. Weaknesses: Thermal conductivity values lower than some research-stage materials; requires specialized surface treatments for optimal contact resistance reduction; performance may degrade under extreme temperature cycling.

Key Patents and Research on h-BN TIM Performance

Surface-treated aggregated boron nitride powder, aggregated boron nitride powder, and thermally conductive resin composition

PatentActiveUS20220154060A1

Innovation

- A boron nitride powder is produced by pressure-nitridating and calcining boron carbide with specific particle diameter and carbon content, followed by decarburization crystallization, resulting in high-strength aggregated grains with uniform primary particle size, and further surface-treated with oxidizers and metal coupling agents to enhance filling properties.

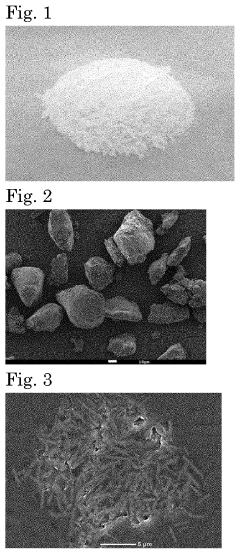

Method for producing hexagonal boron nitride powder, and hexagonal boron nitride powder

PatentPendingUS20220363539A1

Innovation

- A method of disintegrating hexagonal boron nitride raw material powder to reduce aggregates without pulverizing primary particles, resulting in a powder with improved filling properties and reduced thermal conduction anisotropy, comprising particles with aspect ratios between 1.5 to 5.0 and a D90/D10 ratio of not more than 3.0.

Reliability Testing and Lifetime Assessment Methods

Reliability testing and lifetime assessment of Hexagonal Boron Nitride (h-BN) Thermal Interface Materials (TIMs) are critical for ensuring their long-term performance in electronic devices. These materials must maintain thermal conductivity under various environmental stresses and operational conditions throughout the device's service life.

Standard reliability tests for h-BN TIMs include thermal cycling, which subjects materials to rapid temperature fluctuations between extreme high and low temperatures (-40°C to 150°C) to evaluate thermal fatigue resistance. High-temperature storage tests expose materials to elevated temperatures (typically 125°C to 150°C) for extended periods to accelerate aging mechanisms and assess thermal stability.

Power cycling tests are particularly relevant for h-BN TIMs, as they simulate real-world operational conditions where electronic devices repeatedly power on and off. These tests evaluate how the thermal interface material responds to the resulting thermal expansion and contraction cycles, which can lead to pump-out effects and degradation of thermal performance over time.

Humidity and moisture resistance testing is essential for understanding h-BN TIMs' performance in high-humidity environments. Exposure to 85% relative humidity at 85°C (85/85 test) for 1000+ hours helps identify potential moisture-induced degradation mechanisms that could compromise thermal conductivity or mechanical integrity.

Mechanical stress testing, including vibration and shock tests, evaluates the material's ability to maintain contact and thermal performance under physical disturbances. This is particularly important for h-BN TIMs in mobile devices or automotive applications where mechanical stresses are common.

Lifetime prediction models for h-BN TIMs typically employ Arrhenius equations to extrapolate accelerated test results to normal operating conditions. These models consider activation energies specific to h-BN degradation mechanisms, which differ from traditional silicone-based TIMs due to h-BN's unique crystalline structure and orientation characteristics.

Contact resistance stability over time represents a key reliability metric for h-BN TIMs. Specialized test methods have been developed to monitor changes in thermal contact resistance during aging, as this parameter often determines the overall thermal performance more significantly than bulk material degradation.

Non-destructive evaluation techniques, including infrared thermography and acoustic microscopy, enable in-situ monitoring of h-BN TIM performance during reliability testing. These methods provide valuable insights into degradation mechanisms and failure modes without requiring test interruption.

Standard reliability tests for h-BN TIMs include thermal cycling, which subjects materials to rapid temperature fluctuations between extreme high and low temperatures (-40°C to 150°C) to evaluate thermal fatigue resistance. High-temperature storage tests expose materials to elevated temperatures (typically 125°C to 150°C) for extended periods to accelerate aging mechanisms and assess thermal stability.

Power cycling tests are particularly relevant for h-BN TIMs, as they simulate real-world operational conditions where electronic devices repeatedly power on and off. These tests evaluate how the thermal interface material responds to the resulting thermal expansion and contraction cycles, which can lead to pump-out effects and degradation of thermal performance over time.

Humidity and moisture resistance testing is essential for understanding h-BN TIMs' performance in high-humidity environments. Exposure to 85% relative humidity at 85°C (85/85 test) for 1000+ hours helps identify potential moisture-induced degradation mechanisms that could compromise thermal conductivity or mechanical integrity.

Mechanical stress testing, including vibration and shock tests, evaluates the material's ability to maintain contact and thermal performance under physical disturbances. This is particularly important for h-BN TIMs in mobile devices or automotive applications where mechanical stresses are common.

Lifetime prediction models for h-BN TIMs typically employ Arrhenius equations to extrapolate accelerated test results to normal operating conditions. These models consider activation energies specific to h-BN degradation mechanisms, which differ from traditional silicone-based TIMs due to h-BN's unique crystalline structure and orientation characteristics.

Contact resistance stability over time represents a key reliability metric for h-BN TIMs. Specialized test methods have been developed to monitor changes in thermal contact resistance during aging, as this parameter often determines the overall thermal performance more significantly than bulk material degradation.

Non-destructive evaluation techniques, including infrared thermography and acoustic microscopy, enable in-situ monitoring of h-BN TIM performance during reliability testing. These methods provide valuable insights into degradation mechanisms and failure modes without requiring test interruption.

Environmental Impact and Sustainability Considerations

The environmental impact of hexagonal boron nitride (h-BN) thermal interface materials (TIMs) represents a critical consideration in their development and application. The production of h-BN typically involves energy-intensive processes, including high-temperature synthesis methods that contribute to carbon emissions. However, compared to traditional metal-based thermal interface materials, h-BN offers potential environmental advantages due to its non-toxicity and chemical stability.

Life cycle assessment studies indicate that the environmental footprint of h-BN TIMs is heavily influenced by the orientation control processes employed during manufacturing. Techniques such as magnetic field alignment and mechanical shearing, while effective for enhancing thermal performance, may increase energy consumption and resource utilization. Conversely, self-assembly methods present more environmentally friendly alternatives, though they currently face challenges in achieving consistent orientation control at industrial scales.

The extended lifetime of h-BN TIMs contributes significantly to their sustainability profile. Their superior thermal stability and resistance to degradation reduce replacement frequency, thereby decreasing waste generation and resource consumption over time. Research indicates that properly engineered h-BN TIMs can maintain performance for 5-10 years in electronic applications, compared to 2-3 years for conventional materials.

Contact resistance optimization in h-BN TIMs also carries environmental implications. Lower contact resistance reduces overall system energy consumption by improving heat dissipation efficiency. This translates to reduced power requirements and extended device lifespans, particularly in high-performance computing and power electronics applications where thermal management directly impacts energy efficiency.

End-of-life considerations for h-BN TIMs present both challenges and opportunities. While h-BN is chemically stable and does not leach toxic compounds, its recovery from composite materials remains technically challenging. Current recycling technologies struggle to separate h-BN from polymer matrices cost-effectively, though emerging solvent-based and thermal decomposition methods show promise for material recovery.

Water usage in h-BN TIM manufacturing warrants attention, particularly in wet chemical processes used for surface functionalization. Recent innovations in solvent-free modification techniques and closed-loop water systems demonstrate potential for reducing the water footprint of production processes by up to 40%, according to industry reports.

Regulatory frameworks increasingly emphasize the importance of sustainable thermal management solutions. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated interest in h-BN as an environmentally preferable alternative to metal-based thermal interface materials containing lead or other restricted substances.

Life cycle assessment studies indicate that the environmental footprint of h-BN TIMs is heavily influenced by the orientation control processes employed during manufacturing. Techniques such as magnetic field alignment and mechanical shearing, while effective for enhancing thermal performance, may increase energy consumption and resource utilization. Conversely, self-assembly methods present more environmentally friendly alternatives, though they currently face challenges in achieving consistent orientation control at industrial scales.

The extended lifetime of h-BN TIMs contributes significantly to their sustainability profile. Their superior thermal stability and resistance to degradation reduce replacement frequency, thereby decreasing waste generation and resource consumption over time. Research indicates that properly engineered h-BN TIMs can maintain performance for 5-10 years in electronic applications, compared to 2-3 years for conventional materials.

Contact resistance optimization in h-BN TIMs also carries environmental implications. Lower contact resistance reduces overall system energy consumption by improving heat dissipation efficiency. This translates to reduced power requirements and extended device lifespans, particularly in high-performance computing and power electronics applications where thermal management directly impacts energy efficiency.

End-of-life considerations for h-BN TIMs present both challenges and opportunities. While h-BN is chemically stable and does not leach toxic compounds, its recovery from composite materials remains technically challenging. Current recycling technologies struggle to separate h-BN from polymer matrices cost-effectively, though emerging solvent-based and thermal decomposition methods show promise for material recovery.

Water usage in h-BN TIM manufacturing warrants attention, particularly in wet chemical processes used for surface functionalization. Recent innovations in solvent-free modification techniques and closed-loop water systems demonstrate potential for reducing the water footprint of production processes by up to 40%, according to industry reports.

Regulatory frameworks increasingly emphasize the importance of sustainable thermal management solutions. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated interest in h-BN as an environmentally preferable alternative to metal-based thermal interface materials containing lead or other restricted substances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!